Anti-Clogging Wire Mesh for Wet & Sticky Screening

Anpeng manufactures Anti-Clogging Wire Mesh—also known as self-cleaning screen mesh—for vibrating screens used in quarry, mining, and aggregate processing. This screen media is designed to reduce blinding (material sticking over openings) and pegging (near-size particles wedging in the apertures), which are common causes of capacity loss and frequent shutdown cleaning. As a direct manufacturer, we supply custom apertures, wire sizes, panel dimensions, and edge finishing to match your screen deck and operating conditions.

What Is Anti-Clogging Wire Mesh?

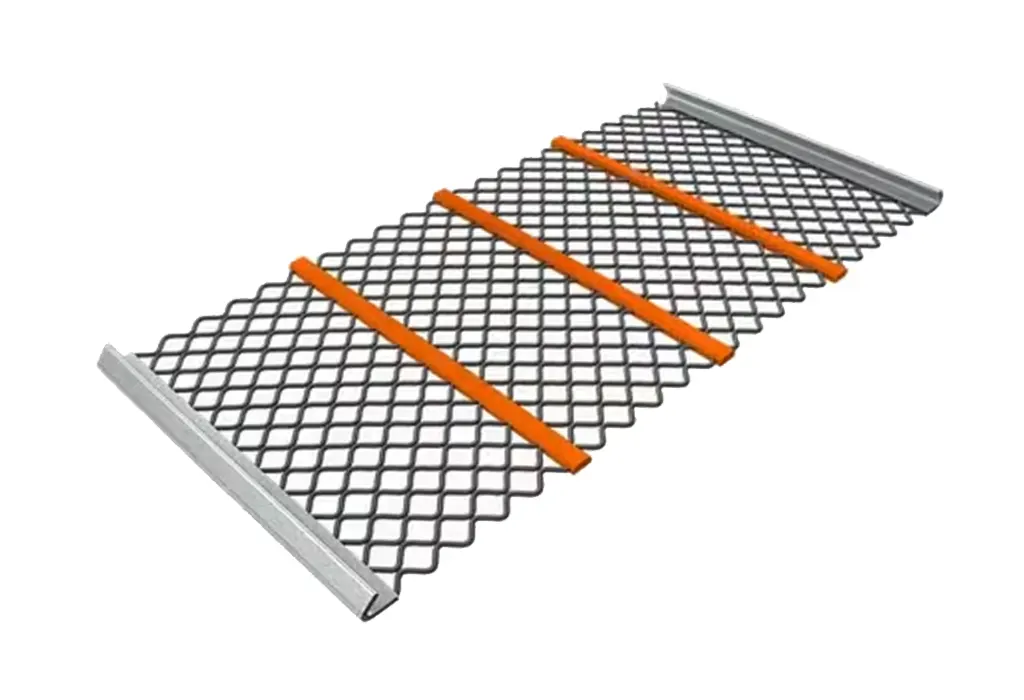

Anti-clogging wire mesh is a specialized screening surface made with a flexible wire structure that helps the deck “self-clean” during vibration. Instead of relying only on rigid openings, the wire design allows small independent movements under vibration, which helps break material adhesion and release near-size particles that would otherwise lodge in the apertures. It is commonly used for wet screening, clay-bearing feed, and any application where standard woven wire screens frequently blind or peg.

Problems It Solves in Real Screening Lines

When openings start to block, screening efficiency drops quickly. Anti-clogging mesh is typically selected to reduce the common issues that cause unstable output: frequent blinding on wet material, pegging from near-size particles, reduced capacity due to partially blocked open area, excessive manual cleaning and downtime, and inconsistent product gradation when the deck is not running “open.”

Key Benefits

Reduced blinding & pegging: keeps the deck more open in wet or sticky screening

More stable throughput: helps maintain capacity compared to frequently blinded screens

Better screening efficiency: improves the “effective open area” during operation

Less downtime: reduces the need for manual cleaning and unexpected stops

Custom fit: panel size and edge finishing matched to your vibrating screen system

Product Specifications

| Specification | Details |

|---|---|

| Product Name | Anti-Clogging Wire Mesh (Self-Cleaning Screen Mesh) |

| Manufacturer | Anpeng (Direct Manufacturer) |

| Screen Media Type | Self-cleaning / Anti-blinding wire screen mesh for vibrating screens |

| Material Options | High-Carbon Steel, Spring Steel (65Mn), Stainless Steel 304/316 (optional) |

| Design / Structure | Flexible wire structure to reduce blinding & pegging (matched to duty and cut size) |

| Opening Size (Aperture) | 2–120 mm (custom available) |

| Wire Diameter | Custom based on abrasion and impact duty |

| Panel Size | Custom per screen deck layout (panel or full-sheet options) |

| Edge Finish | Plain edges, Hooked edges, Reinforced edges (match your tensioning system) |

| Mounting / Tensioning | Clamp bar tensioning; bolt-down or other fixing options (as required) |

| Recommended Feed Condition | Wet, sticky, clay-bearing, or near-size pegging conditions |

| Recommended Duty | Aggregate and mining screening where standard woven wire frequently blinds or pegs |

| Customization | Aperture, panel size, edge finishing, material grade, and mesh structure available upon request |

| Quotation Info Needed | Aperture (mm), panel size (L×W), edge type, quantity, material screened, and issue (blinding or pegging) |

| Packing | Bundles or export pallets with protective wrapping; labeled by specification & order ID |

Why Choose Anpeng as Your Anti-Clogging Wire Mesh Manufacturer

As a direct manufacturer, Anpeng delivers reliable anti-clogging screen mesh with consistent specs, deck-fit customization, and practical support—helping you reduce blinding/pegging and keep your screening line running smoothly.

We produce panels to match your deck size, edge style (hooked/plain/reinforced), and mounting system, so replacement is faster and fitment issues are minimized.

Controlled material selection and manufacturing help keep aperture accuracy and panel consistency stable, supporting predictable screening performance.

Share your feed condition and problem (blinding or pegging). We’ll recommend a suitable design and provide export-ready packing with dependable lead times.

FAQs

What is anti-clogging wire mesh?

Anti-clogging wire mesh is a self-cleaning screen media designed to reduce blinding and pegging on vibrating screens. Its flexible wire structure helps keep openings more effective during vibration, improving screening stability on wet or sticky feed.

What’s the difference between self-cleaning mesh and standard woven wire mesh?

Standard woven wire mesh is rigid and works well on dry, free-flowing material. Self-cleaning mesh is designed for difficult screening where moisture, clay, or near-size particles cause frequent blockage. It helps reduce plugging and maintain capacity in those conditions.

Is it better for blinding or pegging?

It can help with both, but performance depends on material behavior and the selected structure. For sticky fines, the goal is usually reducing blinding. For near-size wedging, the focus is reducing pegging. Sharing your site issue helps us recommend the best design.

Will anti-clogging mesh fit my existing vibrating screen?

In most cases, yes. We manufacture custom panel sizes and edge finishes (hooked/plain/reinforced) to match your deck system. Send your current panel measurements or photos for confirmation.

What information do you need for a quotation?

Please provide aperture (mm), panel size (L×W), edge type, quantity, and the material screened. Also tell us whether your main issue is blinding or pegging and whether the feed is dry or wet.

How long does it last compared with standard mesh?

Service life depends on abrasion level, impact, material size distribution, and operating conditions. In difficult screening where standard mesh is frequently blinded, self-cleaning mesh can reduce downtime and improve effective operating time. We can recommend a suitable wire selection based on your duty.