If you want the best screening results, you usually find self-cleaning screens work better for most jobs. You know, every operation has its own challenges. The right choice in the harp screen vs self-cleaning screen debate depends on your materials and goals. Take a moment and think about what you need your screen to handle. Your decision shapes your results.

Key Takeaways

- Self-cleaning screens work best with sticky or wet materials. They help lower downtime and need less fixing.

- Harp screens are great for moving lots of material fast. They are also good for sorting dry and rough materials.

- Think about what kind of material you have before picking a screen. Sticky materials do better with self-cleaning screens.

- Self-cleaning screens can cost more at first. But they help you save money on work and new parts later.

- You must take care of your screens often. Harp screens need to be cleaned more, which can stop work.

- Think about what is most important for your work. You might want to focus on speed, strength, or saving money.

- Use the checklist given to help you know what you need before you choose a screen.

- Do not make mistakes like picking the wrong mesh or not cleaning your screens. This helps your screens work their best.

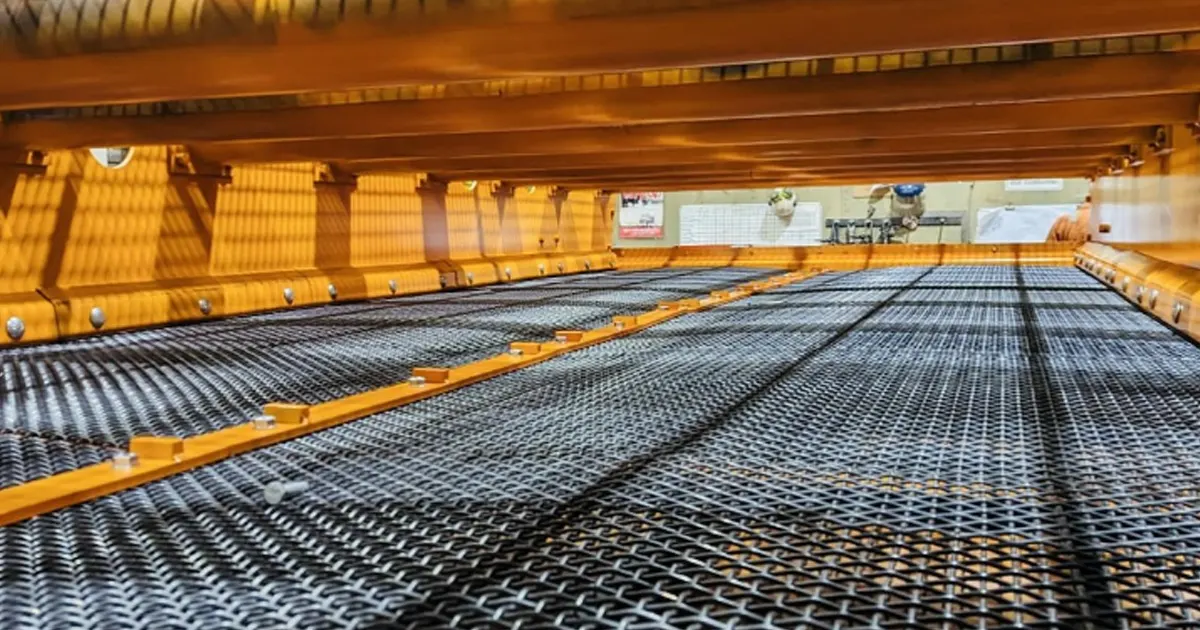

Harp Screen vs Self-Cleaning Screen: Quick Comparison

Feature Overview

Do you want a quick way to compare these screens? Look at this table. It shows the main features side by side. You can see efficiency, maintenance, durability, cost, and which materials each screen can handle.

| Attribute | Harp Screens | Self-Cleaning Screens |

|---|---|---|

| Cost | You pay more for corrosion-resistant alloys. They last up to three times longer in tough jobs. | You pay more at first, but you save on maintenance and downtime later. |

| Maintenance | Tensioned wires help stop material from building up. This cuts downtime almost in half. | Self-cleaning features mean you spend less time cleaning by hand. |

| Durability | Stainless steel versions last longer, even in harsh places. | Built to last, with less wear because of self-cleaning action. |

| Material Compatibility | Stainless steel works best for acidic stuff. Polyurethane is great for rough, abrasive materials. | Handles more types of materials because of self-cleaning design. |

Tip: If you work with sticky or rough materials, self-cleaning screens can help you work faster and with less trouble.

Pros and Cons

Let’s look at the main good and bad points for each screen. This helps you pick the best one for your job.

Harp Screens

- Good for fine screening and high efficiency with some materials.

- Tensioned wires help stop blinding, so you get more uptime.

- Stainless steel and polyurethane options make them last longer.

- Not great with very sticky or wet materials.

- You might need to clean more often if you use tough materials.

Self-Cleaning Screens

- Best for efficiency when you handle sticky, wet, or mixed materials.

- You spend less time on maintenance because of self-cleaning action.

- Longer service life means you replace them less often.

- Higher starting cost can be a problem.

- Not needed for simple, dry screening jobs.

When you compare harp screens and self-cleaning screens, think about your daily problems. Do you want less downtime and more efficiency? Are your materials tough to handle? Your answers will help you choose the right screen for your needs.

Performance Factors

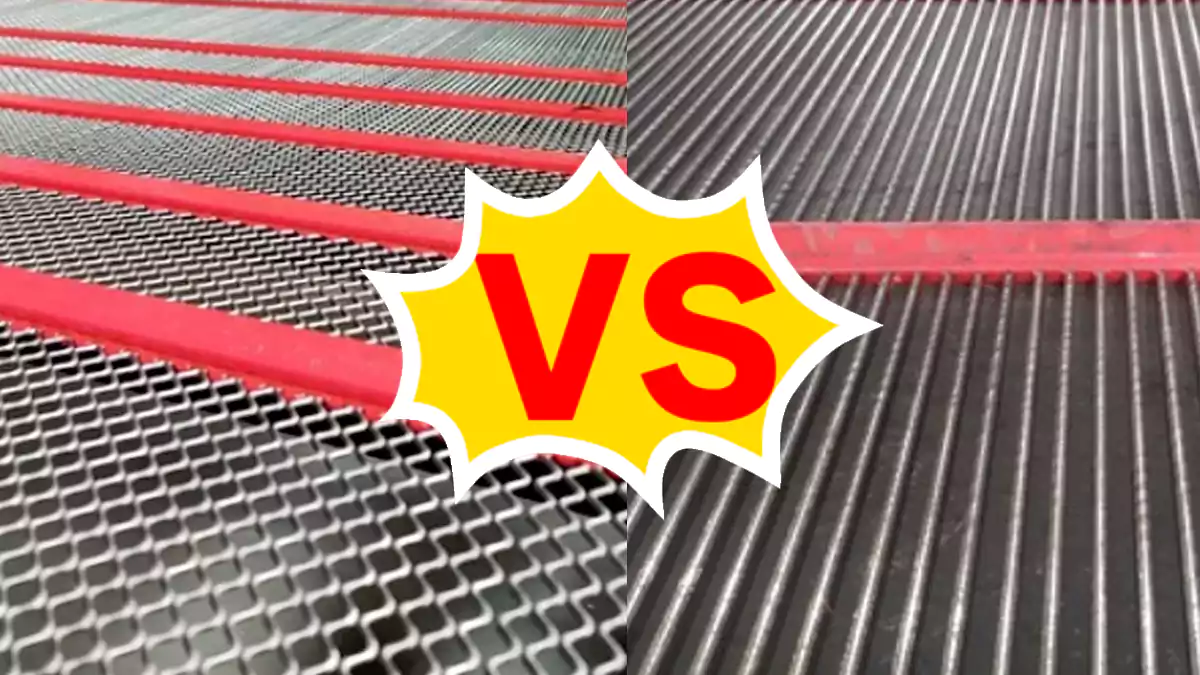

Screening Efficiency

You want your screening to work well. Screening efficiency is important when you need to sort materials quickly and correctly. Let’s see how harp screens and self-cleaning screens compare.

Throughput

Throughput means how much material goes through your screen in a certain time. Harp screens are great at this. Their design gives you lots of open space. More material can move through, so throughput is higher. Harp screens are good for big jobs. They keep the flow steady and help you reach your goals.

Self-cleaning screens also have strong throughput. Their surface stops material from blocking the holes. You spend less time fixing clogs. This keeps your screening efficient, especially with sticky or mixed materials.

Tip: For high-efficiency screening, pick screens with big open spaces and features that stop clogging.

Accuracy

Accuracy means you get the right size material every time. Harp screens are very precise. Their wires stay tight and keep the holes the same size. You get cleaner separation and fewer mistakes.

Self-cleaning screens use flexible wires or strips. These move as material goes through. The movement shakes off stuck pieces. You get accurate sizing, even with wet or sticky materials. Self-cleaning screens are good for tough jobs where accuracy matters.

Handling Difficult Materials

Some materials are hard to screen. Sticky, wet, or rough materials can slow you down. Let’s see how each screen deals with these problems.

Sticky or Wet Materials

Sticky or wet materials often block screens. Harp screens can handle some moisture, but they have trouble with very sticky stuff. You may need to stop and clean them more often.

Self-cleaning screens fix this problem. Their wires move and bend. This shakes off sticky bits. You spend less time cleaning and more time working. Screening stays efficient, even with wet materials.

Note: If you work with clay, mud, or damp rocks, self-cleaning screens help your operation last longer.

Abrasive Materials

Rough materials wear out screens fast. You need a strong screen for them. Harp screens are made for big, precise jobs. They give you high throughput and last longer. Their open design lets more material through and keeps products clean.

Self-cleaning screens stop plugging and blocking. Their surface stays clear, which is important with rough materials. You can use thinner wires, making them better for some jobs. You get longer life and less downtime.

- Harp screens are tough and give high efficiency in hard places.

- Self-cleaning screens cut down on maintenance and keep efficiency high with rough materials.

Callout: If you work with sand, gravel, or crushed stone, both screens work well. Choose based on if you want more throughput or less maintenance.

Screening efficiency depends on your material and your goals. Harp screens give you high throughput and accuracy. Self-cleaning screens keep your operation going with sticky or rough materials. Pick the screen that fits your daily needs.

Maintenance & Durability

Cleaning Needs

Manual vs. Self-Cleaning

Cleaning screens can be a big hassle. With a harp screen, you often stop work to clean by hand. This takes time and can get messy fast. If you use self cleaning wire mesh, you do not need to clean as much. The wires move and shake off stuck stuff. You spend less time scraping and more time working.

Let’s see how downtime changes with each screen:

| Screen Type | Downtime Reduction for Cleaning | Maintenance Time Reduction | Manual Cleaning Requirement |

|---|---|---|---|

| Self-Cleaning Screens | 95% | 50% | No |

| Traditional Harp Screens | N/A | N/A | Yes |

Self cleaning wire mesh almost gets rid of cleaning downtime. You do not have to worry about cleaning by hand. This means your plant can run longer without stopping.

Downtime

Downtime is bad for your work. Every time you stop to clean, you lose time and money. Self cleaning wire mesh helps you avoid this problem. The screen clears itself, so you do not need workers to clean it. This keeps your plant safe and working well.

Tip: If you want more uptime, use anti-clogging screens. They help stop clogging and keep your plant running.

Wear Resistance

Material Fatigue

Screens go through a lot of stress. You need a screen that can handle tough jobs and not break. Harp screens use hardened steel for rough materials. This makes them last longer. Self cleaning wire mesh has a design that stops clogging. Less clogging means less stress on the wires and a stronger screen.

Here’s a quick look at what affects wear resistance:

| Factor | Harp Screens | Self-Cleaning Screens |

|---|---|---|

| Material Properties | Require hardened steel for abrasive materials | Benefit from designs that prevent clogging |

| Screening Objective | Ideal for high precision applications | Suitable for damp, sticky materials |

| Media Type & Application | Best for heavy-duty tasks | Perfect for preventing clogging in sticky materials |

Blinding & Pegging

Clogging causes blinding and pegging. Blinding is when small pieces stick and block the holes. Pegging is when same-size pieces get stuck in the holes. Both problems slow down your work and lower your product quality.

Here are some common reasons screens fail:

- Choking gets worse during the rainy season.

- Plant output goes down.

- Product size changes, so you make less money.

- More cleaning means higher labor costs and unsafe work.

- Wire mesh does not last as long because of extra weight and hammering.

- Dust goes with big pieces and hurts crusher liner plates.

You also see:

- Pegging happens when same-size pieces get stuck in the holes.

- Blinding happens when wet or humid material makes small pieces stick.

Particles close to the hole size can get stuck or plug the holes. Smaller pieces can also get stuck when they try to pass through. Blinding blocks the screen and lowers your production.

Note: To avoid clogging, pick self cleaning wire mesh. It helps stop blinding and pegging, so your screen stays clear.

Service Life

You want your screen to last a long time. Self cleaning wire mesh gives you longer service life. Its design stops clogging and cuts down on wear. You do not have to replace the screen as often. Harp screens also last, especially with hardened steel. But if you work with sticky or wet stuff, clogging can make them wear out faster.

If you want a screen that works hard and lasts, choose anti-clogging screens. They help stop clogging and keep your plant running well.

Callout: Picking the right screen helps your plant run longer, saves on repairs, and makes your product better.

Cost Considerations

Initial Cost

You probably notice the price tag first when you shop for a new screen. Harp screens usually cost less upfront. You pay more if you want corrosion-resistant alloys or special materials. Self-cleaning screens come with a higher starting price. You invest more at the beginning, but you get features that help you save money later.

Tip: If you run a small operation or only need basic screening, harp screens can fit your budget. If you want less hassle and more uptime, self-cleaning screens might be worth the extra cost.

Operating Expenses

Labor & Cleaning

You spend money every time you stop to clean your screen. Harp screens need more frequent cleaning. Workers must scrape off stuck material, which takes time and adds to labor costs. Self-cleaning screens shake off debris on their own. You save on labor and parts because you do not need to clean as often.

- You spend less on labor with self-cleaning screens.

- You avoid long shutdowns, so your production line keeps moving.

- High-quality self-cleaning screens prevent clogging, so you do not replace parts as often.

Replacement Frequency

Screens wear out over time. Harp screens need replacement sooner if you handle sticky or abrasive materials. Self-cleaning screens last longer. Micro-vibrations dislodge trapped particles, so material does not build up. You reduce unplanned downtime by 40%. You can use the same screen for two or three times longer compared to regular mesh.

| Screen Type | Cleaning Frequency | Replacement Interval | Downtime Reduction |

|---|---|---|---|

| Harp Screen | High | Shorter | Low |

| Self-Cleaning Screen | Low | Longer | High |

Note: If you want to cut costs on replacements and keep your plant running, self-cleaning screens give you more value.

Long-Term Value

You want your investment to pay off. Self-cleaning screens cost more at first, but you save money over time. You spend less on labor, cleaning, and replacements. Your plant runs longer without stopping. You get more product and fewer headaches.

Harp screens work well for simple jobs. You pay less upfront, but you might spend more on cleaning and replacements. If you handle tough materials or want less downtime, self-cleaning screens offer better long-term value.

Callout: Think about your daily challenges. If you want to save money and keep your operation smooth, self-cleaning screens can help you reach your goals.

Best Use Cases

Harp Screen Applications

Ideal Materials

You need a screen that can handle hard jobs. Harp screens work well with many materials. Polyurethane screens last much longer than woven wire screens. Their flexible design helps stop clogging. They are lighter, so you use less energy. Woven wire screen cloth is the most popular choice. It has more holes for screening but wears out faster. Rubber screen panels are good for dry or rough materials. They last longer but have fewer holes. Polywedge panels drain water well and are easy to put in. Rubber panels are great for big, heavy jobs. They take hits and work in wet or dry places.

Tip: Polyurethane screens are best for wet or rough materials. They last longer and clog less.

Industry Examples

Harp screens are used in many jobs. They are used for primary scalping. You see them in topsoil work. Recycling plants use harp screens. Sand screening uses them too. You get high productivity and better efficiency. Harp screens work well and use less fuel. Multi-use screens fit many jobs. You can use them for primary scalping, topsoil, recycling, and sand screening.

- Primary scalping

- Topsoil handling

- Recycling processes

- Sand screening

Callout: Harp screens help your operation run smoothly. You get more uptime and less clogging.

Self-Cleaning Screen Applications

Ideal Materials

You want a screen that keeps working with sticky or wet stuff. Self-cleaning screens use special wire mesh. They stop blinding and pegging. You get longer wear life. Polyurethane panels last longer and are good for mining. Engineered media fights wear, breaking, and blinding. Self-cleaning mesh is used for sticky compost. Polyurethane panels are great for mining because they resist wear.

| Material Type | Properties | Applications |

|---|---|---|

| Self-cleaning wire | Stops blinding and pegging | Efficient screening |

| Polyurethane | Lasts long, strong, works well in mining | Mining operations |

| Engineered media | Fights wear, breaking, and blinding | Aggregate operations |

Note: Self-cleaning screens are best for jobs with lots of clogging. You get more efficiency and less downtime.

Industry Examples

Self-cleaning screens are used in many industries. Mining uses them for more uptime and steady flow. Crushing circuits use them for tough materials like clay and wet stuff. Fine screening stages get better efficiency. Dewatering uses self-cleaning screens for easier maintenance and lasting reliability. Final sizing jobs depend on them for advanced screening.

| Application Area | Performance Metrics |

|---|---|

| Mining Operations | More uptime, steady flow, better accuracy, less maintenance, safer work, lower costs |

| Crushing Circuits | Handles tough materials, especially wet and clay-rich |

| Fine Screening Stages | Better efficiency and sustainability |

| Dewatering Processes | Easier maintenance, lasting reliability |

| Final Sizing Operations | Important part of advanced screening systems |

- Mining operations

- Crushing circuits

- Fine screening stages

- Dewatering processes

- Final sizing operations

Callout: Self-cleaning screens give you more value with sticky, wet, or mixed materials. Your plant stays productive and safe.

Decision Guide: Harp Screen vs Self-Cleaning Screen

Choosing between harp screen vs self-cleaning screen can feel tricky. You want the best fit for your operation, but you also want to avoid costly mistakes. Let’s break it down so you can make a smart choice.

Checklist for Selection

You can use this checklist to help decide which screen works best for your needs. Ask yourself these questions before you buy:

- What type of material do you handle most often? Is it sticky, wet, abrasive, or dry?

- How much downtime can you afford for cleaning and maintenance?

- Do you need high throughput or precise sizing?

- What is your budget for initial investment and long-term costs?

- How often do you replace screens in your operation?

- Are you looking for less manual labor and more automation?

- Do you have issues with blinding or pegging in your current setup?

- What is your main goal: efficiency, durability, or cost savings?

Tip: If you deal with sticky or mixed materials, self-cleaning screens usually give you less downtime and more efficiency. If you work with dry, simple materials, harp screens can save you money upfront.

Common Mistakes

You want to avoid mistakes that can hurt your operation. Many industry professionals make these errors when choosing between harp screen vs self-cleaning screen:

- Wrong mesh selection. If you pick the wrong mesh, you can lose valuable material or let fines slip through.

- Overloading screens. Pushing too much material through can lower efficiency and force you to reprocess.

- Skipping maintenance. Ignoring small repairs can lead to bigger problems and more downtime.

You might also run into these issues:

- Selecting the wrong screen media leads to improper material separation and cross-contamination.

- Improper installation causes uneven material distribution and alignment problems.

- Uneven feed distribution increases the risk of equipment damage and slows down your process.

- Incorrect operating speed and angle makes material bounce off or pile up, which lowers efficiency.

- Lack of equipment maintenance reduces production and creates safety hazards.

You now have a clear guide to help you choose between harp screen vs self-cleaning screen. Take your time, ask the right questions, and keep your operation running smoothly.

Conclusion

You’ve seen how self-cleaning screens usually fit most jobs, but harp screens can save you money for simple tasks. Your best choice depends on your materials and goals. Use the checklist and decision guide to help you decide. Here’s a quick table of what to consider:

| Factor | What to Do |

|---|---|

| Assess Needs | Know your requirements |

| Weigh Pros and Cons | Compare options |

| Check Alignment | Match with your goals |

| Run a Small Test | Try before you commit |

You get honest advice here. Anpeng Wire Mesh Filter Equipment Co., Ltd. builds tough screens for mining, aggregate, concrete, and recycling.

FAQ

What’s the main difference between harp screens and self-cleaning screens?

You see harp screens use tensioned wires for high throughput. Self-cleaning screens have flexible wires that shake off stuck material. Both help you screen, but self-cleaning screens handle sticky stuff better.

Can I use self-cleaning screens for dry materials?

Yes, you can use self-cleaning screens for dry materials. You get less downtime, but harp screens might save you money if your material stays dry and easy to handle.

How often do I need to replace these screens?

You replace harp screens more often if you handle sticky or abrasive materials. Self-cleaning screens last longer because they resist clogging. You save money and time with fewer replacements.

Will self-cleaning screens reduce my labor costs?

Absolutely! You spend less time cleaning. Workers don’t need to scrape off stuck material. You see lower labor costs and more uptime.

Are harp screens good for fine screening?

Harp screens work well for fine screening. You get high accuracy and steady throughput. If you need precise sizing, harp screens help you reach your goals.

What materials work best with self-cleaning screens?

You get the best results with sticky, wet, or mixed materials. Self-cleaning screens handle clay, mud, compost, and damp rocks. Your plant stays productive and efficient.

Do I need special tools to install these screens?

No, you don’t need special tools. You can install both harp and self-cleaning screens with basic equipment. You save time and avoid extra costs.