Flip Flow Screens

Flip Flow Screens are designed for difficult screening conditions where conventional decks struggle—especially with fine, wet, sticky, clay-contaminated, or clog-prone materials. The key is the flexible polyurethane screen mats that repeatedly stretch and relax under vibration, creating a “trampoline” effect that helps keep apertures open and material moving.

ANPENG supplies custom flip flow screen mats/panels tailored to your cut size, deck layout, and fixing method, so they can be fitted to different flip-flow screen machines and screen frames.

What Is a Flip Flow Screen?

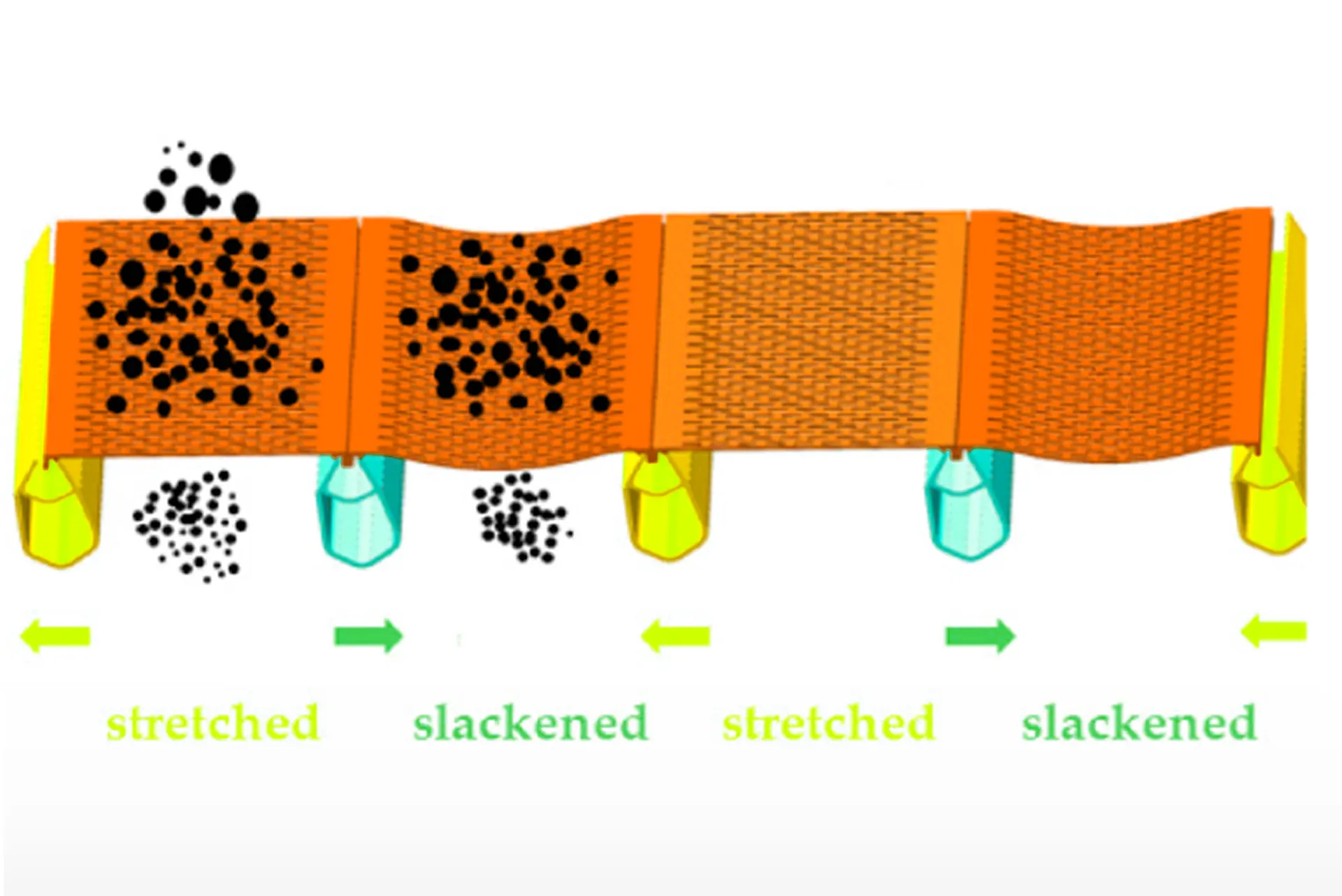

A flip flow screen (often called a flip-flop screen) uses elastic polyurethane screen mats mounted on a special frame system. Instead of staying rigid, the mats are continuously expanded and compressed, which helps prevent blinding and pegging when processing sticky or wet feed.

How Flip Flow Screens Work

Think of the screening surface like a flexible trampoline:

The machine drives a motion that makes the mat tighten and loosen repeatedly.

The mat’s rapid flexing creates high acceleration at the screening surface.

That movement helps shake loose material before it bridges, sticks, or wedges.

The “breathing” action keeps apertures more open when you’re screening sticky fines.

In short: flip flow screens improve uptime when normal decks keep plugging.

Where Flip Flow Screens Are Used

Flip flow screening is commonly selected for “hard-to-screen” bulk materials, including:

Mining & coal: wet fines, clay contamination, fluctuating feed conditions

Quarry & aggregate: high fines, seasonal moisture swings, sticky feed zones

Recycling: mixed waste streams, C&D fines, compost/biomass-type materials

They are typically used in fine-to-medium separations where plugging limits throughput.

Technical Specifications

| Specification | Details |

|---|---|

| Screen Mat Material | Polyurethane (PU) elastic mats (formulation customizable by duty) |

| Aperture Type | Square openings or slotted openings (based on cut size & material behavior) |

| Aperture Range | 0.2–50 mm (custom available) |

| Mat Thickness | Customized by deck position, impact level, and wear pattern |

| Deck Fitment | Made to match your screen model, deck layout, and panel/mat spacing |

| Width | Custom per deck width |

| Length | Custom per deck length |

| Edge Connection | Molded edges / bolted edges / clamped edges (depending on frame design) |

| Support & Fixing Method | Compatible with common flip-flow frames (rails, clamps, or bolting systems) |

| Recommended Applications | Fine, wet, sticky, clay-contaminated, or clog-prone materials |

FAQs

Are flip flow screens the same as self-cleaning wire screens?

Not exactly. Self-cleaning wire screens reduce clogging through wire geometry and micro-movement. Flip flow screens use elastic polyurethane mats that actively stretch/relax, generating high acceleration at the deck.

What materials are flip flow screens best for?

Fine, wet, sticky, clay-rich, or clog-prone materials—where blinding/pegging is limiting performance.

What cut sizes can flip flow screens handle?

They’re commonly applied from very fine cuts up to medium cuts (often cited around 0.2–50 mm, application-dependent).

Do flip flow screens eliminate blinding completely?

They greatly reduce it, but extreme moisture/clay, poor feed distribution, or overload can still cause issues—process adjustments may still be required.

Can you supply mats to fit different screen brands/models?

Yes—what matters is your deck layout and fixing method. Share your deck dimensions and connection style, and we’ll match fitment.

What should I provide for a quote?

Material type, moisture, target cut size, tph, screen model/deck layout, and current problems (blinding, pegging, carryover, wear pattern).

How do I know if I need flip flow instead of woven wire?

If woven wire gives good efficiency when dry but plugs when wet/sticky, flip flow is often considered because the mat motion keeps apertures open.

What are common maintenance focus points?

Check mat edges/fasteners, wear at the feed end, and any loose seating that can cause abnormal movement.