Mining Screen Mesh

Anpeng manufactures heavy-duty mining screen mesh for vibrating screens used in mining and mineral processing. Our woven wire screen media is designed for reliable separation, consistent sizing, and stable performance under continuous vibration. Whether you need mesh for scalping, sizing, or final classification, we produce screen panels with custom apertures, wire diameters, panel dimensions, and edge finishes to fit your screen deck.

As a direct manufacturer, we help you reduce downtime and improve screening efficiency by matching the right mesh specification to your ore type, moisture condition, abrasion level, and mounting system.

What Is Mining Screen Mesh?

Mining screen mesh (also called mining screening mesh or mining screen media) is the screening surface installed on vibrating screens to separate ore and aggregates into different size ranges. It’s used across mining operations to remove oversize material, split feed into multiple grades, and keep final product sizing consistent. The best mesh selection depends on your target cut size, whether the material is dry or wet/sticky, how abrasive and impact-heavy the feed is, and how your screen deck is mounted or tensioned.

Mining Screen Mesh Options We Manufacture

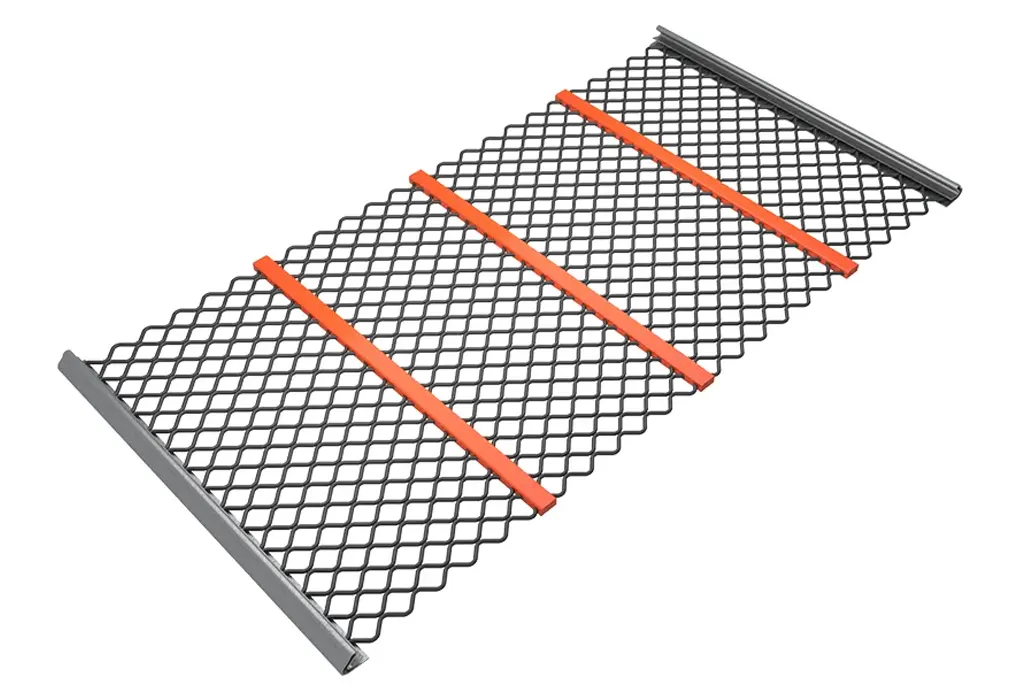

Below are the most common screening media options. Choose by feed condition, target cut size, impact level, and mounting system.

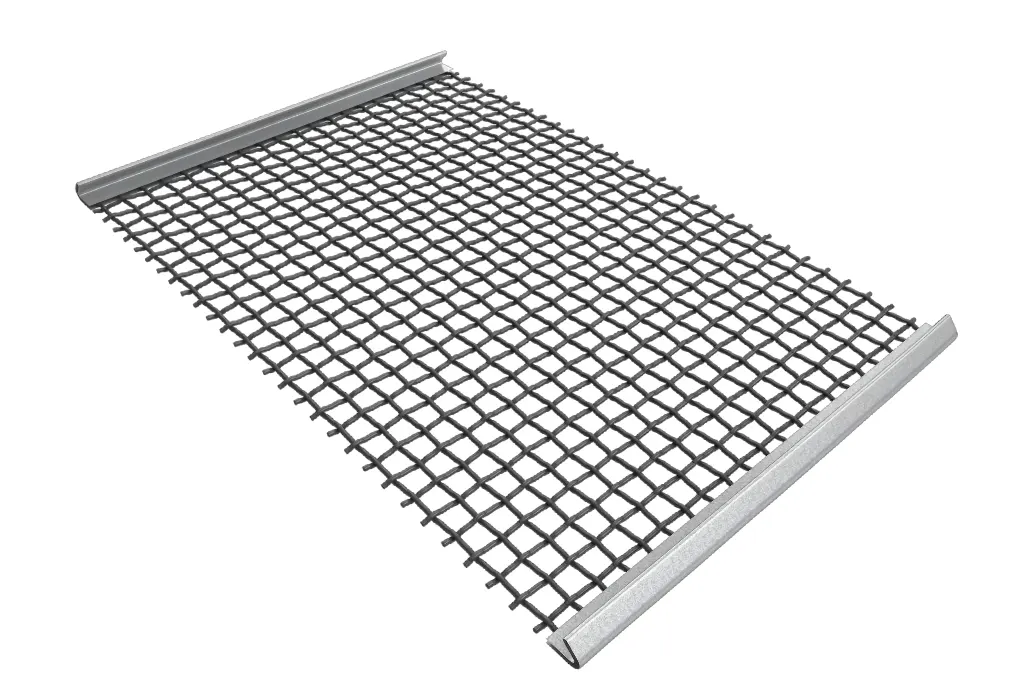

Woven Wire Mining Screen Mesh

Woven wire is the most widely used screen media for mining vibrating screens because it offers high open area and efficient screening. We produce crimped woven panels with strong structure to maintain stable openings over long runs.

Best for: general ore screening, abrasive feed, high-capacity sizing.

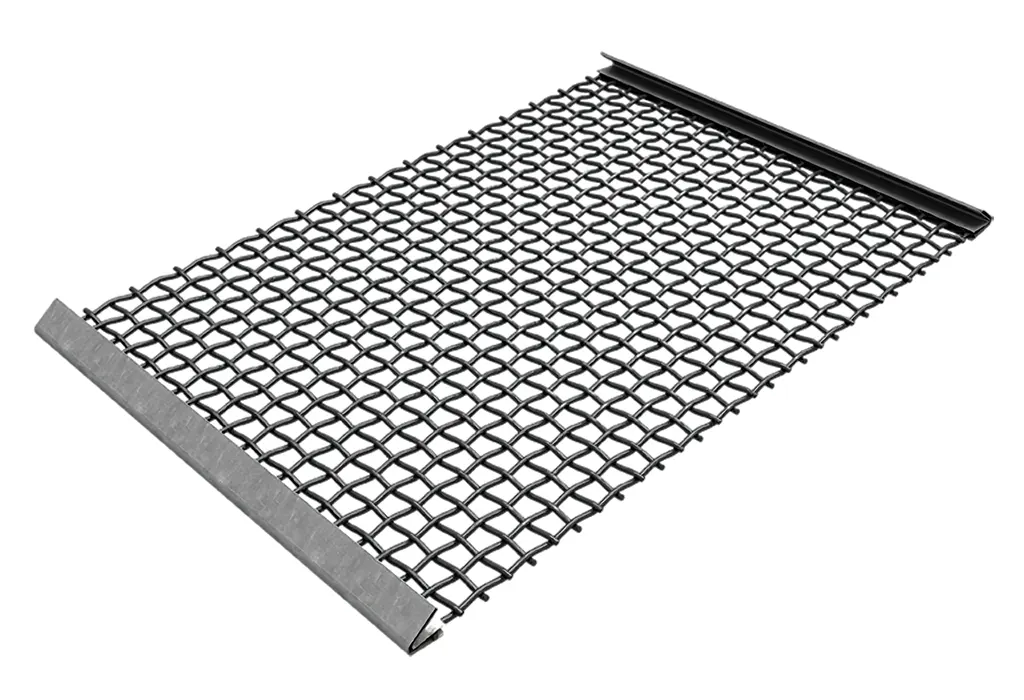

Self-Cleaning Mining Mesh

If your material contains moisture, clay, or sticky fines, standard mesh can blind or peg. Anti-clogging designs are made to reduce buildup and help maintain throughput.

Best for: wet or clay-heavy feed, materials that frequently blind standard mesh.

Key Benefits for Mining Operations

Stable cut size: consistent apertures help keep product sizing under control

High screening efficiency: optimized open area supports throughput and capacity

Longer service life: choose material grade and wire diameter based on abrasion/impact

Better uptime: anti-clogging options help reduce blinding and manual cleaning

Deck-fit customization: panel size and edge finishing matched to your mounting system

Product Specifications

| Specification | Details |

|---|---|

| Product Name | Mining Screen Mesh (Woven Wire Screen Media for Vibrating Screens) |

| Manufacturer | Anpeng (Direct Manufacturer) |

| Screen Media Type | Crimped Woven Wire Screen Mesh; Anti-Clogging / Self-Cleaning Mesh (optional) |

| Material Options | High-Carbon Steel, Spring Steel (65Mn), Stainless Steel 304/316 (optional) |

| Weave / Crimp Type | Pre-crimp, Intermediate Crimp, Lock Crimp (selected based on aperture & duty) |

| Opening Size (Aperture) | 2–120 mm (custom available) |

| Wire Diameter | 1.0–14.0 mm (custom available) |

| Open Area | Optimized by aperture & wire diameter to balance throughput and wear life |

| Panel Size | Custom per screen deck layout (panel or full-sheet options) |

| Edge Finish | Plain edges, Hooked edges, Reinforced edges (match your mounting/tensioning system) |

| Mounting / Tensioning | Clamp bar tensioning; bolt-down or modular fixing (as required) |

| Surface Finish | Plain / Oiled (rust protection) / Galvanized (optional) / Coated (optional) |

| Recommended Duty | Scalping, sizing, and classification on mining vibrating screens (abrasion & impact duty) |

| Typical Materials | Iron ore, copper ore, gold ore, limestone, granite, basalt, coal, and other mineral aggregates |

| Customization | Aperture, wire diameter, weave type, panel size, edge finishing, material grade, and packing available upon request |

| Quotation Info Needed | Opening (mm), wire diameter (mm), panel size (L×W), edge type, quantity, ore type, dry/wet condition |

| Packing | Bundles or export pallets with protective wrapping; labeled by specification & order ID |

How to Choose the Right Mining Screen Mesh

Start with the target cut size, then match the mesh to your operating conditions. If you’re screening abrasive ore or high-impact feed, wire diameter and crimp structure usually matter as much as the opening size. If the material is wet, clay-heavy, or tends to stick, anti-clogging/self-cleaning options can make a big difference in keeping the deck open and reducing cleaning downtime. Finally, confirm the deck measurements and mounting style—panel size and edge finishing (hooked/plain/reinforced) should match your tensioning system so the mesh stays stable under vibration.

Fast selection tip: Send your screen deck drawing or your current mesh sample measurements. We can recommend aperture, wire diameter, crimp type, and edge finishing quickly.

Why Choose Anpeng as Your Mining Screen Mesh Manufacturer

We manufacture screen mesh panels with controlled material selection, weaving, and finishing, so specs remain consistent from batch to batch.

Strong crimp structure helps maintain stable openings and reduces deformation during long runs.

We produce custom panel sizes and edge finishes to match your screen deck, so installation is faster and tensioning is more reliable.

FAQs

What is mining screen mesh used for?

Mining screen mesh is used on vibrating screens to separate ore and mineral aggregates into different size fractions. Depending on where it is installed in the circuit, it can remove oversize material for equipment protection, split feed into multiple grades for processing or stockpiling, or control final sizing so product specs stay consistent.

How do I choose the right opening (aperture) for my ore?

Aperture is mainly selected based on your target cut size, but it should also consider material shape, moisture, and fines content. Wet or sticky feed can behave differently from dry material, so the “best” aperture is often a balance between sizing accuracy and stable throughput. If you share your target sizes and feed condition, we can recommend a suitable opening range.

How do I select wire diameter for longer wear life?

Wire diameter is usually chosen based on abrasion level and impact load. Thicker wire generally improves wear resistance and strength, which can be important for harsh mining duties, while thinner wire can increase open area and throughput. We help you pick a practical balance based on ore type, tonnage, and expected service life.

What’s the difference between woven wire mesh and self-cleaning mesh?

Woven wire mesh is a standard high-efficiency option for many mining applications, especially dry screening. Self-cleaning (anti-clogging) designs are better when moisture, clay, or sticky fines cause blinding or pegging. If your deck frequently plugs and needs cleaning, self-cleaning options can keep capacity more stable.

How can I reduce blinding and pegging on my screen deck?

Blinding and pegging often come from wet fines, clay, or particle shape. Using anti-clogging mesh is one of the most effective ways to reduce plugging. It also helps to confirm correct deck tensioning and choose a mesh design that matches your vibration parameters and feed condition.

Can you make hooked edges and custom panel sizes?

Yes. We manufacture custom panel sizes and edge finishing (hooked/plain/reinforced) to match your screen deck. If you provide a drawing, screen model, or your current panel measurements, we can produce a direct-fit replacement.

What information do you need for a fast quotation?

For an accurate quote, please provide opening size, wire diameter, panel size (L×W), edge type, quantity, and basic operating conditions (ore type + dry/wet/sticky). If you don’t have exact specs, a photo of the current panel and measurements also helps.