Tools Used in Mining: Types, Uses, and Equipment List

When you enter mining, you will see that the tools used in mining are very important. These tools help people

Technical insights, application tips and industry news from Anpeng on screening media, wire mesh and self-cleaning screens to help you improve plant performance.

When you enter mining, you will see that the tools used in mining are very important. These tools help people

You use things made from minerals every day. Mining and Processing means taking useful materials from the earth. Then, these

You may ask how people get manganese from the ground. The manganese mining process uses different machines for each step.

You likely know how annoying it is when feed is not steady or when equipment stops working without warning in

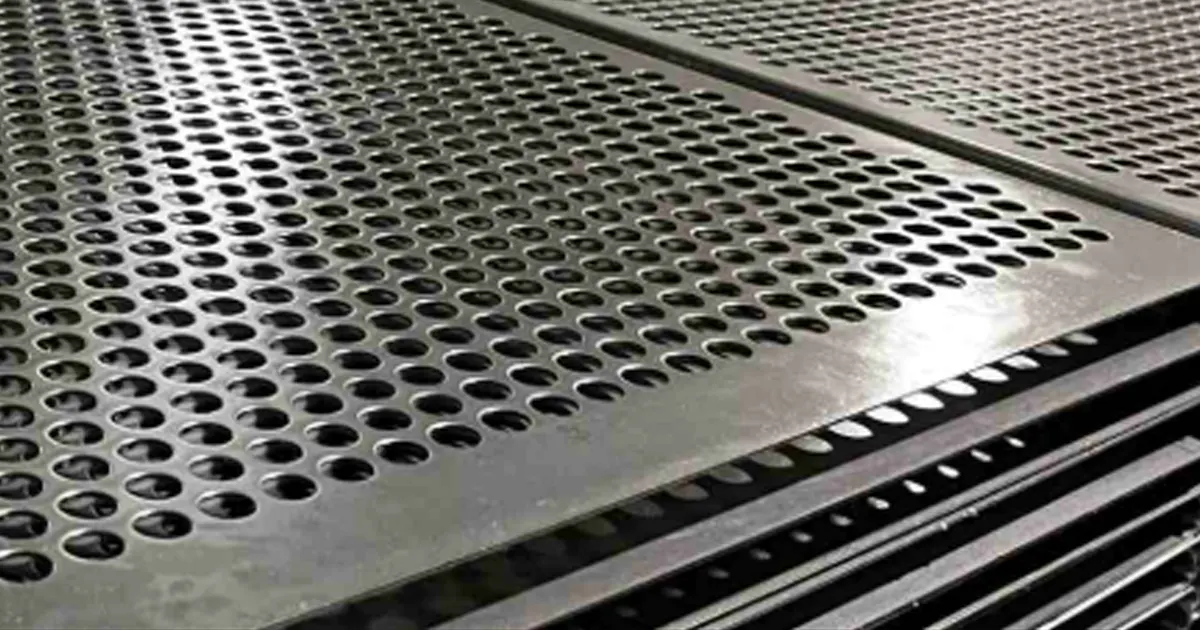

You can find perforated plates in many places. They are on building facades, car parts, and mining screens. These plates

You get crushed stone screenings by putting crushed stone through several steps. First, big rocks are broken into smaller pieces.

Choosing the right perforated plate material is important. It affects how well your screening equipment works. Picking the best metal

When you see a perforated plate, you notice a metal sheet with many small holes. These holes are not just

When you pick perforated plate pitch, think about your use. You should look at hole size, open area, and strength.