Rubber Screens

Rubber screen panels are impact-absorbing screening media designed for vibrating screens in mining, quarry, aggregate, and recycling plants. If your top deck takes heavy hits, noise is a concern, or you’re fighting pegging and carryback in wet conditions, rubber screens are often a practical choice.

- Absorb impact and help protect the deck structure

- Lower operating noise compared with metal screens

- Flexible openings that can reduce pegging in coarse duty

- Modular panels for easier replacement and maintenance

What Are Rubber Screens?

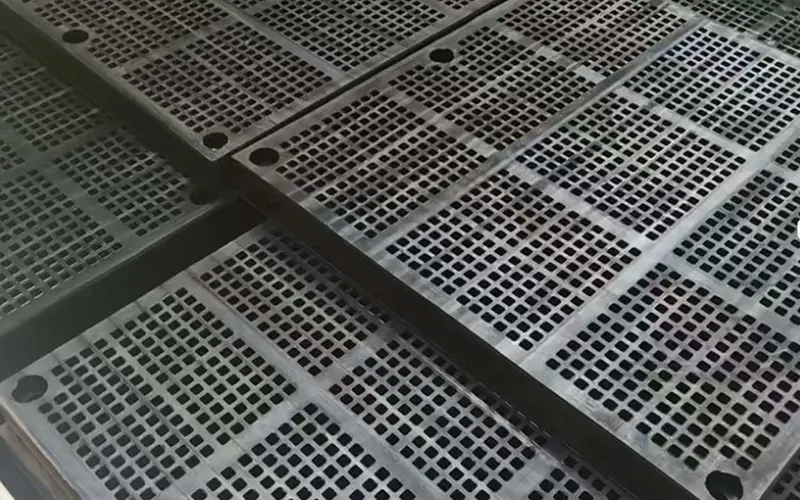

Rubber screens (also called rubber screen panels) are molded screening panels installed on vibrating screen decks. Instead of rigid metal wires, the screening surface is made from a rubber compound selected for durability and flexibility. In operation, the panel flexes under load, which helps absorb impact energy and can reduce material wedging in the openings.

Rubber screens are commonly used where the feed is aggressive (large lumps, high impact), where safety and noise reduction matter, and where a modular panel setup is preferred for maintenance.

Where Rubber Screens Work Best

Rubber screens are typically used in these duties:

Scalping / primary screening (top deck): handling large lumps and high impact

Coarse sizing: when you need rugged screening with stable performance

Wet screening circuits: where carryback, pegging, and buildup are common

Plants prioritizing lower noise and safer handling

If your main goal is maximum open area and very tight sizing, woven wire screens may be a better fit. If the goal is impact resistance and lower noise, rubber panels are often the better tool.

Key Benefits

Rubber helps cushion the strike from large rocks and heavy feed. This can reduce damage at the feed end and help the deck run more smoothly.

Rubber surfaces generally run quieter than metal wire screens or plate media, especially in coarse, high-impact zones.

Because rubber has some flexibility, near-size particles are less likely to wedge and stay stuck in the openings (depending on material shape and moisture).

Most rubber screen systems are built as panels. You can replace the high-wear area (often the feed end) without changing the entire deck.

Rubber panels are typically easier and safer to handle than sharp wire edges, especially during change-outs.

Why Choose ANPENG Rubber Screens?

built to handle impact, abrasion, and coarse-duty conditions in mining and aggregate plants.

panels are produced to match your screen deck layout and fastening system, helping reduce bypass and panel movement.

we recommend the right aperture style and panel design based on your material, moisture, target cut size, and throughput.

FAQs

Are rubber screens best for top deck or bottom deck?

Rubber is most commonly used on top decks and impact zones. For tight sizing on bottom decks, you may also compare woven wire or PU/urethane.

Do rubber screens work for wet screening?

They can, especially for coarse duties where carryback and pegging are concerns. Good sealing and correct opening choice are important.

Square vs slotted openings—how do I choose?

Square openings are common for general separation. Slotted openings can help flow and reduce pegging for certain particle shapes and conditions.

How do I confirm the fixing system?

You’ll need the screen model/deck layout and the current fastening style (bolt-down, pin & sleeve, rail/clip, etc.). Photos help.

When should I choose rubber instead of PU?

Choose rubber when impact is high and noise reduction matters. Choose PU/urethane when abrasion is high and sizing needs are tighter.

What information do you need for a quote?

Material type, moisture, target cut size, tph, screen model, deck layout, and current issues (wear, pegging, carryback, breakage).