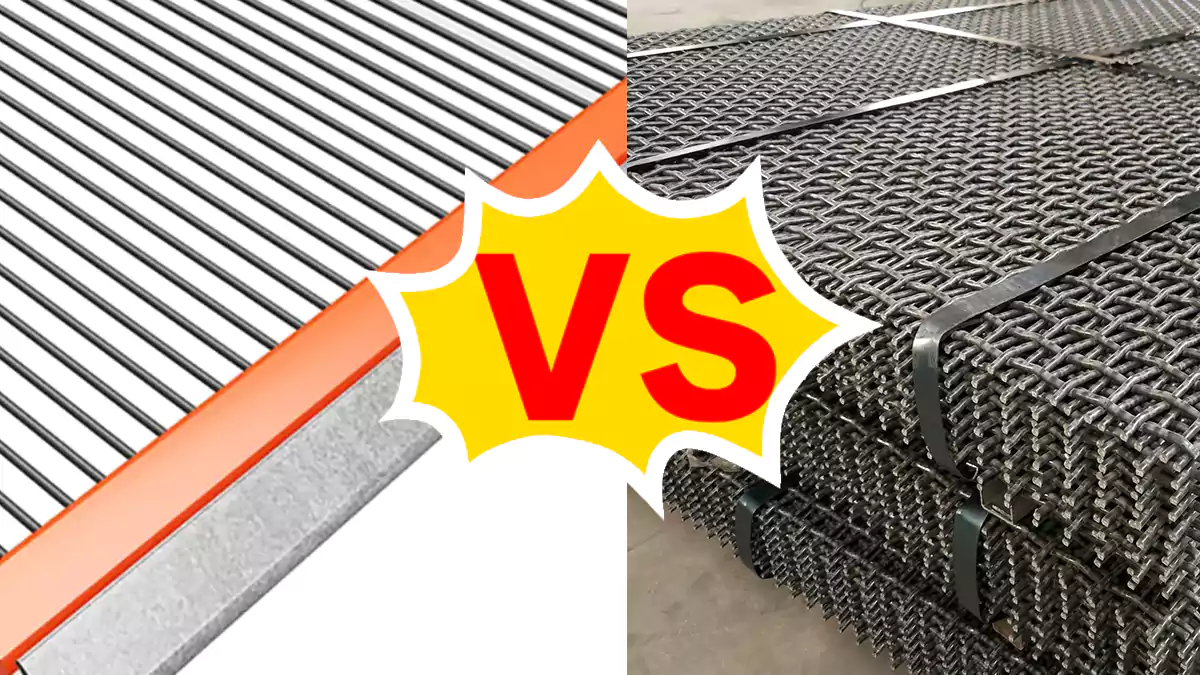

If you want to screen small materials effectively, piano wire screens are usually the best choice. However, if you need something robust for tough jobs, woven wire screens are a better option. When comparing piano wire screens vs woven wire screens, you’ll notice differences in open area, flexibility, and their ability to prevent clogging. It’s important to consider their performance, durability, cost, and common issues before making a selection.

- Piano wire screens allow more material to pass through.

- Woven wire screens maintain their strength longer in demanding applications.

Key Takeaways

- Piano wire screens work well with fine, sticky, or wet materials because they bend easily and clean themselves.

- Woven wire screens are stronger and last longer, so they are good for hard jobs and rough materials.

- Piano wire screens have more open space, so more material can go through fast, which helps work get done quicker.

- Woven wire screens need less fixing and last longer, so you do not have to replace them often.

- Pick piano wire screens for fast sorting and woven wire screens for tough jobs.

- Think about what kind of material you have and how big it is when you pick a screen to make sure it works best.

- Checking the screens often can help them last longer and make everything work better.

- Piano wire screens may cost more at first, but they can save money later because you do not have to stop work as much.

Piano Wire Screens vs Woven Wire Screens

Main Differences

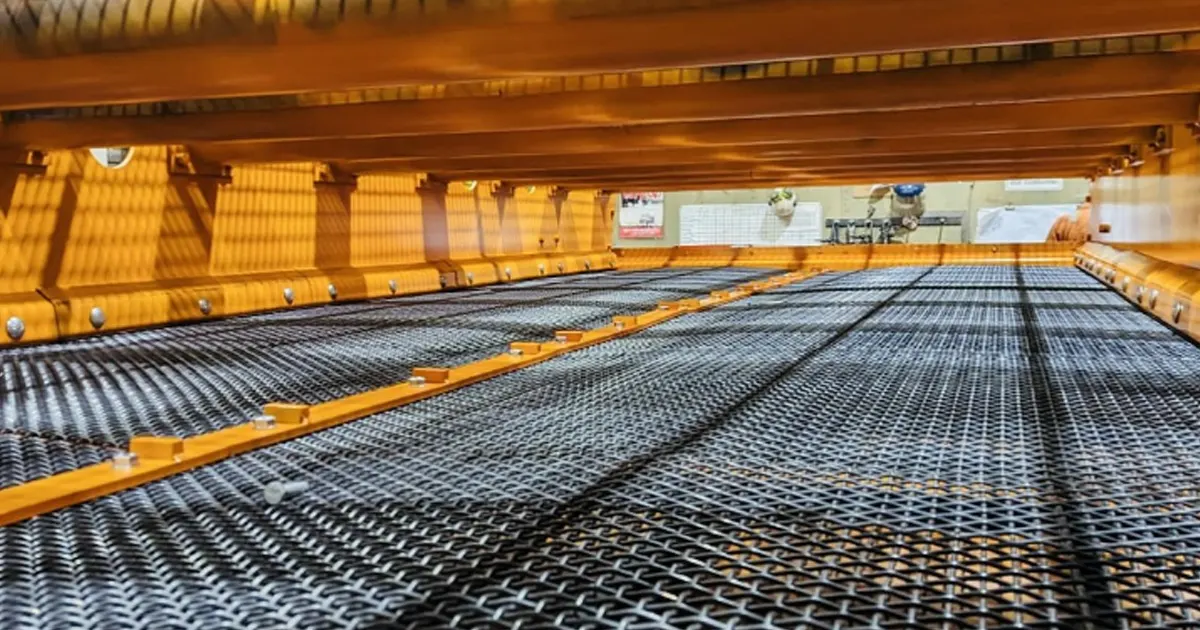

You may ask what makes piano wire screens different from woven wire screens. Their structure and how you use them are not the same. Piano wire screens have long wires held in sliding bars. This gives more open space and makes them flexible. Woven wire screens use wires woven together in many ways. These screens are stronger and last longer.

Here’s a table that shows the differences:

| Feature | Piano Wire Screens | Woven Wire Screens |

|---|---|---|

| Structure | Long wires in sliding bars, more open area | Woven wires, strong and durable |

| Application | Wet, sticky, or fine materials | Tough jobs, many types of materials |

| Customization | Easy to change wire size and spacing | Many weaving styles and edge types |

Both screen types can be changed to fit your needs. Piano wire screens let you change wire size and spacing easily. Woven wire screens have different edge types and weaving patterns. For tough jobs, woven wire screens last longer. For fine screening, piano wire screens work best.

Tip: Piano wire screens stop clogging with sticky or wet materials. Woven wire screens are better for heavy-duty jobs because they are stronger.

Open Area and Throughput

Open area and throughput are important when you compare these screens. Piano wire screens have more open space. This means you can get more work done faster. More open area lets more material go through.

- Piano wire screens can produce up to five times more than long-slot woven screens.

- Woven wire screens have less open area, but thicker wires last longer.

Here’s a table showing how each screen works in processing:

| Screen Type | Wear Life | Open Area | Trade-offs |

|---|---|---|---|

| Woven Wire | Moderate | Lower | Thicker wires last longer, less open area |

| Piano Wire | Shorter | Higher | More open area, faster throughput |

If you need fast screening, piano wire screens are best. If you want your screens to last longer, woven wire screens are better.

Material Suitability

Picking the right screen depends on the material you want to process. Piano wire screens and woven wire screens fit different jobs. Piano wire screens use strong spring wire, manganese steel wire, or stainless steel wire. You can use them for wet, sticky, dry, or rough materials. Woven wire screens use tough spring steel wires. They work for many wet and dry materials, but not sticky ones.

Here’s a table to help you choose:

| Screen Type | Materials Used | Suitable For |

|---|---|---|

| Piano Wire Screen | Strong spring wire, manganese steel wire, stainless steel wire | Wet, sticky, dry, rough materials |

| Woven Wire Screen | Tough spring steel wires | Many wet and dry materials, not sticky |

Piano wire screens do better in hard screening jobs. They clean themselves and stop clogging. Woven wire screens have trouble with sticky materials. Piano wire screens give better screening and keep layers even. Woven wire screens are less efficient in tough jobs.

Note: Piano wire screens are best for self-cleaning and fine screening. Woven wire screens are best for strength and tough jobs.

Piano wire screens and woven wire screens each have their own benefits. For precise screening and self-cleaning, pick piano wire screens. For strength and long-lasting screens, choose woven wire screens.

Performance Factors

Screening Efficiency

When you look at screening, you want to get the most material through your screen with the least trouble. This is where efficiency comes in. Piano wire screens give you high efficiency because they have more open space. More open area means more material can pass through quickly. You will notice that these screens work best when you need to separate fine or sticky materials. Woven wire screens offer good efficiency too, but they focus more on strength and lasting longer. If you want the best screen efficiency for fine screening, piano wire screens are the way to go.

Pegging and Blinding

Pegging and blinding can slow down your work and lower your efficiency. These problems happen when material gets stuck in the screen holes or covers them up. Let’s break down what causes these issues:

- Pegging happens when particles get stuck in the holes of the screen. This is common with materials that are almost the same size as the holes or have odd shapes, like long or flaky pieces.

- Blinding happens when small particles stick together and cover the screen. This often comes from moisture or static electricity.

Piano Wire Screens

You will find that piano wire screens handle pegging and blinding much better than woven wire screens. The flexible wires move as the machine vibrates. This movement helps shake off sticky or wet material. Because of this, you do not need to stop and clean the screen as often. If you work with sticky, wet, or fine materials, piano wire screens keep your screening running smoothly and help you avoid downtime.

Woven Wire Screens

Woven wire screens can have more trouble with pegging and blinding, especially with sticky or clumpy materials. The wires do not move as much, so particles can get stuck and block the holes. You may need to clean these screens more often to keep your efficiency up. If you use woven wire screens for tough jobs, you should check them often for blocked holes.

Material Flow

Material flow is how easily your material moves across the screen. Piano wire screens help material flow better because of their flexible wires and larger open area. This means less buildup and fewer stoppages. Woven wire screens give you steady flow for most jobs, but they can slow down if you get a lot of pegging or blinding. If you want smooth, fast material flow, piano wire screens are a smart choice.

Tip: If you want to boost your efficiency and keep your screening line moving, pick the screen that matches your material and job needs.

Durability and Wear

Lifespan

You want your screen to last as long as possible. Piano wire screens usually have a shorter lifespan. The thin wires can wear out faster, especially if you use them for rough materials. Woven wire screens stand up to heavy use. The thicker wires and strong weave help them resist damage. If you need a screen for tough jobs, woven wire screens give you more time before you need a replacement.

Here’s a quick comparison:

| Screen Type | Lifespan | Best Use Case |

|---|---|---|

| Piano Wire | Shorter | Fine, sticky, or wet materials |

| Woven Wire | Longer | Heavy-duty, abrasive jobs |

Note: If you want a screen that lasts longer, woven wire screens are the better choice for most demanding jobs.

Abrasion Resistance

Abrasion can ruin a screen fast. Piano wire screens handle light and sticky materials well, but rough or sharp materials can break the wires. Woven wire screens offer better abrasion resistance. The wires are thicker and the weave protects them from scratches and cuts. You can use woven wire screens for gravel, rocks, or other tough materials. Piano wire screens work best when you need high quality screening for fine materials, but they struggle with abrasive loads.

Here are some signs your screen needs better abrasion resistance:

- You see wires breaking or bending.

- Material cuts grooves into the screen.

- The screen loses its shape.

If you notice these problems, you might need to switch to a woven wire screen for better quality and longer life.

Maintenance

You want to spend less time fixing your screen and more time working. Piano wire screens need more frequent checks. The flexible wires can move and shake off material, but they also wear out faster. You may need to replace wires or adjust the bars often. Woven wire screens require less maintenance. The strong weave keeps the screen in shape and reduces the need for repairs.

Here’s a simple maintenance checklist:

- Inspect the screen for broken wires.

- Clean off stuck material.

- Check for loose edges or bars.

- Replace damaged parts quickly.

Tip: Regular maintenance keeps your screen working at high quality and prevents downtime.

If you want a screen that needs less attention, woven wire screens are easier to manage. Piano wire screens give you great quality for fine screening, but you must watch them closely.

Cost and Value

Initial Cost

When you look at the price tag, piano wire screens usually cost more than woven wire screens. You might wonder why. Piano wire screens use special wires and a design that lets each wire move on its own. This makes them more expensive to make. Woven wire screens have a simpler design and cost less up front. If you want to save money at the start, woven wire screens seem like a good deal.

Here’s a quick comparison:

| Screen Type | Initial Cost | Why? |

|---|---|---|

| Piano Wire | Higher | Special wires, self-cleaning design |

| Woven Wire | Lower | Simple weave, less material needed |

If you have a tight budget, you may pick woven wire screens first. But remember, the first price is not the only thing to think about.

Operating Cost

You need to think about more than just the price you pay at the start. Operating cost means how much you spend to keep your screen running. Piano wire screens can help you save money over time. Their self-cleaning wires keep the holes open, so you do not need to stop for cleaning as often. This means you get more capacity and less downtime. You spend less on labor and repairs.

Woven wire screens may cost less at first, but you might need to clean or replace them more often. If your material causes pegging or blinding, you will lose capacity and spend more time fixing problems. Over time, these small costs can add up.

Here are some things that affect operating cost:

- How often you need to clean the screen

- How many times you must replace worn-out parts

- How much downtime you have during screening

Long-Term Value

When you think about long-term value, you want a screen that gives you the best results for the money you spend. Piano wire screens stand out because of their self-cleaning design. Each wire vibrates on its own, which helps stop blinding and pegging. This keeps your screening line moving and gives you a longer wear life. Even though you pay more at the start, you may save money in the long run because you do not need to replace the screen as often.

Woven wire screens have a lower price and a high open area, but they may wear out faster. You might need to buy new screens more often, especially if you work with tough or sticky materials. If you want a screen that lasts and keeps your capacity high, piano wire screens can be worth the extra cost.

Tip: Think about how much work your screen will do and how often you want to replace it. Sometimes, paying more at the start means you save more later.

Choosing the Right Vibrating Screen

Application Scenarios

You need to choose the best vibrating screen for your work. Different screens are good for different jobs. Let’s see where piano wire screens and woven wire screens are used in mining. Look at this table for a quick summary:

| Application Scenario | Description |

|---|---|

| Coarse Ore Screening | Screens big pieces of ore. |

| Sizing Screens | Sorts materials by size to make work easier. |

| Material Classification | Separates mined materials to check quality. |

| Custom Solutions | Gives special options for unique mining needs. |

| Overall Wear Parts | Offers parts that help screens last longer and work better. |

Piano wire screens are used when you need to screen sticky or wet materials. Woven wire screens are used for tough jobs where strength is important. Both types are used in mining, aggregate, concrete, and recycling.

If you work in concrete recycling, picking the right screen can change how well your job goes. Here’s what you should know:

The screen you pick affects how much you recover, how well you separate materials, and how clean your recycled concrete is. Different screens, like dynamic disc screens, trommels, and vibratory screens, have special benefits for sorting mixed materials and making recycling better.

Regular screens, like trommels or star screens, can clog or wrap. Dynamic disc screens help stop these problems and let you change screen size easily for different materials.

Good screening helps you recover metals, sort by weight, sort by hand, and make less waste.

You should match your screen to your material and your goals. If you want fast separation and less downtime, piano wire screens are helpful. If you need strength and long life, woven wire screens are a good pick.

Selection Tips

You need to pick the right vibrating screen for your job. Here are some tips to help you:

- Type of Material and Particle Size

Check what you want to screen. Piano wire screens are best for fine, sticky, or wet materials. Woven wire screens are best for big, rough, or hard materials. - Screening Capacity and Efficiency

Think about how much material you need to screen. Make sure your screen can handle the amount and works well. - Screen Size and Deck Configuration

Choose the right size and setup for your needs. The right deck helps you get more from your screen. - Vibration Mechanism and Frequency

Pick a screen with the right vibration type and speed. This helps separate materials faster and keeps your work smooth.

You also need to think about your environment. Here are some things to remember:

- Wetness and clay can change which screen works best.

- Piano wire screens clean themselves and stop blinding, so you get more work done and your screens last longer.

- Woven wire screens cost less but can clog or peg in wet jobs.

To pick the right vibrating screen, start by looking at your material and your environment. Ask yourself these questions:

- What size and shape is the material?

- Is the material wet, sticky, or dry?

- How much material do you need to screen each hour?

- Do you want a screen that cleans itself or one that lasts longer?

Vibrating screens are used in many industries. Mining, aggregate, concrete, and recycling all need the right screen for the job. When you pick the right vibrating screen, you get better results, less downtime, and more value from your equipment.

Tip: Always check how your screen works and how much care it needs. The right vibrating screen can save you money and keep your work going strong.

Common Issues and Solutions

Pegging and Blinding Solutions

It can be frustrating when material sticks or blocks your screen. Pegging and blinding slow down your work and make things harder. There are many ways to fix these problems. Look at this table for some easy solutions:

| Solution | Description |

|---|---|

| Adjustments to screen energy | Adding energy and using flexible surfaces keeps fine particles from sticking. |

| Use of ball trays | Balls bounce on the screen and knock off stuck material. |

| Heated screen decks | Heating dries out moisture so fine material flows instead of sticking. |

| Increase stroke | More energy helps lift stuck particles out of holes. |

| Change shape of holes | Different hole shapes stop certain particles from getting stuck. |

| Different surface media | Rubber or polyurethane surfaces help reduce plugging and blinding. |

| Increase speed | Faster screen speed pushes material through and lowers blinding. |

| Adjust stroke | Changing stroke can lower the chance of blinding. |

| Use flexible screen media | Flexible media shakes off fine particles before they stick. |

If you need more help, self-cleaning screens made from polyurethane work well. They resist wear and shake off material easily, but cost more money. Woven wire screens are cheaper and let stuck material pass through, which helps stop pegging.

Wear Management

You want your screen to last a long time. Managing wear is important for tough jobs. Here are some good steps you can follow:

- Check installation to avoid changing hole size.

- Keep clearances for easy adjustments and checks.

- Sample lubricant to stop bearing failure.

- Lubricate as the manufacturer says.

- Stop buildup of dirt around moving parts.

- Make sure belts are tight to avoid slipping.

- Support screens right to prevent damage.

- Inspect cross-members and drive systems often.

- Cover housing tubes and decking to protect screens.

- Clean screens as the manufacturer recommends.

- Write down all maintenance for better planning.

A good maintenance plan can make your equipment last up to 50% longer. You will have fewer breakdowns, better screening, and lower costs over time.

Installation Tips

Installing your screen the right way matters a lot. Here are some tips to help you:

- Clean screen decks before starting to stop blinding.

- Check and adjust mesh tension so your screen works well.

- Lubricate bearings as recommended to keep parts moving.

- Check drive belts for wear every week.

- Check vibration amplitude and frequency every month.

- Inspect for cracks or fatigue every year.

If you follow these steps, your screen will work better and last longer. You will spend less time fixing problems and more time working. Good installation and regular checks keep your screening efficient and your equipment in great shape.

Conclusion

You have learned the main ways piano wire and woven wire screens are different. Piano wire screens are good when you want quick screening and less clogging. Woven wire screens are stronger and last longer for hard jobs. Here is a helpful guide:

| Screen Type | Application | Advantages |

|---|---|---|

| Piano Wire Screens | High-speed sifting in quarrying | Resilient, smooth surface, less aggregate trapping |

Think about what material you have and what job you need to do before choosing a screen. If you want strong screening media for mining, aggregate, or recycling, Anpeng is a screening media manufacturer that provides reliable piano wire screens and woven wire screens for demanding applications.

FAQ

What is the main difference between piano wire and woven wire screens?

You will notice that piano wire screens have flexible wires that move and help prevent clogging. Woven wire screens use a strong, fixed weave. You should pick based on your screening objectives and the type of material you handle.

How do I choose the right screen for my material?

You need to look at your material’s particle size distribution. If you work with fine or sticky materials, piano wire screens work best. For rough or heavy materials, woven wire screens last longer and handle tough jobs better.

Can I use both screen types for the same job?

You can use both, but it depends on your capacity requirements. Piano wire screens give you faster throughput for fine materials. Woven wire screens offer more strength for heavy loads. Always match your screen to your job needs.

How do these screens affect separation points?

You will see that piano wire screens give you sharper separation points for fine screening. Woven wire screens work better for larger sizes. Pick the screen that matches the size you want to separate.

Which screen type is easier to maintain?

You will find that woven wire screens need less maintenance because they are stronger. Piano wire screens need more checks since the wires can wear out faster. Regular cleaning and inspection help both types last longer.

What should I do if my screen keeps clogging?

You should try a piano wire screen if you have clogging problems. The flexible wires shake off stuck material. You can also adjust vibration or use self-cleaning screens to help keep your screen clear.

Are these screens good for wet materials?

You can use piano wire screens for wet or sticky materials. They clean themselves and keep material moving. Woven wire screens work for wet jobs too, but they may clog more often.