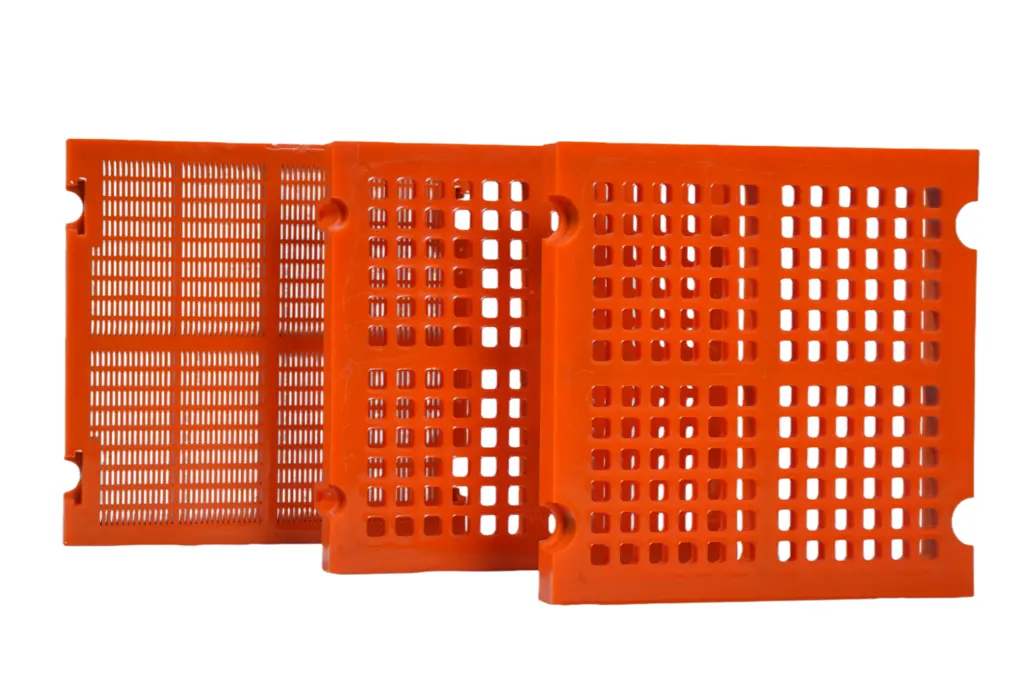

Polyurethane Screens

Polyurethane screens (also called PU screen panels or urethane panels) are wear-resistant screening media used on vibrating screens in mining, quarry, aggregate, and recycling plants. They’re a practical choice when you need longer wear life, stable apertures, and modular panels that are easier to replace than full wire decks.

ANPENG manufactures polyurethane screening media and supplies custom panels matched to your screen model, deck layout, and operating conditions.

What Are Polyurethane Screens?

Polyurethane screens are molded or cast panels made from polyurethane material, designed as screening surfaces for vibrating screens. Unlike woven wire cloth that relies on metal wires, PU panels use a resilient polymer structure that handles abrasion well and maintains a stable aperture shape over time.

In many abrasive circuits, polyurethane screens are selected to reduce frequent change-outs and improve uptime—especially in high-wear zones where wire cloth may wear or break quickly.

Where Polyurethane Screens Work Best

Polyurethane panels are commonly used in:

Abrasive materials: hard rock, ore, sharp aggregate, mineral processing

High wear zones: feed end and impact areas

Sizing and classification: when stable apertures help maintain consistent product gradation

Plants prioritizing lower noise: compared with metal screening surfaces

Operations that prefer modular maintenance: replace worn panels instead of the whole deck

If your main issue is severe blinding from very wet/sticky fines, you may also consider self-cleaning wire screens or flip flow mats. PU panels excel in wear resistance, but material behavior still matters.

Key Benefits

Excellent abrasion resistance for harsh screening duty

Long wear life in many abrasive applications

Stable apertures for consistent sizing and repeatable separation

Reduced noise compared with many metal screen media

Modular panel design for faster change-outs and less downtime

Good corrosion resistance for many wet processing environments (depending on your plant conditions)

Technical Specifications

| Specification | Details |

|---|---|

| Product Type | Polyurethane (PU) Screen Panels / Urethane Panels / PU Mesh Panels |

| Material | Polyurethane (PU) (compound customized by duty and wear requirements) |

| Aperture Shape | Square, Slotted (custom shapes available) |

| Aperture Range | 0.3–100 mm (custom available) |

| Panel Thickness | Custom by deck position and impact level (commonly 10–60 mm) |

| Open Area | Optimized per cut size and panel design (balanced for capacity vs wear life) |

| Hardness | Typically 75–95 Shore A (custom available) |

| Reinforcement | Optional steel frame / embedded steel bars (depending on panel design) |

| Fixing System | Pin & Sleeve, Bolt-Down, Rail/Clip, Modular Locking (match your screen deck) |

| Panel Size | Custom per deck layout (module sizes matched to your screen model) |

| Operating Temperature | -40°C to +80°C (higher temperature options available upon request) |

| Recommended Duty | Sizing & classification for abrasive materials; high-wear zones on vibrating screens |

| Customization | Aperture, thickness, hardness, fixing method, and panel dimensions available upon request |

FAQs

When should I switch from woven wire to polyurethane screens?

When abrasion is high and wire cloth wears out too quickly, PU panels often provide longer service life and easier modular replacement.

Are polyurethane screens good for wet screening?

They can be used in wet circuits, but heavy clay/fines may still cause blinding depending on aperture and setup. Slot designs and process support can help.

Square vs slotted apertures—how do I choose?

Square openings are common for general sizing. Slotted openings may improve flow and reduce pegging for certain particle shapes or conditions.

How do I confirm the fixing system?

Confirm your deck’s mounting style (pin & sleeve, bolt-down, rail/clip, etc.). Photos of the current deck and panels are helpful.

What information do you need for a quote?

Material type, moisture, target cut size, tph, screen model, deck layout, and current issues (wear, pegging, blinding, carryover).

How can I extend wear life at the feed end?

Use the correct impact-zone panel design, keep supports in good condition, ensure proper fastening, and monitor wear patterns early.