You sometimes need a material that is strong and hard. It also needs to bend without breaking. 65mn carbon steel has these features. It has a lot of carbon and manganese in it. This makes it a high-carbon alloy steel. It is very good at resisting wear. People use it to make springs and swords. It is also used in screen mesh for mining and crushing. This steel helps machines last longer when work is hard.

Key Takeaways

- 65Mn carbon steel is very strong and hard. It can bend and snap back easily. This makes it good for tough jobs.

- The steel has about 0.65% carbon. It also has 1.1% to 1.2% manganese. These help it last longer and stay tough.

- People use 65Mn for springs and mining screens. It is also used for machine parts that wear out. It lasts a long time and saves money on repairs.

- Heat treatment like quenching and tempering makes 65Mn harder and tougher. This helps it work well in heavy jobs.

- 65Mn carbon steel does not cost much and can be used in many ways. But it needs a coating to stop rust if it gets wet.

- When picking materials for mining or factories, think about 65Mn. It can handle hard hits and lots of shaking.

- To get the best results, use careful heat treatment steps. This helps 65Mn parts stay strong and bend without breaking.

- Engineers like 65Mn because it bends and goes back to shape. It is great for parts that need to flex but not snap.

65Mn Carbon Steel Overview

What Is 65Mn Carbon Steel

You may wonder what the name “65Mn” means. The “65” stands for the average carbon content, which is about 0.65%. The “Mn” shows that this steel contains manganese as a main element. You can see the main components in the table below:

| Component | Percentage |

|---|---|

| Carbon | ~0.65% |

| Manganese | 1.1% – 1.2% |

65mn carbon steel belongs to the high-carbon alloy steel group. You find this steel in many industries because it combines strength, hardness, and elasticity. These qualities make it a top choice for parts that must handle heavy loads and resist wear. You often see it in mining, aggregate, and sand washing plants. It is popular for screen mesh and screen plates, which need to last long and stay tough under harsh conditions.

Key Features

You choose 65mn carbon steel when you need a material that can bend without breaking and return to its shape. This steel offers high strength and hardness, so it does not wear out quickly. It also has good elasticity, which means it can flex and spring back. These features help screen mesh and wear parts in mining equipment work longer and need less maintenance.

You can find 65mn carbon steel in many sectors:

- Automotive industry: Used for leaf springs and coil springs that must handle heavy loads and vibrations.

- Mechanical engineering: Ideal for springs in machines, making them more efficient and lowering maintenance costs.

- Agricultural equipment: Used in suspension systems and tension springs, giving reliable performance in tough environments.

- Hardware manufacturing: Used for small springs in tools and appliances, where accuracy matters.

You see the value of 65mn carbon steel in mining and screening. It stands up to constant impact and friction. This makes it perfect for woven wire screen mesh, crusher mesh, and vibrating screen mesh. You get longer service life and better performance in your equipment.

Tip: If you work in mining or maintain screening equipment, choosing 65mn carbon steel for your screen mesh can reduce downtime and save costs.

Chemical Composition & Equivalent Grades

Chemical Composition

Main Elements

You need to know what makes 65Mn carbon steel special. Its chemical makeup gives it the strength and flexibility you want for tough jobs like mining screen mesh and crusher parts. Here is a table showing the main elements in 65Mn carbon steel:

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.62–0.70 |

| Manganese (Mn) | 0.90–1.20 |

| Silicon (Si) | 0.17–0.37 |

| Phosphorus (P) | ≤0.035 |

| Sulfur (S) | ≤0.035 |

| Chromium (Cr) | ≤0.25 |

| Nickel (Ni) | ≤0.25 |

Each element plays a key role:

- Carbon (C): Raises hardness and strength. You get a steel that resists wear and keeps its edge, which is vital for screen mesh and wear plates.

- Manganese (Mn): Boosts hardenability and toughness. This helps your equipment handle heavy impacts and keeps springs elastic.

- Silicon (Si): Adds strength and elasticity. Your screen mesh can flex without breaking, even under constant vibration.

- Phosphorus (P) and Sulfur (S): Kept low to avoid brittleness and cracks.

- Chromium (Cr) and Nickel (Ni): Present in small amounts. They help with strength and corrosion resistance but do not change the main features.

Role of Manganese

Manganese stands out in 65Mn carbon steel. You get more than just hardness. Manganese improves wear resistance, so your screen mesh lasts longer in abrasive environments. It also helps the steel harden during heat treatment. This means you can shape and temper parts for the exact balance of strength and flexibility you need.

Note: High manganese content makes 65Mn ideal for mining and screening. Your equipment can handle shocks and keep working longer, reducing downtime and replacement costs.

Equivalent Grades

You may see different names for 65Mn carbon steel in other countries. Knowing the equivalents helps you source the right material for your project.

| Standard | Equivalent Grade |

|---|---|

| AISI | 1065 |

| JIS | SUP6 |

AISI 1065

In the American system, you find 65Mn as AISI 1065. Both grades have similar carbon and manganese levels. You get the same balance of hardness, strength, and elasticity. If you work with U.S. suppliers, ask for AISI 1065 to match 65Mn’s performance.

JIS SUP6

In Japan, the JIS SUP6 grade matches 65Mn. This steel is popular for springs and wear parts. You can use JIS SUP6 in place of 65Mn for mining screens, crusher mesh, and other elastic components. The properties stay consistent, so your equipment performs as expected.

When you choose 65Mn, AISI 1065, or JIS SUP6, you ensure your screen mesh and wear parts meet the demands of mining, aggregate, and sand washing plants. You get reliable performance and long service life.

Properties of 65Mn Carbon Steel

Mechanical Properties

Strength & Hardness

65Mn carbon steel is very strong and hard. It can handle heavy loads and lots of hits. This makes it great for mining screen mesh and crusher parts. The table below shows how 65Mn compares to other steels:

| Steel Type | Tensile Strength | Yield Strength | Toughness | Brittleness |

|---|---|---|---|---|

| 65Mn | Higher | Higher | Lower | More prone |

| 50Mn | Lower | Lower | Better | Less prone |

| 60Si2Mn | Comparable | Comparable | Better | Less prone |

Here are some common values for 65Mn carbon steel:

| Property | Typical Value/Range (Metric) | Typical Value/Range (Imperial) |

|---|---|---|

| Tensile Strength | 900 – 1100 MPa | 130 – 160 ksi |

| Yield Strength (0.2%) | 600 – 800 MPa | 87 – 116 ksi |

| Hardness | 40 – 60 HRC | – |

After heat treatment, 65Mn can reach about 58 HRC. The highest hardness can be up to 64 HRC. This means your screen mesh will not wear out fast. It will last longer, even in tough mining jobs.

Elasticity & Toughness

65Mn carbon steel can bend and go back to its shape. It does not crack easily. This helps your equipment handle shaking and heavy use. You can trust this steel for springs and screen plates.

- 65Mn has high tensile strength and yield strength. This makes it good for springs and car parts.

- The steel’s toughness helps in places with lots of stress, like mining plants.

65Mn is more brittle than 50Mn or 60Si2Mn. If you need extra shock resistance, think about this. For most mining and screening jobs, 65Mn works well because it is strong and flexible.

| Steel Type | Hardness | Elastic Limit | Fatigue Resistance |

|---|---|---|---|

| 65Mn | Higher | Lower | Higher |

| 60Si2Mn | Lower | Higher | Higher |

Physical Properties

Density & Conductivity

Here are some basic facts about 65Mn carbon steel:

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Density | 7.85 g/cm³ | 0.284 lb/in³ |

| Electrical Resistivity | 0.0006 Ω·m | 0.000035 Ω·in |

The density means your parts are strong but not too heavy. The electrical resistivity is normal for carbon steels. You do not usually pick this steel for electric uses. But it matters if you worry about static or grounding.

Corrosion Resistance

65Mn carbon steel does not resist rust very well. It has a lot of carbon and not much chromium or nickel. This makes it rust faster, especially in wet or harsh places. If you use this steel for mining mesh or crusher parts, add a coating. Use oil, paint, or electroplating. These coatings help your parts last longer and need less fixing.

Tip: Always check where you use your steel. If your plant is wet or has chemicals, add a protective layer to your 65Mn carbon steel parts.

65Mn carbon steel is strong, hard, and flexible. These features make it a top pick for mining, screening, and crushing. It works well where you need parts that last and can spring back.

Uses and Applications

Springs and Swords

65mn carbon steel is used to make springs and swords. This steel is strong and can bend without breaking. It helps parts bend and go back to their shape. In cars, it is used for suspension springs. These springs help cars carry heavy things and stay steady. In factories, this steel is picked for tools and dies. It does not wear out fast, so you do not need to replace it often. This saves money. In airplanes, it is used for landing gear parts. The steel is strong but not heavy, which keeps planes safe and light.

| Industry/Sector | Specific Application Example | Key Steel Properties Utilized in this Application | Reason for Selection |

|---|---|---|---|

| Automotive | Suspension Springs | High tensile strength, elasticity | Required for durability and performance |

| Manufacturing | Tooling and Dies | Wear resistance, toughness | Essential for long tool life |

| Aerospace | Landing Gear Components | High strength-to-weight ratio | Critical for safety and performance |

People use 65mn carbon steel for swords because it stays sharp and does not bend easily. The steel is tough, so blades made from it stay strong when used.

Screen Mesh & Wear Parts

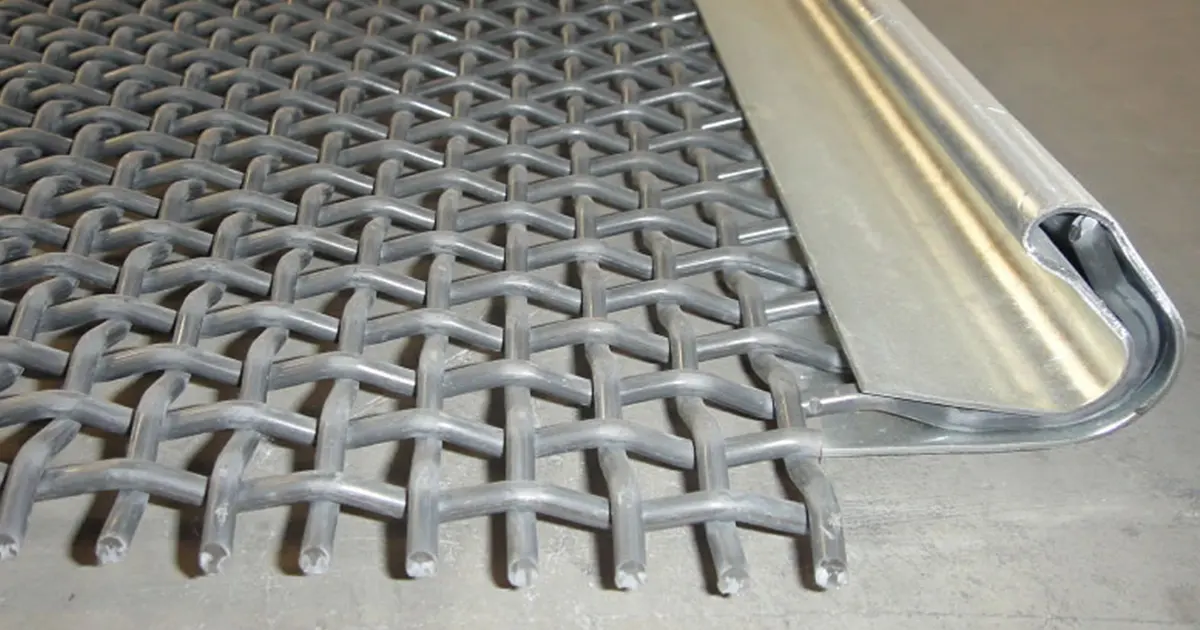

65mn carbon steel is used for screen mesh and wear parts in mining and sand plants. The steel is tough and does not wear out quickly. This helps machines last longer and need less fixing.

Woven Wire Screen Mesh

Woven wire screen mesh made from 65mn carbon steel is used in mining and quarries. The mesh can take lots of hits and shaking. It keeps its shape and does not break, even when rocks hit it hard. This means you do not have to replace it often.

Crusher & Vibrating Screen Mesh

Crusher mesh and vibrating screen mesh are put in crushing and screening machines. The steel does not wear down fast, so it protects the machines. This keeps work going without stopping. The mesh also does not rust easily, so it works well in wet places.

| Advantage | Description |

|---|---|

| Durability | 65Mn steel is very tough and lasts a long time. |

| Wear Resistance | It does not wear out fast, even with lots of rubbing. |

| Corrosion Resistance | The steel does not rust quickly, so it works in wet places. |

Tip: If you take care of screening machines, using 65mn carbon steel for mesh and wear parts means you fix things less often.

Other Industrial Uses

65mn carbon steel is used in many other places. Big machines use it for parts that must be strong and not break after many uses. Things like hair clips and watches use this steel because it can bend and go back to shape. Small parts made from this steel work well and last a long time.

- Industrial machinery: Used for parts that must be strong and last long.

- Consumer products: Used in hair clips and watches because it bends and springs back.

You pick 65mn carbon steel when you need parts that last, do not wear out fast, and can bend. This steel helps in mining, making things, and even in everyday items.

Heat Treatment

Annealing

Annealing makes 65Mn carbon steel softer. This helps you cut and bend it more easily. You heat the steel until it is very hot. Then you let it cool down slowly in air or a furnace. This slow cooling takes away stress inside the steel. It also makes the steel’s structure better. After annealing, the steel is less likely to break. It is easier to work with and shape. People use annealed steel to make screen mesh and crusher plates. This way, the parts do not crack when you form them.

Tip: Annealing helps you get smooth edges. It also means fewer problems when you cut or shape mining screen mesh.

Quenching

Quenching makes 65Mn carbon steel very hard. It also helps the steel resist wearing out. You heat the steel until it is very hot. Then you cool it quickly in oil or water. This fast cooling changes the inside of the steel. The steel gets a fine martensitic structure. This makes it tough and strong. For mining screen mesh and crusher parts, this is important. The steel can take hard hits and rough use.

The table below shows what quenching does for 65Mn carbon steel:

| Aspect | Improvement |

|---|---|

| Microhardness | Increased by 42% |

| Wear Depth | Reduced by up to 58% |

| Friction Coefficient | Reduced by 8% |

| Microstructure | Refined martensitic structure |

| Residual Stress Distribution | Enhanced surface hardness |

Quenching helps your screen mesh last longer. It also lowers wear and friction. Your equipment works better and needs less fixing.

Tempering

After quenching, 65Mn carbon steel can be too hard. It may also break easily. Tempering helps fix this problem. You heat the steel again, but not as hot as before. Then you let it cool down. This makes the steel less brittle and more tough. For mining and screening, you want steel that is hard but not easy to crack.

The right tempering temperature depends on what you need:

| Tempering Temperature (°C) | Effect |

|---|---|

| 200 – 300 | Reduces brittleness and improves toughness |

If you want the steel to stay very hard, use a lower tempering temperature:

| Tempering Temperature (°C) | Target Hardness (HRC) | Application |

|---|---|---|

| 150 – 250 | 61 – 55 | Wear-resistant, high hardness mesh |

You need to balance hardness and toughness. For mining screen mesh, you want steel that is hard but can also bend. Tempering helps you get this balance.

Note: Good heat treatment makes 65Mn carbon steel great for mining and sand plants. Your screen mesh and wear parts last longer and save you money.

Process Steps

Temperatures & Cooling

You need to follow precise steps to heat treat 65Mn carbon steel. This process helps you get the right balance of hardness, toughness, and elasticity. These qualities matter most for mining screen mesh and crusher plates.

Here is a typical heat treatment sequence for 65Mn carbon steel:

- Heat the steel to your chosen quenching temperature. You can pick from 790 °C, 810 °C, 830 °C, 850 °C, or 870 °C. Use a steady rate of 10 °C per second.

- Hold the steel at this temperature for 5 minutes. This step lets the heat reach every part of the steel.

- Quench the steel right away in oil. This fast cooling locks in the hard structure you want.

- Repeat the quenching process if you need extra hardness or wear resistance. You can do this up to four times.

- After quenching, grind and polish the steel. Use finer grades of emery paper and diamond paste for a smooth finish.

- For quality checks, you can use a special chemical bath. Dip the steel in a solution of saturated picric acid and detergent at 60–70 °C for 80–100 seconds. This step helps you see the steel’s microstructure under a microscope.

Tip: Always control your heating and cooling steps. This ensures your screen mesh and wear parts get the best mix of strength and flexibility.

The table below shows how different quenching temperatures affect the steel:

| Quenching Temperature (°C) | Resulting Hardness (HRC) | Best Use Case |

|---|---|---|

| 790 | 58–60 | Springs, elastic mesh |

| 830 | 60–62 | Crusher mesh, wear plates |

| 870 | 62–64 | Extreme wear applications |

Achieving Desired Properties

You want your 65Mn carbon steel parts to last long and work well. The right heat treatment helps you reach this goal. Each step in the process changes the steel’s structure. You get a fine martensitic grain, which gives high hardness and wear resistance.

- For screen mesh, you need steel that is hard but not brittle. Use lower quenching temperatures and temper at 200–300 °C.

- For crusher plates, aim for higher hardness. Use higher quenching temperatures and temper at a lower range to keep the steel tough.

You can adjust the number of quenching cycles. More cycles give higher hardness and better wear resistance. This is useful for parts that face constant impact and friction, like mining screens.

Note: If you skip steps or rush the process, your steel may crack or wear out fast. Always follow the full heat treatment cycle for the best results.

When you use these process steps, you get 65Mn carbon steel parts that resist wear, flex under load, and last longer in tough mining and screening jobs. This means less downtime and lower costs for your plant.

Comparison with Other Steels

65Mn vs 60Si2Mn

You might need to pick between 65Mn and 60Si2Mn for mining screen mesh. Both steels work well, but they are not the same. 65Mn has more carbon and less silicon. This means it is harder and resists wearing out. Springs and dampers made from 65Mn last longer in tough jobs. 60Si2Mn has more silicon. This makes it bend better and less likely to crack. You see 60Si2Mn in big machines, trains, and car coil springs.

Here is a simple comparison:

| Property | 65Mn | 60Si2Mn |

|---|---|---|

| Carbon Content | High | Moderate |

| Silicon Content | Low | High |

| Hardenability | Good | Improved |

| Applications | Springs, dampers | Heavy machinery, automotive |

| Sensitivity to Cracking | Yes | No |

You use 65Mn for springs, clockwork, and vibration dampers. It is also good for clutch springs. 60Si2Mn is best for coil springs in big machines and vehicles. If you want steel that is harder and wears out less, choose 65Mn. If you need steel that bends more and cracks less, pick 60Si2Mn.

Tip: For mining and screening, 65Mn lasts longer and handles impacts better.

65Mn vs AISI 1065

You may see AISI 1065 as another name for 65Mn. Both steels have almost the same carbon and manganese. They act the same in machines. AISI 1065 is used a lot in the United States. You can use it for springs, screen mesh, and wear plates in mining. The main difference is the country and how easy it is to get. If you buy from American suppliers, ask for AISI 1065 to match 65Mn.

Pros & Cons

When you pick 65Mn carbon steel, you should look at its good and bad sides. This helps you know if it is right for your mining or screening job.

| Advantages of 65Mn Steel | Disadvantages of 65Mn Steel |

|---|---|

| High Wear Resistance | Brittleness |

| Good Elasticity | Prone to Cracking |

| Cost-Effective | Corrosion susceptibility |

| Heat Treatment Capabilities | Lack of weldability |

| High Hardness and Strength | High heat associated brittleness |

| Good Fatigue Resistance | Difficult machining |

| Versatility | Temperature restrictions |

- Advantages: 65Mn does not wear out fast. It bends well and handles lots of hits. It is not expensive and works well with heat treatment. You can use it for screen mesh and wear plates that get hit a lot.

- Disadvantages: 65Mn can break and crack, especially after heat treatment. It rusts easily. Welding and cutting are hard. You need to cover parts with paint or oil in wet places.

| Steel Grade | Cost Comparison | Composition Details |

|---|---|---|

| 65Mn | Lower | Simpler high-carbon grade without chromium alloying |

| 60CrMnA | Higher | Contains chromium, which adds to the cost due to processing requirements |

Note: If you want steel that is cheap and works well for mining screen mesh, 65Mn is a good choice. It resists wear and bends well, but you must watch out for breaking and rust.

Conclusion

You now know that 65Mn carbon steel is very hard and strong. It can also bend and spring back. This makes it great for mining screen mesh, springs, and wear parts. Heat treatment makes it last longer and resist wearing out. But it is not as tough and needs a coating to stop rust. Look at the table below to see the main things to think about:

| Characteristic/Limitations | Details |

|---|---|

| Carbon Content | 0.62%-0.67% |

| Hardness after Treatment | HRC 40-50 |

| Wear Resistance | Better than low-alloy wear steel |

| Corrosion Resistance | Not good, needs a coating |

| Suitable Applications | For jobs with light hits and sliding |

Pick 65Mn carbon steel if you want strong, low-cost parts and can stop rust. Experts say it is best for tough jobs where strength is more important than rust. If you need help or special advice, contact our team. We make woven screen mesh and plates for mining and can help you choose what works best for you.

FAQ

What makes 65Mn carbon steel ideal for mining screen mesh?

You get high wear resistance and elasticity with 65Mn. This steel handles heavy impacts and constant vibration. Your screen mesh lasts longer and needs less maintenance in mining and sand washing plants.

Can you weld 65Mn carbon steel easily?

You may find welding 65Mn difficult. The high carbon content increases the risk of cracking. You should use preheating and post-weld heat treatment if welding is necessary.

How does 65Mn compare to stainless steel for screen mesh?

65Mn offers higher hardness and better elasticity. Stainless steel resists rust better. You should choose 65Mn for wear resistance and elasticity, especially in dry or abrasive environments.

What heat treatment gives the best results for 65Mn screen mesh?

You should use quenching followed by tempering. This process gives your mesh high hardness and toughness. It helps the mesh resist wear and flex without breaking.

Is 65Mn carbon steel suitable for wet environments?

You need to protect 65Mn from rust in wet areas. Apply oil, paint, or electroplating. Without a coating, the steel may corrode quickly.

What are the main uses of 65Mn in mining equipment?

You find 65Mn in woven wire screen mesh, crusher mesh, and vibrating screen plates. These parts need to resist wear and flex under heavy loads.

How do you maintain 65Mn screen mesh for longer life?

You should clean the mesh regularly and check for damage. Apply protective coatings to prevent rust. Replace worn sections promptly to keep your equipment running smoothly.

Why do engineers prefer 65Mn for elastic components?

You get a strong, hard material that springs back after bending. This makes 65Mn perfect for springs, dampers, and screen mesh in tough mining conditions.