Choosing between manganese steel vs stainless steel can feel tricky. You want something that lasts, right? In dry places with low humidity, both types stand up well. When humidity rises, especially above 80%, you see steel lose strength faster. Stainless steel handles wet, chemical-heavy spots better, while manganese steel shines in tough, high-impact jobs. Think about where you plan to use the steel. I’ll help you figure out which one fits your needs best.

Key Takeaways

- Manganese steel is great for tough jobs like mining. It is very strong and gets harder when used a lot.

- Stainless steel works best in wet places. It does not rust easily and is simple to clean.

- Pick manganese steel if you need something that can handle a lot of wear, like in crushers or big machines.

- Use stainless steel in kitchens or hospitals because it is clean and does not rust.

- You must take care of manganese steel often. Check it and clean it so it does not rust or wear out.

- Stainless steel does not need much care. Just keep it clean and do not use rough cleaners to keep it shiny and strong.

- Think about where and how you will use the steel before you choose.

- Pick the right steel for your job.

- Both manganese and stainless steel can be recycled. But it is easier and more common to recycle stainless steel.

Manganese Steel vs Stainless Steel: Durability

Lifespan in Harsh Environments

Industrial and Mining Use

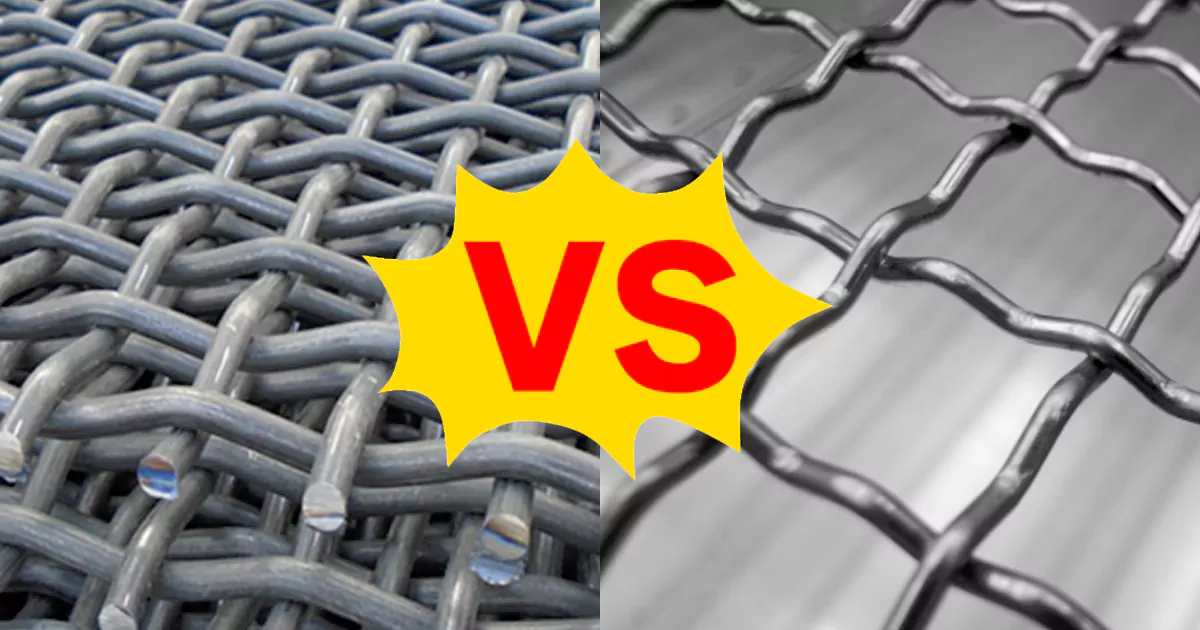

When you look at manganese steel vs stainless steel in tough places like mining and aggregate sites, you see big differences. Manganese steel stands out in mining. It handles heavy hits and rough treatment every day. You find it in rock crushers, loader buckets, and big screens. This steel gets harder the more you use it. That means it lasts longer when rocks and gravel hit it again and again.

- Manganese steel, especially Hadfield steel, is famous for its wear resistance in mining.

- High-manganese cast steels can self-harden under high loads. This helps them survive in mining and aggregate environments.

- Studies focus on how manganese steel changes inside when used in mining, showing why it works so well.

Stainless steel does not do as well in these spots. It can resist rust, but it does not handle big impacts or constant grinding like manganese steel. If you need something for mining or aggregate work, manganese steel is the better choice.

Wet and Humid Conditions

Now, think about wet and humid places. Here, stainless steel takes the lead. It fights off rust and keeps its strength even when the air is damp. You see it in food plants, water treatment, and outdoor gear. Manganese steel can rust faster in these spots, especially if you do not keep it clean. If you need steel for wet or humid jobs, stainless steel will last longer.

Wear and Impact Resistance

Abrasion Performance

Wear is a big deal when you pick steel. You want something that does not wear out fast. Let’s look at how manganese steel vs stainless steel perform when things get rough.

| Material / Steel | Condition / Comparison | Main Findings |

|---|---|---|

| Duplex stainless steel | After heat treatment | Hardness and wear resistance increase. |

| Mn8 steel vs. Hadfield steel | Wear performance comparison | Mn8 steel has better wear resistance due to stronger work hardening during service. |

| Medium manganese steel vs. martensitic wear-resistant steel | Impact wear comparison | Medium manganese steel shows better impact wear resistance. |

| 6Mn–2Cr steel vs. Hadfield steel | Low-impact condition | 6Mn–2Cr steel lasts about 1.5× longer than Hadfield steel. |

| Mn5 steel | After heating treatment | Toughness and wear resistance improve due to microstructural changes. |

You see that manganese steel wins in most mining and aggregate jobs. It gets tougher the more you use it. This is called work hardening. Stainless steel can get harder with heat, but it does not match manganese steel in abrasive wear resistance.

Impact Strength

Impact strength means how well steel takes a hit without breaking. Manganese steel shines here. It can take a beating and keep going. That is why you see it in crushers and big machines. Stainless steel is strong, but it is not made for heavy impacts. If you need steel for jobs with lots of banging and crashing, manganese steel is your best bet.

Corrosion Resistance

Chemical Exposure

Corrosion resistance matters when chemicals are around. Manganese steel can rust faster if manganese ions build up. This happens in salty or chemical-heavy places. If you add chromium to the mix, the steel resists rust better. Stainless steel does well because it has more chromium. It forms a thin layer that protects it from rust. But, if you put stainless steel in strong acids or hot, harsh chemicals, this layer can break down. Then, the steel can rust just like any other metal.

Maintenance Needs

You need to think about how much work it takes to keep your steel in good shape. Manganese steel needs regular checks in wet or salty places. If you see rust, you need to clean it off fast. Stainless steel is easier to care for. It does not need as much cleaning, and it stays shiny longer. If you want less work, stainless steel is a good pick for wet or chemical jobs.

Tip: For mining and aggregate work, pick manganese steel for its toughness and wear resistance. For wet, humid, or chemical-heavy spots, go with stainless steel for better corrosion resistance and easier care.

Key Differences: Manganese Steel vs Stainless Steel

When you compare manganese steel and stainless steel, you see some big differences. These differences come from what goes into each steel, how you can work with them, and how much they cost. Let’s break it down so you can pick the right one for your job.

Material Composition

The stuff inside each steel makes a huge difference. You can think of steel like a recipe. Change the ingredients, and you get a new flavor and new powers.

Manganese Content

Manganese steel gets its strength from a high amount of manganese. This element makes the steel tough and hard to wear down. It also helps the steel stay strong when you hit it over and over. Here’s a quick look at what manganese does:

| Element | Role in Steel |

|---|---|

| Manganese | Increases tensile strength and hardness, enhances wear resistance, and stabilizes austenitic structure. |

You see manganese steel in places where things get rough, like mining and crushing rocks. The high manganese content is what gives manganese steel properties like amazing toughness and the ability to get harder the more you use it.

Chromium and Nickel in Stainless Steel

Stainless steel uses chromium and nickel to fight off rust and stay shiny. These elements help the steel last longer in wet or chemical-heavy spots. Here’s what they do:

| Element | Role in Steel |

|---|---|

| Chromium | Improves corrosion resistance, forms a protective oxide layer, and increases strength at high temperatures. |

| Nickel | Enhances corrosion resistance, improves ductility, and stabilizes the austenitic structure. |

You can count on stainless steel to stay strong and look good, even when things get damp or dirty. The mix of chromium and nickel is what gives stainless steel its famous rust-fighting power.

Machinability and Workability

Now, let’s talk about how easy it is to cut, weld, or shape each steel. This matters if you need to make parts or fix things.

Welding and Cutting

Manganese steel is tough, but it’s not easy to work with. When you try to cut or weld it, you run into some problems:

- Rapid work-hardening: The steel gets harder as you cut it, which wears out your tools fast.

- High heat generation: Cutting makes a lot of heat, which can damage your tools and the steel.

- Difficult chip control: The steel makes long, twisty chips that can mess up your work.

- Increased machining time and costs: You spend more time and money because you need special tools and slower speeds.

Stainless steel is easier to cut and weld. You can use regular tools, and you don’t have to worry as much about the steel getting too hard or making a mess.

Work Hardening Effects

Both manganese steel and stainless steel can get harder when you work them. This is called work hardening. For manganese steel, this is a superpower. The more you hit or use it, the tougher it gets. That’s why you see it in crushers and heavy machines. But this also means it’s hard to cut or shape.

Stainless steel also gets harder when you work it, but not as much as manganese steel. You still need to be careful with your tools, but it’s not as tricky.

Tip: If you need to cut or weld a lot, stainless steel will save you time and money. Manganese steel is best when you need something that can take a beating.

Cost and Availability

You want to know how much each steel costs and how easy it is to get. Prices can change, but here’s what you need to know.

Price Factors

Many things can change the price of steel. Here’s a table to help you see what matters most:

| Factor | Description |

|---|---|

| Energy-Intensive Production Process | Making stainless steel uses a lot of energy. Higher energy costs mean higher prices. |

| Transportation and Shipping Costs | Moving steel costs money. If fuel prices go up, so does the steel price. |

| Supply Chain Disruptions | Things like storms or world events can slow down steel delivery and make prices jump. |

| Global Demand | If more people want steel, prices go up. Industries like cars and buildings use a lot of steel. |

| Trade Tariffs and Import/Export Regulations | Government rules can add extra costs to steel. |

| Currency Fluctuations | If money values change, steel prices can change too. |

| Recycling of Stainless Steel | Using recycled steel can make prices lower. |

| Sustainability and Green Manufacturing Practices | Eco-friendly ways to make steel can help lower costs over time. |

Sourcing Challenges

The market for manganese steel is growing fast. In 2021, the global manganese alloys market was worth over $23 billion. Experts think it will almost double by 2031. More car makers want manganese steel because it’s strong and light. This helps cars use less fuel and make less pollution.

Stainless steel is also in high demand. Many industries need it, so prices can go up if there are shortages or shipping problems. You can usually find stainless steel more easily than manganese steel, but both can face delays if the world market changes.

Note: Manganese steel properties make it perfect for tough jobs, but you need special tools and skills to work with it. Stainless steel is easier to handle and more common in stores.

Quick Recap

- Manganese steel is super tough and gets harder with use, but it’s hard to cut and costs more to machine.

- Stainless steel fights rust and is easier to shape, but it doesn’t handle heavy impacts as well.

- Think about what you need: toughness and wear resistance, or easy care and rust protection.

Applications: Choosing the Right Steel

When you pick steel, you need to match it to your job. Some jobs need steel that is very tough. Other jobs need steel that does not rust. Let’s see where manganese steel and stainless steel work best.

Best Uses for Manganese Steel

Mining Equipment

You find manganese steel in mining machines a lot. This steel can take lots of hits and hard use. It lasts longer in crushers and loader buckets. It is also used for excavator teeth. Manganese cone crushers use this steel because it gets harder when hit. This means you do not have to replace parts as often.

| Application | Benefit Description |

|---|---|

| Mining Equipment | High wear resistance and toughness for durability. |

| Railway Tracks | Impact resistance and durability for safe transport. |

| Crushing Machinery | Ability to withstand tremendous wear during operations. |

Armor Plating

If you need strong protection, manganese steel is a great pick. Armor plating uses this steel because it can take big hits. It does not crack or break easily. The more you use it, the tougher it gets.

Heavy-Duty Screens

Heavy-duty screens in mining plants use manganese steel. Companies like Anpeng Wire Mesh Filter Equipment Co., Ltd. use it for their screens. This steel stands up to rough materials and lasts longer. You save money because you do not need to buy new screens often.

Tip: Manganese steel is best for jobs with lots of wear and impact.

Best Uses for Stainless Steel

Kitchens and Bathrooms

Stainless steel is great for kitchens and bathrooms. You see it in sinks, dishwashers, and faucets. It does not rust and is easy to keep clean. Pots, pans, and cutlery use stainless steel because it looks nice and handles heat well.

| Use | Properties Supporting Use |

|---|---|

| Sinks and Dishwashers | Corrosion-resistant, easy-to-clean, hygienic |

| Pots and Pans | Heat-resistant, aesthetic |

| Cutlery and Knives | Easy-to-clean, corrosion-resistant |

Medical and Food Equipment

Hospitals and food factories use stainless steel a lot. Its smooth surface keeps germs away. Cleaning is easier, so places stay safer. You do not need as much disinfectant, and the steel stays shiny.

Ceremonial Blades

Ceremonial blades often use stainless steel. It does not rust and is easy to care for. In wet places, stainless steel keeps its sharp edge and looks good. Damascus steel may stay sharp longer, but stainless steel is easier to keep nice.

Selection Tips

Wear vs. Corrosion Needs

Think about where you will use the steel. If you need steel for lots of hits and wear, pick manganese steel. It gets tougher the more you use it. For places with water or chemicals, stainless steel is better. It fights rust and stays clean.

- Manganese steel is best for high-impact and rough jobs.

- Stainless steel is best where you need rust protection.

Maintenance Considerations

You may want steel that is easy to care for. Manganese steel needs regular checks in wet or acidic places. Stainless steel is easier to clean and needs less work. If you want less upkeep, choose stainless steel.

Note: Pick your steel for the job. Mining and heavy-duty work need manganese steel. Kitchens, hospitals, and wet places need stainless steel.

Maintenance and Longevity

Taking care of your steel parts helps them last longer and work better. You want to avoid sudden breakdowns and keep everything running smoothly. Let’s look at how you can care for manganese steel and stainless steel, and how to get the most out of both.

Caring for Manganese Steel

Cleaning and Inspection

You need to check and clean manganese steel parts often, especially in tough jobs like mining. Regular inspection and cleaning stop dirt and rust from building up. Here’s what you should do:

- Look for signs of wear, cracks, or rust.

- Lubricate moving parts to cut down on friction.

- Clean off any dirt or chemicals right away.

- Stick to a set schedule for checks and cleaning.

If you follow these steps, you can prevent early wear and keep your manganese steel strong.

Repair Guidelines

When you spot damage, act fast. Here’s a simple plan to keep your manganese steel in top shape:

- Follow the service intervals your manufacturer suggests.

- Adjust your maintenance schedule if your site is extra busy or harsh.

- Use a checklist for inspections and repairs so you don’t miss anything.

- Keep spare parts organized and ready.

- Train your team to notice and fix problems quickly.

Tip: A good routine keeps your manganese steel working longer and saves you money on big repairs.

Caring for Stainless Steel

Preventing Rust

Stainless steel fights rust well, but you still need to help it out. Use these best practices to keep it looking good and working right:

| Best Practice | Description |

|---|---|

| Proper Drainage | Make sure water does not pool on surfaces. |

| Regular Cleaning | Clean and check crevices to remove dirt and chemicals. |

| Non-absorbent Gaskets | Use gaskets and seals that do not soak up water. |

| Rinse Surfaces | Wash away salt and other stuff that can cause rust. |

| Corrosion Inhibitors | Use these in places with lots of salt or chemicals. |

| Protective Coating | Add a coating if your steel is outside or in a harsh spot. |

Routine Upkeep

Keep your stainless steel shiny and strong with these habits:

| Best Practice | Description |

|---|---|

| Immediate Cleaning | Wipe off spills and dirt as soon as you see them. |

| Avoid Abrasives | Don’t use rough pads that can scratch the surface. |

| Warm Water Flush | Rinse with warm water after cleaning to remove any residue. |

| Passivation | Use citric acid to help the steel build a strong rust barrier. |

Note: If you see any spots or color changes, clean them right away to stop rust from spreading.

Maximizing Service Life

Installation Best Practices

How you install your steel parts matters. To get the longest life from manganese steel and stainless steel, remember these tips:

- Follow the maker’s installation rules.

- Protect surfaces from scratches and bumps.

- Keep up with regular maintenance.

A good start means fewer problems later.

When to Replace

Sometimes, you need to swap out old parts before they fail. Watch for these warning signs:

- Small, deep holes (pitting corrosion) that weaken the steel.

- Cracks on the surface (stress corrosion cracking) that can lead to breaks.

- Changes in color or shape that show rust or damage.

Regular checks help you spot trouble early and keep your equipment safe.

Remember: Taking care of your steel saves you time, money, and stress. A little effort goes a long way!

Conclusion

Choosing the right steel is key to longer service life, fewer shutdowns, and better performance in demanding operations. For applications exposed to heavy impact and severe abrasion, manganese steel is the most reliable option thanks to its excellent work-hardening capability. In wet or chemically aggressive environments, 316L stainless steel offers strong corrosion resistance and long-term stability. For food-contact or medical-related use, 304L stainless steel remains a safe and widely trusted material.

At Anpeng Wire Mesh Filter Equipment Co., Ltd., we design and manufacture durable screening solutions for heavy-duty industries. Our products include Woven Wire Screens, Self-Cleaning Screens, and PU-Mesh Screens, widely applied in Aggregate, Mining, Concrete, and Recycling operations. If you are unsure which material or screen type fits your working conditions, our technical team is ready to help you select the best solution based on your wear level, impact load, and site environment. Choosing high-quality steel with high recycled content can also support sustainability goals while maintaining strong performance.

Need help? Ask an expert before you buy.

FAQ

What makes manganese steel so tough?

Manganese steel gets tougher the more you use it. When you hit or wear it, the surface hardens. This process is called work hardening. You can count on it for jobs with lots of impact.

Does stainless steel rust?

Stainless steel resists rust because it has chromium. This metal forms a thin layer that blocks moisture. If you scratch or damage the surface, rust can still form. Keep it clean for best results.

Which steel is easier to cut and weld?

You will find stainless steel much easier to cut and weld. Manganese steel gets harder when you work on it. You need special tools for manganese steel.

Where should I use manganese steel?

You should use manganese steel in places with heavy wear and impact. Here are some examples:

- Mining equipment

- Crusher parts

- Heavy-duty screens

Is stainless steel safe for food and medical use?

Yes! Stainless steel is safe for kitchens, hospitals, and food factories. It does not react with food or medicine. You can clean it easily.

How do I choose between manganese steel and stainless steel?

Think about your job. If you need toughness and wear resistance, pick manganese steel. If you want rust protection and easy care, choose stainless steel.

Can I recycle these steels?

| Steel Type | Recyclable? | Notes |

|---|---|---|

| Manganese Steel | Yes | Needs special processing |

| Stainless Steel | Yes | Widely recycled |

You can recycle both types. Stainless steel recycling is more common.