How to Choose Rubber Screen Panels: Sizes, Hardness, Mounting

To learn how to choose rubber screen panels effectively, you must match panel size, hardness, and mounting to your material,

Technical insights, application tips and industry news from Anpeng on screening media, wire mesh and self-cleaning screens to help you improve plant performance.

To learn how to choose rubber screen panels effectively, you must match panel size, hardness, and mounting to your material,

You may ask which one lasts longer, rubber screens vs polyurethane screens. In mining, new tests show that polyurethane screens

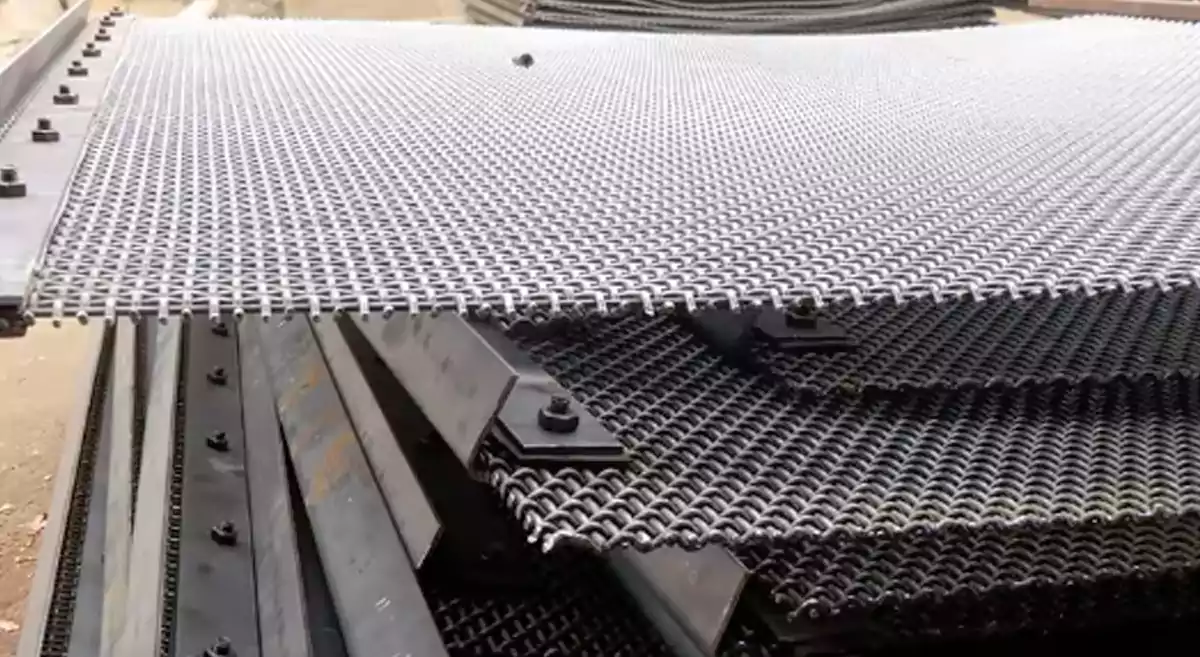

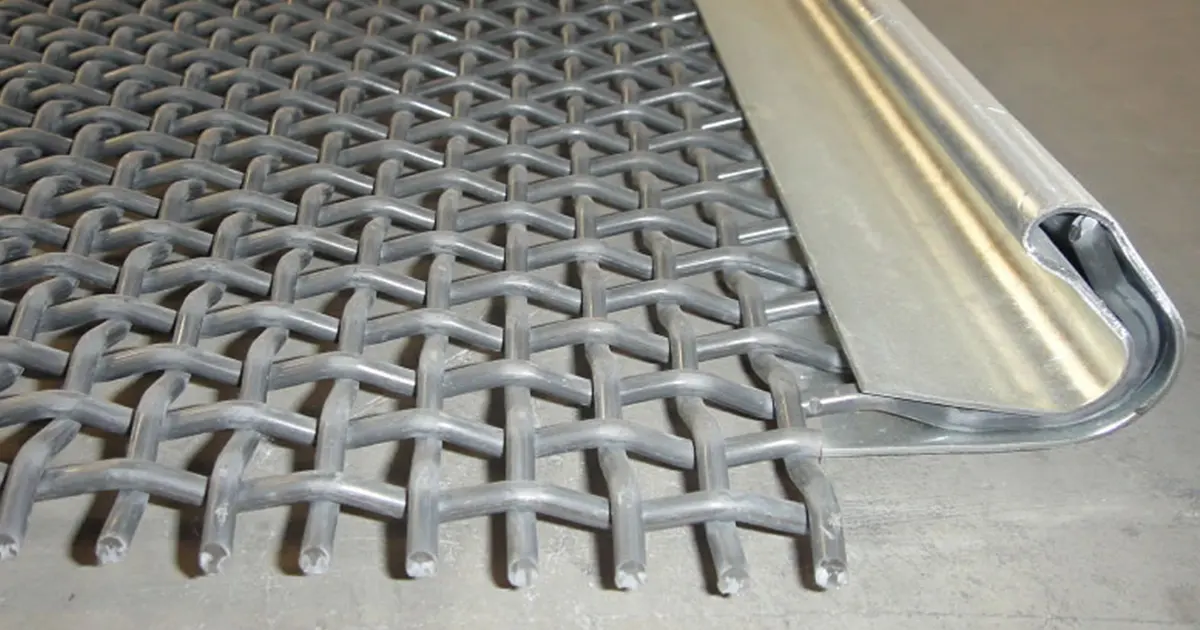

You need tough and reliable screens for your quarry or mining site. When comparing rubber screens vs wire mesh screens,

Here are the top 10 quarry screen mesh suppliers for 2026: You should pick the best quarry screen mesh supplier

You want screening that is quick and works well. When considering trommel vs vibrating screen, it’s important to note that

Knowing trommel screen parts helps you do better in sorting materials. Every part, like the drum and mesh system, has

If you’re wondering what is trommel screen, it’s a machine designed to sort materials by size. So, what is trommel

You might look at a pile of gravel and wonder if there’s any real difference between limestone screenings vs crushed

You sometimes need a material that is strong and hard. It also needs to bend without breaking. 65mn carbon steel