When you think about metal mesh design, you see how it helps keep people safe. It also makes work easier in big industries. Metal mesh comes in many types. Each type has its own strong points. You might see perforated, expanded, welded, and woven wire mesh. These are used in mining, construction, or recycling. The material you pick matters a lot. Mesh size and smart design also change how well the mesh works.

- Environmental rules make companies use greener ways.

- New health rules mean good mesh panels are needed.

- Tax breaks help companies build better and stronger mesh.

There are real problems to solve, but the right mesh can help you do your job better.

Key Takeaways

- Metal mesh design helps keep people safe and work better in many jobs.

- Picking the right mesh type, like perforated or welded, is important for each use.

- Think about things like how well the material fights rust and how strong it is to make it last longer.

- Mesh size and aperture change how well it filters and how much can pass through.

- You can change the mesh to fit special project needs.

- Taking care of the mesh often helps it last longer and work well.

- Knowing the main features of metal mesh helps you pick the best one for your project.

- Metal mesh can be used in mining, building, recycling, and food processing.

What Is Metal Mesh Design?

Definition

Metal mesh design is about making and picking mesh screens for jobs. These jobs include separating things, filtering liquids, or keeping equipment safe. Metal mesh works in many industries because it is tough. You choose the right mesh pattern, wire thickness, and material for your needs. Mesh size and aperture size are important. They help decide how well the mesh can separate or filter things. Woven wire mesh is used when you need strength and flexibility. Metal mesh design helps your project work well and last longer.

Tip: When picking mesh materials, think about corrosion resistance and temperature tolerance. These features help your mesh last longer in tough places.

Industrial Roles

Metal mesh is used in many industrial jobs. Here are some main uses:

- Filtration: Metal mesh filters particles in food, chemical, and pharmaceutical plants.

- Structural Support: Metal mesh gives strength and support in construction and manufacturing.

- Aesthetic Design: Metal mesh is used for decorative panels or screens in buildings.

Metal mesh design helps you pick the right mesh for each job. This gives better results and safer workspaces.

Key Properties

When you look at metal mesh, you should check its key properties. These features help you choose the best mesh for your job.

Transparency

Metal mesh lets light and air go through. You can see through it, which helps when you need to see things. For example, mesh screens are used in safety barriers or ventilation panels.

Flexibility

Some mesh types bend and shape easily. Woven wire mesh is strong and flexible. You can use it for custom mesh designs or curved surfaces. Flexibility helps you fit mesh into tight spaces or odd shapes.

Structural Integrity

You want your mesh to stay strong under pressure. Welded wire mesh gives sturdy support for fences or concrete reinforcement. Mesh strength and durability are important for heavy-duty jobs. You need to check wire gauge and mesh pattern to make sure your mesh can handle the load.

Here’s a quick look at common metal mesh types and their properties:

| Type of Metal Mesh | Distinguishing Properties |

|---|---|

| Wire Mesh | Lightweight, durable, versatile; used in filtration, protection, and structural applications. |

| Woven Wire Mesh | Strong and flexible; used in filtration, sieving, and architectural applications. |

| Welded Wire Mesh | Sturdy and rigid; commonly used in construction, reinforcement, fencing, and animal enclosures. |

| PVC-Coated Mesh | Corrosion-resistant; used for outdoor applications like fencing and decorative purposes. |

When you plan your industrial screen design, always check mesh strength, durability, and performance. The right screen mesh types help you reach your goals, whether you need self-cleaning screens, polyurethane screens, or custom mesh designs.

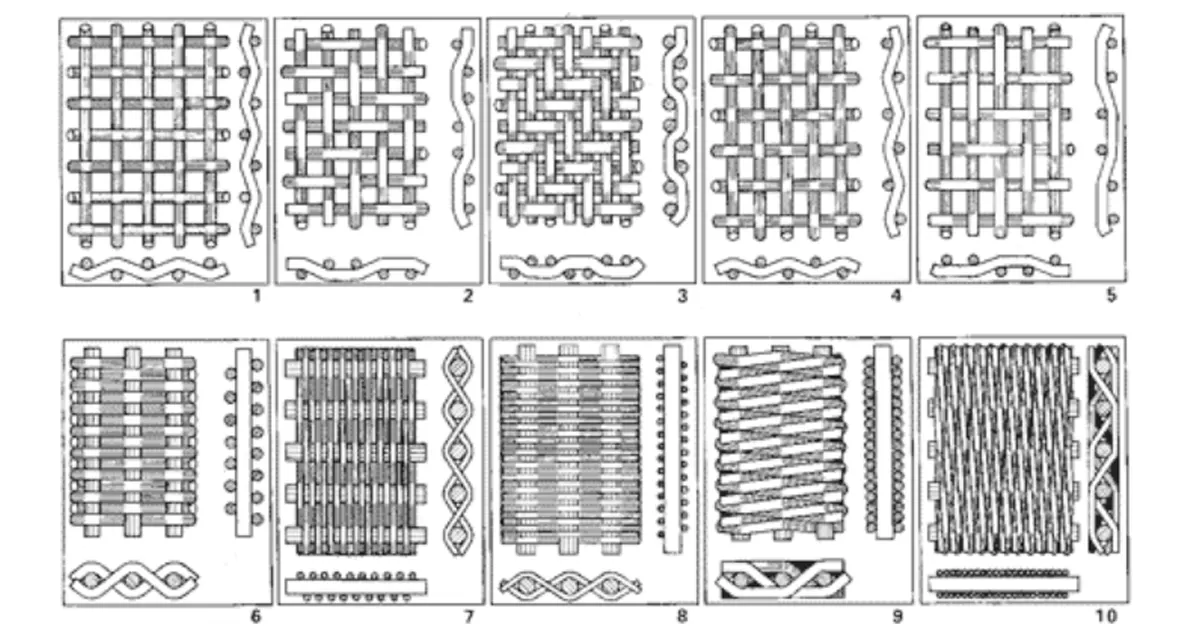

Types of Metal Mesh

When you look at metal mesh, you see each type is good for certain jobs. Let’s talk about three common types you might use.

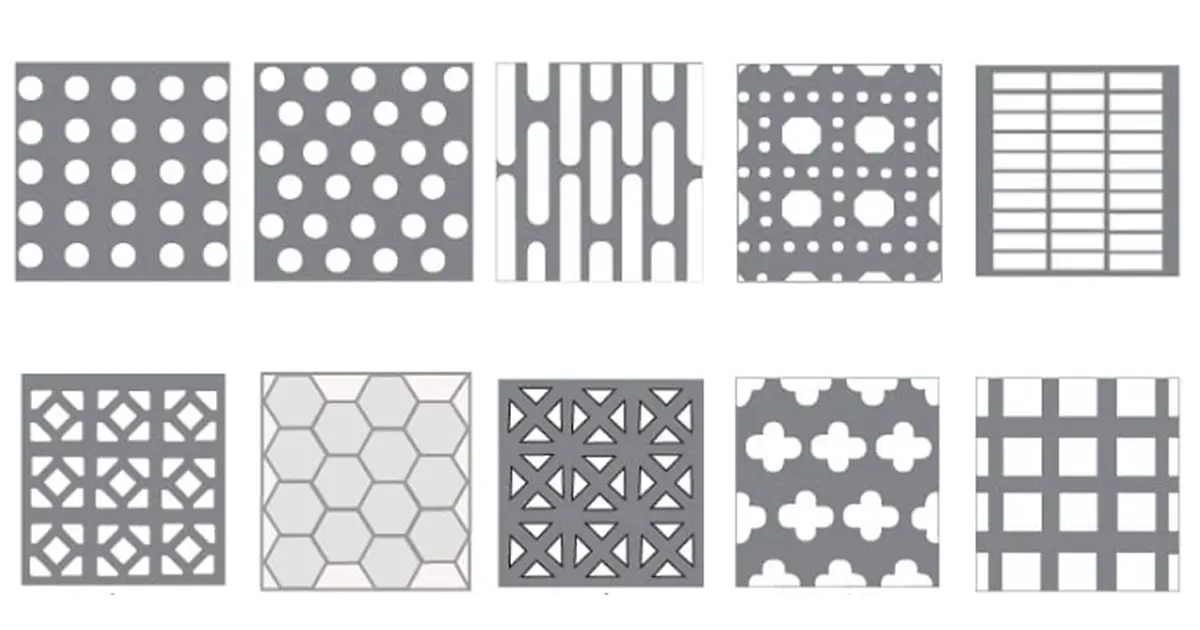

Perforated Mesh

Perforated mesh has holes punched in metal sheets. You can pick different patterns, like round or square shapes. This mesh gives both strength and a nice look. People use it to filter liquids or let air move through. It also makes buildings look cool. Perforated mesh works for screens, guards, and decorations.

Here’s a table that shows how perforated mesh is different from other types:

| Type of Metal Mesh | Structure | Applications |

|---|---|---|

| Perforated Metal | Holes punched through metal, customizable | Filtration, aesthetic design, strength, screens, guards |

| Expanded Metal | Diamond-shaped holes, cut and stretched | Flooring, gates, machine guards, safety platforms |

| Wire Mesh | Woven or welded strands | Flexible screens, filtration, fencing |

You can change the hole size, pattern, and thickness to fit your needs.

Tip: If you want something strong and cool-looking, perforated mesh is a good pick.

Expanded Mesh

Expanded mesh starts as a solid sheet. Machines cut and stretch it to make diamond shapes. The sheet stays in one piece, so it is extra strong. Expanded mesh is tough and bends a little. You see it in factories, warehouses, and outside areas.

Here’s why expanded mesh is great for hard jobs:

- It can hold heavy things and take rough use.

- People use it for safety platforms, stairs, and walkways because it stops slips.

- You can see through it, which helps keep people safe.

- It works for machine guards and filters too.

Expanded mesh keeps things safe and lasts a long time. You don’t have to worry about it breaking or bending fast.

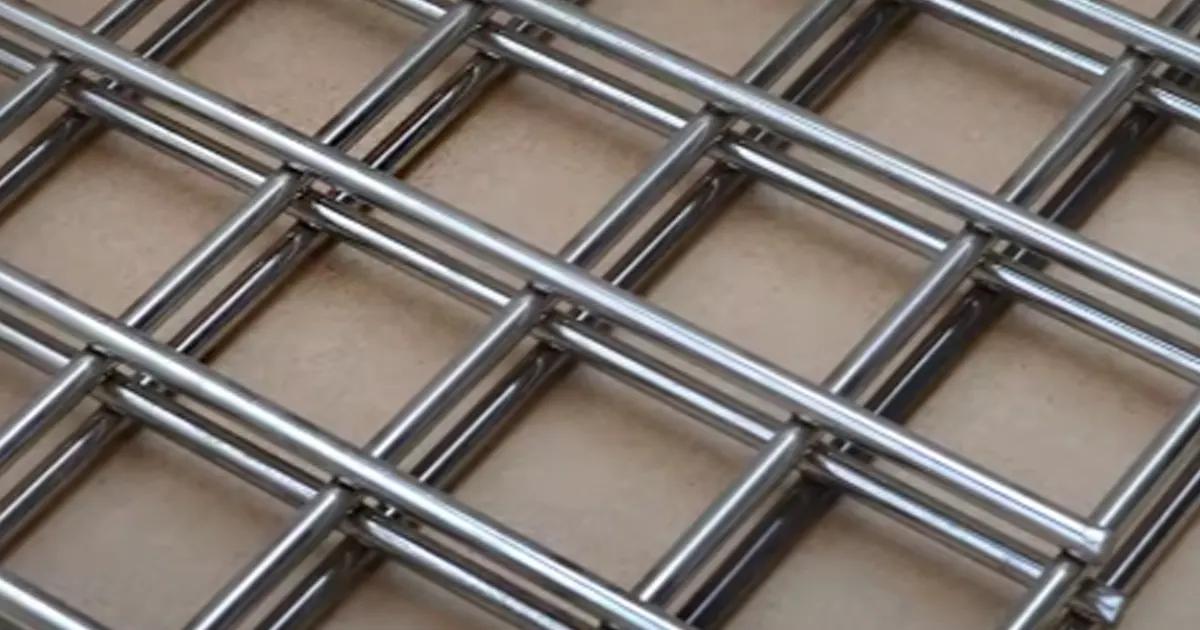

Welded Mesh

Welded mesh is made by joining wires together at every crossing. This makes it very strong and stiff. You see welded mesh in building sites, fences, and concrete work. It can handle a lot of weight and lasts for years.

Look at this table to see what makes welded mesh special:

| Characteristic | Description |

|---|---|

| Strength | High strength-to-weight ratio for security fencing and barriers |

| Durability | Stands up to weather and heavy loads |

| Versatility | Fits many uses in construction, agriculture, and security |

| Easy Installation | Simple to set up for homes, businesses, and factories |

| Concrete Reinforcement | Helps concrete stay strong and crack-free |

You can trust welded mesh when you need something that will not bend or break. It is easy to put in place and works for many things.

When you choose a type of metal mesh, think about what your project needs. Perforated mesh gives style and strength. Expanded mesh is tough and safe. Welded mesh is strong and lasts a long time. Each type helps you solve problems and makes your work easier.

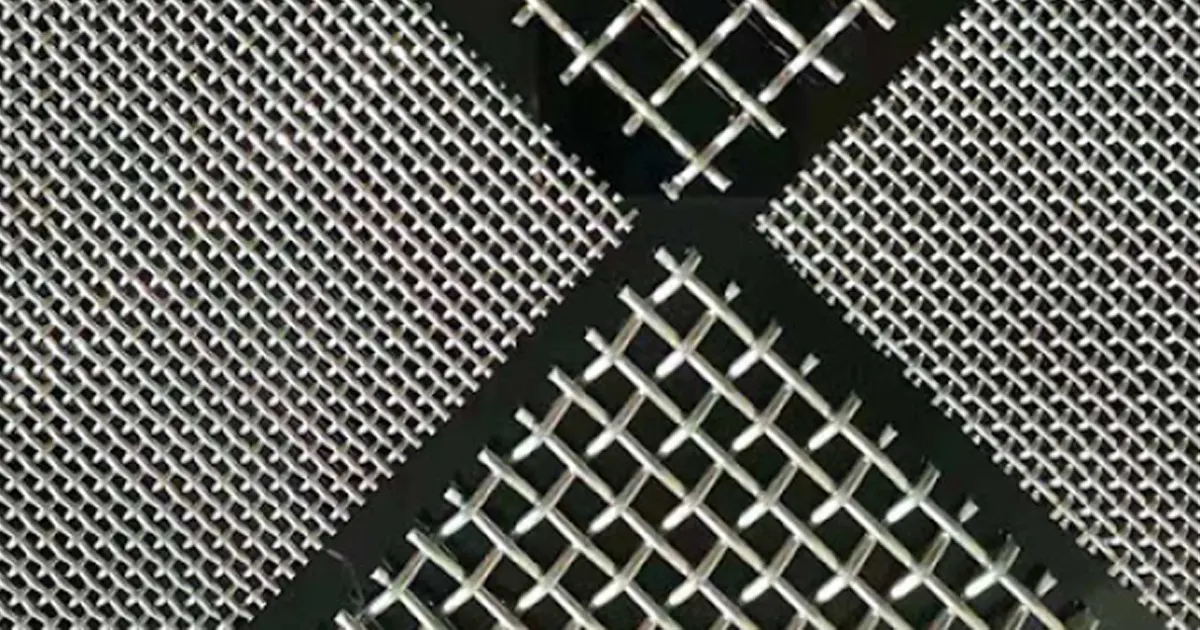

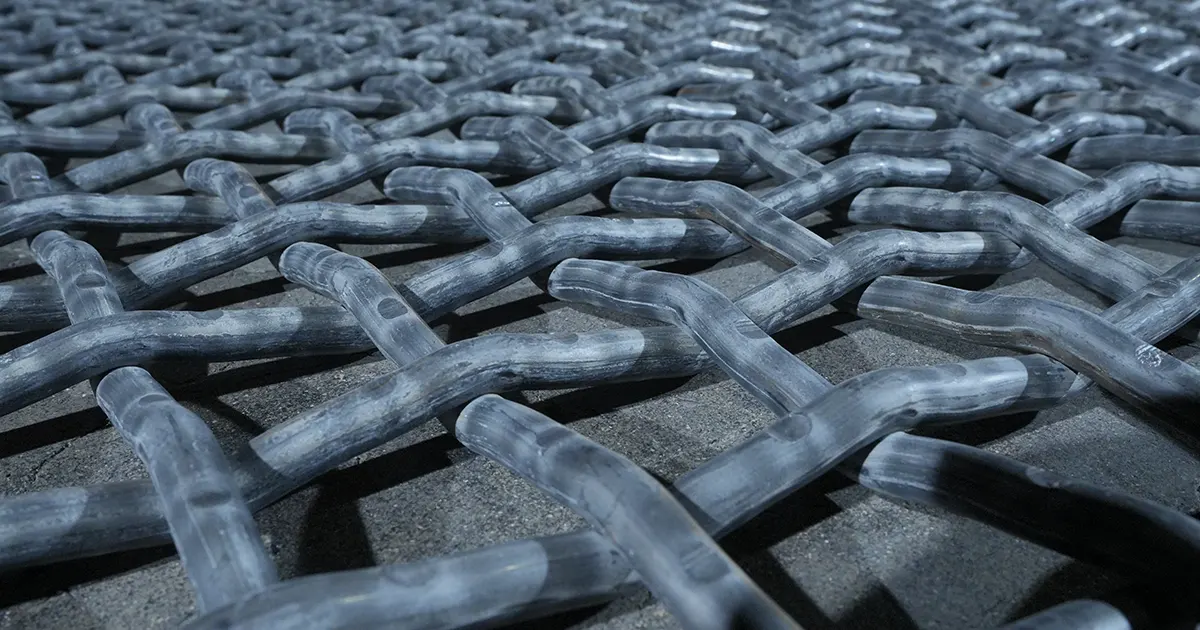

Woven Wire Mesh

If you need to filter or separate things, woven wire mesh is a good choice. You see it in places like mining, food factories, and recycling plants. This mesh is made by weaving wires together. The wires go over and under each other. This makes the mesh strong and bendy. You can pick how thick the wires are. You can also choose the size of the holes for your job.

Woven wire mesh is both strong and flexible. You can bend it to fit around curves. It also fits into small spaces. If you need a special shape, this mesh can change to fit. It works well and lasts a long time, even in hard places.

Did you know? Woven wire mesh can handle heat and chemicals. It keeps working when other materials stop working.

You might ask how woven wire mesh helps with filtering and separating. Look at this table to see what it does best:

| Feature | Benefit |

|---|---|

| Precise contaminant retention | It filters well without blocking the flow. |

| High temperature and chemical resistance | You can use it in tough places and it stays strong. |

| Customizable specifications | You can pick the hole size and material you need. |

| Exceptional durability | It works well under pressure and during cleaning. |

| Higher throughput | You do less maintenance and get more work done. |

You can use woven wire mesh to sort, sift, or protect machines. It is used in conveyor belts, screens, and guards. You also see it in self-cleaning screens and polyurethane screens. The size of the mesh and holes is important for how well it works.

If you need to separate tiny pieces or filter liquids, woven wire mesh gives you control. You can pick the right mesh material and strength for your job. You get a mesh that fits your needs and lasts a long time.

Here are some reasons to pick woven wire mesh:

- You want mesh that bends but stays strong.

- You need to filter liquids or powders very well.

- You work where there is heat, chemicals, or heavy use.

- You want to change the mesh size or shape for your tools.

Woven wire mesh is one of the most useful screen mesh types. You can use it for special designs or regular jobs. When you look at all the types, woven wire mesh gives you many choices for strength, bending, and how well it works.

Metal Mesh Materials and Geometric Parameters

When you use metal mesh, you should know what it is made of. The shape of the mesh also matters for your project. Picking the right metal mesh materials helps you get good results. You need to understand the geometric parameters too. Let’s look at what you should check.

Common Materials

There are many metal mesh materials you can pick. Each material has its own good points. Some work well in hard places. Others are light or easy to bend.

Carbon Steel

Carbon steel is used a lot for metal mesh. It has high tensile strength and impact resistance. This means the mesh can hold heavy things and take rough use. Carbon steel does not fight rust well. You may need to coat it or use it inside. If you want strong mesh that lasts, carbon steel is a good choice.

Aluminum Alloy

Aluminum alloy is another popular metal mesh material. It is light and easy to carry. You can bend it without much trouble. Aluminum does not rust as fast as plain steel. You see aluminum mesh where weight is important, like in cars or planes. If you need mesh that is not heavy, aluminum alloy is smart.

Here’s a table that shows how metal mesh materials are different:

| Material Type | Mechanical Properties |

|---|---|

| Plain Carbon Steel | High tensile strength, high impact resistance, low wear and corrosion resistance. |

| Stainless Steel | Excellent corrosion resistance, high-temperature resistance. |

| 304 Type | Corrosion resistant, withstands outdoor exposure, oxidation resistance at 1400 degrees. |

| 316 Type | Enhanced corrosion resistance to salts and acids, increased pitting resistance. |

| 410 Type | Heat treatment up to 760 degrees, corrosion resistance, heat resistance, anti-oxidation property. |

| 430 Type | Resistant to chemical attack and high temperatures, antioxidant at 870 degrees. |

| Duplex Stainless Steels | Good resistance to chloride pitting and crevice corrosion, varying corrosion resistance properties. |

Tip: Always match your metal mesh materials to the job. If you need more corrosion resistance, stainless steel is a better choice than carbon steel.

Geometric Parameters

The shape and size of metal mesh are important. You should think about weight, how exact the size is, and the size of the holes. These things help you get the right mesh for your project.

Weight

Weight changes how you put in and use metal mesh. Lighter mesh like aluminum is easier to set up. Heavy mesh like carbon steel is stronger but harder to move. You should balance weight and strength for the best results.

Dimensional Accuracy

Dimensional accuracy means your mesh fits just right. If you need high precision, check the thickness, width, and length. Good measurements stop gaps or overlaps. You get better safety and performance when your mesh fits well.

Aperture Size

Aperture size is the size of the holes in your mesh. Small holes help filter tiny things. Big holes let more air or liquid go through. The right aperture size helps you control flow and separation. In factories, fine mesh with small holes gives more surface area and helps catalytic work. But, it also makes it harder to push fluids, so you need more energy. You must balance precision and energy use for the best results.

Note: If you want more precision, choose a mesh with smaller apertures. But remember, this can make your system work harder to push fluids through.

When you pick metal mesh materials and set geometric parameters, you control how your mesh works. You get the precision you need for your job, whether you want strength, flexibility, or exact filtering. Always check weight, dimensional accuracy, and aperture size to make sure your metal mesh fits your needs.

Key Principles of Metal Mesh Design

Material Selection

When you start with metal mesh design, you need to pick the right material. This choice affects how your mesh works and how long it lasts. You might use woven wire mesh, polyurethane, or stainless steel. Each one has its own strengths.

- Stainless steel works well in places with lots of moisture or chemicals. It resists rust and keeps its quality over time.

- Polyurethane screens are tough and flexible. They handle heavy use and resist wear, so you get longer life.

- Woven wire mesh gives you both strength and flexibility. You can use it for jobs that need bending or shaping.

If you work in harsh environments, you should look for materials that fight corrosion and have high tensile strength. Here are some things to check:

- Corrosion resistance keeps your mesh strong in wet or salty places.

- Tensile strength helps your mesh hold heavy loads.

- Weight matters for easy handling and installation.

- Cost-effectiveness lets you balance quality with your budget.

You want your metal mesh to last and perform well. Good material selection means you get better quality and fewer problems down the road.

Tip: Always match your mesh material to your job. If you need more protection from rust, stainless steel is a smart pick.

Mesh Size & Aperture

Mesh size and aperture are important design considerations in metal mesh design. Mesh size tells you how many openings are in one square inch. Aperture size is the size of each opening. These two things decide what particles can pass through your mesh.

If you use a screen with a higher mesh size, you get smaller openings. This means only tiny particles can go through. For example, a 36 mesh screen has 36 openings per square inch, while a 150 mesh screen has 150. You need to match your mesh size to the material you want to separate.

Here’s a table that shows how aperture size affects feed rate and efficiency:

| Aperture Size (mm) | Optimal Feed Rate (kg·s–1·m–2) | Screening Efficiency Trend |

|---|---|---|

| 7 | 5.25 | Increases then decreases |

| 8 | 5.5 | Increases then decreases |

If you pick a mesh with larger openings, you let bigger particles pass. Smaller openings keep finer materials. You should always match your mesh to the particle size you need to separate.

- The right mesh size and aperture help you get better throughput and efficiency.

- You can control how much material passes through and how well you separate it.

- Good mesh size and aperture mean you get higher quality results.

Note: If you want to separate fine particles, choose a mesh with smaller apertures. But remember, this can slow down your process.

Strength & Durability

Strength and durability are key principles of metal mesh design. You want your mesh to stand up to heavy use and last a long time. Woven wire mesh gives you both strength and flexibility. You can bend it without breaking, so it works for many jobs.

Polyurethane screens are known for their durability. They resist wear and tear, so you get more life from your mesh. If you need mesh for tough jobs, polyurethane is a good choice.

To make sure your mesh has the right strength and durability, you can test it in different ways:

- Tensile testing checks how much force your mesh can handle before it breaks.

- Corrosion resistance tests show how well your mesh stands up to salty or acidic conditions.

- Flexural strength assessments measure how much your mesh can bend before it yields.

- UV resistance testing makes sure your mesh does not break down in sunlight.

- Compliance with safety standards keeps your mesh free from harmful substances.

You want your metal mesh to keep its quality over time. Strong mesh means fewer repairs and less downtime. Durable mesh gives you better performance and saves you money.

Tip: Always check the strength and durability of your mesh before you use it. This helps you avoid problems and get the best quality for your project.

Customization

You may ask how metal mesh design can match your needs. Customization lets you fix problems that regular mesh cannot. You can pick the size, shape, and features you want. This gives you more control over how the mesh works and lasts.

Here are some ways to customize metal mesh:

- Pick special sizes for machines or tight spaces.

- Add coatings to stop rust, chemicals, or bad weather.

- Change the wire to make it stronger or more bendy.

- Adjust mesh density to change airflow or keep things safe.

- Set exact measurements so the mesh fits just right.

Here is a table that shows how each customization helps you:

| Customization Aspect | Benefit |

|---|---|

| Custom Sizes | Fits special sizes in factories or other places |

| Special Coatings | Makes mesh last longer and stops damage from weather |

| Unique Design Specifications | Meets special needs for how it looks or works |

| Wire Composition | Changes how strong or flexible the mesh is |

| Mesh Density | Helps control air or keeps things safe |

| Measurements | Makes sure the mesh fits your setup perfectly |

You can use custom mesh in mining, building, recycling, or food plants. For example, you may need woven wire mesh with small holes to filter tiny pieces. You might want polyurethane screens that last longer for hard jobs. If you need self-cleaning screens, you can pick the right mesh size and coating to make cleaning easier.

Tip: Custom mesh saves you time and money. It lasts longer and works better for your job.

When you talk to a supplier, tell them what you need and what problems you have. They can help you choose the best mesh material, strength, and design. You get a mesh that fits your work and helps you do better.

Customization makes screen design more flexible. You can fix problems, make things safer, and get better results. No matter what shape, coating, or mesh type you need, you can get a product that works for you.

Benefits and Applications of Metal Mesh

Mining

You see metal mesh everywhere in mining. It keeps workers safe and helps you get the job done faster. Heavy-duty welded wire mesh works well for roof support in underground mines. You install it during bolting cycles to hold loose rocks in place. This makes the mine safer for everyone. You can pick from many metals, sizes, and weaves. Metal mesh stands up to freezing cold and extreme heat. It does not break down when things get rough.

You want something that lasts. Metal mesh resists abrasion, corrosion, and rust. Galvanized hardware cloth is a good choice for diamond and mineral extraction. It holds up in harsh, abrasive environments. You can use it for screening, filtering, and even as a barrier. The versatility of metal mesh means you can use it in many mining jobs.

- Available in many metals and sizes

- Strong and long-lasting

- Works in hot or cold places

- Resists rust and wear

- Fits many mining tasks

Tip: When you need safety and strength, choose the right mesh size and material for your mine.

Construction

You use metal mesh in construction for safety and support. It helps you build strong structures and keeps sites secure. You see it in fences, bridges, and scaffolding. Metal mesh makes sure only the right people get in. It also keeps buildings stable.

Here’s a quick look at how you use metal mesh in construction:

| Application | Benefit |

|---|---|

| Security Fencing | Stops trespassers and stands up to force |

| Infrastructure Reinforcement | Makes bridges and scaffolds safer and stronger |

| Road Construction | Holds up retaining walls and embankments for better stability |

You can trust metal mesh to handle tough jobs. It gives you peace of mind on busy sites. You get both safety and durability.

Recycling

You need to sort materials fast in recycling plants. Metal mesh screens help you separate waste from valuable items. The mesh size matters a lot. Smaller openings let you control what passes through. This means you can sort materials by size with high accuracy.

Perforated plate screens give you strength and are easy to clean. Mesh screens are simple to replace, but you may need to clean them more often. The right mesh size and opening area make your sorting process more efficient.

- Mesh size controls what gets through

- Finer mesh gives you better sorting

- The right opening area boosts efficiency

The principle of metal mesh design helps you pick the best screen for your recycling line. You get better results and less downtime.

Note: Always match your mesh type to the materials you need to separate. This keeps your plant running smoothly.

Food Processing

You see metal mesh everywhere in food processing plants. It helps you keep food safe and clean. Stainless steel mesh stands out because it does not rust and is easy to clean. You can use it for many jobs, like moving food, drying, or filtering.

Stainless steel mesh is used in food packaging to create durable, air-tight containers, ensuring hygiene and preventing spoilage. Its antimicrobial properties and ability to withstand extreme temperatures make it ideal for maintaining food quality during storage and transport.

You want your food to stay fresh and free from germs. Metal mesh helps you do that. It does not let bacteria grow because it does not rust. You can wash it with hot water or strong cleaners, and it will not break down. This keeps your food safe for everyone.

Here are some ways you use metal mesh in food processing:

- Conveyor belts move food from one place to another. They are strong, easy to clean, and do not rust.

- Drying racks let air move around food. This helps dry fruits, vegetables, or meat without letting germs grow.

- Filters and sieves catch unwanted bits. They keep your food pure and safe to eat.

You also want your equipment to last. Metal mesh does not wear out fast. It stands up to heat, cold, and lots of use. You can trust it to keep working day after day.

Stainless steel mesh is essential in maintaining sanitary conditions in food processing. Its corrosion-resistant properties prevent rust, which can harbor bacteria, thus ensuring that food products remain uncontaminated. The use of sanitary filters made from stainless steel helps remove solid particles, enhancing product purity and safety.

Let’s look at why you pick metal mesh for food processing:

- Durability: It lasts a long time, even with heavy use.

- Hygienic: You can clean it easily, so food stays safe.

- Safety: It is non-toxic and meets health rules.

You get all these benefits and applications of metal mesh when you choose the right type for your plant. You keep your food safe, your workers happy, and your business running smoothly.

Other Uses

You might think metal mesh only works in factories, but it does much more. You see it in buildings, stores, and even greenhouses.

- Architectural and decorative elements: Metal mesh panels make building walls and ceilings look modern. They also help with sound control.

- Ventilation and climate control: You use mesh in data centers and greenhouses. It lets air flow but keeps out bugs and dust.

- Retail and commercial security: Stores use mesh panels to show off products but stop theft. You can see what is inside, but it is still safe.

Metal mesh gives you style, safety, and function in many places. You can use it to solve problems and make spaces look great.

Architectural Steel Mesh

When you see architectural steel mesh, it is more than a building part. It mixes strength, style, and smart design. This metal mesh brings new ideas to modern buildings. You can use it outside or inside. Let’s find out why architectural steel mesh is popular today.

Dimensional Accuracy

Dimensional accuracy is very important for architectural steel mesh. You want every piece to fit just right. If the mesh is not exact, you might get gaps or overlaps. This can mess up how your project looks and works. Factories use special machines and skilled workers to make mesh panels. The panels match your design perfectly. This helps you build smooth walls, ceilings, and facades. You also save time when you put the mesh in place because it fits well.

Tip: Always check the size before you buy. Accurate mesh panels make your work easier and keep your building safe.

Visual Depth

Architectural steel mesh gives buildings a special look. You can make cool textures and depth that stand out. When sunlight shines on the mesh, you see neat light and shadow patterns. This makes spaces look bright and lively. You can use architectural steel mesh for walls, room dividers, or ceilings. It adds structure, light, and style to any room.

- You get cool texture and depth.

- The mesh makes buildings look interesting.

- You see great light and shadow effects.

- Spaces feel bigger and more friendly.

- The mesh helps with sound and fire safety.

- You support green building with your design.

Architectural steel mesh helps you follow new building styles. You can make modern buildings that look good and meet safety and green rules.

Weather Resistance

You want your building to last a long time. Architectural steel mesh stands up to bad weather. It does not rust or break down, even in tough places. The chromium in the steel makes a shield. This keeps the mesh strong when it gets wet, meets chemicals, or sits in the sun. You do not need to fix it much, so you save time and money.

Here’s a table that shows how weather resistance helps you:

| Attribute | How It Makes Mesh Last Longer |

|---|---|

| Corrosion Resistance | Stops damage from water and chemicals |

| UV Resistance | Keeps mesh safe from sunlight |

| Structural Integrity | Handles rain, snow, and wind |

| Maintenance Needs | Needs little care |

| Product Life | Can last up to 30 years if you take care of it |

Handwoven architectural steel mesh works well, even when the weather is bad. You can use it outside, on building fronts, or for security screens. The mesh keeps its shape and stays strong, so your building is safe and looks good for many years.

Note: If you want your building to last, pick architectural steel mesh that resists weather.

Architectural steel mesh gives you style, strength, and value that lasts. You can use it for many things, like inside rooms or outside walls. When you use good ways to make architectural steel mesh, you get panels that fit your needs and match new building styles.

Choosing the Right Metal Mesh

Assessing Needs

You want your project to work well, so you must know what you need. Every job is different. When you pick architectural steel mesh, think about your environment. Some jobs need mesh that can take high heat. Other jobs need mesh that does not rust or get damaged by chemicals. You should also check the size of things you want to filter or separate. If you work with thick or sticky stuff, viscosity matters too. Pressure drop is important if you want smooth flow.

Here’s a simple checklist to help you:

- Check how hot your process gets.

- Think about damage from chemicals or water.

- Look at how thick your materials are.

- Measure the size of things you want to filter.

- Think about how much pressure and flow you need.

- Check your budget and costs.

You also need to match the mesh material to your job. Titanium and special alloys help stop rust and damage. Mesh size and aperture size let you control what goes through. If you want your process to run well, pick the right architectural steel mesh from the start.

Throughput & Efficiency

Throughput and efficiency matter when you pick architectural steel mesh. The right mesh helps you make more and saves time. You want mesh that lets enough stuff pass but still filters out what you do not want. Mesh with the right aperture size gives you the best flow.

Let’s see how architectural steel mesh helps your process:

| Aspect | Impact on Manufacturing Efficiency |

|---|---|

| Heat Distribution | Uses energy better and makes more products |

| Process Control | Keeps temperature steady for better quality |

| Continuous Operation | Makes work faster |

| Customization | Lets you change speed and temperature |

If you use architectural steel mesh in your factory, you get more control. You can change mesh size and aperture to fit your needs. This helps you keep up with new trends and stay ahead.

Maintenance

You want your architectural steel mesh to last a long time. Good care keeps your mesh strong and safe. Clean your mesh every month with mild soap and warm water. This stops dust and dirt from building up. Check your mesh for cracks, dents, or damage. If you see problems, fix them fast. Do not use mesh that looks weak or broken.

Here are some easy maintenance tips:

- Write down when you clean and check your mesh.

- Teach your team how to handle and care for mesh.

- Use coatings if your mesh faces bad weather or chemicals.

- Do not use harsh cleaners or rough tools.

- Follow the weight and height rules when you install mesh.

If you do these things, your architectural steel mesh will stay strong. You will avoid big repairs and delays. Good setup and regular checks make your mesh safer and better.

Matching Mesh Type

Picking the right architectural steel mesh is very important. You want mesh that fits your project and your budget. The right mesh type helps your project work better and saves money. First, think about what you want your mesh to do. Do you need it for a building wall, a security screen, or just for decoration? Each job needs a different kind of mesh. Some mesh is strong, while others look nice or let air move through.

Here are some questions to help you pick the best mesh:

- What will your architectural steel mesh be used for?

- Do you need it to be strong or just look good?

- Will it be outside in bad weather or near chemicals?

- Do you want it to be easy to put in place?

- How much money can you spend on this project?

When you answer these questions, you can choose the right mesh. For outdoor jobs, pick mesh that does not rust. For inside jobs, you might want mesh with cool patterns. Matching mesh type helps in many jobs. In product design, the right mesh lets you test things faster and saves money. In medicine, mesh helps make implants that fit better. Oil and gas companies use mesh to study rocks and get more oil. Scientists use mesh to study big systems and save time.

Tip: Ask your mesh supplier for help early. They know which mesh works best and can help you save money.

Think about how much the mesh will cost over time. Sometimes, expensive mesh lasts longer and needs fewer repairs. Some mesh is light and easy to move, so you save time and work. Here is a table to help you compare mesh types:

| Mesh Type | Best For | Ease of Installation | Durability | Visual Appeal |

|---|---|---|---|---|

| Architectural Steel Mesh | Facades, security, decor | High | Excellent | Modern |

| Perforated Metal Mesh | Ventilation, screens | Medium | Good | Customizable |

| Expanded Metal Mesh | Walkways, safety platforms | Medium | High | Industrial |

| Welded Wire Mesh | Fencing, reinforcement | High | Excellent | Simple |

When you pick the right mesh, your project goes better. It is easier to install, lasts longer, and looks the way you want. Architectural steel mesh can be used for many things. You can use it for walls, security, or cool designs inside.

If you want your project to be special, take time to pick the best mesh. You will get better results, spend less money, and finish your work faster. Your building will look nice and stay strong for many years.

Conclusion

You know metal mesh design uses smart choices. Mesh size, material, and durability are important. Picking the right mesh helps things work better and keeps people safe. Dimensional accuracy means your mesh fits well and does its job. Here are some main ideas:

| Design Principle | Key Feature | Benefit |

|---|---|---|

| Selective Exclusion | 2mm Pore Size | Keeps what you want, filters out the rest |

| Structural Integrity | Rigid Metal Mesh | Stays strong under stress |

If you want a mesh that matches your needs, ANPENG is a good choice. They have woven wire mesh, self-cleaning screens, and polyurethane screens. You can get custom designs and good quality from them.

FAQ

How do you choose the right mesh size for mining?

First, check the size of the particles you want to separate. If you use a smaller mesh size, you can screen finer materials. In mining, pick a mesh size that matches your ore or mineral. This helps you get better results and more material through the screen.

What are the benefits of polyurethane screens in high-wear environments?

Polyurethane screens last longer than metal ones. They resist damage from rubbing and can hold heavy loads. You spend less time fixing them and save money on repairs. These screens are good for hard jobs in mining and recycling.

When should you use woven wire mesh?

Use woven wire mesh when you need both strength and flexibility. It works well for filtering, sieving, and special mesh designs. Woven wire mesh can bend to fit curves and handle high heat.

What makes self-cleaning screens useful in industrial screen design?

Self-cleaning screens help stop clogging. You do not have to clean them as often. They keep working well and help your plant run smoothly. These screens make your work faster and easier.

How does aperture size affect screening efficiency?

Aperture size decides what can go through the mesh. Bigger apertures let larger pieces pass. Smaller apertures keep finer materials in. Pick the right aperture size for your job to get the best results.

Can you customize metal mesh design for special applications?

Yes, you can change mesh materials, strength, and aperture size. Custom mesh fits your machines and solves special problems. You get better results and screens that last longer.

What are the main applications for metal mesh in industry?

You see metal mesh used in mining, construction, recycling, and food plants. It helps with filtering, separating, supporting structures, and keeping places safe. Metal mesh design makes jobs last longer and work better.