You see punch plate material used every day in many industries. These industries rely on punch plate material to sort, filter, or separate different products. Choosing the right punch plate material is important because it can make your equipment last longer and help your equipment work better. When you compare punch plate material options like stainless steel, carbon steel, or aluminum, you notice big differences. Check this table to see how each punch plate material performs:

| Material | Strength | Corrosion Resistance | Weight | Applications |

|---|---|---|---|---|

| Stainless Steel | High | Excellent | Moderate | Food processing, chemical plants |

| Carbon Steel | Very High | Moderate | Heavy | Mining, quarrying, construction |

| Aluminum | Moderate | Good | Light | Portable equipment, wet environments |

Key Takeaways

- Punch plate materials are very important for sorting and filtering things in many industries. They also help separate products.

- Stainless steel does not rust easily. This makes it great for food factories and chemical plants.

- Carbon steel is strong and not expensive. It works well for hard jobs like mining and building.

- Aluminum is light and does not rust. It is good for tools you can carry and for using outside.

- Wear-resistant steel is made for hard places. It lasts a long time in mining and quarrying.

- Picking the right punch plate material helps machines last longer. It also lowers repair costs.

- You can choose different hole shapes, sizes, and patterns for your project.

- Taking care of your punch plate and picking the right material helps machines work better and saves money over time.

What Is Punch Plate Material?

Definition and Function

Punch plate material is a kind of steel plate. It goes through a process called steel punching. Special tools make holes in the plate. These plates are called perforated metal. The holes can be round, square, or other shapes. The holes help sort, filter, or separate things. Perforated metal is strong and tough. You can use it to connect beams or columns. It also works for making mounting holes in car parts. Punch plate keeps things sturdy. It lets you add bolts or fasteners where needed.

Here’s why punch plate material is special:

- It starts as a solid steel plate.

- A punch and die set makes a pattern of holes.

- The finished plate is called perforated metal or perforated sheet metal.

- It is strong and can handle heavy loads and rough use.

Common Industrial Uses

Perforated metal is used in many industries. It is not just for looks. It does important jobs every day. In factories, machines use it to sort or filter products. In cars, it helps make the chassis lighter by removing extra metal. Aerospace companies use it for panels and parts that need to be strong and light. Electronics makers use it for cutouts for switches and displays. Furniture makers use it for hardware and decoration.

Some common uses are:

- Electrical and electronics: Cutouts for switches, screens, and displays.

- Automotive and aerospace: Lightweight panels and chassis parts.

- Signage and advertising: Strong letters and logos.

- Furniture: Hardware attachment and decoration.

Perforated metal is used in many places. You see it in cars and even in chairs.

Perforated Plate vs. Punch Plate

People sometimes use “perforated plate” and “punch plate” to mean the same thing. Most of the time, they do. Both start as a solid plate and get holes punched in them. The main difference is how people use the words. Some say perforated metal for sheets with lots of small holes. Others say punch plate for thicker, tougher plates used for heavy jobs. The process is almost the same. You use a punch and die to make the holes. The result is a strong piece of perforated metal. It can sort, filter, and separate things.

Tip: If you need something strong for mining or construction, ask for a punch plate. If you want something for decoration or light filtering, look for perforated metal or perforated sheet metal.

Types of Punch Plate Material

When you look at punch plate materials, you see many choices. Each one has its own strengths and best uses. Here’s a quick table to help you spot the main differences:

| Material | Distinguishing Characteristics |

|---|---|

| Stainless Steel | Corrosion resistance, durability, looks good, but can wear down tools |

| Aluminum | Lightweight, easy to shape, used in cars and planes, can spring back after bending |

| Copper | Great for carrying electricity, easy to bend, used in wires and electronics |

| Mild Steel | Strong, affordable, used in buildings and machines, hole size matters |

| Titanium | Very strong for its weight, resists rust, used in tough jobs |

Let’s break down the most common types you’ll see in perforated punch plate work.

Carbon Steel

Properties

You’ll find carbon steel in many perforated plate products. It stands out for its strength and toughness. Carbon steel can handle heavy loads and rough treatment. It comes in different grades, from mild to high carbon. High carbon steel has even more strength and can take a lot of force before it bends or breaks.

- Strong and durable for tough jobs

- Handles impact and heavy use

- Can be cut, bent, or welded into many shapes

- Costs less than stainless steel or titanium

Applications

You see carbon steel perforated plates everywhere. Builders use them in bridges and buildings. Factories use them for making axles, gears, and shafts. You’ll also spot them in cars, fridges, and washing machines. High carbon steel works well for cutting tools, blades, and springs. If you need a plate that can take a beating, carbon steel is a smart pick.

- Structural parts in buildings and bridges

- Machine parts like gears and shafts

- Household items and appliances

- Cutting tools and heavy-duty springs

Tip: If you want a strong, affordable perforated metal plate for heavy-duty work, carbon steel is a top choice.

Stainless Steel

Properties

Stainless steel is famous for fighting rust and corrosion. It keeps its shine and strength, even in wet or harsh places. You’ll find different grades, like SS 304 and SS 316. SS 316 has more molybdenum, so it resists pitting and rust even better, especially around salt or chemicals. Stainless steel plates last a long time and need little care.

| Feature | Description |

|---|---|

| Corrosion Resistance | SS 316 resists rust 3–5 times better than SS 304, even in salty or acidic spots |

| Maintenance | Needs little cleaning, can last 10–20 years in tough places |

- Easy to clean with mild soap or special cleaners

- Needs only simple checks and care

- Looks good and stays strong for years

Applications

You’ll see stainless steel perforated metal in food factories, chemical plants, and places that get wet. It works well for screens, filters, and guards. People also use it for decorative panels and covers because it looks sharp and stays clean.

- Food processing and kitchens

- Chemical and water treatment plants

- Decorative panels and screens

- Outdoor and marine uses

Note: If you need a perforated plate that fights rust and lasts for years, stainless steel is your go-to.

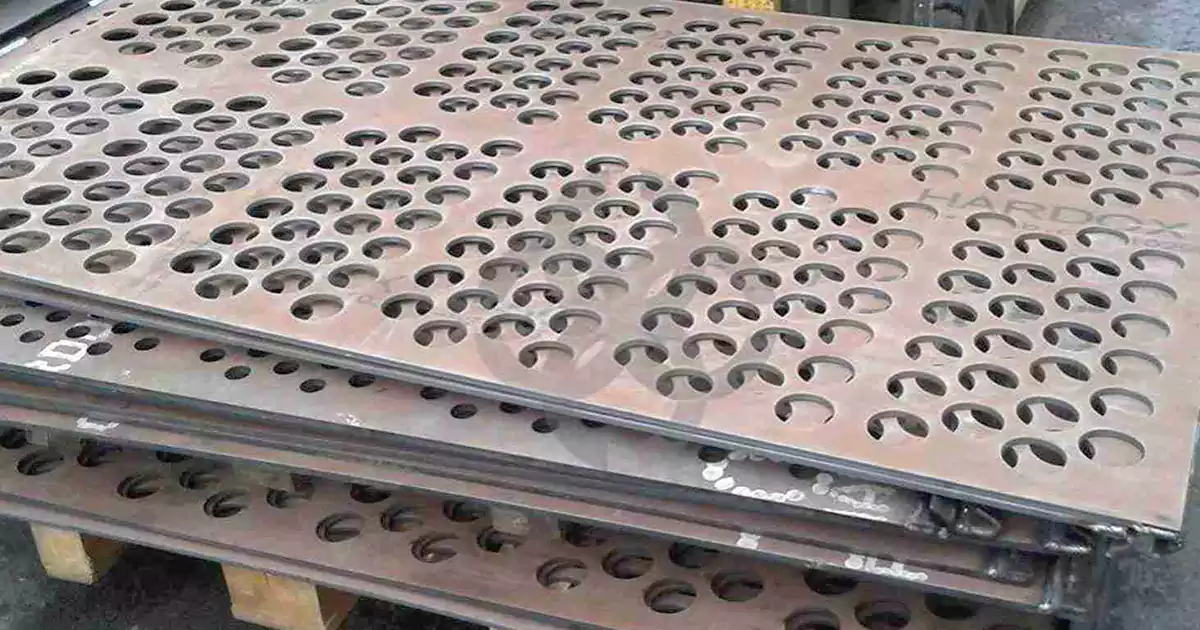

Wear-Resistant Steel

Properties

Wear-resistant steel is built to last in the toughest spots. It stands up to scratches, hits, and constant rubbing. This type of steel has special alloys that make it extra hard. You’ll find it in places where regular plates would wear out fast.

- High hardness and toughness

- Handles abrasion and impact

- Lasts longer in rough conditions

- Needs less replacement and repair

Applications

You want wear-resistant steel for mining, quarrying, and heavy industry. It works great for screens, chutes, and liners that face rocks, gravel, or other hard stuff. If your perforated plate faces a lot of wear and tear, this is the material you need.

- Mining and quarry screens

- Chutes and hoppers in factories

- Liners for heavy equipment

- Any spot with lots of abrasion

Pro Tip: For the harshest jobs, pick a wear-resistant perforated metal plate. It saves you time and money on repairs.

Aluminum and Other Metals

Properties

Aluminum is a good choice if you want something light and strong. It is easy to move and shape. Aluminum does not rust, so you can use it outside or in wet places. Perforated aluminum sheets let air and light go through. They are not heavy. You can cut, bend, or punch them without much trouble.

Other metals like copper, brass, and nickel have their own special features. Copper does not rust and looks nice. Brass is strong and has a gold color. Nickel works well in wet and tough places. Each metal gives you a different mix of strength, looks, and resistance.

Here is a quick look at the good and bad sides of using aluminum for punch plates:

| Advantages of Using Aluminum Punchers | Limitations of Using Aluminum Punchers |

|---|---|

| Clean, burr-free holes save time after punching. | Not good for thick aluminum unless you use special tools. |

| Faster than drilling, great for doing the same job many times. | You need to reach both sides of the sheet for most designs. |

| Less heat means thin sheets do not bend out of shape. | If you do not line things up, holes can be the wrong shape. |

| You can use portable tools in small or far away places. | Buying the tools costs more than simple drill bits. |

| Tools last longer than drill bits if you use them right. | You may need to add oil before each use to stop sticking. |

Applications

You see perforated aluminum sheets in many places. Builders use them for ceilings, walls, and sunshades. You find them in speaker covers, air vents, and furniture. Aluminum is good for screens and guards in machines. It is light, so you can move or put it up easily. Copper and brass sheets are used in fancy panels, lights, and signs. Nickel sheets are used where you need extra strength and rust resistance, like in chemical plants.

Tip: If you want a plate that is light and does not rust for outdoor or design work, try perforated aluminum sheets or copper and brass.

Rubber and Polyurethane

Properties

Rubber and polyurethane punch plates are different from metal ones. These materials soak up shock and make less noise. You can use them if you want less shaking and a quieter place to work. Polyurethane sheets are tough and bendy. They bounce back after being hit and do not tear easily. Rubber sheets help keep your machines safe from damage.

- Made from strong polyurethane rubber that soaks up pressure and stops bouncing.

- Helps keep machines quiet by lowering noise and shaking.

- Polyurethane rubber takes in shock and stops tools and sheets from breaking.

Applications

You often see rubber and polyurethane punch plates in mining, quarrying, and recycling. They are good for sorting sticky or wet stuff. These sheets last longer where metal would wear out fast. You can use them to cover chutes, hoppers, and screens. They also help machines run quietly and smoothly.

Note: If you want less noise and want to protect your machines, rubber and polyurethane punch plates are a smart pick.

Perforated Metal Options

When you pick a perforated plate, you have lots of choices. Each kind of perforated metal sheet has its own mix of strength, toughness, and looks. Here is a table to help you compare:

| Material Type | Strength Characteristics | Durability Features |

|---|---|---|

| Stainless Steel | Fights rust and is very strong | Lasts a long time in many places |

| Aluminum | Light and tough, easy to put up | Looks nice and helps spread sound |

| Steel | Costs less but is still strong | Used a lot in factories and stores |

| Nickel | Very strong, can handle hard jobs | Good for wet and humid places |

| Brass | Strong and hard, does not rust easily | Used in many buildings and for decoration |

| Copper | Does not rust and looks good | Used for design in many places |

Perforated metal gives you more choices than wire mesh or expanded metal. You can pick from many patterns, shapes, and metals. Perforated metal sheets can have solid edges, which makes them stronger and easier to put up. You get a better mix of strength and weight, so your plate is light but tough. This helps if you need to move or install it easily.

You can pick perforated stainless steel sheets for places that need to be strong and not rust. If you want something light and easy to shape, choose perforated aluminum sheets. For special looks or uses, try copper, brass, or nickel sheets. Each choice lets you match your plate to your job.

Remember: Perforated metal sheets let you pick the right mix of strength, weight, and style for your project.

Key Properties of Punch Plate Materials

Strength and Impact Resistance

When you pick a punch plate, you want it to stand up to tough jobs. Strength and impact resistance matter most if your plate faces heavy loads or sudden hits. If you use a punch plate in mining or construction, you know rocks and debris can slam into the surface. A strong plate will not crack or bend easily. Impact resistance means the plate can take a hit and keep working.

You should look at these key mechanical properties:

| Mechanical Property | Description |

|---|---|

| Tensile Strength | Resistance to being pulled apart, affecting the tonnage required for bending. |

| Toughness | Ability to absorb impact energy without fracturing. |

| Material Thickness | Thicker plates need more strength and toughness. |

| Hardness | Resistance to plastic deformation, measured on the Rockwell C scale. |

If you use a laser to cut or shape your punch plate, you want a material that keeps its strength after the process. Some metals lose toughness when exposed to heat, but others stay strong. You can use a laser to make precise cuts without weakening the plate. This helps you get the right shape and size for your job.

Tip: Always check the plate’s thickness and hardness before you use a laser. Thicker plates need more power, and harder plates may need special settings.

Abrasion and Wear Resistance

Punch plates often face rough treatment. Rocks, gravel, and other hard materials scrape across the surface. Over time, this can wear down the plate. Abrasion and wear resistance help your plate last longer. If you use a laser to make holes or patterns, you want a material that keeps its surface smooth and tough.

Wear-resistant steel is a top choice for high-abrasion jobs. It has a hard surface that stands up to constant rubbing. You can use a laser to create custom patterns or holes. This lets you match the plate to your needs. A smooth, hard surface also means less buildup of dirt or debris.

Here are some things to look for:

- High hardness for better wear resistance.

- Smooth surface after laser cutting.

- Ability to keep shape and thickness after many uses.

If you use a laser to cut your punch plate, you get clean edges that resist chipping. This means your plate will last longer and need less repair.

Corrosion Resistance

Corrosion can ruin a punch plate fast, especially in wet or chemical-heavy places. You want a plate that fights rust and stays strong. Stainless steel is a popular choice because it resists rust and keeps its shine. If you use a laser to cut stainless steel, you get clean, rust-free edges.

Corrosion resistance depends on the metal’s makeup. Some metals, like stainless steel and aluminum, have natural protection. Others need coatings or treatments. If you use a laser, you can add holes or shapes without damaging this protection.

Note: Always choose a punch plate with good corrosion resistance if you work in wet, salty, or chemical areas. Using a laser to cut or shape your plate helps keep the surface sealed and smooth.

A punch plate with strong corrosion resistance will last longer and save you money. You will not need to replace it as often, and it will keep working even in tough spots.

Flexibility and Noise Reduction

You might think punch plates are always stiff and loud, but that’s not true. Some punch plate materials offer flexibility and help reduce noise. If you work in a busy plant or near heavy machines, you know how loud things can get. Flexible punch plates can make your workspace quieter and safer.

Rubber and polyurethane punch plates bend and flex when hit. These materials absorb shock and vibration. You get less rattling and banging. If you use these plates, your machines run smoother. Workers feel less tired because there’s less noise and shaking.

Here’s a quick look at how flexible punch plates help:

- Lower noise levels: Flexible plates soak up sound and vibration.

- Less wear on equipment: Machines last longer when plates absorb shock.

- Safer work environment: Less vibration means fewer accidents.

Tip: If you want a quieter workspace, try rubber or polyurethane punch plates. They work well in places where metal plates would be too noisy.

You can also find flexible punch plates in recycling plants and quarries. These places deal with sticky or wet materials. Flexible plates keep things moving and stop jams. You spend less time fixing problems and more time getting work done.

Maintenance and Lifespan

You want punch plates that last a long time and need little care. Maintenance and lifespan matter if you want to save money and avoid downtime. Some materials need more attention than others. If you pick the right punch plate, you spend less time fixing and more time working.

Here’s a table to help you compare maintenance needs:

| Material Type | Maintenance Level | Lifespan | Common Issues |

|---|---|---|---|

| Stainless Steel | Low | Very Long | Rare rust spots |

| Carbon Steel | Moderate | Long | Rust, wear |

| Rubber/Polyurethane | Low | Long | Tearing, stretching |

| Aluminum | Low | Moderate | Dents, scratches |

Stainless steel punch plates need little cleaning. You can wipe them down with soap and water. They resist rust and last for years. Carbon steel plates need more care. You might need to check for rust or repaint them. Rubber and polyurethane plates need simple checks for tears or stretching. Aluminum plates stay clean but can dent if you drop something heavy.

Note: Regular checks help you spot problems early. Clean your punch plates and look for damage. Replace worn plates before they break.

If you choose the right material, your punch plates last longer. You save money on repairs and replacements. You also keep your machines running smoothly. Picking the best punch plate for your job means less stress and more success.

Types of Punches and Manufacturing Process

Punches and Dies

Making punch plates uses a simple process. A pressing machine with a punch and die makes holes in metal sheets. First, you put the metal sheet between the punch and the die. The punch tool pushes down and makes holes in the metal. This way, you get holes that are always the same size and shape.

Punching is a way to make shapes and holes in metal sheets. A pressing machine uses a punch and die to make holes that are always the same. You put the metal sheet between the punch and the die.

There are many types of punches for different jobs. Some common ones are drive pin punches, center punches, prick punches, transfer punches, drift pin punches, roll pin punches, decorative punches, letter punches, nail punches, and automatic center punches. Each punch helps you make certain holes or marks. For example, a roll pin punch is good for moving roll pins without hurting the metal. An automatic center punch helps you mark where to start a hole so your tool does not slip.

Here is how punching usually works: You get the metal sheet ready. You put it on the die. The punch tool pushes into the sheet to make holes or shapes. You can do this by hand or use a CNC punching machine for more exact work.

To get the best results, you need a sharp die and the right space between the punch and die. This helps you get smooth parts that fit well and are ready for more work.

Perforation Patterns and Hole Shapes

The pattern and shape of holes in a punch plate are important. You can pick round, square, hexagonal, or slotted holes. Each shape changes how the plate works. Round holes help spread out force and keep the plate strong. Square holes help with water flow and air movement. Hexagonal holes give you more open space for air.

- Round patterns are cheap and strong.

- Square patterns are easy to line up and take hits.

- Hexagonal patterns give the most open space.

- Slotted holes let in more light and air.

If you use a staggered pattern, you can make plates faster and move more stuff through them. Patterns that are even can save money and work better. Odd patterns may look cool but take longer and cost more.

Round holes spread out force and keep the plate strong. Square holes are good for water and air flow. Hexagonal holes give lots of open space and help with air, making the plate work better.

Customization Options

You can change many things about your punch plate. You can pick the metal, the size of the sheet, how thick it is, and the size of the holes. You can also choose where to put holes and where to leave solid metal. Some jobs need tiny holes, and some need big ones, from 20 mm to 500 mm or more.

Here is a table to show your choices:

| Customization Aspect | Details |

|---|---|

| Alloy material | Pick from many metals for your job |

| Sheet dimensions | Choose the width and length you want |

| Thickness | Pick the right thickness for your work |

| Hole size | Choose hole size and pattern, even how much is open |

| Non-perforated areas | Leave some spots solid if you need to |

| Pattern orientation | Set which way the pattern goes |

| Secondary services | Add powder coating, notching, or other finishes |

Punch plates can be used for many things like sieves, conveyor belts, wall panels, sunshades, fences, and decorations. Decorative punches and roll pin punches help you get the look or job you want. If you need to mark metal, letter punches and automatic center punches make it easy. Nail punches help you set nails below the surface for a smooth look.

When you know your choices, you can design a punch plate that fits your project. You get the right holes, the right pattern, and the right metal every time.

Choosing the Right Punch Plate Material

Application Requirements

When you start a new project, you need to think about what your punch plate will do. Will it sort rocks in a quarry? Will it filter water in a chemical plant? Maybe you want to use it in architectural design for a cool building facade. Each job needs a different punch plate. You want to match the plate to your design and your work.

Here are some questions you should ask yourself before you choose:

- What will the punch plate handle? Heavy rocks, sticky mud, or fine sand?

- How much force will hit the plate? Will it face strong impacts or just light pressure?

- Do you need the plate to look good for architecture or design?

- Will the plate be part of building materials or just a machine part?

- Does your design need special shapes or patterns?

If you work in mining, you need a punch plate that can take a beating. For wet places, you want a plate that fights rust. If you care about style, you might pick a plate for architectural design. You can use punch plates for screens, guards, or even as part of the building materials in architecture.

Tip: Always match your punch plate to your design and your job. The right plate makes your work easier and your project stronger.

Matching Properties to Use

You want your punch plate to last. You also want it to work well for your design. Each material has its own strengths. You need to match these properties to your use.

Let’s look at some common scenarios:

| Scenario | Best Material Choice | Why It Works Well |

|---|---|---|

| Mining and Quarrying | Wear-resistant steel | Handles heavy impact and abrasion |

| Wet Environments | Stainless steel or aluminum | Fights rust and corrosion |

| Architectural Design | Aluminum, copper, or brass | Looks good and shapes easily |

| High-Impact Jobs | Carbon steel | Strong and tough for heavy loads |

| Quiet Workplaces | Rubber or polyurethane | Reduces noise and absorbs shock |

If you want your punch plate to be part of a building’s design, you might pick aluminum or copper. These metals look great and fit well with architectural design. For tough jobs, carbon steel or wear-resistant steel is your best bet. If you need quiet, rubber or polyurethane punch plates help keep noise down.

You also need to think about the shape and pattern. Round holes spread out force. Square holes help with water flow. Hexagonal holes give you more open space. Your design should match your needs.

Note: The right punch plate makes your design work better. Pick the material and pattern that fit your job.

Environmental and Cost Factors

Your punch plate will face different environments. You need to pick a material that can handle these conditions. You also want to keep costs low and get the most value.

Here are some things you should think about:

- Temperature: Some punch plates work better in hot or cold places. If your design faces high heat, pick a metal that can handle it.

- Pressure: High-pressure jobs need strong punch plates. Make sure your design uses a plate that won’t crack or leak.

- Acidity, Alkalinity, and Corrosiveness: If your punch plate touches chemicals or salty water, you need a material that resists corrosion. Stainless steel and aluminum work well for these jobs.

You also need to think about cost:

- Material Costs: Some punch plates cost more than others. Stainless steel and copper are pricier, but they last longer. Carbon steel is cheaper but needs more care.

- Service Life: A punch plate that lasts longer saves you money. You won’t need to replace it as often.

- Maintenance Costs: Some punch plates need more cleaning or repairs. Stainless steel and rubber plates need less work. Carbon steel and aluminum may need more attention.

Here’s a quick list to help you choose:

- Pick a punch plate that fits your budget and your design.

- Think about how long the plate will last.

- Check how much work it takes to keep the plate in good shape.

- Match the plate to the environment—hot, cold, wet, or chemical-heavy.

Tip: If you want a punch plate for outdoor architectural design, pick aluminum or stainless steel. They look good and fight rust. For mining, go with wear-resistant steel. It lasts longer and saves money.

You can use punch plates in many ways. They work for screens, guards, and even as part of building materials in architecture. Your design should always match the job and the environment. When you pick the right punch plate, you get better results and save money.

Best Uses for Perforated Metal Punch Plates

Mining and Quarrying

Perforated punch plates are used a lot in mining and quarrying. These plates help sort rocks, gravel, and minerals. When you use a punch plate in a mining screen, it works well and lasts a long time. Perforated metal punch plates can take hard hits from big stones. They also do not wear out fast from scraping. You can pick different hole shapes and sizes for the material you want to separate. Round holes are good for most rocks. Square or slotted holes help with sticky or wet stuff. Stainless steel or wear-resistant steel are best for the hardest jobs. These materials last longer and help you save money on repairs.

Aggregate and Construction

In construction, you need punch plates for sand, gravel, and crushed stone. Perforated punch plates work in screening machines and conveyors. You can use them to sort different sizes of aggregate. This helps you get the right mix for concrete or roads. Perforated metal punch plates also protect your machines from damage. They stop big pieces from getting into crushers or mixers. Carbon steel works for most jobs. If you need more strength, use wear-resistant steel. Aluminum punch plates are good for lighter jobs or portable tools. You can also pick different patterns to control how fast things move through the screen.

Industrial Processing

Factories use perforated punch plates for many jobs. You see these plates in food factories, chemical plants, and recycling centers. Perforated metal punch plates help filter, sort, and protect products as they move through machines. You can use them for drying, washing, or separating things. If you need to move products quickly, you want a punch plate that does not clog or break.

You have many choices for punch plate materials in factories. Here are some common ones:

- Aluminum punch plates, from .020″ to .500″ thick, are good for light or rust-prone jobs.

- Stainless steel punch plates, from .020″ to .250″ thick, fight rust and work in wet or chemical places.

- Cold rolled steel punch plates, from .020″ to .375″ thick, are strong for tough jobs.

- You can also use galvanized, aluminized, copper, or brass punch plates for special needs.

Perforated punch plates help control air flow, drainage, and how products move. You can pick the right hole size and pattern for your job. Perforated metal punch plates also make cleaning and fixing easier. You spend less time on clogs or worn parts. When you pick the right punch plate, your factory runs better and safer.

Tip: Always match your perforated punch plate to your job. The right material and pattern help you get better results and save money.

Wet and Corrosive Environments

Some places have lots of water, chemicals, or salty air. These things can ruin regular punch plates very quickly. If you want your equipment to last longer, you must pick the right punch plate material. Not all metals can survive in these tough places, so you need to be careful when choosing.

If you want a punch plate that does not rust or corrode, you have some good choices:

- Titanium alloys

- Stainless steel

- Copper-nickel alloys

- Aluminum bronze

These materials do more than just stop rust. They also stay strong and keep their shape, even when wet or covered in chemicals. You can use them in water plants, docks, chemical factories, or anywhere with harsh weather.

Hastelloy® C-276 nickel alloy plate is one of the best materials for fighting corrosion. It works well in both oxidizing and reducing places. It does not crack or pit from chloride, and it resists many types of corrosion. The alloy does not get weak during welding, so you can use it right after welding. In chemical plants, it stands up to acids like sulfuric, hydrochloric, formic, acetic, and phosphoric.

If you work by the ocean or in a chemical plant, you know rust can spread fast. Stainless steel is a favorite because it fights rust and still looks nice. Titanium alloys are even better for strong acids or salty water. Copper-nickel alloys and aluminum bronze also work well in seawater and chemical tanks.

Here’s a simple checklist to help you pick the best punch plate for wet and corrosive places:

- Will your plate touch saltwater or chemicals?

- Do you want it to last for years without rust?

- Is easy cleaning important for your work?

- Do you need a plate that stays strong after welding?

If you say yes to any of these, look at stainless steel, titanium, or special alloys like Hastelloy C-276. These materials cost more at first, but they save money later. You will not need to replace your punch plate as often, and your machines will work better.

Remember, picking the right punch plate material matters a lot. You will have less downtime, fewer repairs, and a safer place to work. When you choose a punch plate that resists corrosion, you protect your equipment and keep things running well.

Conclusion

Picking the right punch plate material helps your equipment last longer. It also helps you save money over time. When you choose a material that fits your job, you get better results. You will also have to fix things less often. Look at this table to see how different materials can change your costs:

| Material Type | Tool Wear Impact | Efficiency Improvement | Cost Savings |

|---|---|---|---|

| Softer Materials | Lower wear | Moderate | Reduced costs |

| Harder Materials | Higher wear | High | Increased costs |

If you want the best choice, talk to a manufacturer who knows about metal. They can help you with custom designs. At ANPENG, you can pick from many options. They check quality carefully and help you get any hole pattern or size you need.

FAQ

What is a punch plate used for?

You use a punch plate to sort, filter, or separate materials. It works great in mining, construction, and factories. You can also use it for decoration or as a safety guard.

How do I choose the right punch plate material?

Think about what you need the plate to do. If you need strength, pick steel. If you want something light, try aluminum. For wet places, stainless steel works best.

Can I get custom hole shapes or sizes?

Yes! You can ask for round, square, slotted, or even special shapes. You can also choose the size and pattern that fits your job.

How long does a punch plate last?

A punch plate can last for years if you pick the right material and take care of it. Stainless steel and wear-resistant plates usually last the longest.

Is a punch plate better than wire mesh?

Punch plates are stronger and last longer than wire mesh. You should use a punch plate when you need to handle heavy loads or rough materials.

Can I use punch plates outdoors?

Yes, you can use punch plates outside. Just make sure you pick a material that resists rust, like stainless steel or coated metal.

How do I clean and maintain a punch plate?

You can clean most punch plates with water and mild soap. Check for damage or wear often. Replace the plate if you see cracks or holes getting bigger.