You want to choose the best woven wire mesh screens for your project, but it is easy to make mistakes. Many people forget to check if their screen mesh works well in the environment or if the screen can hold the weight. Some people do not check their screens often, use the wrong materials with the screen, or forget to protect the edges. Look at the table below to see common mistakes and how to fix them. Make sure your screen fits your project, so it works well and lasts a long time.

| Mistake | Solution |

|---|---|

| Failing to consider environmental factors | Check the environment and pick mesh that can resist it. |

| Forgetting to perform regular maintenance | Make a schedule to check for damage often. |

| Pairing with incompatible materials | Use materials that work well together. |

| Underestimating load-bearing capacity | Find out how much weight is needed and pick the right mesh. |

| Neglecting edge protection | Use something to cover and protect the cut edges. |

Key Takeaways

- Know what your project needs before you pick a woven wire mesh screen. This helps make sure the mesh works for your job.

- Pick the right material for where you will use it. Stainless steel works well in tough places. Galvanized steel costs less and is good for easier jobs.

- Take care of your mesh screen often. Check it on a schedule to stop damage. This helps your mesh screen last longer.

- Make sure the mesh size and wire thickness fit your project. These things change how well it filters and how much weight it can hold.

- Think about the weave pattern. Plain weave is flexible. Twill weave is strong. Dutch weave is best for tiny filtering jobs.

- Protect the edges of your mesh screen so they do not fray. Use covers to make it last longer.

- Talk to suppliers or experts if you need help. They can help you pick the best mesh for your needs.

- Order early, especially if you need special sizes. This stops delays and helps you get the right mesh when you need it.

What Is Woven Wire Mesh?

Definition and Structure

Woven wire mesh is easy to spot in many places. It is special because of how it is made. Wires are woven together at right angles. This is like making fabric. Each wire goes over and under the next one. This creates a grid with small holes. The grid can bend and fit different shapes. You can pick from many sizes and thicknesses. Fine mesh is good for tiny things. Bigger mesh works for larger items. Woven wire mesh is used for perforated screens and window panels. It also helps keep out insects. The wires can bend to fit odd shapes. If you do not protect the edges, the mesh might fray.

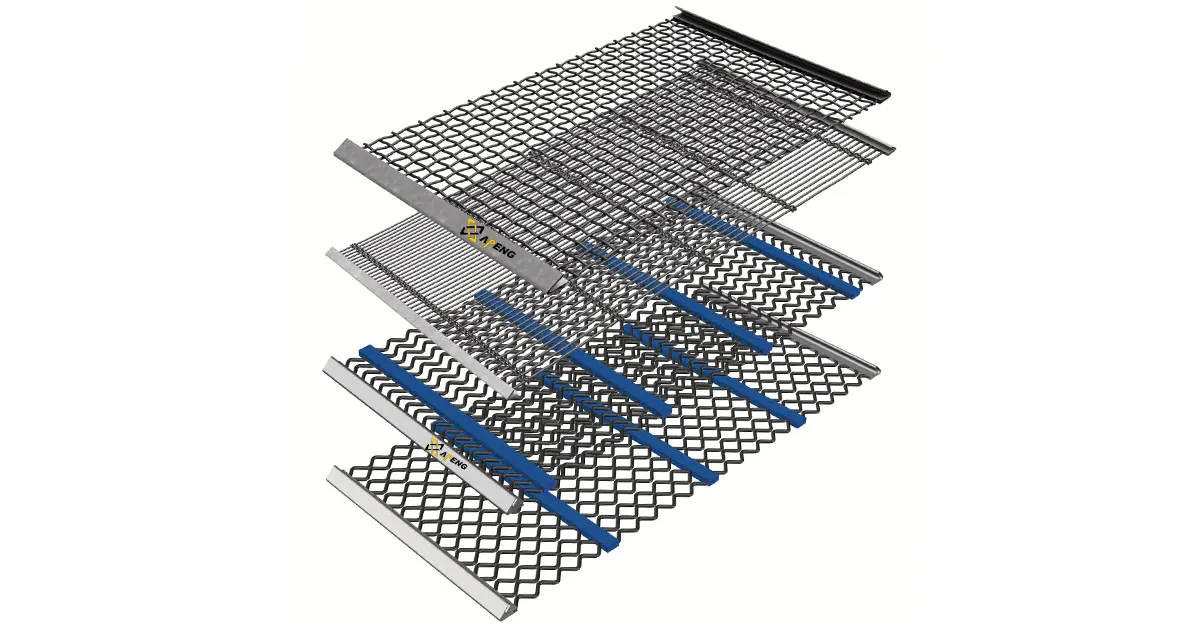

Woven vs. Welded and Expanded Mesh

Woven wire mesh is different from welded or expanded mesh. Welded wire mesh is made by joining wires at certain points. This makes welded mesh strong and helps it keep its shape. Welded mesh can have weak spots at the welds. This is a problem if you need it to last long. Woven wire mesh uses tension from weaving. This makes it flexible but not as strong as welded mesh. Expanded mesh starts as a solid sheet. It is cut and stretched to make diamond-shaped holes. Expanded mesh is good for tough jobs. It does not bend as easily as woven wire mesh.

Here is a table that shows the main differences:

| Type of Mesh | Advantages | Disadvantages |

|---|---|---|

| Woven Wire Mesh | – Costs less because it needs less work. | – Not as strong as welded metal. |

| – Bends easily for odd shapes. | – Small things may fall through holes. | |

| – Comes in many sizes and thicknesses. | ||

| Welded Wire Mesh | – Strong and keeps its shape well. | – Costs more because it takes more work. |

| – Handles heavy loads and strong forces. | ||

| – Made to last and can be coated to stop rust. |

Pick the mesh that fits your needs. Woven wire mesh is good if you want choices and flexibility. Welded mesh is better if you need strength. Expanded mesh works well for tough screens.

Industrial Uses of Woven Wire Mesh

Woven wire mesh is used in many industries. It is not just for screens or window panels. Here are some ways it is used:

- Chemical plants use wire mesh for filtering and separating.

- Mining companies use wire mesh to screen minerals and ores.

- Car factories use wire mesh in air and oil filters.

- Architects use wire mesh for design and function in buildings.

- Environmental workers use wire mesh for waste and water treatment.

- Aggregate industries use wire mesh to sort materials.

- Recycling centers use wire mesh to help sort and recover items.

- Concrete workers use wire mesh for support and strength.

- Factories use wire mesh in many machines and filters.

Woven wire mesh fits many jobs. You can use fine mesh for small things. Tough mesh works for heavy loads. Wire mesh is good for insect protection and window screens. Just match the type and size to your project.

Project Requirements for Best Woven Wire Mesh Screens

Before you pick a woven wire mesh screen, you need to know what your project needs. If you skip this, your screen might not work well or could break early. Let’s look at what you should check so your wire mesh fits your job and lasts longer.

Application Purpose

You must know why you need a woven wire mesh. Each job has its own needs. Some screens are for filtering, others are for sorting or keeping things safe. If you want to filter liquids or gases, look at how well the mesh can filter. The mesh size and how close the wires are decide what gets through. For sorting, pick a mesh that matches the size of the things you want to separate. If you use mesh for safety, it must be strong and last a long time.

Screening, Filtration, Sizing

Screening means you sort things by size. You use wire mesh screens to separate rocks or other items. Filtration is different. Here, you want to catch small things and let air or liquid go through. The size of the holes in the mesh controls what gets filtered. Sizing means you pick a mesh that matches the size of the things in your project. If you need to be exact, use a fine mesh. For bigger things, a coarse mesh is better.

Tip: Always check the mesh count and wire thickness. These numbers show how well the screen will work for your job.

Protection and Aesthetics

Sometimes, you use mesh to keep people safe or to make things look nice. If you need a safety barrier, pick a mesh that can take hits and stress. For looks, choose a mesh that fits your design and looks good. Some jobs need both safety and style, like fences or building panels. Make sure your mesh does both jobs.

| Purpose | Requirements | Advantages |

|---|---|---|

| Screening | Particle size, mesh count | High precision, fast sorting |

| Filtration | Filtration properties, density | Clean separation, better quality |

| Protection | Strength, impact resistance | Safety, long-lasting |

| Aesthetics | Design, finish, appearance | Visual appeal, custom options |

Environmental Factors

Your project needs can change with the environment. If your mesh faces water, chemicals, or rough use, you need a mesh that can handle these. Wet stuff can block the mesh and wear it out. Chemicals can hurt the mesh and cause problems. Rough materials can break the mesh over time.

Moisture, Chemicals, Abrasion

Water can make things stick and block the mesh holes. This makes your mesh work less well. Chemicals can harm the mesh, especially if you use the wrong kind. For chemical plants or near the sea, 316 stainless steel is best because it does not rust. Molybdenum in this steel helps stop damage from chemicals. Always check if your mesh matches the chemicals you use. Rough stuff is also a problem. If your job uses sharp or hard things, pick a mesh with thicker wires for more strength.

- Chemicals can make the mesh break down.

- Wet stuff can block the mesh and wear it out.

- Rough things can break the mesh and make it work worse.

- For chemical jobs, use 316 stainless steel for better strength.

Load and Stress Needs

You need to know how much weight and force your mesh will face. This is important for safety and how well it works. For heavy jobs, check the wire thickness and open space. Thicker wires make the mesh stronger. You can use the formula A = π × (d / 2)² to find the area of the wire. This helps you know how much weight the mesh can hold. The open space also matters. It shows how much stuff can go through. Use OA = (1 − (wire diameter / pitch)²) × 100 to check this.

Particle Size, Weight, Impact

Particle size matters for filtering and sorting. Pick a mesh that matches the size of the things in your job. Micron ratings help you choose the right mesh. For heavy loads, check the wire thickness and how the mesh is held up. If the weight is spread out, the mesh can handle it better. If your job has lots of loading, check your mesh often for damage. Safety is always important. Make sure your mesh meets safety rules and can take the hits in your job.

| Standard | Application | Description |

|---|---|---|

| API Standards | Petroleum Industry | Specs for screening and impact resistance |

| FDA CFR Title 21 | Food Industry | Safety requirements for contact surfaces |

| ASME BPE | Bioprocessing | Safety and performance standards |

- Check particle size and flow for filtering.

- Look at wire thickness for strength and flow.

- Make sure your mesh meets safety rules for your job.

Note: Always match your mesh to your project needs. This helps you get the best results and keeps your mesh working safely and well.

Choosing the Right Material for Woven Wire Mesh

When you pick wire mesh for your project, think about the material first. The kind of wire mesh you choose changes how well your screen works. It also affects how long it lasts and how much you need to fix it. You want strong wire mesh that fits your job and can handle the place where you use it. Let’s look at the main types of woven wire mesh materials and see which one is best for you.

Stainless Steel Screen Mesh

Stainless steel is a great choice for woven wire mesh. It is strong and works well in tough places. If you need wire mesh for hard jobs, stainless steel is a good pick.

Corrosion Resistance

You want your wire mesh to last a long time. This is important if your screen faces water, chemicals, or salty air. Stainless steel does not rust easily because it has a special layer called chromium oxide. This layer keeps the wire mesh safe from rust and damage. If you work near the ocean, in chemical plants, or in wet places, stainless steel woven wire mesh is the best choice.

Here is a table that shows how stainless steel compares to other materials:

| Material | Corrosion Resistance | Ideal Environments | Applications |

|---|---|---|---|

| Stainless Steel | High resistance due to chromium oxide layer | Marine settings, high chloride exposure | Infrastructure, industrial screens, wire mesh products |

| Aluminum | Good resistance, but more prone to galvanic corrosion | Less corrosive, lightweight needs | Aerospace, automotive, packaging |

You can see that stainless steel screen mesh works better in tough places than most other wire mesh.

Longevity

You want your woven wire mesh to last for many years. Stainless steel lasts a long time and does not need much fixing. It is very strong, so your screen mesh will keep working even in hard jobs. If you compare stainless steel to galvanized steel, you will see that stainless steel lasts longer and needs less repair.

| Feature | Galvanized Steel | Stainless Steel |

|---|---|---|

| Corrosion Resistance | Moderate; zinc coating wears off | Exceptional; great for tough jobs |

| Strength and Durability | Good for standard jobs | Superior; best for heavy-duty screens |

| Cost Considerations | Lower upfront cost, more upkeep | Higher cost, saves money long-term |

If you want wire mesh that saves you money over time, stainless steel woven wire mesh is a smart choice.

Galvanized Steel Mesh

Galvanized steel is another good choice for wire mesh. It works well for many jobs and costs less at first. The zinc coating helps stop rust, but it does not last as long as stainless steel.

Cost and Durability

If you do not have much money to spend, galvanized steel woven wire mesh is a good idea. It costs much less than stainless steel. In fact:

- Stainless steel costs about 4-5 times more than galvanized steel.

- Galvanized steel is cheaper at first, so it is good for projects where you need to save money.

Galvanized steel is strong, especially if you use hot-dip galvanized wire mesh. Hot-dip galvanized steel can last over 70 years outside without fixing. In normal places, the zinc coating can protect your wire mesh for up to 50 years. If you use your screen mesh in dirty places or near the sea, it lasts 10-20 years unless you add more coatings.

- Hot-dip galvanized steel lasts over 70 years in tough outdoor jobs.

- In coastal or dirty places, expect 10-20 years unless you add more protection.

If you want wire mesh for a short job or need to save money, galvanized steel woven wire mesh is a good pick.

Other Materials

Sometimes you need special wire mesh for different jobs. Aluminum, copper, and special alloys have their own good points. You can use these wire mesh products when you need something light, that carries electricity, or is easy to shape.

Aluminum, Copper, Specialty Alloys

Aluminum woven wire mesh is light and easy to use. It does not rust easily and is strong. If you need a screen mesh that does not weigh much, aluminum is a great choice.

Copper wire mesh is good for carrying electricity and is very reliable. You see copper wire mesh in wires, electronics, and plumbing. Special alloys, like copper-aluminum blends, are even stronger and do not rust as fast.

Here is a table that shows the good things about these wire mesh materials:

| Material | Unique Advantages | Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion resistance, easy to shape | Construction, automotive, aerospace, electrical |

| Copper | Superior conductivity, reliable, corrosion resistance | Wiring, electronics, plumbing, renewable energy |

| Copper-Aluminum Alloys | Strong, improved corrosion resistance, easy to process | Construction, automotive, electronics, furniture |

If you need wire mesh for a special job, custom wire mesh made from these materials can help you. You get wire mesh that fits your needs.

Tip: Always pick a woven wire mesh material that matches your project’s place and needs. You want your screen to last and work well, so do not pick the wrong one. Choosing the right wire mesh helps you get the best results every time.

Mesh Size, Wire Diameter, and Opening Size

Choosing the right wire mesh for your project means you need to look at mesh size, wire diameter, and opening size. These three things decide how well your screen works. If you get them wrong, your wire mesh might not do its job. Let’s break down what each part means and how you can use them to pick the best screen.

Mesh Count Explained

Mesh count is a simple way to measure wire mesh. You count the number of openings in one inch. If you see a #10 mesh, that means there are ten openings in every inch. A higher mesh count means smaller openings. You use mesh count to control what gets through your wire mesh.

- Square weave mesh count shows how many spaces are in one inch. If you want to catch small things, pick a high mesh count.

- Dutch weave mesh count uses two numbers, like 12*64. This tells you how many wires run in each direction.

- Mesh size is just the number of openings per inch. If you need to sort tiny particles, go for a higher mesh count.

Open Area, Particle Control

Open area is the space in your wire mesh that lets things pass through. If you want more flow, pick a wire mesh with a bigger open area. Mesh count helps you control particles. A high mesh count means you catch smaller particles. If you need to screen liquids, open area matters even more. More open area means faster flow.

- Mesh count tells you how many threads are in each inch, but it does not show the opening size.

- Open area decides how much stuff can move through your wire mesh.

- For industrial screening, you want to balance mesh count and open area for the best results.

Wire Diameter Selection

Wire diameter is the thickness of each wire in your wire mesh. You need to pick the right thickness for your job. Thicker wires make your wire mesh stronger. Thinner wires give you more flexibility.

- Thicker wires help your wire mesh handle heavy loads and stress.

- Thinner wires let your wire mesh bend and flex.

- The ratio of wire thickness to hole size changes how your wire mesh works.

- If you use thick wires, your wire mesh will not break as easily.

- Thin wires with big holes let more air or liquid pass, but your wire mesh will not be as strong.

Strength vs. Flexibility

You need to decide if you want strength or flexibility. If your wire mesh faces lots of force, pick thicker wires. If you need your wire mesh to bend, go for thinner wires. Think about your project and choose the wire diameter that fits your needs.

Opening Size and Performance

Opening size is the space between wires in your wire mesh. This decides what gets through and how fast things move. You need to match the opening size to your job. If you want to catch small particles, pick a small opening size. For bigger items, use a larger opening size.

Here’s a table to help you pick the right opening size and wire diameter for your job:

| Application Type | Recommended Opening Sizes | Wire Sizes (Diameters) |

|---|---|---|

| Light Use | 1/16″ – 1/8″ | 0.020″ – 0.035″ |

| Medium Use | 1/8″ – 1/4″ | 0.035″ – 0.065″ |

| Heavy Use | 1/4″ – 1/2″ | 0.065″ – 0.125″ |

Tip: Always check tolerance charts and load tables before you buy wire mesh. These charts show you how much weight your wire mesh can hold and how much it can bend. This helps you avoid mistakes and keeps your project safe.

When you look at mesh size, wire diameter, and opening size, you make sure your wire mesh fits your project. You get better results and your screen lasts longer.

Weave Patterns and Screen Mesh Functionality

Plain Weave

Versatility and Strength

When you look at wire mesh screens, you’ll notice that plain weave is everywhere. This pattern is simple. Each wire goes over and under the next wire, creating a tight grid. You get square openings that let air, water, or particles flow through easily. Plain weave wire mesh works well for fencing, insect screens, and basic filtration systems. You can use it for many jobs because it balances strength and cost. If you want a screen that handles moderate loads and gives you reliable performance, plain weave is a smart choice.

You’ll find plain weave wire mesh in places where you need good flow rates and solid strength. It’s easy to install and doesn’t cost much. You can trust it for general filtration and sorting tasks.

Twill Weave

Durability and Flexibility

Twill weave wire mesh steps up the game when you need more strength. In this pattern, each wire goes over two and under two wires, forming a diagonal look. This design makes the mesh stronger and lets you use finer wires. You get better particle retention and higher durability. Twill weave wire mesh is perfect for industrial filtration, sieving, and high-pressure jobs. If your project faces tough conditions or heavy loads, twill weave gives you the extra support you need.

- Twill weave wire mesh handles demanding tasks.

- You get finer filtration and improved load-bearing ability.

- The diagonal pattern helps the mesh flex without breaking.

You might choose twill weave wire mesh if you need to filter out tiny particles or work in a high-pressure environment. It’s a great option for jobs that push your screens to the limit.

Dutch Weave

Filtration Applications

Dutch weave wire mesh is all about fine filtration. This pattern uses thicker wires running one way and thinner wires running the other way. You get a mesh that catches very small particles but still lets liquids or gases pass through. Dutch weave wire mesh is common in oil and gas refining, food processing, and pharmaceutical filtration. If you need to separate tiny contaminants or work with sensitive materials, Dutch weave wire mesh is your best bet.

Here’s a quick table to help you compare the most common weave patterns and their uses:

| Weave Pattern | Description | Applications |

|---|---|---|

| Plain Weave | Wires alternate over and under, forming a tight grid | Fencing, insect screens, filtration systems |

| Twill Weave | Wires alternate over two and under two, creating a diagonal pattern | Industrial filtration, sieving, high-pressure |

| Dutch Weave | Thicker warp wires, thinner weft wires for fine filtration | Oil/gas refining, food, pharmaceuticals |

Tip: If you want balanced strength and cost, go with plain weave wire mesh. For heavy-duty jobs, twill weave wire mesh gives you more durability. When you need fine filtration, Dutch weave wire mesh is the top choice.

You can see that each weave pattern changes how your wire mesh screen works. Picking the right weave helps you get the best results for your project.

Aesthetic Considerations

You might think woven wire mesh only works for tough jobs, but it can also make your project look great. You can use mesh screens to add style to buildings, fences, or even machine guards. The right weave pattern changes how your project looks and feels.

When you pick a mesh for looks, you want to think about these things:

- Weave Pattern: Each pattern gives a different vibe. Plain weave looks clean and simple. Twill weave adds a cool, diagonal effect. Dutch weave feels tighter and more solid.

- Wire Finish: Shiny stainless steel stands out. Matte finishes look modern and smooth. You can even choose colored coatings for a bold look.

- Opening Size: Small openings give a sleek, private feel. Large openings look open and airy.

Here’s a quick table to help you compare how each weave pattern works for design:

| Weave Pattern | Visual Effect | Best For |

|---|---|---|

| Plain Weave | Simple, balanced | Modern facades, railings |

| Twill Weave | Diagonal, textured | Accent walls, feature panels |

| Dutch Weave | Dense, uniform | Privacy screens, partitions |

You can use woven wire mesh for more than just function. Architects use it for building facades, sunshades, and even ceilings. You might see mesh in stair railings or as a backdrop for signs. Mesh can turn a plain wall into a work of art.

Tip: If you want your project to stand out, try mixing different mesh patterns or finishes. You can layer mesh for a 3D effect or use colored mesh to match your brand.

You don’t need to be an expert to pick a good-looking mesh. Just ask yourself what style you want. Do you like bold and shiny? Go for stainless steel with a plain weave. Want something soft and private? Try a Dutch weave with a matte finish.

You can also talk to your supplier about custom options. Many companies can cut mesh to special shapes or add powder coatings. This helps you match your mesh to your project’s colors and style.

Remember, the right mesh does more than just work well. It makes your project look sharp and professional. Take time to explore your options. You’ll find a mesh that fits both your needs and your style.

Cost, Availability, and Supplier Consultation

Balancing Quality and Budget

When you start looking for woven wire mesh, you might notice that prices can change a lot. You want a screen mesh that fits your budget, but you also want it to last. Here are some things to think about:

- The type of weave matters. Square and slotted weaves can change how well your screen works and how long it lasts.

- Each part of a wire mesh, like the material and weave, affects the price. You need to find a balance between what you pay and how well the screen performs.

- Sometimes, you need to use value engineering. This means you look for ways to get the best performance for your money.

Material choice is a big deal. Stainless steel costs more, but it gives you better durability and a nice look. If you pick a cheaper material, you might save money now, but you could pay more later for repairs or replacements. Customisation also adds to the cost, especially if you want a special size or finish. Don’t forget about installation and maintenance. These can add up over time. If you focus on quality and value, your wire mesh will look better and work better for longer.

Tip: It’s smart to look at the whole project cost, not just the price of the screen mesh. Sometimes, paying a little more up front saves you money in the long run.

Sourcing Reliable Suppliers

You want to buy your woven wire mesh from a supplier you can trust. Not all suppliers offer the same quality or service. Here’s how you can check if a supplier is reliable:

- Ask about their quality control systems. Good suppliers have strong checks to make sure every wire mesh meets the right standards.

- Look for certifications and documents. Suppliers who follow ASTM or ISO standards usually offer better products.

- Check if they give you support and want to build a partnership. This shows they care about your project.

- Make sure the mesh size, wire diameter, and overall quality stay the same with every order.

A reliable supplier will answer your questions and help you pick the right screen for your job. They will also help you with customisation if you need something special.

Lead Times and Custom Orders

You need to plan ahead when you order wire mesh, especially if you want something custom. Most suppliers process standard orders in 1-3 business days, but shipping takes extra time. Custom or large orders need more time to make and deliver.

Here’s a table to help you see typical lead times:

| Order Type | Typical Lead Time |

|---|---|

| Standard wire mesh order | 25–45 days |

| Large or customized order | 40–70 days |

If you order the minimum amount, you might get it in a few days, but this does not include shipping. Most of the time, minimum orders do not ship the same day. Always ask your supplier about lead times before you order. This helps you avoid delays and keeps your project on track.

Note: Planning your order early gives you more options and helps you get the exact woven wire mesh you need.

Consulting Experts and Technical Resources

It can be hard to pick a woven wire mesh screen. There are many choices for materials, sizes, and patterns. You want to choose the right one for your project. Experts and technical resources can help you. They make things easier and help you avoid mistakes.

You can talk to suppliers or technical consultants. These people know a lot about wire mesh screens. They answer your questions and help you pick the best screen. You get advice about material, mesh count, and weave type. Suppliers have catalogs and specification sheets. These papers show you all the options. You can compare wire diameter, opening size, and mesh count. If you know two of these, you can figure out the third. This helps you choose the right screen for your job.

Here are some technical resources you can use:

- Product catalogs with wire mesh details

- Mesh calculators for opening size and mesh count

- Tolerance charts and load tables

- Sample kits with different mesh types

- Technical support from suppliers

You can ask about customization too. Wire mesh comes in rolls, cut pieces, and ready-made parts. If you need a special size or shape, suppliers can help you. Edge protection and coatings make your mesh last longer. These extras help your screen work better.

When you talk to experts, tell them about your project. Share details about the environment, load, and what the screen will do. They use this information to suggest the best options. You get advice on material, weave pattern, and mesh count. This helps you match the screen to your needs.

Here’s a table to show what you should ask about:

| What to Ask | Why It Matters |

|---|---|

| Material type | Affects durability and cost |

| Mesh count | Controls particle size |

| Opening size | Impacts flow and filtration |

| Wire diameter | Changes strength and flexibility |

| Weave pattern | Alters performance and look |

Tip: Always use technical resources before you buy. You save money and get a screen that fits your project.

You do not have to figure everything out by yourself. Experts and technical resources make things simple. You get clear answers and find the best woven wire mesh screen for your job.

Comparing Options and Making Your Final Choice

Selection Checklist

You want to make sure you pick the right wire mesh for your project. A checklist helps you stay organized and avoid missing important details. Here’s a simple table you can use when you compare different wire mesh screens:

| Criteria | Description |

|---|---|

| Material | Preferred materials include stainless steel and aluminum for durability. |

| Durability | Enhanced with powder-coated or galvanized finishes for corrosion resistance. |

| Customization Options | Design should integrate with existing frames while maintaining aesthetics. |

| Security Features | Tightly woven mesh for protection against forced entry. |

| Airflow | Must allow adequate airflow while keeping out insects and debris. |

Go through each item on this list. Ask yourself if the wire mesh you want meets these needs. If you check every box, you know you’re on the right track.

Evaluating Trade-Offs

You will notice that every wire mesh option has pros and cons. Some screens cost less but don’t last as long. Others work better but cost more. You need to balance your budget, performance, and lifespan. Take a look at this table to see how different wire mesh types compare:

| Mesh Type | Initial Cost (₹/m²) | Life (months) | Cost per Month | Efficiency |

|---|---|---|---|---|

| Mild Steel Wire | ₹2,000-4,000 | 3-6 | ₹500-800 | 75-85% |

| Manganese Steel Wire | ₹5,000-8,000 | 6-12 | ₹650-700 | 80-88% |

| Polyurethane Panels | ₹8,000-15,000 | 12-24 | ₹500-650 | 85-92% |

| Rubber Panels | ₹6,000-12,000 | 18-36 | ₹280-400 | 80-88% |

If you want a wire mesh that lasts longer, you might pay more up front. If you need to save money, you can choose a cheaper wire mesh, but you may need to replace it sooner. Efficiency also matters. Higher efficiency means your wire mesh does a better job at screening or filtering. Think about what matters most for your project.

Tip: Write down your top priorities. Is it cost, lifespan, or efficiency? This helps you make a smart choice.

Ensuring Long-Term Performance

You want your wire mesh to keep working well for a long time. Follow these best practices to get the most out of your screen:

- Keep a regular cleaning routine. This stops dirt from blocking your wire mesh.

- Check your wire mesh often for damage or wear.

- Store your wire mesh in a dry, safe place when you’re not using it.

- Use your wire mesh for its intended purpose. Don’t push it beyond its limits.

- Clean your wire mesh gently. Use the right cleaning agents so you don’t harm the material.

If you follow these steps, your wire mesh will last longer and work better. You save money and avoid problems down the road.

Note: Good care and smart choices help your wire mesh stay strong and reliable.

Now you have the tools to compare options, weigh trade-offs, and keep your wire mesh working for years. Take your time, ask questions, and use your checklist. You’ll feel confident when you make your final choice.

Conclusion

Choosing the right wire mesh starts with your application and operating conditions. Define your cut size, material characteristics (size distribution, moisture, abrasion), and the screen deck setup, then select the appropriate aperture, wire diameter, material, and weave type for stable performance and longer service life.

As a professional manufacturer of industrial wire screens, ANPENG provides technical support and custom manufacturing to match your exact requirements. Share your project details and we’ll recommend the best screen media and provide a fast quotation.

Key steps for selecting wire mesh

- Define your application needs (cut size, throughput, working conditions)

- Match the right aperture, wire diameter, material, and weave type

- Consult ANPENG for specification support and custom manufacturing

FAQ

What is the difference between mesh count and opening size?

Mesh count tells you how many openings fit in one inch. Opening size measures the space between wires. You need both numbers to pick the right screen for your job.

How do I know which material is best for my environment?

You should check if your project faces moisture, chemicals, or heavy wear. Stainless steel works well for harsh places. Galvanized steel fits dry, mild jobs. Aluminum is good for lightweight needs.

Can I cut woven wire mesh myself?

Yes, you can cut mesh with wire cutters or a saw. Wear gloves and eye protection. Cover the edges with a frame or tape to stop fraying.

How do I clean and maintain my wire mesh screen?

Brush off dirt with a soft brush. For tough spots, use mild soap and water. Rinse and dry the mesh. Check for damage often to keep your screen working well.

What weave pattern should I choose for fine filtration?

Pick Dutch weave for fine filtration. This pattern traps tiny particles but still lets liquids or gases pass through. It works best for oil, gas, and chemical jobs.

How do I order custom-sized wire mesh?

Contact your supplier with your measurements. Tell them the material, mesh count, wire diameter, and weave pattern you want. Most suppliers can cut mesh to fit your project.

Why does my mesh screen wear out quickly?

Heavy loads, sharp materials, or harsh chemicals can damage your mesh. You may need thicker wires or a stronger material. Ask your supplier for advice if your screen fails often.

Can I use woven wire mesh outdoors?

Yes, you can use it outside. Pick stainless steel or hot-dip galvanized mesh for the best rust protection. Check your mesh often for signs of wear or damage.