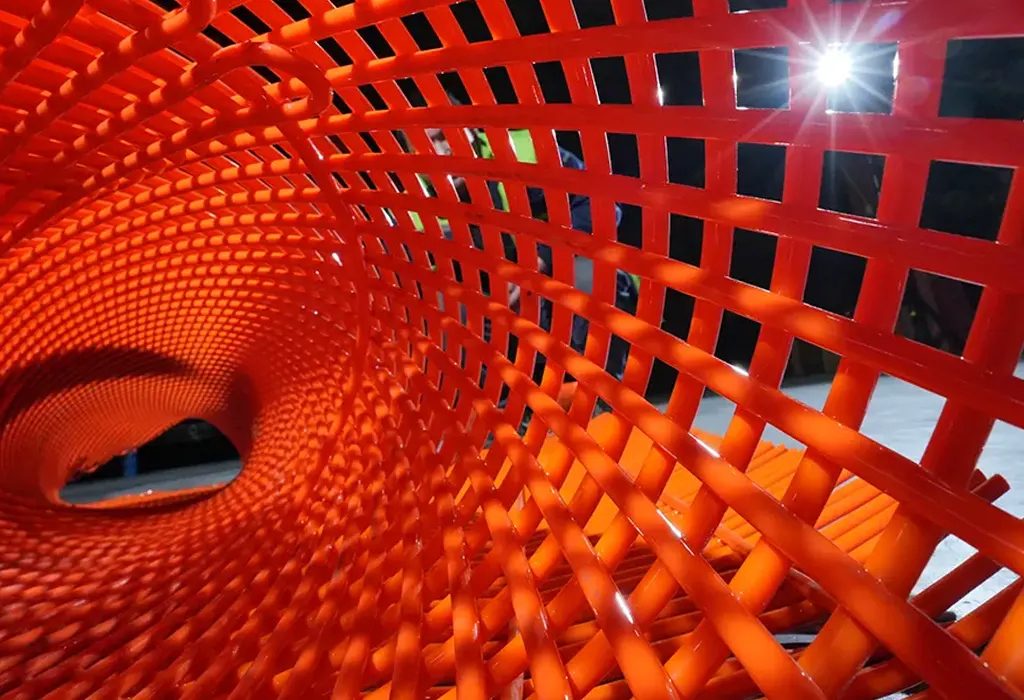

PU Mesh

Anpeng manufactures PU-Mesh screens for mining and aggregate vibrating screens. PU-Mesh is built with a woven steel wire core and a wear-resistant polyurethane coating on the surface. This structure keeps the high open area and strength of wire screens, while improving wear resistance and helping reduce noise and pegging in many screening conditions. As a direct manufacturer, we supply PU-Mesh in custom apertures, panel sizes, and hook/edge styles to match your existing screen deck.

What Is PU Mesh?

PU-Mesh (also called steel-core polyurethane screen mesh or PU-coated wire screen mesh) is a screening media used on vibrating screens to separate aggregates and ores into different size fractions. The screen is made from a woven wire mesh base to maintain strength and opening stability, then coated with polyurethane to protect the wire and improve wear performance. PU-Mesh is commonly supplied as tensioned panels with hooks so it can be installed on standard vibrating screen decks with minimal changes.

Features & Advantages

Because the structure is still based on woven wire, PU-Mesh maintains a high open area for good throughput and screening efficiency. Many operations use it to improve capacity while keeping stable cut size.

The wire core provides a flexible screening surface under vibration. This can help material “release” from the deck in some applications, supporting smoother flow and reducing build-up.

The polyurethane coating protects the wire surface from direct abrasion. In many abrasive duties, PU-Mesh can last significantly longer than standard woven wire screens, with actual service life depending on ore type, impact level, moisture, and operating conditions.

The coated surface is smoother than bare wire, which can help reduce pegging and blinding when material tends to stick or wedge in openings. The polyurethane layer can also dampen impact and vibration noise, supporting a quieter screening environment.

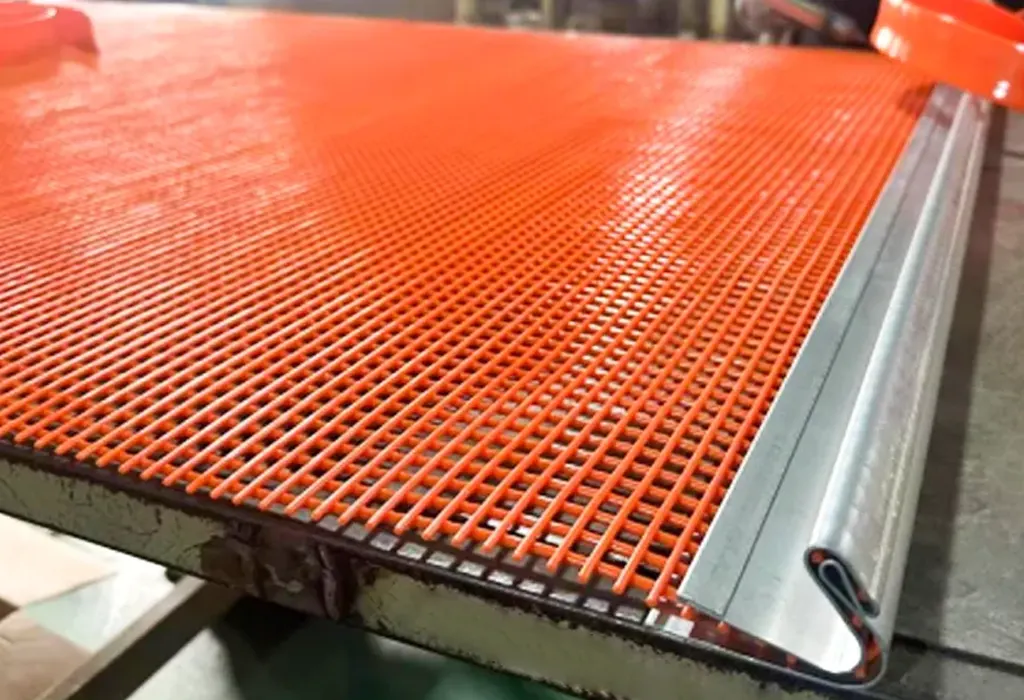

PU-Mesh is designed for practical maintenance. When panel size and hook style are matched to your existing deck, it can be installed as a direct replacement for traditional tensioned wire screens.

PU-Mesh Options (Custom Available)

We manufacture PU-Mesh to match your screening requirements and deck system. Typical options include:

Opening shapes: square, rectangular, slotted (custom patterns available)

Aperture range: customized for your cut size

Hook/edge styles: metal hooks or PU hooks (available upon request)

Panel size: made to your deck layout and replacement panel dimensions

Coating design: tailored for abrasion duty and operating condition

If you’re unsure which opening pattern is best, share your material condition (dry/wet/clay-heavy) and target cut size—our team can recommend a practical specification.

Product Specifications

| Specification | Details |

|---|---|

| Product Name | PU-Mesh Screen (Steel-Core Polyurethane Screen Mesh) |

| Manufacturer | Anpeng (Direct Manufacturer) |

| Construction | Woven steel wire core + wear-resistant polyurethane coating on the surface |

| Screen Type | Tensioned screen panels with hooks (custom edge styles available upon request) |

| Opening Shape | Square, Rectangular, Slotted (custom patterns available) |

| Opening Size (Aperture) | Custom per cut size requirement |

| Wire Core | Steel wire woven base (wire diameter available upon request) |

| PU Coating | Wear-resistant polyurethane coating (coating thickness available upon request) |

| Open Area | High open area maintained by woven wire structure (optimized by aperture & wire core design) |

| Panel Size | Custom per screen deck layout (direct replacement dimensions available) |

| Hook / Edge Options | Metal hooks or PU hooks (match your deck system) |

| Recommended Duty | Aggregate and mining screening: sizing, scalping, and final screening on vibrating screens |

| Typical Applications | Quarry & aggregate plants, mining screening, abrasive materials, wet or sticky feed conditions |

| Customization | Aperture, opening pattern, panel size, hook style, wire core design, and coating design available upon request |

| Quotation Info Needed | Aperture (mm), opening shape, panel size (L×W), hook type, quantity, material screened, dry/wet condition |

| Packing | Export pallets or bundles with protective wrapping; labeled by specification & order ID |

FAQs

What is PU-Mesh screen?

PU-Mesh is a steel-core polyurethane screen mesh used on vibrating screens. It combines a woven wire base for strength and stable openings with a polyurethane coating that improves wear resistance and can help reduce pegging and noise in many applications.

PU-Mesh vs standard woven wire mesh—when should I choose PU-Mesh?

Standard woven wire mesh is widely used for high-efficiency screening, especially for dry material. PU-Mesh is often chosen when abrasion is high, when service life needs to be improved, or when noise and pegging are concerns. The best option depends on the material, cut size, and duty.

Does PU-Mesh reduce pegging and blinding?

In many screening conditions, the smoother polyurethane surface helps reduce pegging and blinding compared to bare wire. Performance depends on feed moisture, fines content, and particle shape, so we recommend the opening pattern based on your operating condition.

Do I need to modify my screen machine to use PU-Mesh?

Usually no. If the panel size and hook style match your existing tensioned screen system, PU-Mesh can be installed as a direct replacement. To confirm, share your deck measurements or photos of your current screen panel.

What opening shapes can you make?

Common options include square, rectangular, and slotted openings. We recommend an opening shape based on your target cut size, material flow, and whether the feed is wet or sticky.

What information do you need for a quote?

For a fast quote, provide aperture (mm), opening shape, panel size (L×W), hook type, quantity, and the material you are screening (dry/wet condition). A photo of your current panel is also helpful.