Dewatering screen mesh size is very important for separating solids and liquids. The usual mesh sizes for dewatering screens go from 4 mesh to 325 mesh. The smallest common opening is 50 mesh or 0.3 mm. Standard mesh sizes help workers pick the right screen. Mesh size changes how well the screen removes water and handles materials.

- Smaller particles go through the screen more easily.

- Bigger particles need a screen with smaller openings.

- Knowing the sizes of the particles helps make the equipment work better.

Every job needs the right match between mesh openings and material type. Picking the right woven wire mesh and screen size makes dewatering work well and helps the screen last longer.

Key Takeaways

- Dewatering screens take out extra water from aggregates fast. This makes them easier to move and store.

- Using a dewatering screen can lower moisture in materials to about 9–10%. This helps make the product better.

- The strong shaking and steep angle of the screen help pull water away from solids well.

- Dewatering screens save time and energy because they dry things faster than old methods.

- These screens can be used in sand and gravel plants.

- They also work in mining jobs and recycling centers.

- A good screen deck helps remove more water and stops clogging. This makes sure the screen works its best.

- Cleaning the screen often keeps the dewatering process smooth and working well.

- Recycling water from the dewatering process is good for the environment. It can also help lower costs.

Dewatering Screen Mesh Size Overview

Standard Mesh Ranges

Common Mesh Numbers

Dewatering screen mesh size is important for separating solids from liquids. Most dewatering screens use mesh sizes from 4 mesh to 325 mesh. Mesh numbers tell how many openings are in one inch of the mesh. A 4 mesh screen has 4 openings in each inch. A 325 mesh screen has 325 openings in each inch. This range works for mining, aggregates, and factories.

Smallest and Largest Openings

The biggest mesh opening is 4.76 mm, which is a 4 mesh. The smallest opening is about 0.044 mm, found in a 325 mesh. These sizes help workers pick the right mesh for big or small materials. Picking the right size helps remove water well and keeps unwanted pieces out.

Mesh Size Numbering Explained

Mesh Count vs. Opening Size

Mesh count means the number of openings in one inch of mesh. A higher mesh number means more openings and smaller holes. For example, a 40 mesh screen has 40 openings in each inch. Its holes are much smaller than a 4 mesh screen. If you multiply the mesh number by the hole size in microns, you get about 15,000. This helps people choose the right mesh for their job.

A dewatering screen works best when the mesh size matches the material. If the mesh is too big, unwanted solids can pass through. If the mesh is too small, water flow slows down. Standard mesh sizes help screens work the same way in different jobs.

Units: mm, microns, inches

Companies use millimeters, microns, and inches to show mesh opening size. The table below shows how mesh numbers match these units:

| U.S. MESH | INCHES | MICRONS | MILLIMETERS |

|---|---|---|---|

| 4 | 0.187 | 4760 | 4.76 |

| 5 | 0.157 | 4000 | 4 |

| 10 | 0.0787 | 2000 | 2 |

| 20 | 0.0331 | 841 | 0.841 |

| 40 | 0.0165 | 400 | 0.4 |

| 50 | 0.0117 | 297 | 0.297 |

| 100 | 0.0059 | 149 | 0.149 |

| 200 | 0.0029 | 74 | 0.074 |

| 325 | 0.0017 | 44 | 0.044 |

Tip: Always check mesh size in all three units. This helps you avoid mistakes when buying or changing dewatering screens.

Woven wire mesh comes in many mesh numbers and sizes. Workers should pick mesh openings that fit their material and job for the best results.

Dewatering Screen Mesh Size Chart

Mesh Size Conversion Table

Mesh to mm and Microns

Picking the right mesh size helps workers get good results. Mesh size means how many openings are in one inch of screen. Each mesh number matches a certain opening size. These sizes are measured in millimeters, microns, or inches. These numbers help people compare screens and pick the best one for their job.

The table below lists mesh numbers, opening sizes, and common uses. This chart helps workers match the mesh to the material and the job.

| Mesh Number | Opening (inches) | Opening (mm) | Opening (microns) | Typical Application |

|---|---|---|---|---|

| 4 | 0.187 | 4.76 | 4760 | Coarse sand, gravel, aggregate |

| 5 | 0.157 | 4.00 | 4000 | Fine gravel, sand, coal |

| 10 | 0.0787 | 2.00 | 2000 | Medium sand, mineral processing |

| 20 | 0.0331 | 0.841 | 841 | Fine sand, silica, salt |

| 40 | 0.0165 | 0.400 | 400 | Silt, fine minerals, food processing |

| 50 | 0.0117 | 0.297 | 297 | Dewatering of fine sand, wastewater solids |

| 100 | 0.0059 | 0.149 | 149 | Sludge, clay, ultra-fine minerals |

| 200 | 0.0029 | 0.074 | 74 | Ultra-fine particles, specialty chemicals |

| 325 | 0.0017 | 0.044 | 44 | Micro-particles, filtration, high-purity applications |

Note: Always check the mesh number and opening size before you put in a new screen. This step stops material loss and makes sure the dewatering works right.

Example Mesh Sizes (4, 5, 50, 325)

A 4 mesh screen has big openings. Workers use it for large gravel or sand. A 5 mesh screen is good for fine gravel or coal. The 50 mesh screen is used for fine sand or cleaning solids from wastewater. The 325 mesh screen has tiny openings. It is best for filtering micro-particles or pure materials.

Typical Applications by Mesh Size

Material Types for Each Size

Different mesh sizes work for different materials. The choice depends on the size of the particles and the type of material. For example, a 4 mesh screen removes water from big rocks. A 50 mesh screen is used for fine sand or silt. A 325 mesh screen catches very small particles in special jobs.

The weave type, panel size, and hook type also change how the screen works. A tight weave keeps small particles in and lets water out. The panel size changes how much material the screen can hold. The hook type helps keep the screen steady when working.

- Coarse mesh (4-10 mesh): Used for gravel, big sand, and aggregate.

- Medium mesh (20-40 mesh): Used for fine sand, salt, and minerals.

- Fine mesh (50-100 mesh): Used for silt, clay, and solids in wastewater.

- Ultra-fine mesh (200-325 mesh): Used for tiny particles and special chemicals.

A vibrating screen machine uses these mesh sizes to separate solids from liquids. Workers pick the mesh based on the material and how dry they want it. The right mesh size helps the screen work better and last longer.

Tip: Always match the mesh size to the size of the particles in your material. This helps the dewatering screen work well and stops clogging or blocking.

Choosing the Right Dewatering Screen Mesh

Key Selection Factors

Picking the right dewatering screen mesh size helps the equipment work well and last longer. There are a few things to think about when making this choice.

Particle Size

Particle size is very important when picking mesh. The mesh lets some particles go through and keeps others on top. Finer mesh sizes catch smaller particles. Coarser mesh sizes let bigger particles pass. How the particles are spread out in the material changes how well the screen works. If there are lots of small particles, screens with fast shaking work best. Big particles do better with screens that shake with bigger movements.

- Mesh size decides which particles can go through.

- Finer mesh sizes hold smaller particles.

- Coarser mesh sizes work for bigger particles.

- How particles are spread out affects how well the screen separates them.

Material Properties

What the material is like also matters for mesh choice. Rough materials need screens that do not wear out fast, like ones made from strong steel, polyurethane, or rubber. Heavy materials need screens that are tough, with strong frames, springs, and motors. The table below shows how different material types change what mesh you should pick:

| Material Property | Effect on Mesh Selection |

|---|---|

| Abrasiveness | Needs tough mesh or polyurethane so it does not wear out. |

| Density | Needs a strong screen with extra support and power to hold heavy loads. |

Moisture Content

How wet the material is changes how the screen works. Wet stuff can block finer mesh sizes and make the screen less effective. If the material is very wet, you may need a mesh with bigger openings or a screen that shakes more to keep the mesh clear. If the material is dry, you can use finer mesh sizes to catch smaller particles.

Tip: Always check how wet the material is before picking a mesh. This helps stop clogging and makes sure the screen works smoothly.

Throughput Needs

How much material you need to process each hour affects mesh choice. If you need to move a lot of material, you need a mesh that lets water flow but still keeps the right particles. If the mesh openings are too small, the process slows down. If the openings are too big, unwanted particles might get through. Matching how much material you want to process with the mesh size helps the screen work well and stops slowdowns.

Mesh Selection Steps

There are clear steps to follow when picking the right mesh. Doing these steps helps you match the mesh to your job and what you want to get out of it.

Assessing Application

- Decide what you want the dewatering screen to do. Figure out if you need to remove water from big or small materials.

- Look at the material. Check the size, shape, wetness, and heaviness of the particles.

- Think about where you will use the screen. Look at dust, temperature, and humidity.

- Figure out how many hours the screen will run. Decide if it will work all the time or just sometimes.

- Set what you need for handling the material. Decide how much and how fast you need to process.

Matching Mesh to Output

- Find out the smallest and biggest particles in your material.

- Pick a mesh size that does the separation you want. Choose a standard mesh size that fits your job.

- Think about what kind of mesh or panel you need. Pick the right material for roughness and heaviness.

- Try out different mesh sizes if you can. Testing helps you find the best one.

- Ask a manufacturer or supplier for advice. Experts can help you get a custom solution for your needs.

Note: Always work with a trusted supplier when picking a dewatering screen mesh size. Manufacturers know a lot and can help you design a solution that fits your job.

Careful picking makes sure the dewatering screen does its job well. Matching mesh size, material type, and how much you need to process helps the screen work better and last longer. The right mesh or panel makes a big difference in how well and how long the screen works.

Dewatering Screen Applications

Mining and Aggregates

Dewatering screens help mining and aggregate workers separate water from solids. People use these screens for coal, sand, and gravel. Each material needs a different mesh size for the best results.

Coal, Sand, Gravel

Coal uses a mesh with medium-sized openings. Coal pieces are not all the same size, so workers pick a mesh that keeps most solids but lets water pass. Sand needs a finer mesh because sand grains are smaller. Gravel needs a coarse mesh since gravel pieces are much bigger. The usual mesh size for these jobs is about 0.16 mm, but companies can make special mesh sizes if needed.

A vibrating screen machine helps sort these materials fast. Workers pick woven wire mesh panels based on how big the pieces are and how much water is in the mix. For coal, mesh sizes from 0.16 mm to 1 mm work well. Sand screens often use mesh sizes from 0.3 mm to 0.8 mm. Gravel screens need bigger mesh openings, usually more than 2 mm.

Note: Using the right mesh size for the particle size helps the screen work better and stops material loss.

| Material | Typical Mesh Size (mm) | Mesh Type | Application |

|---|---|---|---|

| Coal | 0.16 – 1.0 | Woven wire mesh | Dewatering, tailings |

| Sand | 0.3 – 0.8 | Woven wire mesh | Dewatering, mineral sands |

| Gravel | 2.0+ | Woven wire mesh | Dewatering, aggregates |

Industrial and Specialty Uses

Factories and special industries also use dewatering screens. These places process food and clean dirty water. Each job needs a careful mesh choice to handle different particle sizes and wetness.

Food, Wastewater

Food factories use dewatering screens to separate liquids from solids like fruit pulp or veggie bits. Workers pick a fine mesh to catch small pieces and keep the food good. Wastewater plants use dewatering screens to take solids out of water. The mesh size depends on how big the solids are in the water. Fine mesh panels, like 0.3 mm or smaller, work best for catching silt and sludge.

Woven wire mesh panels last long and separate things well in these places. Workers watch the particle size and change the mesh size to keep dewatering working well. The right mesh size stops clogging and keeps things running smoothly.

- Food processing: Fine mesh (0.3 mm or less) for pulp, seeds, and small solids.

- Wastewater: Fine mesh (0.3 mm or less) for sludge, silt, and suspended solids.

Tip: Check the mesh size and condition often to stop problems and keep the output good.

Picking the right mesh size for each job helps the dewatering screen work well. Workers should always think about particle size, wetness, and how much material they need to process before picking a mesh or woven wire mesh panel.

Optimizing Dewatering Performance

Efficiency Tips

Preventing Blinding

Blinding happens when particles block mesh openings. This slows water flow and makes dewatering less effective. Operators can stop blinding in different ways:

- Pick a mesh size that fits the particle size. Finer mesh screens can block faster, especially with sticky or wet particles.

- Use flexible screen materials like polyurethane or rubber. These materials help stop particles from getting stuck.

- Check screen tension often. Loose screens let particles settle and block holes.

- Choose the right hole shape. Square holes can trap particles, but slots let odd-shaped pieces pass.

- Pick strong mesh materials that resist wear and plugging.

- Match mesh size to the particle size spread for better solids removal.

Tip: Check tension often and use flexible woven wire mesh panels. This helps keep the screen clear and working well.

Balancing Throughput and Quality

Operators need to balance how much material goes through the screen and the quality of what comes out. The right mesh size is important for this. Here are some good steps:

- Do a particle size check to pick the best mesh size.

- Set clear quality goals and compare them to standards.

- Test and change mesh choice based on real results and material changes.

| Mesh Size (µm) | Turbidity (NTU) | Notes |

|---|---|---|

| 2000 | 0.45 | Bigger flocs can be separated with larger mesh |

| 50 | 0.32 | Good at lowering turbidity |

| 20 | 0.20 | Smaller mesh lowers turbidity even more |

“In one project, smaller openings and faster shaking improved water and clay balance. A thin mud layer helped catch fine particles, showing real results can be better than theory.”

Screen Maintenance

Extending Mesh Life

Good care helps mesh last longer and keeps dewatering working well. Operators should do these steps:

- Clean inside the screen to remove buildup.

- Wash the outside with safe cleaners to stop rust.

- Lubricate moving parts to lower wear.

- Check shock absorbers for less shaking.

- Get skilled technicians for regular checks.

- Make and follow a maintenance plan to find problems early.

- Do not run the screen with too much material for long.

- Make sure no material stays on the mesh before shutting down.

- Put the equipment in a good place to avoid damage from bad conditions.

Note: Cleaning often and careful use help mesh last longer and keep dewatering working well.

Operators who pick the right mesh size, stop blinding, and take care of their equipment get better results. These steps help the dewatering screen work well and make woven wire mesh panels last longer.

Mesh Material Options

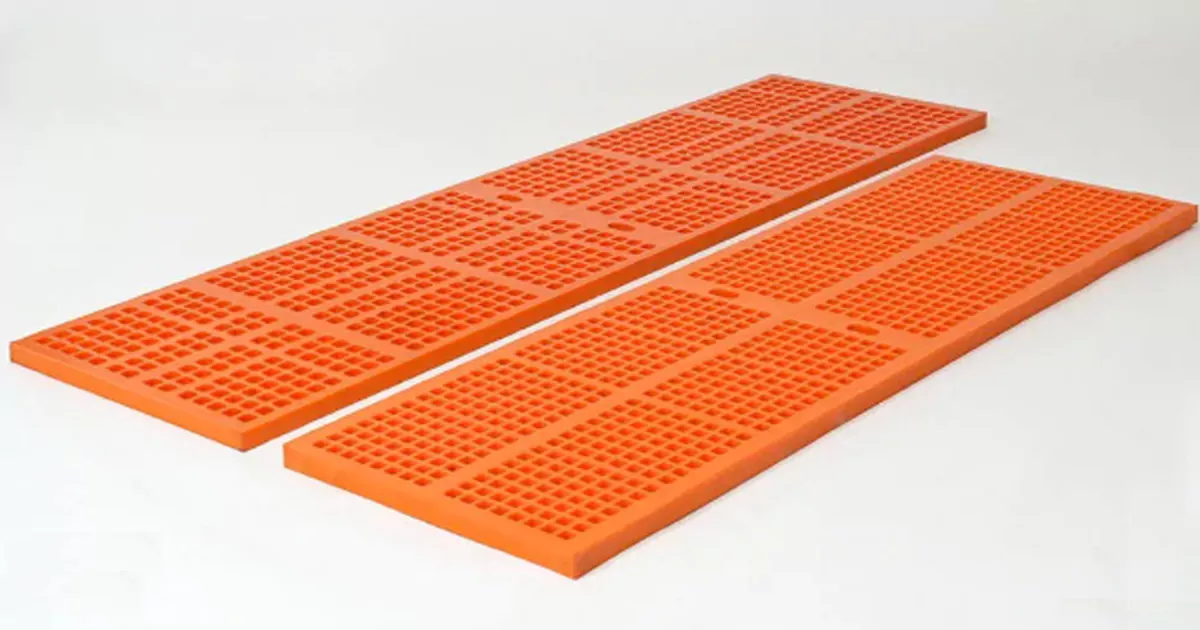

Woven Wire vs. Polyurethane

Pros and Cons

Picking the right mesh material is very important for dewatering. The two main choices are woven wire and polyurethane. Each one has good points and some problems for different jobs.

Woven wire mesh has lots of open space. This lets water drain quickly and separates solids well. It is best when you need a lot of open area. But woven wire wears out faster, especially with rough materials. You will need to replace it more often. This can mean more time spent fixing and higher costs.

Polyurethane mesh is known for being very tough. It lasts at least twice as long as woven wire. Polyurethane does not tear or stick easily. It also stands up to chemicals, so it works well in hard places. Its strong surface can make it last up to ten times longer than wire mesh. Polyurethane helps stop blinding and pegging, so dewatering stays steady. Workers like that it is light and simple to put in. It also makes less noise when running.

The table below shows how they compare:

| Feature | Woven Wire Mesh | Polyurethane Mesh |

|---|---|---|

| Wear Resistance | Moderate | Very High |

| Service Life | Shorter | Much Longer |

| Open Area | Maximum | High |

| Chemical Resistance | Low | High |

| Maintenance | Frequent | Minimal |

| Noise Reduction | Low | High |

| Weight | Heavier | Lightweight |

Tip: Polyurethane mesh is great for both wet and dry jobs. It is very useful when you need to control moisture.

Material Selection Tips

Durability and Cost

Choosing the best mesh material depends on a few things. Durability and price are big factors. Polyurethane mesh lasts a long time and is very strong. It can take heavy loads and handle over 200,000 tons of material. This means it needs less fixing and saves money over time.

Woven wire mesh costs less at first and has the most open space. But it does not last as long, so you may spend more later. Polyurethane mesh costs more to buy, but it saves money because it lasts longer and needs fewer changes.

When picking mesh material, think about these things:

- Check if the temperature, chemicals, or weather will affect the mesh.

- Make sure the mesh fits the roughness and chemicals in your material.

- For hot jobs, use heat-resistant mesh like stainless steel.

- For cold jobs, pick mesh that stays strong and bendy.

- If the screen shakes a lot, use mesh that does not get tired out.

- Think about how much open space you need versus how long the mesh will last.

- Figure out the cost for each ton you process, not just the price to buy.

Note: The right mesh material helps the screen work better, saves money, and makes the screen last longer.

Conclusion

Picking the right dewatering screen mesh size helps things work better and makes the product good. Operators get many clear benefits:

- The right mesh size removes water well and stops clogging.

- Good mesh size helps keep product quality high.

- Better efficiency means lower costs and more work done.

Mesh size charts and careful steps help workers avoid expensive mistakes. These tools make sure the screen fits the material and job. Talking to experts helps you get the best size and system for your needs. Specialists can design, test, and suggest the best mesh for each job.

As a professional dewatering screen mesh manufacturer, ANPENG produces screen media to your exact material, moisture target, and machine requirements—custom mesh size, wire diameter, open area, panel size, and edge finishing are all available. Tell us your feed material, particle size range, slurry concentration, and screen model, and our engineers will recommend the best mesh size and build a solution that delivers fast drainage, less blinding, and stable product quality.

Contact us now to get a manufacturer-direct quote and a tailored mesh recommendation for your site.

FAQ

What is a dewatering screen?

A dewatering screen is a machine that takes water out of solids. It has mesh panels that let water go through but hold particles on top. People use it in mining, building, and cleaning dirty water.

How do you choose the right mesh size?

Operators look at the size of the particles and how wet the material is. They pick mesh openings that keep the smallest particle they want. Trying different mesh sizes helps find the best one for each job.

Why does mesh material matter?

Mesh material changes how strong and useful the screen is. Woven wire mesh has lots of open space but wears out faster. Polyurethane mesh lasts longer and stands up to chemicals. The best choice depends on the material and where you use it.

How often should you replace the mesh?

How often you change mesh depends on wear, material, and how much you use it. Operators check screens often for damage or clogging. Most people replace mesh when it stops working well or gets holes.

What causes blinding in dewatering screens?

Blinding happens when particles block the mesh holes. Sticky or wet materials cause this problem. Operators stop blinding by picking the right mesh size and cleaning screens often.

Can dewatering screens handle fine particles?

Dewatering screens can work with fine particles by using smaller mesh sizes. Ultra-fine mesh panels catch silt, clay, and sludge. Operators pick mesh based on the smallest particle in the material.

Where are dewatering screens used?

People use dewatering screens in mining, food factories, and cleaning dirty water. These machines help take water out of coal, sand, gravel, and sludge from factories.

How does maintenance affect dewatering performance?

Regular care keeps screens working well. Cleaning, checking tension, and changing worn mesh help stop clogging and make screens last longer. Good care makes dewatering work better.