When you check polyurethane screens price, many things affect cost. Material cost, design, how it is made, and brand matter. How many you buy and extra fees also change the price. If the price of polyurethane raw materials goes up or down, your total cost can change fast. You should watch market trends to know what to expect.

If you want to save money in the long run, better quality polyurethane may give you more value over time.

Key Takeaways

- The price of polyurethane screens changes with material costs, design difficulty, and how they are made.

- Watch market trends for raw materials to guess price changes and plan your budget well.

- Buying better quality polyurethane screens can save money over time because they last longer and need less fixing.

- Ordering in bulk can give you big discounts, so always ask about prices for bigger orders to save more.

- Pick standard screen sizes for faster delivery and cheaper prices, but custom designs may be needed for special uses and will cost more.

- Check the reputation of brands and suppliers because well-known names usually give better quality and help, making sure you get a good product.

- Remember extra costs like shipping, taxes, and installation when planning your budget for polyurethane screens so you do not get surprised.

- Keeping up with regular care and getting professional installation can make your screens last longer, which lowers costs and makes them work better.

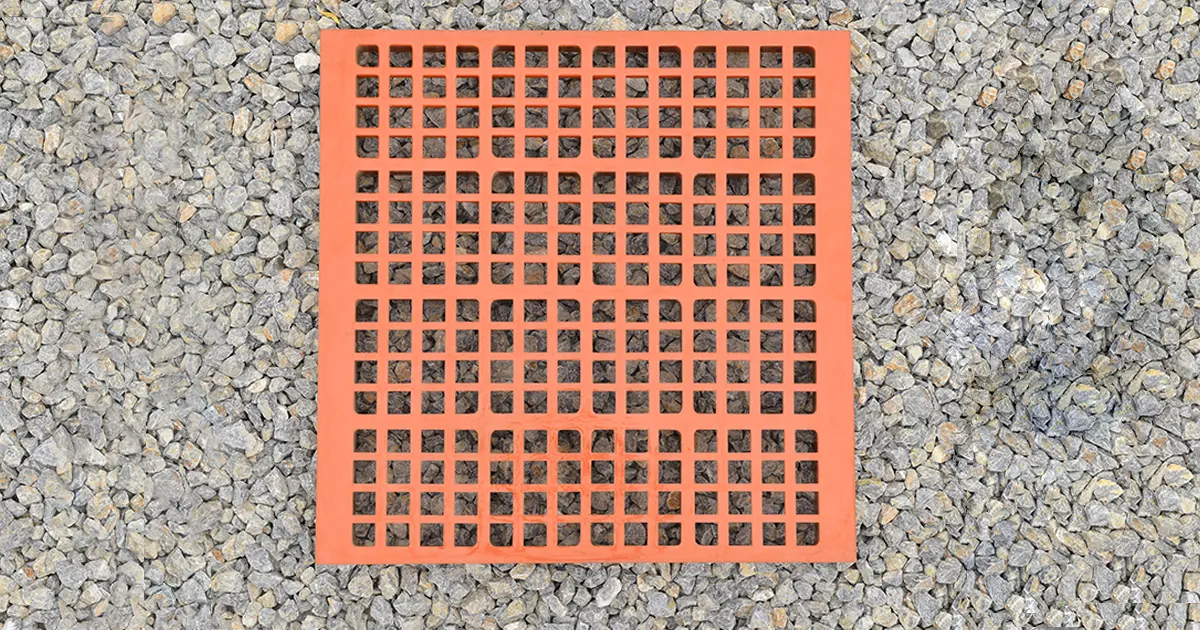

Polyurethane Screens Price Factors

When you check polyurethane screens price, many things change the final cost. Let’s look at what matters for your budget and your work.

Material Cost

Raw Material Fluctuations

Polyurethane is the main part of these screens. The price of polyurethane can go up or down. It goes up when more people need it for mining or building. It goes down if there is a lot of supply or less demand. North America and Europe have steady prices. Asia-Pacific is growing fast because of more mining and new cities. When polyurethane costs more, you pay more for each screen. If you want to plan your spending, watch these price changes.

Polyurethane screens usually cost more than steel or rubber screens. The first price can be 30% to 50% higher. But they last longer and need less fixing. Over time, you might save money, especially if you use many tons each day.

Supply Chain Impact

Problems in the supply chain can also raise prices. If shipping is slow or raw materials are hard to get, prices can jump. Sometimes, factories use new polyurethane types to meet demand. These new types can make screens last longer or work better. You should ask your supplier how they handle supply chain problems.

Design And Size

Standard Vs. Custom

You can choose standard screen sizes or order custom shapes. Standard screens cost less and ship faster. Custom screens fit special machines or jobs. They cost more because they need special molds and extra work. If you need high accuracy or special jobs, you may need a custom screen.

Shape Complexity

Simple shapes are cheaper to make. If you want a screen with many holes or curves, the price goes up. Polyurethane screens often have holes for better screening. They are light and do not rust, but making them takes skill. Custom designs for special jobs cost more. You pay more, but the screen works better and lasts longer.

Manufacturing Process

Technology Used

Factories use different machines to make screens. Some use advanced machines like 3D printers. This helps make screens more exact and wastes less material. Better machines can lower costs and make screens fit better. You get a screen that lasts longer.

Quality Control

Good quality control means strong, reliable screens. Factories check each batch to make sure they are good. This adds to the cost, but you get fewer problems later. You want screens that last and do not break. Good quality control saves you money on repairs.

Tip: Always ask your supplier about their quality checks. This helps you avoid cheap screens that wear out fast.

What Drives Polyurethane Screens Price?

Here is a quick list of what affects polyurethane screens price the most:

- Raw material cost and market supply

- Design complexity and size

- Manufacturing technology and quality control

- Order size and shipping

- Application needs, like throughput and accuracy

You pay more at first for polyurethane screens, but they last longer and are easier to install. Over time, you spend less for each ton you screen. If you want screens that last, buying quality screen media is a smart choice.

Brand And Supplier Impact

When you look at polyurethane screens price, the brand and supplier you choose can make a big difference. Some brands charge more, but you get better quality and support. Let’s break down what you should watch for.

Brand Credibility

A strong brand often means better performance and longer life for your screen media. You might pay more, but you get peace of mind. Here’s why brand reputation matters:

- Brands with a good name often follow strict quality standards. They test their products to make sure you get the right throughput and durability.

- Companies that use new tech, like automation or AI, can offer screens that last longer and work better in tough screening jobs.

- Some brands focus on meeting safety and environmental rules. If your application needs high compliance, you may need to pay a bit more.

- Buyers often pay extra for brands that promise longer longevity and fewer problems.

Quality Standards

You want screens that meet top standards. For example:

- Red Star uses an open-cast process. Their screens last 1.5 to 2 times longer than regular injection-molded screens. This means less downtime and lower cost over the life of your equipment.

- ASGCO makes cast urethane screens with a steel backing plate. Their exclusive polyurethane blend boosts both durability and performance.

If you want to get the most out of every ton you process, pick a brand that stands behind its quality.

Supplier Location

Where your supplier is based can change both price and delivery time. Local suppliers may offer faster service, but sometimes international suppliers have better deals.

Domestic Vs. International

Check out this quick table to see how location affects your order:

| Quantity (pieces) | Lead time (days) | Price (SGD) |

|---|---|---|

| 1 – 10 | 7 | 32.32 |

| > 10 | To be negotiated | To be negotiated |

Some suppliers set a minimum order of 10 pieces, with prices above USD300 per piece and delivery within 14 working days. If you need screens fast, a local supplier might help. If you want to save on cost, an international supplier could be the answer, but you may wait longer.

After-Sales Support

After you buy, good support matters. You want help with installation, maintenance, and any issues that pop up. Top brands and suppliers offer:

- Quick answers to your questions

- Help with setup and training

- Fast solutions if something goes wrong

This support keeps your screening operation running and protects your investment in polyurethane screens. It also helps you get the best life and performance from your screen media, no matter your application.

Tip: Always ask about after-sales support before you buy. Good support can save you time, money, and stress over the long run.

Order Quantity And Lead Time

When you plan your purchase, order quantity and lead time can change the polyurethane screens price. If you buy more screens at once, you can often get a better deal. Suppliers like to sell in bulk, so they offer discounts for larger orders. You save money and get more value for your business.

Bulk Orders

If you need a lot of screen media, ask about bulk pricing. Many suppliers set a minimum order quantity. This means you must buy a certain number of screens to get the best price. Here’s how it works:

Discounts

Bulk orders usually come with price breaks. You might see a lower cost per screen when you buy ten or more. Suppliers want to move more product, so they reward you for bigger orders. You can use these savings to buy more equipment or invest in better screening technology.

Minimum Quantity

Suppliers often set a minimum order. If you buy less than this amount, you pay a higher unit price. Take a look at this table to see how minimum order quantity affects the price:

| Minimum Order Quantity | Unit Price Impact |

|---|---|

| 10 Pieces | Potentially lower unit price with larger orders |

If you need only a few polyurethane screens, you might pay more for each one. When you order in bulk, you get a better deal and lower your total cost per ton screened.

Lead Time

Lead time is the time it takes for your order to arrive. If you need screens fast, you might pay extra for rush production. Standard lead times cost less, but you wait longer.

Rush Vs. Standard

Rush orders get priority in the factory. You pay more, but your polyurethane screens arrive sooner. Standard orders take longer, but you save money. If your screening operation can wait, choose standard lead time. If you need to keep your plant running, rush delivery helps you avoid downtime.

Tip: Always check lead times before you order. Ask your supplier if they offer rush service or discounts for standard delivery. Planning ahead helps you get the best price and keeps your screening process smooth.

Order quantity and lead time play a big role in your final cost. If you buy in bulk and plan your delivery, you get more value from your polyurethane screens and keep your operation running without delays.

Additional Costs

When you look at the price of screens, you need to think about extra costs. These can sneak up on you if you do not plan ahead. Let’s break down what you might pay besides the screen itself.

Shipping And Taxes

Getting your screens from the supplier to your site costs money. You might see these charges on your invoice.

Freight Charges

Freight charges depend on how far your screens travel and how heavy they are. If you order from overseas, shipping can cost a lot. Sometimes, suppliers offer free shipping for big orders. You should always ask about delivery options before you buy.

Here’s a quick table to help you compare:

| Shipping Method | Estimated Cost | Delivery Time |

|---|---|---|

| Air Freight | High | Fast |

| Sea Freight | Medium | Slow |

| Local Courier | Low | Fast |

If you want your screens fast, air freight works best. If you want to save money, sea freight is the way to go. Local courier is great for small orders.

Tip: Ask your supplier if they can bundle shipping with other items. You might save money if you order more at once.

Import Duties

Import duties are taxes you pay when you bring screens into your country. These fees change based on where you live and where the screens come from. Some countries have high import taxes. Others have trade deals that lower the cost. You should check with customs before you order. This helps you avoid surprise charges.

Installation And Maintenance

Buying screens is just the start. You need to set them up and keep them working well.

Professional Setup

You might need a pro to install your screens. Some suppliers offer installation as part of the deal. Others charge extra. If you want your screens to work right, a skilled installer helps a lot. You should ask if installation is included in your quote.

- Professional setup makes sure your screens fit your machines.

- You avoid mistakes that could damage your equipment.

- You save time and get your operation running faster.

Ongoing Upkeep

Screens need care to last longer. You should clean them and check for wear. Some suppliers offer maintenance plans. These plans cost extra but help you avoid big repairs later.

Here are some things to watch for:

- Regular cleaning keeps screens working well.

- Checking for damage helps you spot problems early.

- Replacing worn parts saves you money in the long run.

If you use polyurethane screens, you might spend less on upkeep. These screens resist wear and last longer than other types.

Note: Always ask your supplier about maintenance tips. Good upkeep means fewer headaches and lower costs over time.

Cost Efficiency Of Polyurethane Screens

Initial Vs. Long-Term Cost

When you look at polyurethane screens, you might notice the price is higher at first. You pay about 20–30% more than you would for rubber screens. This can make you wonder if the extra cost is worth it. The answer depends on how you use your screen media and what you expect from your application.

Here’s what happens over time:

- Polyurethane screens last longer because of their durability.

- You replace them less often, so you save money on new screens.

- The cost per ton processed drops as you get more use out of each screen.

If you care about throughput and accuracy, you’ll see that the initial investment pays off. You spend more up front, but you get better value as the years go by. The ease of installation also helps you start working faster, which means less downtime.

Tip: Think about how many tons you process each month. The more you use your screens, the more you save in the long run.

Maintenance Savings

You want your operation to run smoothly. Polyurethane screens help you do that. They cut down on unplanned downtime by 60%. That means your machines keep working and you don’t lose money waiting for repairs.

Here’s how maintenance savings add up:

- You spend less time fixing screens.

- You avoid surprise breakdowns.

- The investment usually pays back in 18–24 months.

- Over five years, you can see net savings of 140–160%.

If you compare this to traditional screen media, you’ll notice a big difference. Polyurethane screens need less care and fewer replacements. You get more life out of each screen, and your maintenance team can focus on other jobs.

Note: Ask your supplier about maintenance plans. Good upkeep can make your screens last even longer.

Service Life

Longevity matters when you choose screen media. Polyurethane screens stand out because they last much longer than other types. You get more life from each screen, which means fewer replacements and less hassle.

Check out this table to see how service life compares:

| Screen Type | Average Service Life (months) |

|---|---|

| Rubber | 6–12 |

| Polyurethane | 18–36 |

If your application needs high accuracy and steady throughput, you’ll appreciate the longer service life. You spend less time swapping out screens and more time getting work done. The durability of polyurethane screens means you can trust them to handle tough jobs without wearing out fast.

Tip: Longer service life means lower cost per ton and better cost efficiency for your operation.

Cost Per Ton

When you buy screen media for your operation, you want to know if you’re getting the best deal. One of the smartest ways to measure value is by looking at cost per ton. This number tells you how much you spend for every ton of material you process. If you keep this number low, you boost your cost efficiency and make your business more competitive.

Let’s break it down. Imagine you pay more up front for polyurethane screens. At first, it might seem like a big hit to your budget. Over time, though, these screens last longer and need fewer replacements. You spend less on repairs and downtime. That means your cost per ton goes down, even if the initial price is higher.

Here’s a simple table to show how different screens can affect your cost per ton:

| Screen Type | Initial Cost | Average Life (months) | Tons Processed | Cost Per Ton |

|---|---|---|---|---|

| Rubber | $100 | 8 | 10,000 | $0.01 |

| Polyurethane | $130 | 24 | 40,000 | $0.003 |

You can see that polyurethane screens give you more tons for your money. The longer life means you don’t have to stop your machines as often for screen media installation. Less downtime means you keep your maximum throughput and avoid costly delays.

But there’s more to it than just the price tag. You also need to think about installation. If you choose screens that are easy to install, you save on labor costs. Quick screen media installation gets your plant running faster. You also want screens that keep their shape and size. Good screen sizing accuracy helps you get the right product every time, so you don’t waste material or time.

Here are a few tips to help you lower your cost per ton:

- Choose screen media with a long life and strong wear resistance.

- Ask your supplier about installation support or training.

- Track your throughput and downtime to spot savings.

- Check if your screens keep their sizing accuracy over time.

Tip: Always review your cost per ton every few months. Small changes in screen choice or installation can make a big difference in your cost efficiency.

When you focus on cost per ton, you make smarter choices for your operation. You get more value from your screen media and keep your business running at its best.

Conclusion

When you choose polyurethane screens, look at more than price. Think about the material and design. The supplier also matters a lot. Each one changes how much you spend to run your plant. You should care about value, not just cost per ton. Ask suppliers for clear prices. Tell them what you need for your screening job. This helps you get the best screen for your work. Anpeng Wire Mesh Filter Equipment Co., Ltd. gives you strong screens. These screens help you save money and keep your plant working well.

| Why Choose Anpeng? | What You Get |

|---|---|

| Fast Delivery | Big factory and many lines for making screens |

| Reliable Quality | Good checks and steady performance |

| Lower Long-Term Cost | Less downtime and fewer times you need new screens |

FAQ

What makes polyurethane screens more expensive than rubber or steel screens?

You pay more for polyurethane screens because they last longer and resist wear. The material costs more, but you save money over time since you replace them less often.

Can I order custom sizes or shapes for my screens?

Yes, you can order custom screens. Custom sizes or shapes cost more because they need special molds and extra work. Standard screens ship faster and cost less.

How do I know if I need professional installation?

If you want your screens to fit perfectly and work right away, you should get professional installation. Some suppliers offer this service. Ask before you buy.

Do polyurethane screens need special maintenance?

You do not need special tools for maintenance. Clean your screens regularly and check for damage. Polyurethane screens resist wear, so you spend less time fixing them.

How does order quantity affect price?

Buying more screens at once usually gets you a discount. Suppliers like bulk orders. If you buy only a few, you pay a higher price per screen.

What is the average service life of polyurethane screens?

Polyurethane screens last about 18 to 36 months. Rubber screens last 6 to 12 months. You get more value and fewer replacements with polyurethane.

Are there extra costs besides the screen price?

Yes, you might pay for shipping, import duties, installation, and maintenance. Always ask your supplier for a full quote so you know all costs.

How can I lower my cost per ton processed?

Choose screens with long life and strong wear resistance. Track your throughput and downtime. Ask your supplier about installation support and maintenance tips.