Mesh size tells you how many openings fit across one inch of a screen. In industrial screening, mesh sizes help you know what particles will pass through or stay on top of the screen. A higher mesh number means smaller openings, so only finer particles get through. Take a look at this chart to see how mesh number matches up with particle size:

| Mesh | Opening (µm) |

|---|---|

| 20 | 841 |

| 40 | 420 |

| 100 | 149 |

| 200 | 74 |

| 325 | 44 |

When you understand mesh sizes, you can pick the right woven wire mesh for your job. This helps you separate materials quickly and get the results you want.

Key Takeaways

- Mesh size shows how many openings are in one inch. If the mesh number is higher, the openings are smaller.

- Knowing mesh sizes helps you pick the best screen. This helps you separate materials well.

- Mesh sizes use industry standards. This makes sure people understand each other in different jobs.

- There is an opposite link between mesh number and particle size. Bigger mesh numbers let only small particles go through.

- Mesh density depends on wire thickness and openings. This changes how strong and bendy the mesh is.

- Picking the right mesh size can help things separate better. It can also stop problems like clogging.

- Self-cleaning screens can lower maintenance. They help your mesh last longer by stopping blockages.

- Always think about what you need for your job. You should look at particle size and the environment when you choose mesh.

Mesh Sizes Explained

What Is Mesh Size

When you look at a screen or filter, you might wonder how small the holes are. Mesh size gives you that answer. It tells you how many openings fit across one inch of the screen. If you see a label that says “20 mesh,” that means there are 20 little openings in every inch. This number helps you figure out what size particles can pass through.

Mesh sizes follow industry standards. You might see different systems, like the US Standard Sieve Series (ASTM E11), the Tyler Mesh System, or ISO 3310. These standards make sure everyone means the same thing when they talk about mesh size.

Here’s a quick look at how mesh sizes compare:

| Mesh Size | Openings per Inch | Approximate Opening Size |

|---|---|---|

| 4 mesh | 4 | ~5–6 mm |

| 20 mesh | 20 | ~1 mm |

| 60 mesh | 60 | ~0.25 mm (250 µm) |

| 200 mesh | 200 | ~0.074 mm (74 µm) |

| 325 mesh | 325 | ~0.043 mm (43 µm) |

You can see that as the mesh size number goes up, the openings get smaller. This is important when you need to separate materials by size.

Tip: Mesh sizes are not just for one industry. You’ll find them in mining, food processing, construction, and even in your kitchen sifter.

Mesh Number and Particle Size

Mesh number and particle size work together. The mesh number tells you how many holes are in one inch. The particle size tells you how big the particles are that can pass through those holes. There’s an inverse relationship here. When the mesh number goes up, the opening size goes down. That means only smaller particles can get through.

Check out this table to see how mesh number matches up with particle diameter:

| Mesh Size | Particle Diameter (μm) |

|---|---|

| 4 | 5205 |

| 8 | 2487 |

| 10 | 1923 |

| 14 | 1307 |

| 18 | 1000 |

| 20 | 840 |

| 25 | 710 |

| 30 | 590 |

| 35 | 500 |

| 40 | 420 |

| 45 | 350 |

| 50 | 297 |

| 60 | 250 |

| 70 | 210 |

| 80 | 177 |

| 100 | 149 |

| 120 | 125 |

| 140 | 105 |

| 170 | 88 |

| 200 | 74 |

| 230 | 62 |

| 270 | 53 |

| 325 | 44 |

| 400 | 37 |

| 550 | 25 |

| 800 | 15 |

| 1250 | 10 |

You might see mesh sizes written as a single number or as a range. For example, “-100 mesh” means all particles pass through a 100 mesh screen. If you use the right mesh size, you get better separation and more consistent results.

- If you pick a mesh with a high number, you catch only the smallest particles.

- If you use a mesh with a low number, you let bigger pieces through.

Mesh Density and Wire Arrangement

Mesh density means how tightly the wires are woven together. It depends on the mesh count (openings per inch) and the thickness of the wires. You’ll find different types of mesh for different jobs. Here’s a quick guide:

| Type of Wire Mesh | Description | Common Uses | Benefits |

|---|---|---|---|

| Woven Metal Mesh | Wires crisscross and weave together. | Filtration, fencing, architecture | Flexible, durable, precise. |

| Welded Wire Mesh | Wires welded at each crossing point. | Construction, agriculture | Strong, affordable, good for structure. |

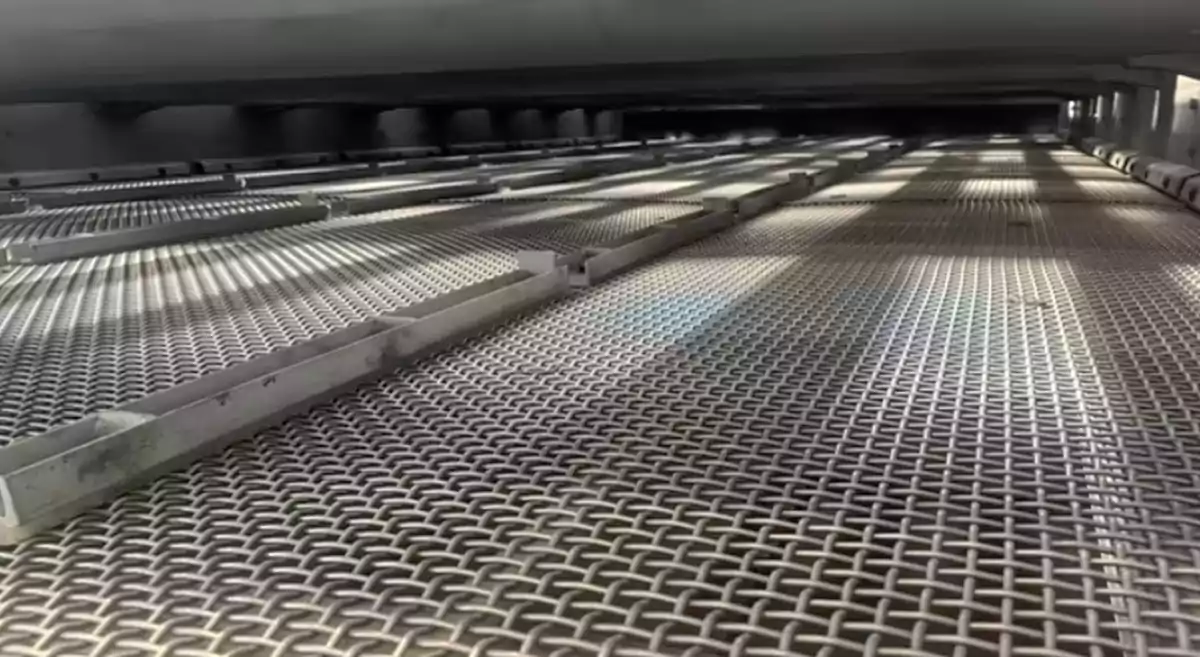

| Heavy Duty Metal Mesh | Built for tough jobs and heavy loads. | Conveyor belts, security barriers | Robust, long-lasting, handles stress. |

| Impact of Wire Diameter | Thicker wires give strength; thinner wires offer flexibility. | Varies | Changes strength, weight, and flexibility. |

| Mesh Pattern | The way wires are arranged affects airflow, visibility, and filtering. | Varies | Changes how the mesh works for each task. |

Mesh density is measured by mesh count, wire diameter, and opening size. Standards like ASTM E11 and ASTM E2016 help keep these measurements consistent. You’ll also see micron ratings, which tell you the smallest particle that can pass through. Mesh sizes matter because they decide how well you can separate, filter, or protect materials.

Note: If you need a strong mesh for heavy loads, choose one with thicker wires and a lower mesh count. For fine filtering, go for a higher mesh count and thinner wires.

Mesh sizes play a big role in every industry, from mining to food processing. When you understand mesh size, mesh number, and mesh density, you can pick the right screen for your job.

Measuring Mesh Size

U.S. Mesh Size and Sieve Size

You may wonder how experts measure mesh in labs and factories. They use strict rules to make sure results are always reliable. In the U.S., mesh is measured using ASTM and AASHTO standards. These rules help you compare mesh from different companies and keep screening the same.

Here are the main standards:

| Standard | Description |

|---|---|

| ISO 3310-1:2016 | Sets mesh size, materials, and limits for test sieves. |

| ASTM E11 | Lists how USA Standard ASTM Test Sieves are made. |

| AASHTO M92 | Gives rules for making and using test sieves in transport. |

There are three main types of ASTM sieves:

- USA Standard ASTM Test Sieves: Made to last and easy to track.

- USA Standard ASTM Inspection Test Sieves: Used for careful and repeatable checks.

- USA Standard ASTM Calibration Test Sieves: Checked for very high accuracy.

Tip: For the most exact mesh measurement, pick calibration test sieves. These give a 99.73% confidence that openings are even.

U.S. mesh rules often match world standards, so you can use mesh from other countries without big changes. For example:

| U.S. Standard | International Standard | Similarities |

|---|---|---|

| ASTM 3/8in | ISO 9.5mm | Same opening sizes, wire thickness, and limits |

| ASTM 8in | ISO 200mm | Most sieve cloth sizes fit both frames |

| ASTM 12in | ISO 300mm | Popular sizes, matched rules |

Units: Microns, Inches, Millimeters

Mesh is measured in different units. You will see mesh openings listed in microns, inches, or millimeters. Each unit helps you know the real size of the mesh opening.

Here is how you change between units:

| Measurement Type | Conversion Formula |

|---|---|

| Microns | Microns = 25,400 ÷ Mesh Size |

| Inches | 1 inch = 25,400 microns |

| Millimeters | 1 mm = 1,000 microns |

If you have a mesh size of 100, use the formula above to find the opening in microns. Divide 25,400 by 100 to get 254 microns. To change that to millimeters, divide by 1,000. You get 0.254 mm.

Note: Mesh measured in microns is common for fine screening. Inches and millimeters are used for bigger mesh openings.

The unit you pick can change how you choose mesh for your job. If you work with grit sizes, not all grains are the same size. A 60–100 grit mesh has both bigger and smaller grains, which changes how well your mesh filters things.

You will also see mesh and micron sizes used for strainers. Both show what size particles can go through, so you can choose the right mesh for your needs.

Aperture Size vs Mesh Number

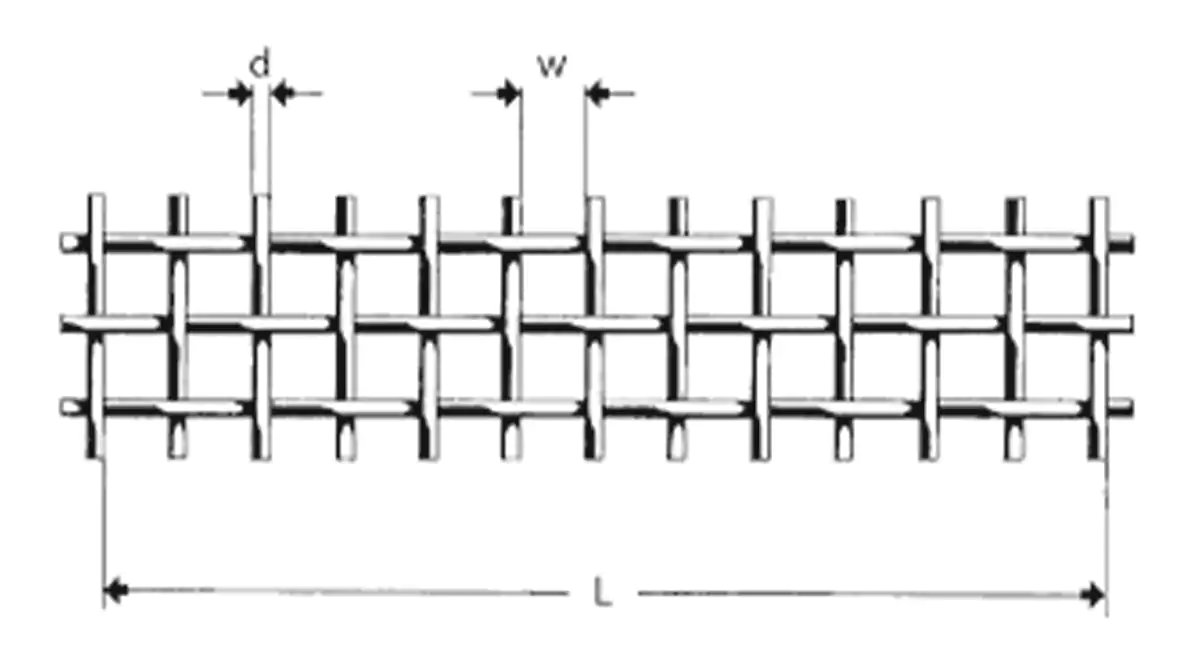

Let’s look at the difference between mesh number, aperture size, and wire thickness. These three things work together to decide how your mesh works.

- Mesh number tells how many openings are in one inch.

- Aperture size is the space between wires.

- Wire thickness is how thick each wire is.

Here is a simple formula to show the relationship:

Aperture Size = (1 / Mesh Count) – Wire Diameter

If you make the wire thicker but keep the mesh number the same, the aperture size gets smaller. Less material can pass through. If you use thinner wire, the aperture size gets bigger. This lets more material through but may make the mesh weaker.

Block Quote: Thicker wire makes your mesh stronger and last longer. Thinner wire gives bigger openings, which can help screening work better.

You need to balance these things for your job. If you want to screen tiny particles, pick a higher mesh number with thin wire. If you need strength for heavy loads, choose a lower mesh number with thick wire.

Here is a table to show how mesh number and aperture size change your screening:

| Mesh Number | Description |

|---|---|

| Higher mesh number | Smaller openings, best for tiny particles |

| Lower mesh number | Bigger openings, best for large particles |

| Aperture Size | Real size, changes flow and how well it works |

When you pick mesh, always think about mesh number, aperture size, and wire thickness. This helps you get the best results for your screening job.

Particle Size and Mesh

Inverse Relationship Explained

When you look at mesh screens, you see something cool. The mesh number and particle size go in opposite directions. If you pick a mesh with a bigger number, the holes get smaller. Only tiny particles can go through small holes. If you choose a mesh with a smaller number, the holes get bigger. Bigger holes let larger particles slip through.

Here’s how this works:

- Mesh size and particle size go in opposite ways.

- When mesh size goes up, the particles that pass get smaller.

- When mesh size goes down, the particles that pass get bigger.

This helps you control what materials you separate. You can catch big pieces or let small ones pass. Mesh screens help you pick the right hole size for your job.

Mesh Size Impact on Material Separation

The mesh you pick changes how well you separate things. If you use mesh with small holes, you trap tiny particles. Only the finest material gets through. If you use mesh with big holes, you let bigger particles go through. The largest pieces stay out.

When you screen materials, fine particles pass through the mesh. More large particles stay on top of the screen. Changing how you run the process can help it work better. Big holes let more material pass but may not sort fine particles as well.

Let’s see how mesh size changes your results:

- Mesh size affects how well you separate particles. Big mesh sizes let bigger particles pass. Small mesh sizes trap smaller particles.

- Picking the wrong mesh size can cause problems. You might get clogged screens or mixed materials. This can make your filter work badly.

- Some industries need exact mesh sizes. For example, in medicine, you need the right mesh to keep products pure and particle size the same.

The hole size decides how clean and pure your separated materials are. Here’s a table to show what changes when you pick different hole sizes:

| Aspect | Description |

|---|---|

| Hole Size of the Mesh | Decides what size particles get separated. How much material passes depends on hole size. |

| Effect on Screening | Rubber mesh needs bigger holes than wire mesh to split sizes well. |

| Undersize and Oversize Proportion | It’s important to know if the material meets quality rules. You need to check the amount of small and large pieces. |

When you pick mesh, think about the hole size and the particles you want to separate. The right mesh gives you clean material and keeps your process working well. If you want better results, match your mesh size to your needs. Watch how the hole size changes what goes through.

Screening Media Types

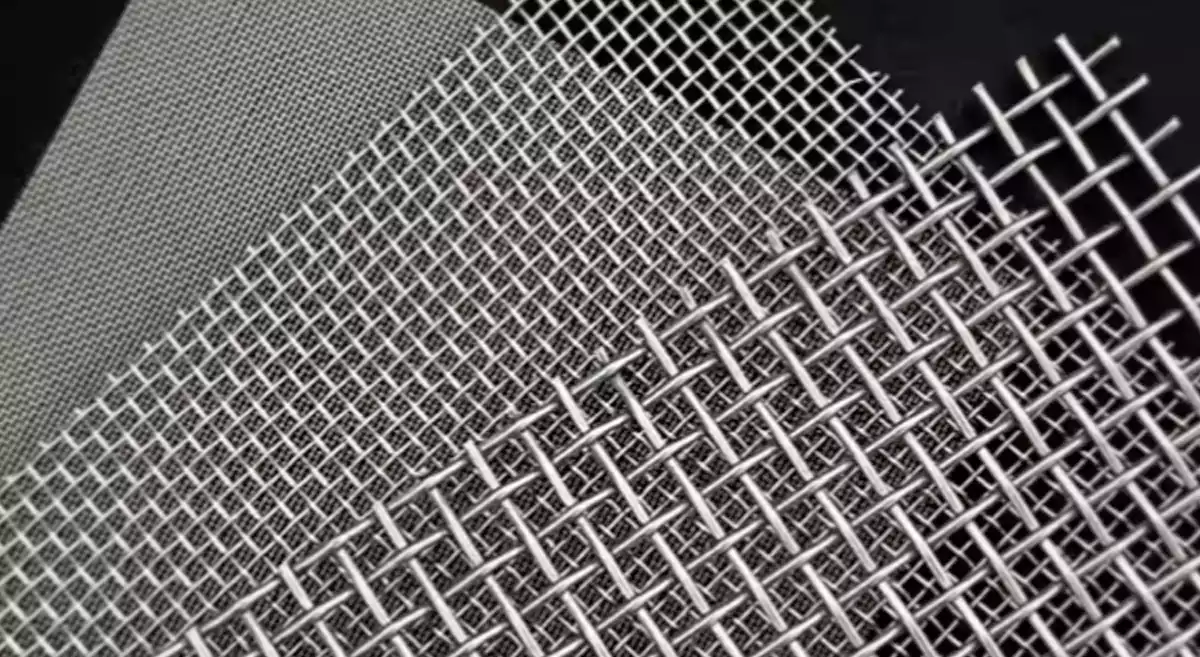

Woven Wire Mesh Selection

Woven wire mesh helps you separate materials. You can pick how big the holes are. Choose mesh with more holes per inch for tiny particles. Use mesh with fewer holes per inch for bigger pieces. Woven wire mesh can be made in different patterns. You decide how fast and accurate your screening is. The wire thickness matters a lot. Thick wires make the mesh strong and last longer. Thin wires give more open space, so things move faster. Woven wire mesh comes with openings from 4 inches to 20 microns. This means you can use it for many jobs.

Tip: Always check wire thickness and holes per inch before buying woven wire mesh. This helps you get the right mix of strength and flow.

Here’s a look at different screening media and how mesh size changes:

| Type of Screening Media | Characteristics | Mesh Size Variation |

|---|---|---|

| Woven Wire Mesh | Used a lot, strong, can be made thick or thin | Changes with wire thickness and hole size |

| Polyurethane | Tough plastic, good for wet jobs, can be changed | Molded for special needs, hole size changes |

| Rubber | Good for big, rough stuff, lasts longer than wire | Fewer holes than wire mesh, lets less through |

| Hybrid | Mixes wire with rubber or plastic, stops clogging | More open space than polyurethane, lasts longer than wire mesh |

Self-Cleaning Screens and Mesh Size

Mesh screens can get clogged. Self-cleaning screens help stop this problem. These screens have special shapes to keep stuff moving. They stop holes from getting blocked. You clean less and work more.

Self-cleaning screens have many good points:

| Advantage | Explanation |

|---|---|

| Reduced Maintenance Costs | You clean them less, so you save money and time. |

| Extended Screen Life | They last up to three times longer than regular wire mesh. |

| Less Downtime | You avoid long stops, so work keeps going. |

| Reduced Clogging and Blinding | Good self-cleaning screens stop clogging and last longer. |

| Lower Maintenance Bills | They keep your system working well without extra work, so you save money. |

If you want your mesh to work well, pick self-cleaning screens. You get fewer clogs, longer life, and less stopping.

PU-Mesh Screens for Abrasion

Some jobs need tough mesh. PU-mesh screens use polyurethane, which is very strong. These screens work well with rough materials or wet jobs. You can shape PU-mesh screens for your needs. You can pick the holes per inch that fit your job.

PU-mesh screens last longer than regular woven wire mesh in hard jobs. You get strong screens and need fewer replacements. If you want mesh that fights wear and keeps working, PU-mesh screens are a good choice.

Note: When you pick mesh, think about what you are screening and how many holes per inch you need. The right mesh keeps your work running well.

Examples and Calculations

Calculating Mesh Size from Aperture

You might wonder how to figure out the mesh size just by looking at the screen. It’s easier than you think! Here’s a simple way to do it:

- Lay a ruler across one inch of the mesh.

- Count the number of openings along that inch. Make sure you include both the wires and the spaces between them.

- The total number of openings in that inch is your mesh count.

Let’s try an example. If you count 40 openings in one inch, your mesh size is 40 mesh. This means the mesh will catch any particle larger than the opening size and let smaller ones pass through.

Tip: Always double-check your count. If you miss a wire or opening, you might get the wrong mesh count and end up with the wrong screen for your job.

You can also use a formula to estimate the opening size if you know the mesh count and wire diameter:

Aperture Size = (1 / mesh count) – wire diameter

This helps you see if a certain particle will fit through the mesh or get caught.

Choosing Mesh Size for Applications

Picking the right mesh size can make a big difference in your results. You want to match the mesh to the size of the particle you need to separate. Here are some things to keep in mind when you choose:

- The open area percentage tells you how much space is available for particles to pass through. This matters for things like filtration, airflow, or even letting light through.

- If you know the void space in your mesh, you can control how many particles get through and how fast they move.

- The right mesh size can help you boost flow rates and improve how well your screen filters out unwanted particles.

Here’s a handy table to help you decide:

| Factor | Description |

|---|---|

| Opening Size | Match the mesh opening size to the size of the particles you need to filter or screen. |

| Wire Diameter | Thicker wires offer greater strength and durability; thinner wires provide a higher open area. |

| Material | Stainless steel is ideal for corrosive environments; brass is suitable for conductivity. |

| Open Area Percentage | A higher open area allows for better flow rates but may reduce filtration efficiency. |

| Mesh Type | Woven wire mesh is versatile; welded wire mesh offers stability; rigid mesh is for flat surfaces. |

Let’s say you need to filter sand. You measure the average particle size and pick a mesh with an opening just a bit smaller. If you want to separate dust from air, you’ll need a much finer mesh count to catch those tiny particles.

Note: Always think about the size and shape of your particles, the strength you need, and how much material you want to move through the mesh.

Here’s a quick mesh size conversion chart for reference:

| Mesh Size | Opening (mm) | Opening (µm) |

|---|---|---|

| 10 | 2.00 | 2000 |

| 40 | 0.42 | 420 |

| 100 | 0.15 | 149 |

| 200 | 0.074 | 74 |

| 325 | 0.044 | 44 |

With these tips and examples, you can choose the right mesh for any job. Just remember to check your mesh count, think about your particle size, and use the chart when you need a quick answer.

Common Terms and Conversion

Glossary: Mesh, Aperture, Micron, Inch

You might see a lot of words when you look at mesh screens. Let’s break down the most important ones so you can understand what they mean and use them with confidence.

| Term | Definition |

|---|---|

| Mesh | The number of wires or openings per inch. This tells you how fine or coarse the screen is. |

| Aperture Size | The measured opening between wires. This is the space where particles pass through. |

| Micron | A unit of length equal to one-millionth of a meter. You use this to describe tiny particles. |

| Inch | A standard unit of length. Mesh sizes are often measured by how many openings fit in one inch. |

Tip: Mesh size shows you how many openings are in one inch. If the mesh number goes up, the openings get smaller. That means you catch finer particles.

Here’s a quick list to help you remember:

- Mesh size tells you how many openings are in each inch.

- Aperture size is the actual gap between wires.

- Microns measure very small particles or openings.

- Inches are used for bigger measurements and mesh counts.

If you work with mesh screens, you’ll see these terms all the time. Knowing what they mean helps you pick the right screen for your job.

Mesh Size Conversion Chart

Choosing the right mesh size can feel tricky. You want to match the size of the particles you need to filter with the right mesh. A mesh size conversion chart makes this much easier. You can see at a glance which mesh will work for your material.

Here’s how you can use a mesh size conversion chart:

- Find the particle size you want to filter out.

- Look for the mesh size that matches your particle size. For example, 60 mesh (250 microns) works well for fine sand.

- If you need to catch a range of particle sizes, check several mesh sizes to see which ones fit your needs.

Note: As mesh number increases, the openings get smaller. You can use microns for very fine measurements, especially when you need to go beyond 325 mesh.

Here’s a handy chart to help you convert mesh sizes:

| Mesh Size | Opening (mm) | Opening (µm) |

|---|---|---|

| 10 | 2.00 | 2000 |

| 40 | 0.42 | 420 |

| 60 | 0.25 | 250 |

| 100 | 0.15 | 149 |

| 200 | 0.074 | 74 |

| 325 | 0.044 | 44 |

| 400 | 0.037 | 37 |

If you use this chart, you can quickly match your material to the right mesh. You save time and avoid mistakes. You also make sure your screening process works the way you want.

Want to catch even smaller particles? Look for mesh sizes above 325 and use micron measurements for the best results.

With these terms and the conversion chart, you can choose mesh screens with confidence. You’ll know exactly what to look for and how to get the results you need.

ANPENG Screening Solutions

Product Range Overview

When you need screening media, you want choices that fit your job. ANPENG gives you many products, so you can solve almost any screening problem. Some jobs need strong screens for big rocks. Other jobs need screens that last longer with sticky or fine materials. ANPENG has something for every need.

Here’s a quick list of what you can pick:

| Media Type | Application Description |

|---|---|

| Metal Screens | Best for heavy-duty, high-impact tasks (e.g., large aggregates). |

| Polyurethane Screens | Offer superior wear life and resist blinding for fine, abrasive, or corrosive materials. |

| Self-Cleaning Screens | Perfect for damp, sticky materials to prevent clogging. |

Metal screens are good when you need strength and toughness. You use them in mining or building, where big pieces hit the mesh hard. Polyurethane screens last longer and work well with fine or rough materials. If you have sticky or wet stuff, self-cleaning screens help keep things moving and stop clogs.

Tip: You do not have to use just one kind. You can mix different screens to get the best results for your material.

Matching Mesh Size to Application

Picking the right mesh size makes your work easier and faster. ANPENG helps you choose the mesh size that fits your needs. You should think about what you are screening and how the mesh will work.

Here are some important things to think about:

| Criteria | Description |

|---|---|

| Particle Size | The size of particles that the mesh will filter or support is crucial for effective application. |

| Wire Thickness | Thicker wires provide greater strength and durability, essential for heavy-duty applications. |

| Material Selection | The type of material affects the mesh’s performance and longevity in specific environments. |

| Environmental Factors | Consideration of exposure to water, chemicals, and rough usage is vital for mesh durability. |

| Load and Stress Needs | Understanding the weight and force the mesh will encounter ensures safety and functionality. |

Start by looking at the particle size you want to separate. If you need to catch tiny pieces, pick a mesh with small holes. For bigger pieces, use a mesh with larger holes. Wire thickness is important too. Thick wires make the mesh stronger, which is good for heavy loads. Thin wires let more material pass, but they may wear out faster.

Material choice matters. Stainless steel is good for wet or harsh places. Polyurethane lasts longer with rough materials. You also need to think about the environment. If your mesh faces water, chemicals, or rough use, pick something that can handle it.

Note: Always check how much weight and force your mesh will face. If you expect heavy hits, pick a stronger mesh to keep your work safe.

ANPENG’s team can help you find the best mesh size and type for your job. You get a solution that fits your needs and keeps your work running well. With the right mesh, you save time, have less downtime, and get better results.

Conclusion

You’ve learned how mesh size, wire thickness, and tension all play a big part in screening results. Here’s what matters most:

- Mesh count and thread diameter affect how well you separate materials.

- The size of mesh openings decides what passes through.

- Open area percentage helps you pick the right screen for your job.

- Fabric thickness and tensile strength keep your mesh working longer.

Keep the glossary and conversion chart handy. When you know these basics, you can choose the best mesh for any job. ANPENG offers options that fit your needs, so you get reliable results every time.

FAQ

What does mesh screen size mean for powder?

Mesh screen size tells you how small the holes are. If you work with powder, a higher mesh screen number means smaller holes. You can separate fine powder from bigger pieces by picking the right mesh screen size.

How do I choose the best mesh screen for powder?

You should look at the size of your powder particles. If you want to catch fine powder, pick a mesh screen with a high number. For coarse powder, use a mesh screen with a lower number.

Can I use any mesh screen for all types of powder?

No, you need to match the mesh screen to your powder. Some powder needs a fine mesh screen, while other powder works better with a coarse mesh screen. Always check your powder size before you choose.

Why does my powder clog the mesh screen?

Powder can clog the mesh screen if the holes are too small or if the powder is sticky. Try using a self-cleaning mesh screen or pick a mesh screen with bigger openings for your powder.

Tip: If your powder keeps clogging, clean your mesh screen often and check for damage.

How do I clean a mesh screen after screening powder?

You can use a soft brush or gentle air to clean the mesh screen. Make sure you remove all powder from the mesh screen. If powder sticks, soak the mesh screen in warm water and let it dry before using it again.

What mesh screen size works best for fine powder?

A mesh screen with a high number, like 200 or 325, works best for fine powder. This mesh screen catches tiny powder particles and lets only the smallest powder pass through.

Can I use the same mesh screen for powder and liquids?

You can use a mesh screen for both powder and liquids, but you need to check the mesh screen size. Some mesh screens work better for powder, while others are made for liquids. Always match the mesh screen to your material.

Does mesh screen material matter for powder screening?

Yes, the mesh screen material matters. Stainless steel mesh screens last longer when you screen powder. If you use mesh screens with powder that is wet or sticky, pick a mesh screen that resists rust and wear.

Note: Always check your mesh screen for holes or tears before you use it with powder.