Here are some standard punch plate sizes you’ll see often:

- 3/8 inch punch: Great for light sheet metal work.

- 1/2 inch punch: Handy for construction and general fabrication.

- 3/4 inch punch: Used for heavy-duty mining screens.

Knowing Punch Plates Sizes helps you pick the right punch for your job. Different types of punch give you different results. Think about your material and the punch you need. With the right punch, you get the best performance.

Key Takeaways

- Know common punch sizes like 3/8 inch for light jobs and 3/4 inch for tough jobs. Pick the right size for your work.

- Flat punch plates help sort and screen things. They give a strong surface and are simple to change.

- Curved punch plates help things move easily. They work well in mining and quarrying.

- Modular punch plates are flexible. You can change hole sizes and shapes without getting a new plate.

- Choose punch plates based on your material and job. Using the right size helps you work better and make fewer mistakes.

- Take care of punch plates to make them last longer. Clean and check them often so they do not break.

- Use custom punch plates for special jobs. They can be made to fit your needs and help you do better work.

- Standard punch plate sizes help save time and money. They make changing plates easy and keep quality the same.

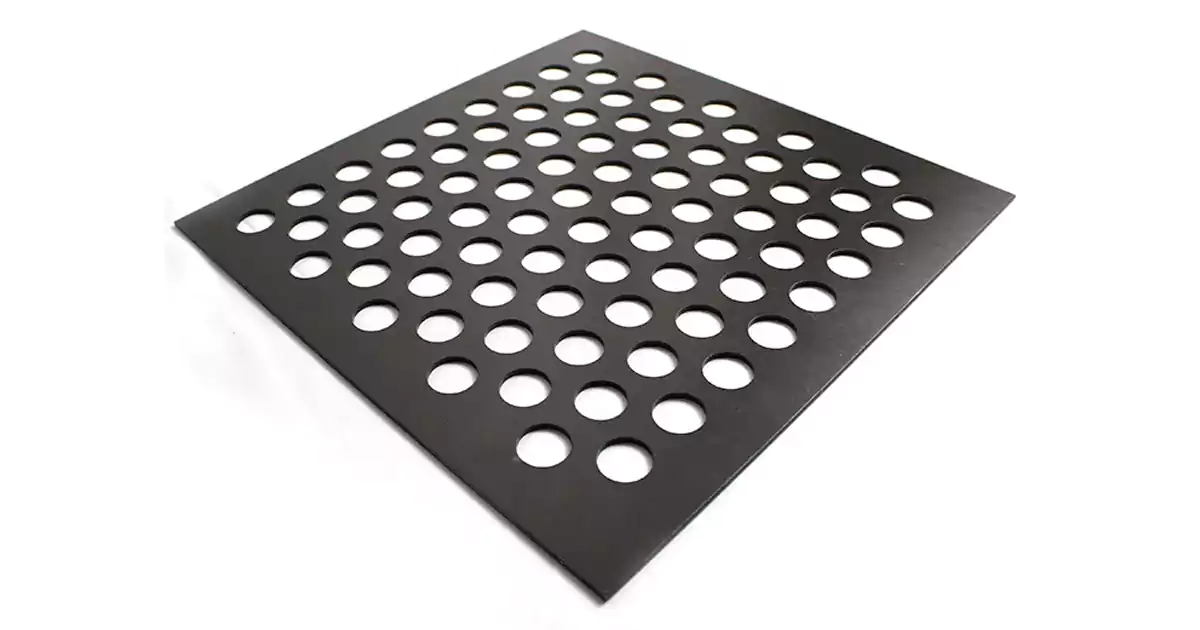

Punch Plates Sizes and Dimensions

When you start looking at punch plates sizes, you’ll notice there are a lot of options. Let’s break down the most common punch sizes and plate dimensions you’ll see in the industry.

Standard Punch Sizes

You’ll find that punch sizes can vary depending on what you need. Some jobs call for tiny holes, while others need something much bigger. Picking the right punch makes your work easier and faster.

Common Ironworker Punch Sizes

Ironworker machines use a range of punch sizes. Here are some of the most popular ones you’ll see:

- 3/8 inch punch: Good for lighter jobs and thin metal.

- 7/16 inch punch: Handy for medium-duty work.

- 1/2 inch punch: A favorite for general fabrication.

- 5/8 inch punch: Used for thicker plates.

- 3/4 inch punch: Great for heavy-duty applications.

You might also see hole punch sizes from 1/4 inch up to 5/16 inch (about 6 to 8 mm). The 5/16 inch punch is the most common size for many projects.

Cup Punch Size Range

Cup punches give you even more flexibility. You can find cup punch sizes starting as small as 1/32 inch and going up to 31/64 inch. This wide range lets you handle everything from tiny holes to larger openings.

| Punch Type | Size Range |

|---|---|

| Cup Punch | 1/32 to 31/64 inch |

So, whether you need a small punch for a delicate job or a larger one for tough metal, you have plenty of choices.

Plate Dimensions

Punch plates come in different shapes and sizes, too. You want to match your punch to the right plate for the best results.

Maximum and Typical Plate Sizes

Most punch plates you’ll find have standard dimensions. Here are some typical sizes:

- 2000 x 1000 mm (about 6.5 x 3.3 feet): This is a common size for many projects.

- 3000 x 1500 mm (about 9.8 x 4.9 feet): Used for bigger jobs.

- 4000 x 2000 mm (about 13 x 6.5 feet): Great for heavy-duty work.

- Up to 6000 x 2000 mm (about 19.7 x 6.5 feet): For the largest applications.

Tip: Standard punch plates sizes make it easy to find replacements and keep your project moving.

When you use standard punch plates sizes, you save time and money. Manufacturers can make these plates faster and cheaper because they don’t have to create custom parts every time. Standardization also means you get better quality and fewer mistakes. Many factories use standard punch plates sizes to keep costs low and production smooth. You don’t need as many skilled workers, and you can process more workpieces in less time.

| Benefit of Standardization | How It Helps You |

|---|---|

| Cost Savings | Lower prices for standard parts |

| Efficiency | Faster production and delivery |

| Quality | Fewer errors and better results |

So, when you pick from standard punch plates sizes, you make your job easier and your project more affordable.

Types of Punches and Punch Plates

When you look at the types of punches and punch plates, you’ll see that each one has a special job. You can pick from flat, curved, or modular punch plates. Each type works best in certain situations. Let’s break down what makes each one unique and how you can use them.

Flat Punch Plates

Flat punch plates are the most common type you’ll find. These plates have a smooth, even surface. You use them when you need a steady contact area and simple measurements. Flat punch plates work well for screening and sorting materials.

Standard Sizes

You can find flat punch plates in many standard sizes. Most plates come in thicknesses from 3 mm up to 25 mm. The hole sizes usually range from 3 mm to 100 mm. You might also see a standard tubular punch used with these plates, especially for making round holes.

Here’s a quick look at what makes flat punch plates special:

Characteristic | Description |

|---|---|

| Constant contact area | Gives you a known area for measurement |

| Data interpretation | Makes it easy to analyze the contact area |

| Spatial resolution | Not as high as sharp indenters |

| Full contact needs | Needs parallel surfaces to work well |

| Stress concentrations | You’ll see these at the edges of the punch |

Tip: Flat punch plates are easy to replace and maintain. You can swap them out fast when you need a new size or pattern.

Uses in Screening

You’ll use flat punch plates for screening in industries like mining, construction, and recycling. These plates help you sort rocks, gravel, sand, and other materials by size. The holes let smaller pieces fall through while bigger chunks stay on top. If you need to process a lot of material quickly, flat punch plates are a solid choice.

Curved Punch Plates

Curved punch plates have a rounded or arched shape. You’ll see these plates in places where you need to move material smoothly. The curve helps guide rocks or gravel along the plate, which keeps things from getting stuck.

Standard Sizes

Curved punch plates come in many of the same thicknesses as flat plates. You’ll find them in sizes like 2000 x 1000 mm or 3000 x 1500 mm. The holes can be round, square, or slotted, and you can use a standard tubular punch to make these shapes. Curved plates often use thicker steel for extra strength.

Mining and Quarry Applications

You’ll spot curved punch plates in mining and quarrying. These plates handle heavy loads and rough materials. The curved shape helps move rocks and dirt along the screen. This design keeps your equipment running longer and cuts down on jams. If you work with abrasive materials, curved punch plates can save you time and money.

Modular Punch Plates

Modular punch plates give you the most flexibility. You can build a screen using panels that fit together like puzzle pieces. This setup lets you swap out worn sections without replacing the whole plate. You can also mix and match different hole shapes and sizes.

Modular Dimensions

Most modular punch plates come in panels that measure 300 mm x 300 mm or 305 mm x 610 mm. You can choose the thickness and hole size to match your job. Some modular plates use a standard tubular punch for round holes, while others use special shapes for custom needs. If you need tube punch cut sizes or unique patterns, modular plates make it easy.

Custom Installations

You can customize modular punch plates for almost any job. These plates offer high wear resistance, so they last longer in tough conditions. You can pick from square, round, hexagonal, or slotted openings. Some plates have in-line or staggered holes, and you can add blank areas where you don’t want any openings. You can install these panels in hooked sections or as modular panels, so you don’t need to change your whole deck.

Here’s a table that shows what makes modular punch plates stand out:

Feature | Description |

|---|---|

| Wear Resistance | Handles abrasion with many opening shapes |

| Customization | Lets you pick hole patterns and blank spots |

| Installation Flexibility | Comes in hooked or modular panels, no deck conversion needed |

| Design Options | Supports special setups for different jobs |

Note: Modular punch plates work well for custom installations. You can design a screen that fits your exact needs, whether you’re in mining, recycling, or manufacturing.

You’ll see many types of punches used with these plates, including diecutting punches for special shapes. If you need a punch that matches your material and output, modular punch plates give you the most options.

Applications by Size

Mining and Quarrying

Heavy-Duty Screening

If you work in mining or quarrying, you know how important it is to pick the right punch plates sizes for your screens. The right punch makes your job easier and helps you process more material. You often see punch plates with mesh apertures ranging from 1.0mm up to 100.0mm. The wire diameter changes with the mesh size, so you get the strength you need for heavy-duty screening.

Here’s a table showing common punch plates sizes used in mining and quarrying:

| Mesh Aperture | Wire Diameter |

|---|---|

| 1.0mm | 0.6mm, 0.7mm, 0.8mm |

| 5.0mm | 2mm, 2.5mm, 3mm |

| 10.0mm | 3mm, 4mm, 5mm |

| 25.0mm | 6mm, 7mm, 8mm |

| 50.0mm | 8mm, 9mm, 10mm |

| 100.0mm | 10mm, 11.2mm, 12.7mm |

You can see how punch plates sizes change to match the job. Smaller mesh apertures work for fine screening, while larger ones handle big rocks and heavy loads.

Abrasive Material Handling

Mining operations deal with tough, abrasive materials every day. You need punch plates made from abrasion-resistant steel to keep your equipment running. Perforated metal plates are designed for these harsh environments. When you choose the right punch plates sizes, you reduce downtime and save money. Wear plates made from quenched and tempered martensitic steel protect your screens and help them last longer. You can swap out punch plates quickly, so your machines stay in top shape.

Tip: Always check your punch plates for wear. Replacing them before they fail keeps your operation smooth and safe.

Construction and Aggregates

Gravel and Sand Processing

In construction, you use punch plates to sort gravel and sand. The punch size matches the material you want to separate. Smaller punch plates sizes help you filter fine sand, while bigger punches work for gravel. You can pick punch plates with round, square, or slotted holes. This lets you control the output and get the right mix for your project.

- Use small punch sizes for fine sand.

- Choose larger punch sizes for gravel.

- Mix hole shapes for custom sorting.

Durability Needs

Construction sites are busy and rough. You need punch plates that stand up to constant use. Durable punch plates sizes help you avoid breakdowns and keep your project on track. You can pick thicker plates for heavy-duty jobs or lighter ones for quick tasks. The right punch plate size means less downtime and more productivity.

Note: Regular cleaning and inspection of punch plates help you spot problems early.

Dies and Manufacturing

Cut-Off and Compound Dies

Manufacturing uses punch plates in dies for cutting, shaping, and bending metal. You select punch sizes based on the hole you need. The die is always a bit larger than the punch to make cutting easier. You use different punch plates sizes for different parts, so you get the right fit every time.

Here’s a table showing key components in die applications:

| Component | Function |

|---|---|

| Die Plates | Hold and guide the punch and die during operation. |

| Punches and Dies | Cut, bend, and shape materials. |

| Stripper Plates | Keep sheet metal in place and help remove punches. |

| Pilot Punches | Position material accurately. |

| Guide Pins | Align die plates. |

| Springs | Hold workpieces and open die plates. |

| Tolerances | Ensure accuracy and assembly integrity. |

| Material Properties | Affect design and tooling function. |

Additional Functions

You use punch plates for more than just cutting. In manufacturing, punch plates sizes help you create holes, slots, and shapes in sheet metal. The punch size matches the hole, and the die clearance changes with the thickness of the part. If you need a hole smaller than the sheet thickness, you use a different method. Punch plates also help with progressive stamping, where pilot punches keep everything lined up.

- Punch size equals hole size.

- Die is slightly larger for easy cutting.

- Minimum hole diameter matches sheet thickness.

When you pick the right punch plates sizes, you get better results and fewer mistakes. You save time, money, and effort in every step.

Comparison of Punch Plates Sizes

Quick-Reference Chart

You might feel overwhelmed by all the punch plates sizes and types out there. A quick-reference chart can help you see the differences at a glance. This table shows you how punch plates sizes, punch types, and their uses stack up. You can use it to pick the right punch for your job.

| Punch Plate Type | Standard Sizes (mm) | Common Punch Sizes (inch) | Typical Uses | Die Type | Production Speed | Part Complexity |

|---|---|---|---|---|---|---|

| Flat | 2000×1000, 3000×1500 | 3/8, 1/2, 3/4 | Screening, sorting, mining | Simple Die | Very Slow | Low |

| Curved | 2000×1000, 4000×2000 | 1/2, 5/8, 3/4 | Quarrying, abrasive handling | Compound Die | Slow | Medium |

| Modular | 300×300, 305×610 | 1/4, 5/16, custom | Custom installations | Progressive Die | Very Fast | High |

| Custom | Any | Any | Special projects | Transfer Die | Fast | Very High |

You can see how each punch plate type matches up with different punch sizes and die types. Flat punch plates work best for simple jobs. Curved punch plates handle rough materials. Modular punch plates give you flexibility for custom screens. Custom punch plates let you tackle unique challenges.

Tip: Use this chart when you need to compare punch plates sizes for your next project. It saves you time and helps you avoid mistakes.

Key Differences

When you look at punch plates sizes, you notice some big differences. Each punch plate type has its own strengths. Flat punch plates give you a steady surface and simple punch options. Curved punch plates move material smoothly and work well with abrasive loads. Modular punch plates let you swap panels and change punch sizes fast. Custom punch plates fit special needs and let you pick any punch size you want.

You also need to think about the die type. Simple dies cost less and work for low-volume jobs. Compound dies handle more complex punch shapes. Progressive dies speed up production and use automation. Transfer dies work for large or deep parts and offer high precision.

Here are some things to keep in mind:

- Flat punch plates are easy to replace and maintain.

- Curved punch plates last longer in tough environments.

- Modular punch plates let you change punch sizes without replacing the whole plate.

- Custom punch plates solve unique problems.

If you want high production speed, go with modular punch plates and progressive dies. For simple jobs, flat punch plates and simple dies work best. If you need to handle complex parts, custom punch plates and transfer dies are the way to go.

Note: Always match your punch plates sizes to your material and job needs. The right punch saves you time and money.

You can use this comparison to make smart choices. Pick the punch plate and punch type that fits your project. You get better results and fewer headaches.

Selecting the Right Size

Choosing the right punch plate size can make your work easier and your results better. You want to match your punch plate to your material, your job, and your equipment. Let’s look at what you need to think about before you pick.

Material and Output Needs

You should always start with your material and what you want to make. Here are the main things to check:

- Material Properties: Look at the type and thickness of your material. Harder metals need stronger punch plates. Thicker sheets need bigger punches.

- Target Geometry: Think about the shape you want. The punch and die must match your final part, including bends and angles.

- Press Brake Parameters: Make sure your punch plate fits your press brake machine. Check the tonnage and mounting system.

- Production Requirements: Decide if you need high precision or just a lot of parts. This will change the punch plate you pick.

- Tooling Properties: Check the material and heat treatment of your punch plate. This affects how long it lasts.

If you want to save material, try using advanced nesting software. This helps you cut more parts from each sheet and reduces waste. You can also recycle off-cuts to help the environment. Some materials, like aluminum alloys, resist rust and last longer, so you don’t need extra coatings.

Tip: Always match your punch plate to your material and your output needs. This keeps your work smooth and your tools in good shape.

Industry Standards

Industry standards help you pick the right punch plate sizes for your job. These rules make sure your parts fit and work well. Here’s a quick look at some common standards:

| Specification Type | Details |

|---|---|

| Perforation Patterns | Round, square, slotted, and more available on request |

| Staggered Layouts | 60° staggered pattern is common; affects cost and performance |

| Minimum Hole Size | Should not be less than the thickness of your material |

| Bar Width | Needs to be greater than material thickness to avoid tool failure |

| Margins | Minimum margins on long sides; special margins possible |

| Flatness Tolerances | Can meet AISI flatness tolerances |

You can ask for special patterns or margins if your project needs them. Following these standards helps you avoid mistakes and keeps your work safe.

Equipment Compatibility

Your punch plate must fit your machines. Check these things before you buy:

- Make sure your punch plate matches your press brake or punching machine.

- Look at the mounting system and see if it fits your setup.

- Check if your equipment can handle the punch plate’s weight and thickness.

- Think about energy use. Energy-efficient machines save money and help the planet.

- Use recycling programs for waste and off-cuts to keep your shop green.

If you use the right punch plate for your equipment, you get better results and fewer breakdowns. You also help your team work faster and safer.

Note: Picking the right punch plate size means thinking about your material, your job, and your machines. Take your time and check each step.

Troubleshooting and Customization

Sizing Issues

You might run into sizing problems with punch plates, even if you pick from standard options. Sometimes, the holes are too small for your material, or the plate doesn’t fit your machine. Maybe you notice uneven wear or the plate bends during use. These issues can slow you down and cost you money.

Here’s what you can do:

- Double-check your measurements before you order. Make sure the punch plate matches your machine and your material.

- If you see the plate bending or cracking, try a thicker plate or a different hole pattern.

- For uneven wear, rotate your punch plates or swap them out more often.

- If you need a special fit, ask your supplier about custom options. They can help you get the right size for your job.

Tip: Always keep a spare punch plate on hand. This way, you can swap it out fast if you run into trouble.

Maintenance Tips

Taking care of your punch plates helps them last longer and work better. You don’t need fancy tools—just a few simple habits. Here’s a table with easy maintenance tips you can follow:

| Maintenance Tip | Description |

|---|---|

| Clean punches and dies after each use | Regular cleaning prevents buildup of debris. |

| Apply light machine oil to prevent rust | Lubrication protects against corrosion. |

| Inspect for cracks or deformation | Regular inspections help identify issues early. |

If you clean your punch plates after each use, you stop dirt and metal bits from building up. A little oil keeps rust away, especially if you store your plates for a long time. Checking for cracks or bends helps you catch problems before they get worse. These steps work for all punch plates, no matter the size.

Note: Good maintenance means fewer breakdowns and better results every time you use your punch plates.

Custom Punch Plates

Sometimes, you need more than a standard punch plate. Maybe your project needs a special hole size, a unique pattern, or a certain open area for better material flow. Custom punch plates let you pick exactly what you need.

Here’s how custom options can help you:

| Feature | Description |

|---|---|

| Hole size | You can adjust hole sizes to match your project. |

| Hole pattern and orientation | Change patterns and directions for special jobs. |

| Open area percentage | Pick how much open space you want for better flow and strength. |

| Industry applications | Used in oil and gas, manufacturing, and other fields where exact screening is key. |

If you work in a specialized industry, you know how important it is to get the right punch plate. Custom punch plates give you the flexibility to handle tough jobs, like oil exploration or advanced manufacturing. You can even ask for a standard side outlet if your setup needs it.

Callout: Don’t be afraid to ask for custom punch plates. They can solve problems that standard plates can’t handle.

Conclusion

Knowing about punch plate sizes and types of punches helps you do your project well. Picking the right size makes your equipment work better and last longer. Here are some important benefits:

| Benefit | Description |

|---|---|

| Airflow Efficiency | Good perforation patterns help your system work better. |

| Customization | Special designs match what you need. |

| Advanced Engineering | 3D modeling helps make sure the design is correct before building. |

You can ask a manufacturer if you want a custom size. We focus on mining punch plates and can make custom ones for your job.

FAQ

What is a punch plate?

A punch plate is a metal sheet with holes punched through it. You use it for screening, sorting, or filtering materials in industries like mining and construction.

How do I choose the right punch plate size?

You should match the punch plate size to your material and job. Check your equipment specs and think about the output you want. If you need help, ask your supplier.

Can I get custom punch plates?

Yes! You can order custom punch plates with special hole sizes, patterns, or shapes. Custom plates help you solve unique problems in your project.

How often should I replace punch plates?

You should inspect your punch plates regularly. Replace them when you see cracks, bends, or uneven wear. Keeping spare plates on hand helps you avoid downtime.

What materials are punch plates made from?

Most punch plates use steel, stainless steel, or abrasion-resistant alloys. You pick the material based on your job and the type of material you process.

Do punch plates work for wet materials?

Yes, punch plates can handle wet materials. You may need special coatings or stainless steel for better durability and rust resistance.