When you want the Best Polyurethane Screen Panels, you need panels that last a long time. They should fit your machines. They also need to be good for your budget. What you need depends on what you process. Minerals, coal, and recycled materials all need different things. For example, mineral processing needs good separation. Recycling is about sorting things well. Wet or dry places and tough work areas are important too. Go step by step to pick the right panel for your work.

| Application | Criteria for Selection |

|---|---|

| Mineral Processing | Good at separating minerals |

| Coal & Steel | Makes handling materials better |

| Recycling | Sorts materials well |

| Mining | Filters well for better extraction |

| Cement Plants | Separates and screens materials well |

| Others | Used in water treatment, farming, and more |

| Fastest Growing | Recycling is growing fast because of green practices |

Key Takeaways

- Pick panels that fit your needs, like the material and how wet it is.

- Choose the right mesh size for your particles. Small particles need a fine mesh. Big particles need bigger holes.

- Think about where you will use the panels. Heat and chemicals can change how the panels work.

- Make sure the panel size and shape fit your equipment. This helps them work better.

- Look at the price now and how much you save later. Polyurethane panels last longer and need less fixing.

- Check if the supplier is known for good products and help. A good supplier gives better panels and service.

- Do not make mistakes like using the wrong panels or skipping maintenance. This helps your panels last longer.

- Use a checklist to look at features and decide what you need most when picking polyurethane screen panels.

Define Application Needs

To pick the right screen media, you must know your job. You need panels that fit your material and moisture. The work area matters too. Let’s look at what you should check.

Material Type & Moisture

Wet vs. Dry Screening

You must find out if your materials are wet or dry. Wet screening needs panels that fight rust and corrosion. Polyurethane screens are good for this. They clean themselves and last a long time. Water goes through them easily, so wet particles do not stick. For dry materials, you want panels that resist scratches and have more open space.

- Polyurethane panels work with water and oil. This makes them last longer.

- They are perfect for jobs like dewatering and demineralization.

- Wet particles do not block the screen, so you get better results.

Particle Size Considerations

Think about how big or small your particles are. Small particles need tiny mesh sizes. Big particles need larger holes. The right mesh and setup help you get the best outcome.

Here’s a simple table to help you decide:

| Factor | Why It Matters |

|---|---|

| Mesh size and configuration | Helps you separate or sort your materials |

| Material compatibility | Makes sure the panel fits your material |

| Open area percentage | Balances strength and how well it screens |

| Installation requirements | Fits your machines and is easy to put in |

Screening Purpose

Sizing, Dewatering, Scalping

You must know what you want your screen to do. Sizing sorts things by size. Dewatering takes water out of materials. Scalping removes big pieces before screening. Each job needs a special panel. Dewatering panels have exact slots and lots of open space. Scalping panels are strong for heavy loads.

- OBEX screens use polyurethane panels for normal screening, dewatering, and washing.

- Conn-Weld Incline Screens are good for scalping and finishing.

- Extreme Duty Scalping Screens handle big and heavy jobs.

Operating Environment

Temperature & Climate

The temperature at your site can change how panels work. Polyurethane works from -22°F to 194°F. If it gets hotter, panels may get soft and weak. In cold weather, they can get hard and crack. Always check your site’s temperature before picking panels.

Chemical Exposure

Some places have chemicals or water with different pH levels. Polyurethane can wear out faster in these spots. Long contact with harsh chemicals or water makes panels break sooner. If your site has these risks, choose panels made for tough places.

Tip: Always match your screen media to your material, moisture, and work area. This helps your panels last longer and work better.

Key Criteria for Polyurethane Screens

Panel Size & Shape

Choosing the right panel size and shape makes a big difference in how your screening system works. If you pick a screen that is too small, you might slow down your process. If you go too big, you could waste money and space. You want to match the panel size to your machine and your material flow.

Standard vs. Custom

You can choose from standard panels or get custom ones made just for your job. Standard panels fit most machines and are easy to replace. Custom panels work best when you have special needs or unique equipment. They can help you get the best polyurethane screen panels for your operation.

- Standard panels are quick to install and cost less.

- Custom panels fit odd shapes or special machines.

- Always check your equipment before you decide.

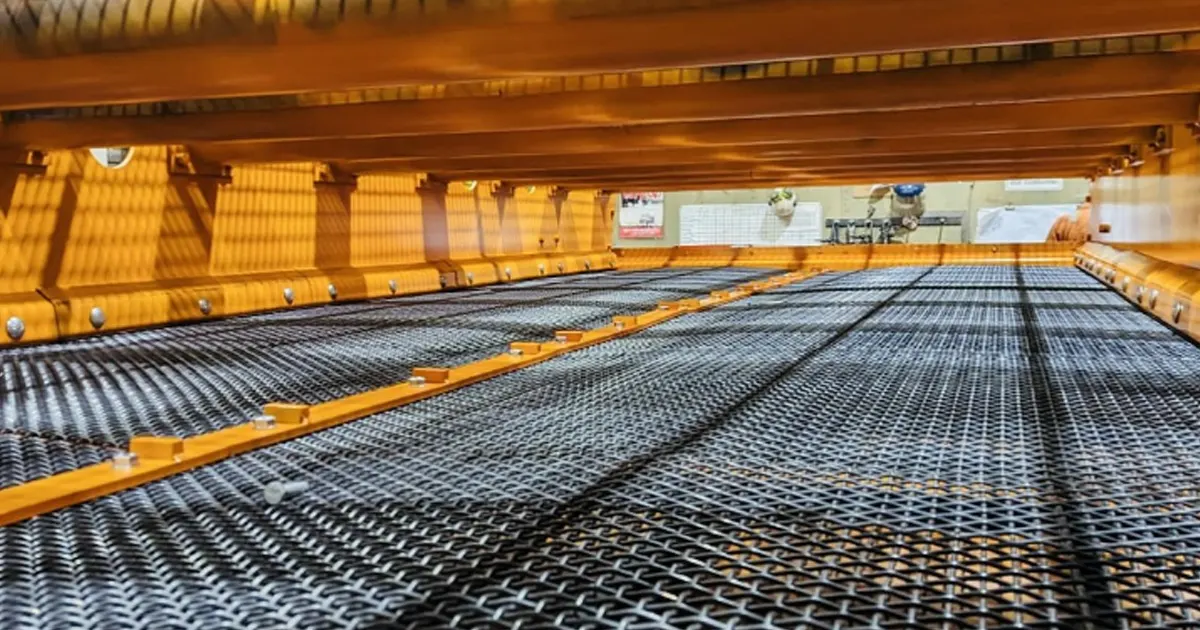

Aperture Design

The shape and size of the holes in your screen media matter a lot. These holes, called apertures, control what gets through and what stays out. You need to pick the right design for your material and your goals.

Square, Slotted, Specialty

- Square apertures work well for most jobs. They give you even sorting and good flow.

- Slotted apertures help when you have long or sticky materials. They also reduce pegging, which happens when pieces get stuck in the holes.

- Specialty shapes can solve tricky problems. For example, tapered holes can stop blinding, where wet or fine particles block the screen.

Tip: If you see a lot of blinding or pegging, try self-cleaning screen media or change the aperture shape. You can also adjust vibration or use spray bars to keep your panels clear.

Load & Throughput

You want your panels to handle the amount of material you process every day. If your panels cannot keep up, you lose time and money. Polyurethane screens are strong and last longer than many other types. They work well in wet or rough jobs and give you durability and longer wear life.

Capacity Needs

Think about how much material you need to move. Polyurethane panels can handle heavy loads without breaking down. They set a new standard for durability and longevity. You get more life out of your panels, which means less downtime and lower costs.

- Check your daily and peak loads.

- Choose panels that match your throughput needs.

- Remember, the right screen media boosts productivity and keeps your operation running smoothly.

Abrasion & Chemical Resistance

When you pick screen media, you want it to last. Some jobs are rougher than others. If you work with sharp rocks or tough minerals, your panels need to handle a lot of wear. Polyurethane stands out because it fights off scratches and damage better than many other materials. This means you get more durability and less downtime.

Material Abrasiveness

Ask yourself, “How rough is my material?” If you deal with sand, gravel, or crushed stone, you need panels that can take a beating. Polyurethane panels do a great job in these settings. They keep their shape and strength, even when things get tough. You also want to think about chemicals. Some sites have water or dust with harsh chemicals. Polyurethane resists many chemicals, so your panels last longer.

Here’s a quick checklist to help you:

- Check if your material is sharp, gritty, or heavy.

- Think about any chemicals in your process.

- Choose panels made for high abrasion and chemical resistance.

Tip: If you see panels wearing out fast, you might need a tougher screen media. Ask your supplier about options for high-abrasion or chemical-heavy jobs.

Installation Fit

You want your panels to fit your equipment just right. If they don’t, you could have leaks, poor screening, or even damage to your machines. The best polyurethane screen panels come in many sizes and shapes, so you can find the perfect match.

Compatibility with Equipment

Before you buy, check your machine’s specs. Look at the size, shape, and mounting style. Some panels snap in, while others bolt down. You want a snug fit for the best results. If you have special equipment, you can ask for custom panels. This way, you get the right fit and top performance.

Here’s a simple table to guide you:

| Equipment Type | Panel Mounting Style | What to Check |

|---|---|---|

| Vibrating Screens | Snap-in, Bolt-on | Panel size, hole pattern |

| Trommel Screens | Bolt-on, Weld-on | Panel shape, thickness |

| Flat Decks | Snap-in, Bolt-on | Panel width, length |

Note: Always double-check your equipment before you order. A good fit means better screening, less noise, and longer panel longevity.

Compare Best Polyurethane Screen Panels

Cost & Value

Upfront vs. Long-Term Cost

When you look for the best polyurethane screen panels, you might notice the price tag first. Polyurethane panels usually cost more at the start than other types, like woven wire screens. Sometimes, you pay two or three times more for these panels. That can feel like a big jump. But don’t stop there—think about what you get for your money.

You want to look at the whole picture, not just the first bill. Polyurethane panels last much longer than wire screens. In many cases, they can last eight to ten times longer. That means you do not have to replace them as often. You save money on new panels, and you spend less time and effort on maintenance. Over time, your operation runs smoother and you avoid extra labor costs.

Here are some things to keep in mind when you compare costs and value:

- Polyurethane panels have a higher upfront cost, but their durability means fewer replacements.

- The lightweight design of these panels helps lower energy use, which saves you money on power bills.

- Flexible panels reduce clogging and blinding, so your screen media works better and you get more done.

- You spend less on labor because you do not have to change panels as often.

- The best polyurethane screen panels give you better screening efficiency, which means you process more material for every dollar spent.

- When you look at cost per ton of material, polyurethane screen media often comes out ahead over time.

You should always think about the total cost over the life of your panels. Sometimes, paying more at the start gives you big savings later. If you want the best value, focus on durability, longevity, and how well your screen media performs every day.

Tip: Don’t just look at the price tag. Think about how long your panels will last and how much work they save you. The best polyurethane screen panels pay off in the long run.

Supplier Reputation

Quality & Support

When you look for the best polyurethane screen panels, you want more than just a good product. You need a supplier you can trust. Supplier reputation matters a lot. It can make your whole experience better or worse. If you pick a supplier with a strong track record, you get peace of mind. You know you will get panels that meet your needs and last longer.

You should always check how a supplier handles quality. Some companies test every batch of panels before they ship them out. Others use strict checks to make sure each panel meets industry standards. If you want the best results, ask your supplier about their quality control process. Do they have certificates or awards? Do they share test results? These things show they care about quality.

Support is just as important as the product itself. You might have questions about installation or need help picking the right panel. Maybe you want to know if custom-designed high-vibration screen media is right for your job. A good supplier will answer your questions fast. They will help you solve problems and keep your operation running.

Here are some things to look for when you choose a supplier:

- Fast and friendly customer service

- Clear answers to your questions

- Help with installation and troubleshooting

- Willingness to offer custom solutions

- Good reviews from other customers

Tip: Always read reviews and ask other companies about their experience with a supplier. A company with a great reputation will have lots of happy customers.

Industry reviews often point out that reliable suppliers stand out because they respond quickly and fix issues fast. If you have a problem with your panels, you want someone who will help right away. You do not want to wait days for a reply. Good support means less downtime and fewer headaches.

You should also think about long-term support. Will your supplier help you if you need replacement parts? Can they offer advice if your screening needs change? A supplier who cares about quality will stick with you for the long haul.

If you want to get the most out of your polyurethane screen panels, pick a supplier who values quality and stands behind their products. This way, you know you are getting panels that work well and last longer. You also get support when you need it most.

Common Mistakes to Avoid

When you pick polyurethane screen panels, you should avoid mistakes. These mistakes can make your screening work worse. If you know what to look for, you can save money. You also keep your machines working well.

Ignoring Compatibility

Equipment Mismatch

You may think every panel fits your machine, but that is wrong. If you do not check compatibility, you can have big problems. Panels that do not fit wear out faster. You will spend more money fixing and replacing them. Your screening slows down, and you lose time. Always check if the panel fits your machine. Make sure it works with your setup. If you skip this, you waste time and money.

Note: Panels made for your equipment last longer. They work better and break down less. You get smoother screening.

Overlooking Maintenance

Cleaning & Inspection

You might think polyurethane panels need no care, but they do. Cleaning and checking them is important. If you skip maintenance, your panels can break early. You may see more clogging or uneven flow. This means more downtime and higher costs. Cleaning keeps panels clear and working well. Checking helps you find damage before it gets worse.

Here’s a table that shows what happens if you skip maintenance:

| Screen Type | Maintenance Requirements | Consequences of Neglecting Maintenance |

|---|---|---|

| Polyurethane (PU) | Needs less maintenance | Lasts longer, costs less to fix |

| Composite | Needs more maintenance | Breaks down faster, costs more |

Tip: Check your panels often. Clean them and look for damage. This easy step saves money and keeps your screens working longer.

Underestimating Conditions

Abrasive or Harsh Environments

You may not know how tough your work site is. If you ignore harsh conditions, panels can wear out fast. Polyurethane screens handle rough jobs better than metal or rubber. They last three to five times longer in hard places. They resist oils, greases, and chemicals. They stay strong where other materials fail.

- Polyurethane panels bend and stay strong.

- They need less care and save money.

- They stand up to tough chemicals and heavy loads.

If you pick the wrong screen media or ignore your site, you lose efficiency. You may see more blinding or uneven flow. Here’s a table to show common mistakes and their effects:

| Common Mistakes | Impact on Screening Efficiency |

|---|---|

| Picking the wrong screen media | Makes sorting materials harder and less efficient. |

| Skipping proper installation and maintenance | Makes screens break and causes problems. |

| Not checking the whole system | Makes screening worse because you miss things like vibration. |

| Ignoring wire diameter | Causes uneven flow and more clogging. |

| Incorrect vibration settings | Makes blinding and pegging worse and slows material movement. |

Callout: If you pay attention to compatibility, maintenance, and site conditions, you get better screening and longer panel life. Do not let simple mistakes cost you time and money!

Selection Checklist for Polyurethane Screens

Assess Application

Gather Data

Start by collecting all the important facts about your screening job. This helps you avoid mistakes and makes choosing easier. Ask yourself some questions. What material will you screen? Is it wet or dry? How big are the pieces? What is the temperature at your site? Are there chemicals that could hurt the panels? Write down your answers. You will need them when you look at different products.

Here’s a simple checklist to help you collect data:

- Material type and moisture level

- Particle size and shape

- Daily and peak load needs

- Operating temperature and climate

- Chemical exposure risks

- Equipment type and mounting style

Check your equipment details too. Look at the size, shape, and how panels attach. If you have special machines, write that down. This information helps you pick panels that fit and work well.

Prioritize Features

Rank Needs

Now, decide which features are most important for your job. Not every panel is the same. Some are stronger, some bend more, and some last longer in bad weather. Make a list of what you need most. Put them in order from most to least important.

Here’s a table that shows how different features change performance:

| Feature | Performance Outcome |

|---|---|

| Hard Segment Content | Makes panels strong, but too much can cause cracks |

| Molecular Weight Distribution | Helps panels resist tearing and stress |

| Additive Formulation | Balances flexibility and durability |

| Reinforcing Fillers | Reduces wear and extends panel life |

| UV Stabilizers and Antioxidants | Keeps panels strong outdoors |

| Manufacturing Process Control | Ensures panels are accurate and reliable |

Think about your work site. If you work outside, UV stabilizers are important. If you handle sharp rocks, you want reinforcing fillers. If you need panels to last, look for good manufacturing process control. Put these features in order based on your needs.

Tip: Write your list in order. Use it when you compare panels. This helps you focus on what matters most.

Evaluate Suppliers

Compare Options

Pick a supplier who meets your needs and helps you. Look for companies with lots of experience and a good name. Check if they have many products. This means you can get custom panels if you need them. Ask if they work on new ideas. Companies that do research often have better products.

Here’s an ordered list to help you compare suppliers:

- Ask about materials and how they make panels.

- Find out how they test their panels for strength.

- Ask for references or stories about real jobs.

Look for great customer support too. Fast help and good advice save you time and keep your work going. Good service after you buy means less waiting and more work done.

Note: A supplier with a good history and helpful support makes your screening job easier and more successful.

Make Final Choice

Confirm Fit

You’ve done your homework. You’ve gathered all your data, ranked your needs, and compared suppliers. Now, it’s time to make your final choice. This step is all about making sure your polyurethane screen panels fit your operation perfectly.

Start by double-checking the specs. Look at your equipment drawings and panel measurements side by side. Make sure the panel size, thickness, and mounting style match your machine. If you skip this, you might end up with panels that don’t fit or work as they should.

You also want to think about how your material moves across the screen. Does your material have lots of flaky or needle-shaped particles? If so, you’ll get better results with slotted apertures. These help reduce lodging and keep your screens clear. If you process round or blocky particles, square apertures might work best. Matching the panel to your particle shape can improve anti-blinding and boost your screening efficiency.

Here’s a quick table to help you see what works best:

| Best Practice | How It Helps Your Operation |

|---|---|

| Match panels to particle morphology | Improves anti-blinding and keeps flow smooth |

| Use slotted apertures for flaky/needle particles | Reduces lodging and keeps screens clear |

| Swap metal panels for polyurethane | Eliminates blinding and raises capacity by 12% |

You should also check how easy it is to install and remove the panels. Some panels snap in, while others bolt down. If you want to save time, look for panels that are easy to handle. This can cut down on downtime and make maintenance a breeze.

Before you place your order, ask your supplier for a sample or a test panel if possible. Try it out on your equipment. See how it fits and performs. If you notice any issues, talk to your supplier right away. Good suppliers will help you adjust the design or recommend a better option.

Tip: Always do a final walk-through before you buy. Check fit, installation, and performance. Don’t rush this step. A little extra time now can save you a lot of trouble later.

When you confirm the fit, you set yourself up for success. You get panels that last longer, work better, and make your operation smoother. You also avoid costly mistakes and downtime. Take pride in your choice—you’ve followed a smart, step-by-step process. Now, you’re ready to enjoy the benefits of the best polyurethane screen panels for your needs.

Conclusion

You can pick the best polyurethane screen panels by using easy steps. First, make sure your panels fit your material and screening needs. Flexible screens let particles move and stop clogging. This can make your work up to 20% better. Use a checklist to compare things like wear resistance, noise reduction, and anti-static features.

| Custom Solution Benefit | How It Helps You |

|---|---|

| Superior capacity and performance | Handles more material, faster |

| Non-blinding properties | Keeps screens clear and efficient |

| Longevity | Lasts up to 12 months |

We create custom polyurethane screen panels for any job. If you need advice or a special order, contact us for expert help!

FAQ

What makes polyurethane screen panels better than metal screens?

Polyurethane panels last longer and fight off damage. They stand up to chemicals and do not wear out fast. They make less noise and are lighter. This makes them easier to put in place.

Can I use polyurethane panels for both wet and dry screening?

Yes, you can use polyurethane panels for wet and dry jobs. They do not rust and stop clogging. This means your screens work well with any material.

How do I know which aperture shape to choose?

Check what kind of material you have. Square apertures are good for round particles. Slotted apertures help with sticky or flat materials. Special shapes fix tricky screening problems.

Do polyurethane panels need special maintenance?

You should clean and check your panels often. Polyurethane needs less care than metal. Looking for damage helps your screens last longer.

Will polyurethane panels fit my existing equipment?

Most suppliers have standard and custom sizes. You can find panels that fit your machine. Always check the mounting style and size before you buy.

How long do polyurethane screen panels usually last?

Panels can last up to ten times longer than wire screens. How long they last depends on your site and how you care for them. You may get up to 12 months or more.

Are polyurethane panels safe for high-temperature environments?

Polyurethane works from -22°F to 194°F. If your site is hotter, ask your supplier for panels made for extreme heat.

What should I do if my panels keep clogging?

Try panels that clean themselves or change the hole shape. You can also use vibration or spray bars. Ask your supplier for ways to stop clogging.