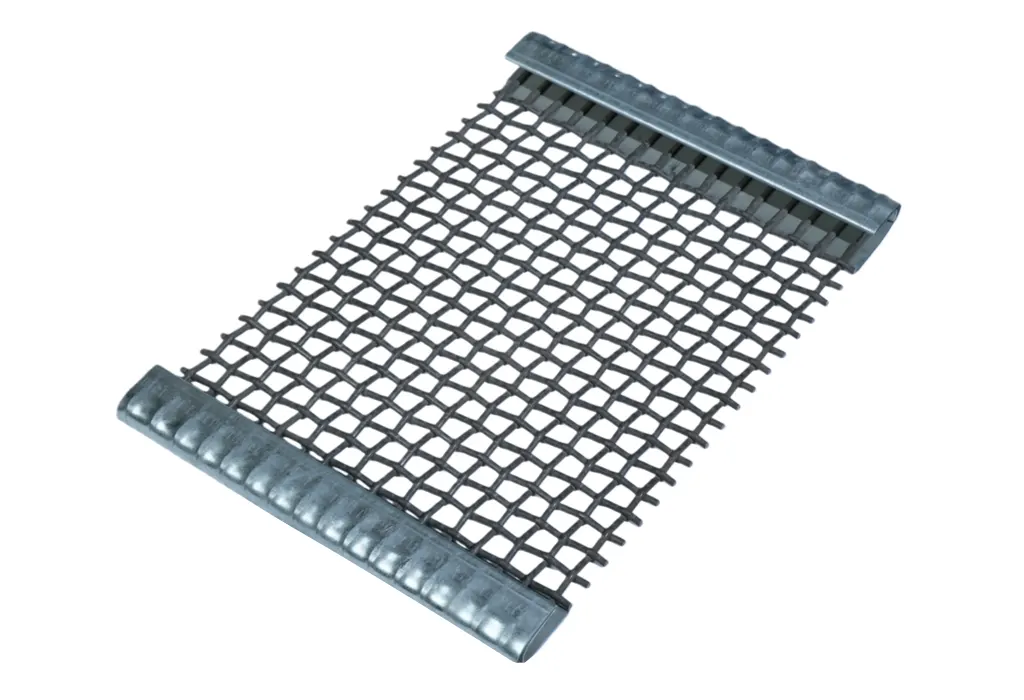

Quarry Screen Mesh

Quarry screen mesh is the woven wire screen media used on vibrating screens in quarries and aggregate plants to separate stone by size. While the screening machine provides vibration and motion, the screen mesh determines cut accuracy, open area, wear life, and blinding risk—which directly impacts throughput and product consistency.

Anpeng is a woven wire screen mesh manufacturer supplying quarry and aggregate operations with stable sizing performance, reliable quality, and custom sizing to match your screen deck.

What Is Quarry Screen Mesh?

Quarry screen mesh is the woven wire screening surface installed on vibrating screens in quarries and aggregate plants. Its primary function is to separate crushed stone and gravel into specific size fractions with consistent grading.

Although the screening machine provides vibration and movement, the mesh itself largely determines screening results—especially cut accuracy, open area, wear resistance, and how well the deck resists blinding or pegging in wet or clay-bearing material. Choosing the right quarry screen mesh helps maintain stable throughput, reduce downtime, and keep your finished product within specification.

Quarry Screening Challenges

Quarry operations often face a combination of heavy impact and abrasive feed. Oversize rock can damage weak screen media, while sharp, hard aggregates accelerate wear. Wet or clay-bearing material can also cause pegging and blinding, reducing effective open area and lowering throughput. Choosing a quarry-appropriate mesh helps keep the deck open, stabilize capacity, and reduce unplanned shutdowns and replacement frequency.

How to Choose Quarry Screen Mesh

For quarry plants, screen selection often starts with the deck position. Top decks typically face the highest impact from oversize rock, so durability and structure are critical. Middle decks usually need a balance of open area and wear life to keep capacity stable. Bottom decks focus on accurate cut size and consistent product grading, and anti-clogging designs can be valuable if fines or moisture cause pegging or blinding.

Fast selection tip: If you tell us your deck position (top/middle/bottom), target cut size, and whether the feed is dry or wet/clay-bearing, we can recommend a suitable mesh type and wire selection.

Product Specifications

| Specification | Details |

|---|---|

| Product Name | Quarry Screen Mesh (Woven Wire Quarry Screening Media) |

| Manufacturer | Anpeng (Direct Manufacturer) |

| Screen Type | Crimped Woven Wire Screen Mesh; Anti-Clogging / Self-Cleaning Mesh (optional) |

| Material Options | High-Carbon Steel, Spring Steel (65Mn), Stainless Steel 304/316 (optional) |

| Weave / Crimp Type | Pre-crimp, Intermediate Crimp, Lock Crimp (selected by aperture & duty) |

| Opening Size (Aperture) | 2–150 mm (custom available) |

| Wire Diameter | Custom based on impact & abrasion duty |

| Open Area | Optimized by aperture & wire diameter to balance throughput and wear life |

| Panel Size | Custom per screen deck layout (panel or full-sheet options) |

| Edge Finish | Plain edges, Hooked edges, Reinforced edges (match your tensioning system) |

| Mounting / Tensioning | Clamp bar tensioning; bolt-down or other fixing options (as required) |

| Recommended Deck Position | Top deck (scalping), middle deck (sizing), bottom deck (final screening) |

| Recommended Duty | Heavy-duty quarry screening: scalping, sizing, and final classification |

| Typical Applications | Quarry crushing & screening plants, sand & gravel, mining aggregates, recycled aggregates |

| Customization | Aperture, wire diameter, crimp type, panel size, edge finishing, and material grade available upon request |

| Quotation Info Needed | Deck position, aperture (mm), wire diameter (mm), panel size (L×W), edge type, quantity, material type & dry/wet condition |

| Packing | Bundles or export pallets with protective wrapping; labeled by specification & order ID |

Why Choose Anpeng as Your Quarry Screen Mesh Manufacturer

As a direct manufacturer, Anpeng supplies quarry screen mesh built for high-impact, abrasive screening—with consistent openings, deck-fit customization, and reliable delivery to help you reduce downtime and keep production stable.

We make panels to your deck size and mounting system, including hooked edges, plain edges, or reinforced edges, so installation is smooth and fitment issues are minimized.

Controlled material selection and production help keep apertures consistent and the mesh structure stable, supporting predictable sizing and product gradation.

Tell us your deck position, cut size, and material condition. We’ll recommend a suitable mesh option and provide export-ready packing with dependable lead times.

FAQs

What is quarry screen mesh used for?

It is used on quarry vibrating screens to separate stone into different size fractions for scalping, sizing, and final product control.

Is quarry screen mesh the same as vibrating screen mesh?

In most quarry contexts, yes—“quarry screen mesh” commonly refers to the woven wire screen media installed on vibrating screens.

How do I choose the right opening size?

Start from your target cut size and product spec. Then adjust based on material shape, moisture, near-size content, and required grading stability.

What causes blinding and pegging?

Moisture, sticky fines (especially clay), and near-size particles commonly block openings. Anti-clogging/self-cleaning designs can reduce this problem.

What information do you need to quote?

Material, wet/dry condition, target aperture, deck size/drawing, mounting style, and deck position are usually enough to confirm specification and pricing.