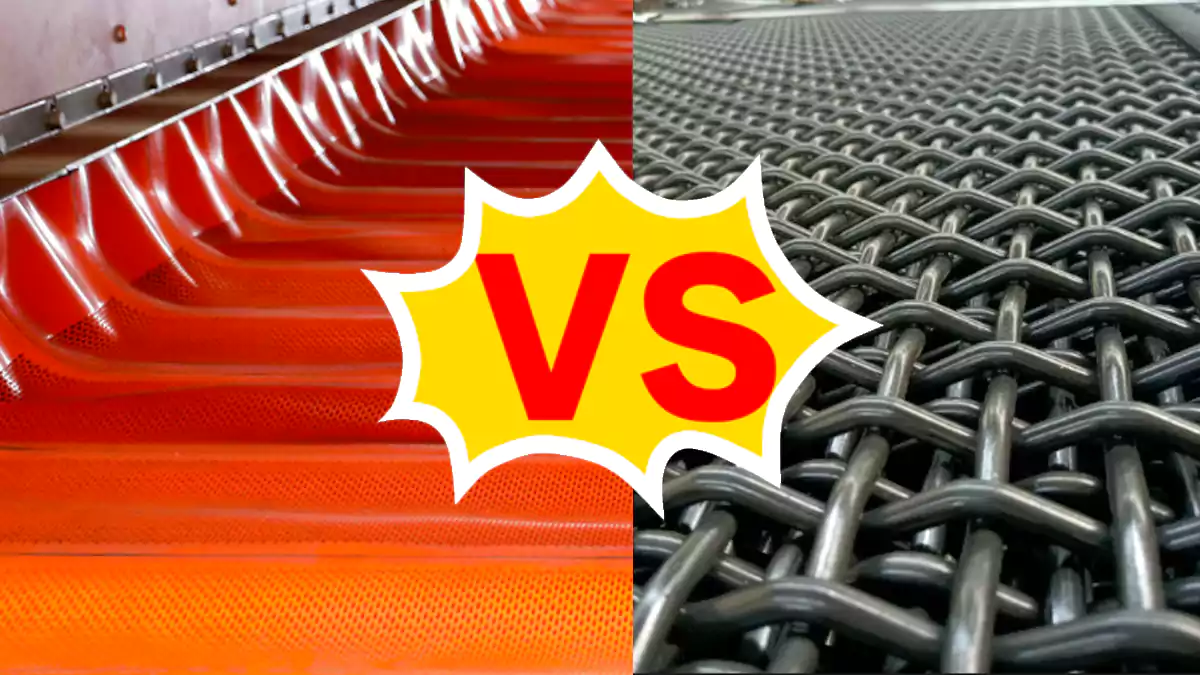

When you compare flip flow screens vs woven wire screens, you notice they are quite distinct. Flip flow screens feature flexible mats that effectively prevent blinding, making them ideal for handling wet, sticky, or small materials. On the other hand, woven wire screens are straightforward and cost-effective, best suited for dry and clean rocks. The type of screen you choose significantly impacts your product quality and can help minimize delays. Selecting the right screen ensures your operations run smoothly and your results remain consistent.

Key Takeaways

- Flip flow screens are great for wet, sticky, or mixed stuff. They work well for hard jobs.

- Woven wire screens cost less and are best for dry, clean stuff. They sort things fast and well.

- Picking the right screen can help your work go smoother. It can also cut down on breaks.

- Flip flow screens stop blinding. This means they can run without stopping to clean a lot.

- Woven wire screens are simple to put in and change. They work for many dry material jobs.

- You need to check and clean both screens often. This helps stop sudden breaks.

- Think about what you are sorting and where you work before picking a screen. This helps the screen work its best.

- Talking to experts can help you choose the right screen for your needs.

Flip Flow Screens vs Woven Wire Screens Overview

When you compare flip flow screens and woven wire screens, you see they both help separate materials. Each type works best in certain jobs. It is important to know how each one works so you can pick the right screen for your needs.

| Screen Type | Core Functionality |

|---|---|

| Flip-flow screens | Made for wet and hard-to-screen materials, which helps make better products. |

| Woven wire screens | Used for dry, grainy materials, making the process faster and easier. |

Flip Flow Screens: Design & Mechanism

Flip flow screens have a special design for tough jobs. They use stretchy panels held between two frames. These panels move back and forth with shaking. The screen has a counterweight system that makes two parts vibrate. This keeps the screen moving and stops things from blocking the holes. The panels keep changing tension, which helps move material forward and separates it better. Flip flow screens are good for sticky, wet, or mixed materials. You often see them used in coal, power, and recycling plants.

Tip: Flip flow screens help stop blinding, so you get less downtime and more steady separation.

Woven Wire Screens: Design & Mechanism

Woven wire screens are simpler. They have a mesh made from wires, usually stainless steel. The wires are woven together in different ways, like plain or twill weave. The mesh can look different, such as slotted or flat-top. These choices change how open the screen is and how long it lasts. Woven wire mesh is strong and works well for dry, grainy materials. You often find these screens in mining, construction, and aggregate work.

Key Differences in Construction

When you look at flip flow screens and woven wire screens, you see some main differences:

- Flip flow screens use stretchy panels and two vibrating parts. Woven wire screens use just one layer of woven wire mesh.

- Flip flow screens are better for wet, sticky, or packed materials. Woven wire screens are best for dry, clean stuff.

- Flip flow screens separate by moving a lot. Woven wire screens depend on the size of the holes in the mesh.

- Flip flow screens are more complicated and might need more care. Woven wire screens are easier to put in and change.

Different vibrating screens have their own good points. Picking the right one helps you separate materials better and have less downtime. If you work with tough materials, flip flow screens might be best. For simple, dry jobs, woven wire screens save money and work well.

Performance Comparison

Screening Efficiency

You want your screens to work well every time. Screening efficiency shows how well screens sort materials by size. Flip flow screens move very fast. This quick shaking helps the panels stay clean. They work better with tough materials because nothing sticks. Woven wire screens are best for dry and loose stuff. They have big open spaces, so sorting is quick. Using the right screen makes your work better and cuts down on waste.

Note: High screening efficiency helps you get more done and keeps your work going smoothly.

Handling Wet, Sticky, or Compacted Material

Wet or sticky material can slow your work. Flip flow screens are good at handling these problems. The flexible panels move in two ways. This keeps the holes open and stops blockages. You do not need to stop often to clean them. Woven wire screens have trouble with sticky or wet stuff. The holes can get blocked, so you may need to stop and fix it. If you work with wet or sticky materials, flip flow screens help you work faster and stop less.

- Flip flow screens: Best for wet, sticky, or packed material.

- Woven wire screens: Best for dry, clean material.

Throughput & Accuracy

Throughput means how much you can process at one time. Accuracy means how well the screen sorts by size. Flip flow screens handle a lot of tough material. The panels move fast and keep things moving. You get steady results and fewer clogs. Woven wire screens work well with dry material. They give good accuracy because the holes do not change. Using the right screen gives you the best results and speed. Picking the right screen helps your plant work its best.

- Flip flow screens: High capacity for sticky or mixed material, steady results.

- Woven wire screens: High capacity for dry material, accurate sorting.

Flexibility & Adaptability

You need screens that can handle different materials and changing conditions. Flexibility and adaptability help you get the best results, even when your material changes or your plant needs to adjust. Flip flow screens and woven wire screens both offer unique ways to adapt to your needs.

Flip flow screens give you many options. You can change the screening mats quickly. The mats come in different sizes, so you can pick the right one for your job. You can use aperture sizes from 3×13mm up to 50×50mm. This means you can screen fine particles or larger chunks. The modular design lets you add more decks if you need to sort more materials at once. You can also adjust the dynamic stroke. This helps you match the screen’s movement to your material. High acceleration, up to 50g, makes the screening process faster and more effective. Flip flow screens work well with sticky, wet, or mixed materials. You can use them for separation cuts as small as 0.2 mm and up to about 50 mm.

Woven wire screens also offer flexibility. You can choose different mesh sizes, usually between 0 and 100 mm (0 to 4 inches). The mesh comes in different shapes, like square or slotted. You can pick the wire thickness to match your material. Woven wire screens are easy to install and replace. You can use them for many types of dry materials. If you need to change the screen, you can do it quickly. The design lets you adjust for gentle screening, which protects delicate materials.

Tip: If your plant handles many types of materials, you should look for screens that let you change mesh or mats easily. This saves time and keeps your operation running.

Here is a table that shows how flip flow screens and woven wire screens adapt to different needs:

| Feature | Flip Flow Screens | Woven Wire Screens |

|---|---|---|

| Aperture Sizes | 3×13mm – 50×50mm | 0 – 100 mm (0 – 4 inches) |

| Modular Construction | Yes, can add decks and change mats | No, single layer mesh |

| Screening Mats | Easily assembled and changed | Mesh can be replaced |

| Dynamic Stroke | Adjustable for different conditions | Fixed, depends on mesh and machine |

| Acceleration | Up to 50g | Standard vibration |

| Material Types | Wet, sticky, mixed, difficult materials | Dry, clean, delicate materials |

Flip flow screens give you more ways to adapt. You can change mats, adjust stroke, and handle tough materials. Woven wire screens let you pick mesh size and wire thickness. You can use them for many dry materials. Both screens help you keep your plant flexible. You can switch between jobs and materials without long delays.

You should think about your material and your plant’s needs. If you work with sticky or wet materials, flip flow screens help you adapt quickly. If you handle dry and clean materials, woven wire screens give you simple flexibility. Picking the right screen helps you stay productive and ready for new challenges.

Pros and Cons: Flip Flow Screens vs Woven Wire Screens

Flip Flow Screens: Advantages

High Efficiency with Difficult Materials

Flip flow screens work great with tough materials. These screens have flexible mats and shake in a special way. This helps with wet, sticky, or packed materials. Other screens often have trouble with these. The moving panels act like a trampoline. This keeps the material bouncing and stops it from sticking. You can use flip flow screens in coal, fertilizer, and metal plants. They help you work faster and keep things moving.

Here is a table that shows how these features help:

| Advantage Description | Impact on Efficiency and Material Handling |

|---|---|

| Designed for wet viscous materials | Increases efficiency in coal, fertilizer, and metals |

| Eccentric shaft creates trampoline effect | Improves screening effectiveness |

| Lightweight structure | Reduces energy use and operating cost |

| Handles more material in the same area | Boosts production efficiency |

| Lower operational speed | Extends equipment lifespan |

| Constant deflection prevents sticking | Enhances material flow, reduces downtime |

| Rubber spring design minimizes vertical impact | Lowers foundation needs and investment |

Tip: Flip flow screens help you process more material in less space. They keep your work going without many stops.

Preventing Downtime from Blinding

You want your screens to stay clear and keep working. Flip flow screens help stop blinding. Blinding happens when stuff blocks the holes. The mats move all the time and shake off sticky bits. You do not need to stop and clean the screen as much. Less downtime means you get more done and stay on schedule.

- Flexible mats keep holes open.

- Less cleaning and fewer stops.

- More reliable work for your plant.

Flip Flow Screens: Disadvantages

Higher Cost & Maintenance

Flip flow screens usually cost more than woven wire screens. The design is more complicated. You might spend more on parts and service. Maintenance takes longer because of the moving parts and mats. If you want top performance, you need to plan for higher cost and regular care.

- Higher starting cost for equipment.

- More parts to check and replace.

- Maintenance takes more time and skill.

Reduced Open Area

Flip flow screens have less open area than woven wire screens. The mats and frame take up space. This means there are fewer holes for material to pass through. Some jobs may have lower throughput. If you need to move lots of dry, clean material, flip flow screens might not be as fast.

- Less open area means lower throughput for some jobs.

- Not best for jobs needing the highest flow rate.

Woven Wire Screens: Advantages

Cost-Effective & Versatile

Woven wire screens are simple and affordable. You can pick from many mesh sizes and wire thicknesses. This makes them good for many jobs, like mining or building. You can change the mesh easily, which saves time and money. Woven wire screens give good results without high cost.

- Lower cost for equipment and parts.

- Easy to install and change mesh.

- Works for many dry, clean materials.

Note: Woven wire mesh can have very small openings. You can use these screens for filtration, particle checks, and even screen printing.

Gentle on Delicate Materials

You can use woven wire screens for delicate or fragile materials. The gentle action protects your product from damage. You can pick different weave patterns to fit your needs. For example, plain weave gives a tight grid for fencing or filters. Twill weave works well for sieving and tough jobs.

| Weave Pattern | Description | Applications |

|---|---|---|

| Plain Weave | Wires go over and under, tight grid | Fencing, insect screens, filtration |

| Twill Weave | Wires go over two and under two | Industrial filtration, sieving |

| Dutch Weave | Thick warp, thin weft for fine filtration | Oil/gas, food, pharmaceuticals |

- Gentle screening keeps your product safe.

- Many weave choices for different jobs.

- Good for fine filters and delicate materials.

Woven Wire Screens: Disadvantages

Prone to Blinding

You may notice that woven wire screens often struggle with blinding. Blinding happens when wet or sticky materials build up on the wire mesh. These materials can block the openings and stop the screen from working well. Sometimes, particles that are almost the same size as the holes get stuck between the wires. This is called pegging. Both blinding and pegging slow down your screening process. You need to stop and clean the screen more often. This can lead to more downtime and less efficiency in your plant. If you compare flip flow screens vs woven wire screens, you see that flip flow screens handle blinding much better.

Tip: Regular cleaning and choosing the right mesh size can help reduce blinding, but you may still face problems with wet materials.

Lower Throughput for Some Materials

Woven wire screens can also limit your throughput, especially with certain types of material. When blinding or pegging happens, fewer particles pass through the screen. This means you process less material in the same amount of time. The precise square openings in woven wire screens can trap particles and slow down the flow. You may need to run your equipment longer or use more energy to reach your production goals. This can increase your cost and make your operation less efficient. For jobs with wet, sticky, or compacted materials, you might want to look at other options.

- Blinding and pegging reduce screening efficiency.

- Lower throughput means more time and energy spent.

- You may need extra maintenance to keep screens working.

If you work with dry, clean materials, woven wire screens can still be a good choice. For tougher jobs, you may need to consider other screen types to keep your plant running smoothly.

Best Uses & Applications

Flip Flow Screens: Ideal Scenarios

Pick a flip flow screen for tough jobs. These screens work with wet, sticky, or mixed materials. Other screens can get blocked by these types. Flip flow screens handle particles from 5 mm to 300 mm. If your material is moist or thick, flip flow screens keep things moving. Heavy-duty models are good for coal and mining. You can use them for construction waste too. Mixed materials are common in these jobs. Choose a screen with more capacity than you need. This helps your work keep going without stops.

| Criteria | Details |

|---|---|

| Material Characteristics | Particle size (5-300mm), moisture content, viscosity |

| Application Scenarios | Heavy-duty models for coal/mining, mixed materials for construction waste |

| Production Capacity Requirements | Choose equipment with slightly higher capacity for continuous operation |

Tip: Flip flow screens are great in cold or wet places. They keep working when other screens get blocked.

Woven Wire Screens: Ideal Scenarios

Use woven wire screens for dry and clean materials. These screens work well for mining, aggregates, and recycling. They give good results and cost less. If you sort recycled concrete or asphalt, woven wire screens help you work faster. Many U.S. producers use high-vibration woven wire screens. They get more uptime and spend less money. You can pick from many wire sizes and openings. This helps you find the best screen for your job. Woven wire screens work unless your material wears them out. If you have high wear, try other screens.

- Dry, clean aggregates

- Recycled concrete and asphalt

- Mining jobs with moderate wear

- Jobs needing quick screen changes

Note: Woven wire screens are used in mining and aggregates. They are easy to change and work for many jobs.

Industry Examples

Both screen types are used in many industries. Here are some examples:

| Industry | Application Description |

|---|---|

| Food and Beverage | Wedge wire screen cylinders for sorting and filtering |

| Sugar Industry | Wedge wire sieve bends for sugar processing |

| Water Treatment | Wedge wire filter nozzles for sand filter tanks |

| Beer Production | Wedge wire screen grids for brewing |

| Chemical Processing | Wedge wire filter screen segments for chemical plants |

| Water Distribution | Wedge wire screen filter nozzles for water systems |

| Agriculture | Starch pressure arc screens and rotary vibrating screens |

You see these screens in recycling, mining, and food processing. Each industry picks the right screen for its needs. In cold places, flip flow screens help you work through wet or freezing weather. In recycling, woven wire screens help you sort concrete and asphalt fast. You can match the screen to your material and job for the best results.

Downtime & Preventing Downtime

Maintenance Needs

You want your screening equipment to work well every day. Flip flow screens need more attention than woven wire screens. The moving parts and flexible mats require regular checks. You should look for signs of wear or damage. Planned screen maintenance helps you spot problems early. Woven wire screens have a simple design. You can inspect them quickly. You may only need to replace the mesh when it wears out. Both types need cleaning, but flip flow screens stay cleaner longer because they resist blinding.

Tip: Set a schedule for maintenance. Check your screens often to catch small issues before they become big problems.

Durability & Lifespan

Screen durability affects how often you need to stop work. Polyurethane flip flow screens last much longer than woven wire screens. You can expect polyurethane screens to last 6 to 12 months. Rubber screens wear out faster, usually in 1 to 3 months. Woven wire screens set the baseline for comparison. Polyurethane screens last 8 to 10 times longer than metal screens. They last 3 times longer than stainless steel screens. You spend less time replacing screens and more time working.

Here is a table that shows how long each screen type lasts:

| Screen Type | Lifespan (Months) | Comparison to Woven Wire Screens |

|---|---|---|

| Polyurethane Screens | 6-12 | Longer than woven wire screens |

| Rubber Screens | 1-3 | Shorter than woven wire screens |

| Woven Wire Screens | N/A | Baseline for comparison |

- Polyurethane screens last dozens of times longer than woven wire screens.

- You reduce downtime by choosing screens with longer lifespans.

Tips for Preventing Downtime

You can keep your plant running smoothly by following a few simple steps. These tips help you avoid unexpected stops and keep your screens working longer.

- Inspect screens regularly. Look for tears, holes, or loose parts.

- Clean screens often. Remove stuck material to keep openings clear.

- Use planned screen maintenance. Replace worn mats or mesh before they fail.

- Choose the right screen for your material. Flip flow screens work best for sticky or wet materials. Woven wire screens suit dry, clean materials.

- Train your team. Teach them how to spot problems and fix them quickly.

Note: Preventing downtime starts with good habits. Regular checks and cleaning help you avoid costly interruptions.

You can reduce downtime by picking durable screens and keeping up with maintenance. When you plan ahead, you spend less time fixing problems and more time getting work done.

Choosing the Right Screen

Assessing Material & Conditions

You need to look closely at your material before selecting the right screen media. Start by checking the particle size. Small particles may need a fine mesh, while larger chunks work better with wider openings. Humidity matters too. Wet or sticky materials often clog traditional screens, so flip flow screens handle these better. Chemical properties can affect how long your screen lasts. Some materials wear out screens faster than others.

You should also think about your screening objectives. Decide if you want high precision or just fast sorting. The working environment plays a big role. High temperatures or strong vibrations can damage some screens. Make sure your screen can handle the conditions in your plant.

Here is a simple guide to help you with selection:

- Check particle size and moisture.

- Decide how precise you need your sorting.

- Look at the temperature and vibration in your plant.

- Think about how your material might wear out the screen.

Tip: Matching your material and conditions to the right screen helps you avoid downtime and keeps your operation running smoothly.

Budget & Operational Goals

Your budget shapes your choices. You pay for the screen up front, but that is only part of the cost. Most of your money goes to running and maintaining the equipment. Power use and repairs add up over time. You should look at the total cost over ten years, not just the price today.

Your operational goals matter too. If you want high capacity requirements, you need a screen that can keep up. Some screens work faster but cost more to maintain. Others are cheaper but may slow down your process. You need to balance your budget with your goals for speed and efficiency.

Here are some things to consider:

- Initial purchase price

- Ongoing costs for power and repairs

- How much material you need to process

- How long you want your screen to last

Note: Planning for long-term costs helps you get the most value from your equipment.

Consulting with Experts

You do not have to make these choices alone. Industry experts can help you find the best screen for your needs. They know how different screens perform with specific materials. You can ask them about capacity requirements, maintenance, and lifespan. They can help you match your screening objectives to the right equipment.

Many companies offer free consultations. You can show them your material and describe your working conditions. They will recommend the best screen for your plant. This saves you time and money. You avoid costly mistakes and get better results.

| Benefit of Expert Advice | How It Helps You |

|---|---|

| Accurate recommendations | Matches screen to your material |

| Cost savings | Avoids wrong purchases |

| Improved productivity | Meets your operational goals |

Tip: Talk to a screening specialist before you buy. Their advice can help you make the best selection for your plant.

Conclusion

You should pick the best screen for your work. Flip flow screens are great for wet or sticky materials. They help you work without many stops, but they cost more. Woven wire screens are strong and last a long time with dry materials. They are also flexible for different jobs. To get the best results, use the right screen for your material and needs. Anpeng Wire Mesh Filter Equipment Co., Ltd. has been making high-quality screens for over 20 years. We specialize in mining, aggregates, and recycling, always prioritizing quality and reliability in our products.

FAQ

What is the main difference between flip flow screens and woven wire screens?

Flip flow screens use flexible mats that move to prevent clogging. Woven wire screens use a mesh made from metal wires. You should pick flip flow screens for sticky materials and woven wire screens for dry, clean materials.

Can I use flip flow screens for dry materials?

Yes, you can use flip flow screens for dry materials. However, you may not need their special features. Woven wire screens usually work better and cost less for dry, clean materials.

How do I know when to replace my screen?

You should check your screen for holes, tears, or worn spots. If you see material passing through that should not, it is time to replace the screen. Regular inspections help you avoid downtime.

Which screen type lasts longer?

Polyurethane flip flow screens usually last longer than woven wire screens. You get more months of use before replacement. Woven wire screens wear out faster, especially with tough or abrasive materials.

Are flip flow screens harder to maintain?

Yes, flip flow screens need more care. You must check moving parts and mats often. Woven wire screens have a simpler design, so you spend less time on maintenance.

What materials work best with woven wire screens?

You should use woven wire screens for dry, clean, and non-sticky materials. They work well with aggregates, sand, gravel, and recycled concrete. They also suit jobs that need quick screen changes.

Can I switch between screen types easily?

You can switch, but you may need to change the frame or support system. Flip flow screens and woven wire screens have different designs. Ask a screening expert before making changes.

How do I prevent blinding on woven wire screens?

You can reduce blinding by cleaning the screen often and choosing the right mesh size. For wet or sticky materials, consider using flip flow screens instead.