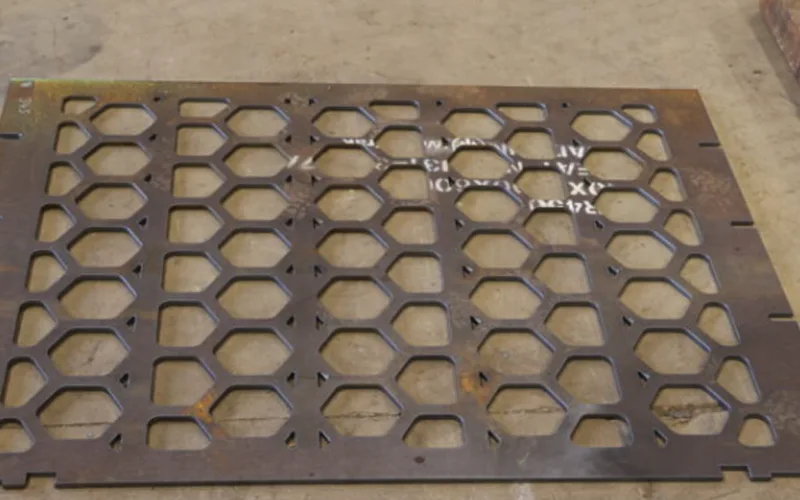

Punch Plates

Punch plates, also called perforated plate screens, are heavy-duty screening media used on vibrating screens for scalping and coarse screening. They are made from steel plate with punched apertures, offering a rigid surface that handles high impact, large feed, and abrasive material better than many flexible screen options. If your top deck sees heavy lumps or you’re tired of premature wire breakage in impact zones, punch plates are often the practical choice.

What Are Punch Plates?

A punch plate is a steel plate with a controlled pattern of holes (round, square, or slotted). The plate is installed on a vibrating screen deck to separate oversize from undersize. Compared with woven wire cloth, perforated plates are more rigid and typically used when strength and stability matter more than maximum open area.

Where Punch Plates Work Best

Punch plates are widely used in:

Scalping (Top Deck): remove oversize early and protect downstream equipment

Primary screening: handle large lumps and high bed depth

High-impact / abrasive duty: blasted rock, hard ore, sharp aggregate

Applications requiring rigid support: stable screening surface under heavy load

Key Benefits

High impact resistance for large feed and heavy duty screening

Rigid and stable surface that holds its shape under load

Reduced risk of wire breakage in high-impact zones

Multiple hole patterns to match flow and separation needs

Good wear life in coarse duty when the right plate material and thickness are selected

Easy to standardize for consistent scalping performance across similar decks

Technical Specifications

| Specification | Details |

|---|---|

| Plate Material | Carbon Steel, High-Carbon Steel, Manganese Steel (65Mn), Stainless Steel (304/316) (custom available) |

| Plate Thickness | Custom by duty and impact level (common for scalping and coarse screening) |

| Hole Shape | Round, Square, Slotted (custom patterns available) |

| Hole Size (Aperture) | Custom to target cut size and material behavior |

| Pitch / Open Area | Optimized for capacity vs strength (based on tph and bed depth) |

| Plate Size | Custom per deck size and layout (panel or full-sheet options) |

| Edge Connection | Hooked edges, Bolt-down, Clamp bar mounting (match your screen system) |

| Surface Options | Plain / Galvanized / Coated (optional, depends on corrosion requirements) |

| Recommended Duty | Scalping and coarse screening on vibrating screens (high impact, abrasive feed) |

Why Choose ANPENG Punch Plates?

Our punch plates are made for harsh scalping duty—large feed, high impact, and abrasive material—so the deck stays stable in demanding conditions.

We produce punch plates to match your deck size, support layout, and mounting style, helping reduce movement, bypass, and premature damage.

Tell us your material, moisture, target cut size, tph, and screen model/deck layout—we’ll recommend the right hole pattern, hole size, and plate thickness for your application.

FAQs

What hole pattern is best for scalping?

Round holes are common for general scalping. For higher flow or certain particle shapes, slotted holes may be preferred. The best choice depends on feed shape and pegging risk.

Punch plates vs woven wire—when should I switch?

If your top deck sees heavy impact and wire cloth breaks too quickly, punch plates are often used in the impact zone or across the full scalping deck.

How do I choose hole size for my target cut?

Start with the size you want to pass/retain, then adjust based on near-size content, feed condition, and acceptable carryover.

Can punch plates handle wet and sticky material?

They can be used, but wet fines may still blind depending on material behavior. Hole pattern and process support (like spray) can matter a lot.

What information do you need for a quote?

Material type, moisture, target cut size, tph, screen model, deck dimensions/layout, and current issues (impact wear, pegging, blinding).

How do I reduce pegging on perforated plates?

Switching hole pattern (e.g., slotting), adjusting hole size/pitch, improving feed distribution, or changing the circuit can help. The right choice depends on whether pegging is from near-size particles or sticky fines.