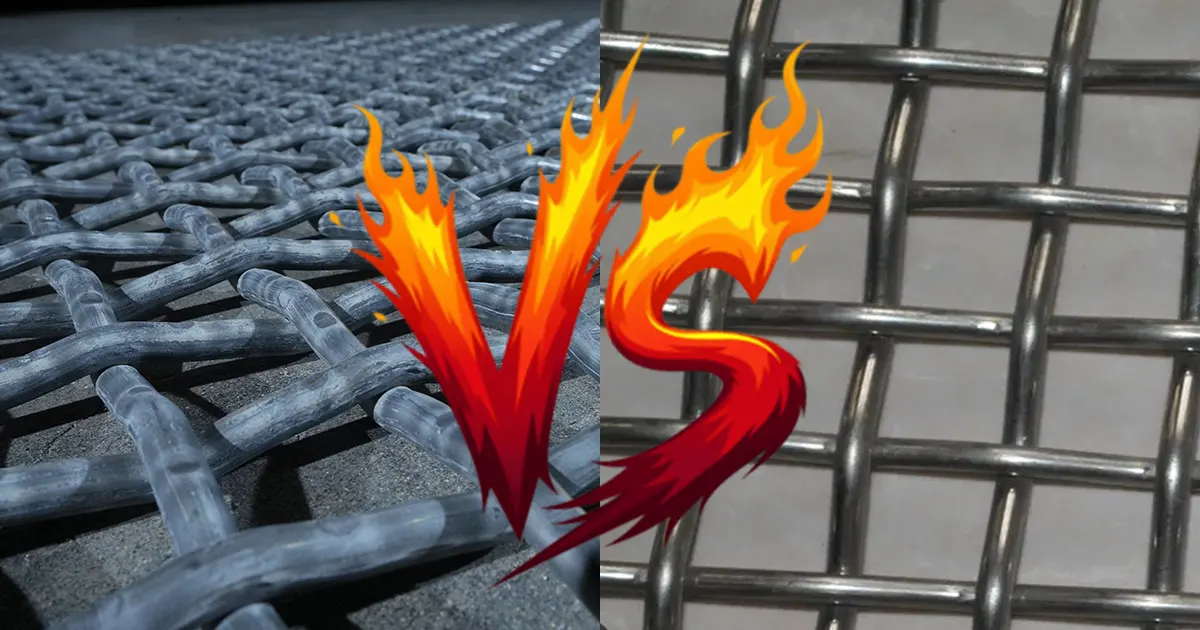

You want your mining screen to last. When you compare Carbon Steel vs Stainless Steel, your choice depends on how tough your site is on equipment. Stainless steel fights off rust and chemical attack better, but costs more. Carbon steel gives you solid strength at a lower price, but it can wear out faster in wet or harsh spots. Check out the table below to see common ways screens can fail, especially if you deal with corrosion or welds:

| Failure Mechanism | Description |

|---|---|

| Pitting Corrosion | Small pits eat away at the metal surface. |

| Crevice Corrosion | Corrosion attacks in tight spaces and gaps. |

| Stress Corrosion Cracking | Cracks spread quickly when stress and chemicals meet. |

| Intergranular Corrosion | Corrosion sneaks along the grain boundaries. |

Think about your site’s moisture, chemicals, and abrasion before you choose.

Key Takeaways

- Pick stainless steel if your site is wet or has chemicals. It does not rust easily and lasts a long time.

- Carbon steel costs less and works well in dry places. It is strong and cheaper than other options.

- Think about how well the material fights rust. Stainless steel protects better from rust than carbon steel.

- Look at how much care each material needs. Stainless steel needs less work to keep it in good shape.

- Choose the right screen for your site’s needs. This choice helps the screen work better and last longer.

- Some high-carbon steels are as strong as some stainless steels. Check the type to get the best results.

- Check and clean carbon steel screens often. Keeping them dry helps them last longer.

- Think about how much you will spend over time. Stainless steel costs more at first but saves money later.

Material Basics

Carbon Steel Overview

You see carbon steel everywhere in mining. It gives you a strong and tough screen for a good price. You can count on it for most dry or less demanding sites. Carbon steel has a simple recipe. It mixes iron with a bit of carbon and a few other elements. This mix makes it hard but not too brittle. You get a screen that stands up to impact and heavy loads.

Here’s a quick look at what goes into carbon steel for mining screens:

| Element | Percentage |

|---|---|

| Carbon (C) | 0.43-0.50% |

| Manganese (Mn) | 0.60-0.90% |

| Phosphorus (P) | ≤ 0.040% |

| Sulfur (S) | ≤ 0.050% |

| Silicon (Si) | 0.15-0.30% |

| Iron (Fe) | Balance |

You notice that iron makes up most of the mix. The small amount of carbon gives the steel its strength. Manganese helps with toughness. The other elements keep the steel clean and stable.

Stainless Steel Overview

Stainless steel steps up when you need more protection. You pick it for screens that face water, chemicals, or salty air. Stainless steel fights off rust and stains. It stays shiny and strong even when things get rough. You pay more for it, but you get a screen that lasts longer in harsh spots.

Stainless steel has a special ingredient—chromium. This element forms a shield on the surface. It blocks rust and keeps the screen looking good. You also find nickel and sometimes molybdenum in the mix. These extras boost strength and corrosion resistance.

Key Differences in Composition

You might wonder what really sets carbon steel and stainless steel apart. The answer comes down to the mix of elements, especially chromium and carbon. Take a look at this table:

| Material Type | Chromium Content | Carbon Content |

|---|---|---|

| Carbon Steel | < 0.1% | 0.05% to 2.0% |

| Stainless Steel | > 10.5% | < 1.2% |

You see that stainless steel has much more chromium. This makes it resist rust and chemical attack. Carbon steel has more carbon, which gives it strength but makes it less resistant to corrosion. If you need a screen for a wet or chemical-heavy site, stainless steel is your best bet. For dry, less aggressive spots, carbon steel gives you good value and solid performance.

Tip: Always match your screen material to your site’s conditions. The right choice saves you money and downtime.

Carbon Steel vs Stainless Steel: Core Properties

Corrosion Resistance Comparison

When you look at carbon steel vs stainless steel, corrosion resistance stands out as a key difference. You want your mining screens to last, especially in wet or chemical-heavy sites. Stainless steel forms a protective layer that blocks rust and keeps your screens looking good. Carbon steel, on the other hand, can rust quickly if you do not protect it.

Take a look at this table. It shows how different materials handle corrosion in mining environments:

| Material Type | Corrosion Rate (mpy) | Standard Deviation (mpy) |

|---|---|---|

| Cast Steel | 13 | 6.7 |

| Wrought Steel | 18 | 4.5 |

| Cast Steel (Copper Mill) | 21 | 3.0 |

| 27-pct-Cr Cast Iron | 0.9 | 0.4 |

You can see that stainless steel and high-chromium alloys have much lower corrosion rates. This means less maintenance and fewer replacements for you.

If your site has a lot of moisture or chemicals, stainless steel gives you peace of mind. You will not have to worry about pitting or crevice corrosion as much. Carbon steel works well in dry, non-corrosive places, but it needs coatings or regular care to keep rust away.

Tip: If you want the best corrosion resistance, choose stainless steel or a high-chromium alloy for your mining screens.

Strength and Hardness

You need your screens to handle heavy loads and impacts. The properties of carbon steel vs stainless steel matter here. Both materials can offer high strength, but the details depend on the grade and how the steel is made.

- High-carbon steels can match or even beat the strength of some stainless steels.

- Stainless steel usually gives you better strength than low-carbon steel, plus it resists corrosion.

- Both materials can be made into abrasion-resistant steel for tough jobs.

If you want a screen that will not bend or break under pressure, look for high strength properties. Stainless steel often gives you a good mix of strength and toughness, especially in grades like duplex stainless steel. Duplex types combine the best of both worlds: high strength and great corrosion resistance.

Note: Always check the grade and heat treatment of your steel. These factors change the properties and performance of your mining screens.

Abrasion and Wear

Mining screens face a lot of wear and tear. Rocks, sand, and ore can grind down your screens fast. You want abrasion-resistant steel to keep your screens working longer.

Carbon steel can be made into tough, abrasion-resistant steel. It handles impact and heavy loads well. Stainless steel also stands up to wear, especially in grades designed for mining. Duplex stainless steel is a top choice if you need both abrasion resistance and corrosion protection.

Here are some properties to consider when you compare carbon steel vs stainless steel for abrasion:

- Abrasion-resistant steel lasts longer in high-wear spots.

- Stainless steel resists both wear and corrosion, so you get double protection.

- Carbon steel gives you good value, but it may wear out faster in harsh conditions.

If your site is dry and not too abrasive, carbon steel works well. For wet, gritty, or chemical-heavy sites, stainless steel or duplex stainless steel will save you money and downtime in the long run.

Callout: Always match the properties of your screen material to your site’s toughest challenges. The right choice keeps your operation running smoothly.

Flexibility and Brittleness

You want your mining screens to handle tough jobs without snapping or bending too much. Flexibility and brittleness matter a lot when rocks hit hard or when screens face heavy loads. Let’s break down how carbon steel and stainless steel stack up.

Carbon steel gives you good flexibility. It bends a bit before it breaks. This helps your screens absorb shocks and impacts. If a big rock drops on the screen, carbon steel can flex and bounce back. You get less risk of sudden cracks.

Stainless steel feels stiffer. It resists bending, so it holds its shape well. Some grades, like austenitic stainless steel, offer more flexibility than others. But many stainless steels can be brittle, especially if you use them in cold weather or under high stress. Brittle screens crack or snap without warning. That’s not what you want in a busy mine.

Duplex stainless steel changes the game. It mixes the best parts of austenitic and ferritic stainless steels. You get higher strength and better flexibility. Duplex screens handle heavy loads and resist cracking. They work well in places where you need both toughness and corrosion resistance.

Here’s a quick table to help you compare:

| Property | Carbon Steel | Stainless Steel | Duplex Stainless Steel |

|---|---|---|---|

| Flexibility | Good | Moderate to Low | Good |

| Brittleness | Low | Moderate to High | Low |

| Shock Absorption | High | Moderate | High |

Tip: If your site faces lots of impact or sudden shocks, carbon steel or duplex stainless steel screens give you better protection. Stainless steel works best where you need shape and corrosion resistance, but watch out for brittleness in tough spots.

You want your screens to last. Pick the material that matches your site’s challenges. Flexibility keeps your operation running. Brittleness can mean downtime and extra costs.

Cost and Maintenance

Upfront Costs

You want to know how much you will spend at the start. Carbon steel screens cost less when you buy them. You can get more screens for your money if you choose carbon steel. This makes it a good pick if you need to cover a large area or if your budget is tight. Stainless steel screens cost more up front. You pay a higher price because they use special metals and need more work to make. Even though you spend more at first, you get a screen that lasts longer and needs less fixing.

Note: The lower price of carbon steel helps you save money at the start, but you may need to replace screens sooner if your site is tough on equipment.

Maintenance Needs

You want your screens to keep working without a lot of trouble. Carbon steel needs more care. You have to check it often for rust and damage. You may need to add paint or coatings to stop rust. If you skip these steps, your screens can wear out fast. Stainless steel needs less work. It fights off rust by itself, so you do not need to check it as much. You can clean it with mild soap and water. Sometimes, you may need to treat it to keep the surface strong.

Here’s a quick look at how often you need to do maintenance:

| Material | Maintenance Frequency | Key Maintenance Needs |

|---|---|---|

| Carbon Steel | More Frequent | Requires ongoing maintenance to prevent rust and corrosion; may need protective layers and regular inspections. |

| Stainless Steel | Less Frequent | More corrosion-resistant; requires proper care with mild detergents and periodic passivation treatments. |

Tip: If you want to spend less time on repairs, stainless steel is the easier choice.

Total Cost of Ownership

You want to know what you will spend over the life of your screens. Carbon steel looks cheap at first, but you may pay more later. You need to fix or replace it more often, especially if your site is wet or has chemicals. The cost of paint, coatings, and labor adds up. Stainless steel costs more when you buy it, but you save money over time. It lasts longer and needs fewer repairs. You do not have to replace it as often, so you spend less in the long run.

- Carbon steel: Lower price at first, but higher costs for upkeep and replacements.

- Stainless steel: Higher price at first, but lower costs for maintenance and longer life.

Callout: Think about the big picture. If your site is tough on screens, stainless steel can save you money and headaches over time.

Performance in Mining Environments

Dry, Non-Corrosive Sites

You might work at a mine where the air stays dry and chemicals do not cause trouble. In these places, you do not see much rust or corrosion. Carbon steel screens shine here. They give you strong support for your rocks and minerals. You save money because you do not need the extra protection that stainless steel offers. You can use carbon steel screens for a long time if you keep them clean and check for damage.

Let’s look at a quick example. You run a quarry in a desert area. The weather stays dry all year. You do not use harsh chemicals. Carbon steel screens handle the job well. You get good value and solid performance.

Tip: For dry and clean sites, carbon steel screens help you keep costs low without giving up strength.

Wet or Corrosive Sites

Now, picture a mine where water splashes everywhere. Maybe you work near the coast, or you use chemicals to process ore. In these spots, rust and corrosion attack your screens fast. Stainless steel steps up in these tough places. It fights off rust and keeps working even when things get wet or salty.

Imagine you manage a gold mine with lots of water and chemical use. If you use carbon steel screens, you will see rust and pitting in no time. Screens break down faster, and you spend more on replacements. Stainless steel screens last longer. They keep their shape and strength, even when the environment gets rough.

Here’s a quick table to help you decide:

| Site Condition | Best Material | Why? |

|---|---|---|

| Dry, Non-Corrosive | Carbon Steel | Low cost, strong, durable |

| Wet/Corrosive | Stainless Steel | Resists rust, lasts longer |

Note: If you see water, salt, or chemicals at your site, stainless steel screens save you time and money.

Highly Abrasive Conditions

Mining can get rough. Rocks, sand, and ore grind against your screens every day. You need a material that stands up to this kind of punishment. Both carbon steel and stainless steel can handle abrasion, but you want to match the right type to your job.

Here’s what you should know:

- Carbon steel screens often perform just as well as stainless steel when it comes to wear resistance.

- Hardness and toughness matter most in abrasive sites. Both materials can be made hard and tough.

- The way rocks hit or slide across the screen changes how each material wears down. Carbon steel does well in both impact and sliding abrasion.

Let’s say you run an iron ore mine with sharp rocks and heavy loads. You can use carbon steel screens with high hardness. They last a long time and cost less. If you also deal with water or chemicals, duplex stainless steel gives you both abrasion resistance and corrosion protection.

Callout: Always check your site’s main challenge—abrasion, corrosion, or both. Pick the screen material that matches your toughest problem.

You want your mining screens to last. Match your choice to your site’s real-world conditions, and you will get the best value and performance.

Choosing the Right Screen Material

Key Selection Questions

You want to pick the best mining screen for your site. Start by asking yourself a few key questions. These will help you match the right material to your needs:

- What are the size, shape, and weight of the particles you need to screen?

- How much material do you need to process each hour?

- What size and shape does your screen need to be? Think about length, width, and angle.

- What is the main job of your screen? Is it for sorting, dewatering, or something else?

- What type of screen media will work best for your applications?

- How easy is it to maintain and repair the screen?

- What are the temperature and moisture levels at your site?

Tip: Write down your answers. This makes it easier to talk with your team or a supplier.

Matching Material to Screen Model

You want your mining screen to last and work well. The material you choose affects how tough your screen is and how long it will last. Here’s what you should think about:

- Some materials handle wear and tear better than others.

- If your site has a lot of water or chemicals, you need a material that fights rust.

- Different screen models work best with certain materials. For example, trommel screens often use high-strength carbon steel, spring steel, or stainless steel.

- The right match means your screen will fit your applications and last longer.

You can find many screen models made for different jobs. When you match the right material to the right model, you get better results and fewer problems.

Application Examples

You might wonder how other mines use these screens. Here are some real-world examples that show how the right choice helps in different applications:

| Feature | Description |

|---|---|

| Heavy-duty mining screens | Built for tough, high-impact environments. |

| Applications | Used in aggregate and mineral processing, ore separation, and classification. |

| Manufacturing | Custom sizes and shapes for each job. |

| Benefits | More material processed, less downtime, and longer service life. |

You see these screens in many applications. They help sort rocks, separate minerals, and keep production moving. When you pick the right material, you get a screen that fits your applications and stands up to daily use.

Callout: Always think about your site’s needs and the applications you run. The right screen material makes your work easier and your operation more reliable.

Maintenance and Longevity Tips

Carbon Steel Care

You want your carbon steel screens to last as long as possible. Start with regular cleaning. Dust, dirt, and leftover minerals can speed up rust. Use a stiff brush or compressed air to clear off debris. Check your screens often for scratches or bare spots. These areas can rust first. If you see any, touch them up with a protective coating or paint.

Keep an eye on moisture. Water is the enemy of carbon steel. If your site gets wet, dry the screens after each shift. Store spare screens in a dry place. You can also use rust inhibitors for extra protection. Tighten bolts and fasteners so the screen stays in place. Loose parts can cause wear and early failure.

Tip: A quick inspection every week can catch small problems before they turn into big repairs.

Stainless Steel Care

Stainless steel screens need less work, but you should not ignore them. Clean them with mild soap and water. Avoid harsh chemicals that can damage the surface. Rinse well and let them dry. If you see fingerprints or smudges, wipe them off with a soft cloth.

Check for signs of pitting or discoloration. Even stainless steel can show wear if exposed to strong chemicals or salt. If you spot any rough patches, use a passivation treatment. This process restores the protective layer on the steel. Make sure you do not use steel wool or wire brushes. These tools can scratch the surface and make it easier for rust to start.

Note: Stainless steel screens last longer when you keep them clean and free from buildup.

Replacement Signs

You want to know when it is time to swap out your mining screens. Watch for these common signs:

- Worn or broken screen media

- Black marks or shiny hooks that show installation issues

- Pegging or blinding, where material clogs the screen holes

- A growing scrap pile, which means your screen is not working well

- Loose tension that leads to early breakage

If you notice any of these problems, plan for a replacement soon. Quick action keeps your operation running and avoids bigger breakdowns.

Callout: Regular checks and fast fixes help you get the most life from your mining screens.

Environmental and Compliance Factors

Sustainability

You care about the planet and your bottom line. When you pick mining screens, you want to know how each material affects the environment. Carbon steel and stainless steel both have pros and cons. Let’s break it down so you can see the difference.

Here’s a table that shows how each material stacks up during its life cycle:

| Phase | Carbon Steel Impact | Duplex Stainless Steel Impact |

|---|---|---|

| Production Phase | Lower embodied carbon (~1.8 – 2.2 kg CO₂e/kg steel) | Higher embodied carbon (~4.5 – 6.5 kg CO₂e/kg steel) |

| Manufacturing Phase | Needs coatings with VOCs, higher environmental cost | No coatings needed, lower environmental cost |

| Use Phase | Needs regular maintenance, higher lifecycle impact | Maintenance-free for decades, lower lifecycle impact |

| End-of-Life Phase | 100% recyclable | 100% recyclable |

You see that carbon steel uses less energy and creates less carbon during production. Stainless steel, especially duplex grades, needs more energy and creates more carbon. During manufacturing, carbon steel screens often need coatings to stop rust. These coatings can release chemicals into the air. Stainless steel screens skip this step, so you get a cleaner process.

When you use carbon steel screens, you spend more time and resources on maintenance. This means more chemicals, more labor, and more waste. Stainless steel screens last longer and need less care. Both types can be recycled at the end of their life, so you do not have to worry about landfill waste.

Tip: If you want a screen that needs less maintenance and creates less waste, stainless steel is a smart choice. If you want to lower your carbon footprint at the start, carbon steel works well.

Industry Standards

You want your mining screens to meet safety and quality rules. Industry standards help you make sure you get strong, reliable screens. These standards tell you what grades and properties to look for.

Here’s a quick table to show you which standards apply:

| Material Type | Standard |

|---|---|

| Carbon Steel | DIN 17223 Grade A |

| Stainless Steel | AISI 304, 316, 309 |

Stainless steel comes in many grades. You might see 201, 302, 304, 304L, or 316. These grades offer good acid resistance, rust resistance, high strength, and toughness. They also stand up to high temperatures and wear. You get a screen that lasts longer and works in tough conditions.

- Stainless steel grades include:

- 201

- 302

- 304

- 304L

- 316

Plain carbon steel is popular in the wire mesh industry because it costs less and works in many jobs. You see it in mining screens, fencing, and other places where you need strength and value.

Note: Always check the standards before you buy. Screens that meet DIN or AISI rules give you peace of mind and help you pass inspections.

You want screens that last, protect the environment, and meet all the rules. When you know the standards and impacts, you make smarter choices for your mine.

Conclusion

You need the right mining screen for your work. Here is a table to help you compare choices:

| Key Decision Points | Carbon Steel | Stainless Steel |

|---|---|---|

| Corrosion Resistance | Lower | Higher |

| Strength | Varies with carbon | Generally high |

| Cost | More economical | Higher |

| Machinability | Easier | More challenging |

Think about these things before you choose:

- Check what your site is like.

- Pick a screen that fits your job.

- Make sure it is strong and fits your budget.

Ask a trusted manufacturer for help. You can get screens made just for your needs. This helps your work go faster and gives you better quality. If you want advice, ANPENG can help you pick the best mining screen for your job.

FAQ

What is the main difference between stainless steel wire mesh and carbon steel mesh for mining screens?

You get better rust protection with stainless steel wire mesh. It works well in wet or chemical-heavy sites. Carbon steel mesh costs less and handles dry spots. You should pick based on your site’s needs.

When should I choose stainless steel wire mesh over traditional carbon steel?

You should pick stainless steel wire mesh if your mine faces water, salt, or chemicals. It gives you excellent corrosion resistance. Traditional carbon steel works best in dry, non-corrosive places.

Does stainless steel wire mesh last longer than high carbon steel screens?

Yes, stainless steel wire mesh usually lasts longer. It resists rust and chemical attack. High carbon steel gives you strength but may wear out faster in tough, wet spots.

How do I clean and care for stainless steel wire mesh?

You can clean stainless steel wire mesh with mild soap and water. Avoid harsh chemicals. Dry it after washing. This keeps your screens strong and looking good.

Is stainless steel wire mesh more expensive than carbon steel mesh?

Yes, you pay more for stainless steel wire mesh. It costs more to make. You save money over time because it lasts longer and needs less fixing.

Can I use stainless steel wire mesh for all mining applications?

You can use stainless steel wire mesh in most mining jobs. It works best where you need rust protection. For dry, low-wear sites, carbon steel mesh may be enough.

What are the signs that I need to replace my mining screen?

You should look for holes, broken wires, or clogged mesh. If you see rust or the screen does not work well, it is time to replace it.