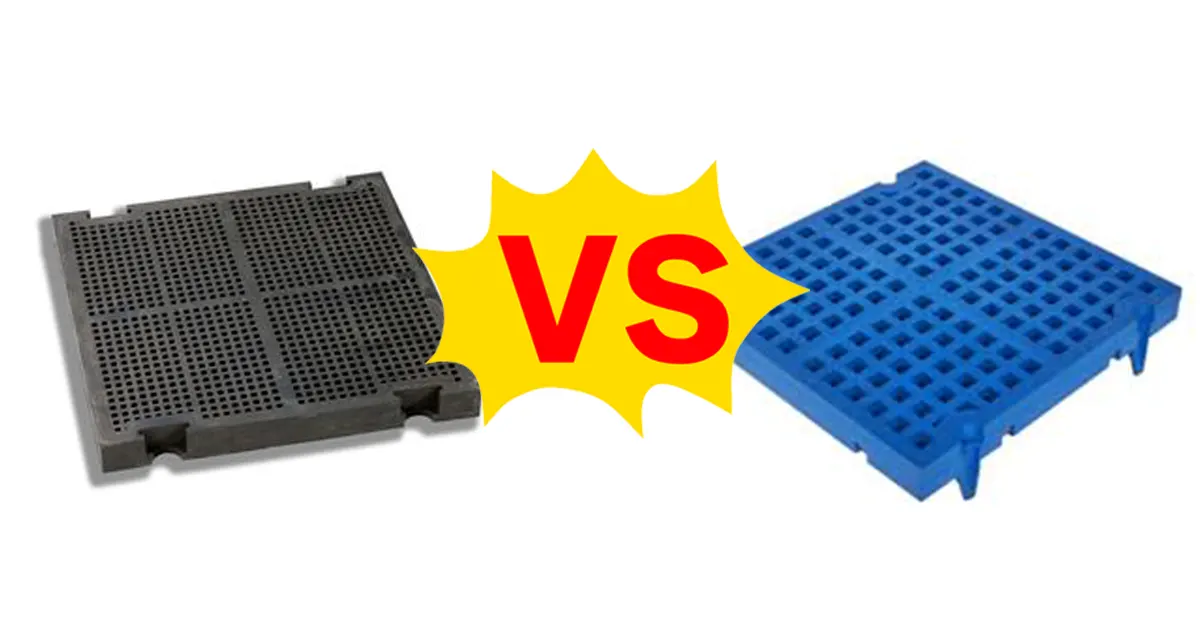

You may ask which one lasts longer, rubber screens vs polyurethane screens. In mining, new tests show that polyurethane screens can last up to six times longer than rubber screens. This is particularly true in tough and rough environments. The table below highlights the main differences:

| Feature | Rubber Screen Panel | Polyurethane Screen Plate |

|---|---|---|

| Material | Natural/synthetic rubber | Polyurethane elastomer |

| Wear Resistance | 3-6 months | 6-12 months |

| Impact Resistance | High | Stable, high tear strength |

| Corrosion Resistance | Moderate | Excellent |

You should choose rubber screens if you need something flexible and strong against impacts. However, polyurethane screens are better suited for rough jobs that require longevity. Anpeng offers both types, allowing you to find the best option for your plant.

Key Takeaways

- Polyurethane screens last much longer than rubber screens. They can last up to six times longer in hard jobs.

- Rubber screens bend easily and soak up hits well. This makes them good for heavy loads.

- Polyurethane screens are very tough against scratches and wear. They work well with rough and dry stuff.

- Use rubber screens for wet and sticky things. This helps stop clogging and blocking.

- Check both screen types often for damage or wear. This helps you avoid expensive breaks.

- Think about the starting price and how much you save later. Polyurethane costs more at first but lasts longer.

- Rubber screens are lighter and easier to put in. This saves time and work money.

- Pick the right screen for your job. This helps you get the best results and work better.

Durability Comparison: Rubber Screens vs Polyurethane Screens

When you look at rubber screens and polyurethane screens, you should think about how long they last in real life. Both have special strengths. How well they work depends on what you are screening and where you use them.

Wear and Abrasion Resistance

Rubber screen media and polyurethane screen media do not wear out the same way. Abrasion resistance means how well a screen can handle rough stuff rubbing against it. Polyurethane is very good at fighting abrasion, especially when things are really rough. Rubber also fights abrasion, but it wears out faster with sharp or rough materials.

Typical Wear Patterns

Rubber and polyurethane show different signs of wearing out. Rubber screens often get grooves and thin spots where lots of material passes. Polyurethane screens may get small pits or smooth areas, but they keep their shape longer. The table below shows how long each type lasts when things are rough:

| Screen Type | Average Service Life (Months) | Comparison to Woven Wire Panels |

|---|---|---|

| Polyurethane Screens | 6 to 12 | 10 to 15 times longer |

| Woven Wire Panels | 0.4 to 1.2 | Baseline |

Rubber screen media usually lasts three to six months. Polyurethane can last up to twelve months. This means you do not have to change them as often, so you save time and money.

Impact of Material Thickness

How thick the screen is matters for how long it lasts. Rubber screens are often thicker, so they can take bigger hits and do not tear as easily. Thick rubber panels can handle big rocks and heavy loads. Polyurethane screens use special elastomers that fight abrasion even when they are thinner. You get more open space for screening and still keep good durability.

Impact Resistance

Impact resistance means how well a screen can take hard hits or shocks. You want high impact resistance if you screen big, sharp, or heavy things.

Flexibility and Shock Absorption

Rubber screens are great at bending and soaking up shocks. Rubber can stretch and bend when hit, so it protects the screen deck. Polyurethane also has strong impact resistance, especially when makers add special ingredients. For example, polyurethane screens with 5% SEBS rubber additives are 40% better at taking hits. Polyurethane also has 42% higher tear resistance in ASTM D624 tests and can hold more than twice the weight of rubber. Polyurethane works well in fast screening jobs when it has 55% to 65% hard segments.

Tip: If your plant gets hit a lot, rubber screens give extra safety. Polyurethane is best when you need both abrasion and impact resistance.

Failure Modes

Knowing how screens break helps you pick the right one. Rubber screens and polyurethane screens break in different ways.

Tearing and Bolt Pull-Through

Rubber screens can tear if you use them with sharp or heavy stuff. Bolts can pull through if the rubber gets too thin. You should check rubber screens often to spot tears early. Polyurethane screens do not tear as easily because they are stronger and have a better structure. Polyurethane’s special makeup helps stop stress points and makes it harder to tear.

Delamination and Cracking

Polyurethane screens can sometimes have layers come apart under stress. They can also crack if hit over and over or if it gets very hot or cold. Rubber screens do not usually have layers come apart, but they can crack if they touch chemicals or sunlight for a long time. You should check both types often to find problems early.

Advantages of Each Material

- Rubber screens are very good at taking hits, bending, and fighting wear. They work well in tough places with lots of impacts.

- Polyurethane screen media is better at fighting abrasion, lasts longer, and works well in rough places.

When you pick between rubber screens and polyurethane screens, think about what you are screening, how often things hit the screen, and how rough the job is. You will get the best value and longest life if you match the screen to your plant’s needs.

Screening Performance: Polyurethane Screen Panels & Rubber Screen Media

When you pick a screen, you want it to work well. Polyurethane screen panels and rubber screen media both have special advantages. Let’s see how they do with throughput, accuracy, blinding, and noise.

Throughput and Open Area

Throughput is how much stuff goes through the screen in a certain time. Open area is the part of the screen that lets things pass. Polyurethane screen panels usually let more material through, especially when you need to move a lot fast.

| Material Type | Throughput Rate | Open Area Percentage |

|---|---|---|

| Polyurethane screen panels | 20-30% better than steel | Reduced compared to rubber |

| Rubber screen panels | Shorter lifespan | Reduced open area compared to polyurethane |

Polyurethane screen panels can last 12 to 18 months. Rubber screen panels wear out in 3 to 4 months. This means you do not have to stop your plant as often, and the screens work better for longer.

Cut Accuracy

Cut accuracy is how well the screen sorts different sizes. Rubber screen media takes hits well, which helps with big pieces. You can pick rubber with different hardness. Softer rubber bends more and stops blinding. Polyurethane gives very good accuracy, especially with small pieces. Thermoset polyurethane lasts a long time. Thermoplastic types are good for wet jobs.

Sizing Consistency

You want your screen to give the same size every time. Rubber screen panels bend under heavy loads, so sizing stays right even with big rocks. Polyurethane keeps its shape longer, so you get steady sizing for a long time.

Blinding and Clogging

Blinding is when stuff blocks the holes in the screen. Clogging is when the holes fill up and stop working. Polyurethane has a surface that does not like water, so it blocks less and clogs less. Rubber screen panels soak up some water, which can cause more blinding.

| Material Type | Open Area | Blinding Issues | Clogging Issues |

|---|---|---|---|

| Rubber | 40% to 60% | Higher frequency | Increased maintenance |

| Polyurethane | 70% to 85% | Drastically reduced | Significantly lower |

Wet vs Dry Material Handling

Rubber screen panels are best for wet, sticky, or clay-filled stuff. They take hits and wear well, so they are good for tough mining jobs. Polyurethane is best for fine, dry material and helps you move more material faster.

Tip: If you work with sticky or wet stuff, rubber screen panels help stop blinding. For dry, fine material, polyurethane works better.

Vibration and Noise Absorption

You want your plant to be quiet and safe. Rubber screen panels make less noise, about 10 to 15 decibels less than metal screens. This makes your plant much quieter. Rubber bends and takes in vibration and shocks. Polyurethane also helps with noise, but rubber is best for noise and vibration control.

Cost and Value: Polyurethane Screen Media vs Rubber

Initial Cost vs Long-Term Value

When you choose a screen for your plant, you want to know how much it costs and how long it will last. Rubber screen media usually costs less at first. Polyurethane screen media costs more, but it gives you better long-term reliability. You spend more money at the start for polyurethane, but you save money over time because you do not need to replace it as often.

Here is a table that shows the difference in cost and value:

| Screen Type | Initial Cost | Average Life (months) | Tons Processed | Cost Per Ton |

|---|---|---|---|---|

| Rubber | $100 | 8 | 10,000 | $0.01 |

| Polyurethane | $130 | 24 | 40,000 | $0.003 |

If you invest in polyurethane, you usually get your money back in about 18 to 24 months. Over five years, you can save up to 160% compared to rubber. You spend less on maintenance and replacement, so your plant runs better.

Tip: Polyurethane screen media helps you save money in the long run, even though you pay more at first.

Replacement Frequency

You want your screen to last as long as possible. Rubber screen media needs to be replaced more often than polyurethane. If you use rubber, you may need to change it every 4 to 8 months. Polyurethane can last 24 to 36 months before you need a new one.

Here is a table that shows how often you need to replace each type:

| Screen Type | Replacement Frequency |

|---|---|

| Polyurethane Screen | 24-36 months |

| Rubber Screen | 4-8 months |

If you use rubber, you spend more time and money changing screens. Polyurethane lets you focus on your work and not worry about replacing screens so often.

Cost per Ton Processed

You want to know how much it costs to process each ton of material. Rubber screen media costs about $0.01 per ton. Polyurethane costs only $0.003 per ton. This means you save money every time you process material.

- Rubber screen media gives you a lower upfront cost, but you pay more over time.

- Polyurethane screen media gives you better long-term reliability and lower cost per ton.

- Polyurethane helps you process more material before you need a new screen.

Note: If you want to lower your costs and keep your plant running longer, polyurethane is the better choice.

You should think about how often you want to change screens and how much you want to spend over time. Rubber works well if you need a quick, low-cost solution. Polyurethane is best if you want long-term reliability and lower costs.

Maintenance and Handling

Installation and Panel Weight

You want your screen panels to be easy to use. Rubber screens make installation simple and fast. You can put in rubber panels quickly. This helps you save money on labor. The panels are light, so you do not need big machines to lift them. This makes your work safer and faster.

Here is a table that shows how rubber screens compare to other options:

| Material | Installation Time | Weight |

|---|---|---|

| Rubber Screens | 50-60% shorter | 50-70% lighter |

| Polyurethane Screens | N/A | N/A |

Rubber panels usually weigh only 4.5 kg each. You can carry them easily and your screening machine does not get too heavy. Polyurethane screens are also easy to handle, but rubber panels are lighter and faster to install.

- Modular rubber panels help you finish maintenance fast.

- Light screens lower the chance of getting hurt and keep your plant safe.

Polyurethane screens last longer than woven wire screens. Their flexible design helps stop clogging and blinding. This means you spend less time fixing problems.

Cleaning and Maintenance Tips

You want your screens to last a long time. Good cleaning and care help you get the most from your screens.

Preventing Plugging

Plugging happens when stuff blocks the holes in your screen. You can stop this by picking screens with flexible surfaces. Polyurethane screens do not clog easily because of their design. Rubber screens also help, especially with sticky or wet stuff.

Tip: Clean your screens often to keep holes open. Use water or air to clear stuck material. Flexible screens shake off debris and keep your plant working well.

Inspection and Replacement

Checking your screens often keeps them working well. You should look for loose parts, tears, or cracks. Make sure the screen fits tight on the frame. If you see damage, change the panel right away to stop bigger problems.

To make screens last longer, install them with even tension. Tighten all parts well. Use new polyurethane tape if you need more shock absorption. Check your screens often to find wear early.

- Check screens every week for signs of wear.

- Change broken panels fast to stop downtime.

- Use the right way to install screens so they do not break early.

Taking care of your screens helps you avoid big repairs and keeps your plant safe. When you follow these steps, both rubber and polyurethane screens last longer.

Safety and Work Environment

Noise Reduction

You want your worksite to be safe and quiet. Loud machines can make people stressed or hurt their hearing. Picking the right screen media helps lower noise and makes work better for everyone.

Rubber and polyurethane screens are quieter than steel screens. Polyurethane screens can make noise more than 10 decibels lower. This change makes your plant sound and feel nicer. When there is less noise, you can talk without yelling. You also feel less tired after work.

- Polyurethane screens lower noise by over 10 dB compared to steel.

- The elastic material soaks up vibrations, so machines are quieter.

- Less noise helps stop hearing loss and lowers stress.

Rubber screens also help with noise. They soak up shocks and stop loud banging. Using rubber or polyurethane screens makes your plant safer.

Tip: If you want a quieter plant, pick rubber or polyurethane screens. Your team will like working in a quieter place.

Operator Safety

You need to keep your team safe at work. Heavy screens and loud machines can cause injuries. Rubber and polyurethane screens help lower these risks.

Rubber screens weigh less than steel screens. You can lift and put them in without special tools. This means you are less likely to hurt your back or have accidents. Polyurethane screens are also lighter than steel, so they are easier to move.

- Lighter screens put less strain on your body.

- Flexible materials help stop cuts and scrapes when you install them.

- Both rubber and polyurethane screens soak up impacts, so flying debris is less likely.

You also have fewer slips and trips. Rubber and polyurethane screens do not have sharp edges or loose wires. You can walk around the plant more safely.

Note: Check your screens often for wear or damage. Change broken panels fast to keep everyone safe.

A safer worksite helps your team stay healthy and focused. When you pick the right screen media, you protect your workers and help your plant do better.

Best Uses: When to Choose Rubber or Polyurethane Screens

Scalping, Sizing, and Final Decks

You need the right screen for each job in your plant. Scalping, sizing, and final decks all do different things. Scalping screens take out big rocks before they reach other machines. Sizing screens sort stuff by size. Final decks give you clean and finished products.

Here is a table that shows the main types of screens and what they do:

| Screen Type | Application Description |

|---|---|

| Grizzly (Scalping) Screens | Used as the first stage in mining to remove oversized rocks, protecting downstream equipment. |

| Vibrating Screens | Versatile screens for stratifying materials; inclined for coarse aggregates, horizontal for fine aggregates. |

| High-Frequency Vibrating Screens | Ideal for fine-particle grading, operating at high RPM for efficient separation. |

| Trommel (Rotary) Screens | Excellent for screening topsoil or wet materials, featuring a rotating drum for gentle handling. |

Rubber screens are good for scalping because they can take big hits. Polyurethane works well for sizing and final decks. It is best when you need fine sorting and long-lasting screens. When you pick rubber screens or polyurethane screens, think about what each deck does.

High Impact vs High Abrasion

You should look at what kind of force your screen will face. Some decks get hit hard by big rocks. Other decks wear down from lots of rubbing.

Here is a table that shows how rubber and polyurethane work:

| Screen Type | High-Impact Performance | High-Abrasion Performance |

|---|---|---|

| Polyurethane | Excellent, with longer wear life in wet conditions | Superior abrasion resistance, lasting 2-6 times longer than steel wire mesh |

| Rubber | Designed for extreme impacts, high efficiency | Effective in high abrasion environments, quick screen change capabilities |

- Polyurethane gives great abrasion resistance. It lasts longer, especially when things are wet. This screen can last two to six times longer than steel wire mesh.

- Rubber screens are made for big impacts. They work fast and are easy to change. These screens are good for tough jobs like mining and coarse screening.

Both rubber screens and polyurethane screens have their own strengths. Use rubber if you need to handle big hits. Polyurethane is better if you want your screen to last longer and have less downtime.

Wet/Sticky vs Dry Material

You need to think about what kind of material you are screening. Wet and sticky stuff can block your screen. Dry materials move faster and do not stick as much.

Here is a table that shows the best choices:

| Material Type | Screening Method | Characteristics |

|---|---|---|

| Dry, Free-Flowing | Dry Screening | Uses regular vibrating screens for quick results. |

| Wet, Sticky | Wet Screening | Needs special tools to stop plugging. |

- High-frequency screens are good for wet fine sand and clay.

- Incline screens help with wet stuff because they stop sticking.

- Rinsing screens use water to wash small pieces through.

- Banana screens help materials spread out and separate better.

Rubber screens are good for wet and sticky materials. They do not plug up easily and keep your plant working. Polyurethane is best for dry, free-flowing materials. You get fast results and less clogging.

When you choose between rubber screens and polyurethane screens, think about your material and what your plant needs. This helps you get better results and longer screen life.

Application Checklist

You want to choose the right screen for your plant. Use this checklist to help you decide between rubber screens and polyurethane screens. Look at your job, your material, and your plant’s needs.

| Criteria | Rubber Screens | Polyurethane Screens |

|---|---|---|

| Screening Type | Coarse jobs need thicker panels for impact | Fine jobs need thinner panels for accuracy |

| Hardness Rating | Softer (40-50 Shore A) gives more flexibility | Harder (60+ Shore A) resists abrasion |

| Screening Environment | Softer works best in wet operations, stops blinding | Harder lasts longer in dry operations |

Checklist Steps:

- Check your material size.

If you screen big rocks or heavy loads, rubber screens work best. If you screen small or fine material, polyurethane screens give better results. - Test your plant’s environment.

Wet and sticky jobs need rubber screens. Dry and abrasive jobs need polyurethane screens. - Look at your deck type.

Use rubber screens for scalping decks. Use polyurethane screens for sizing and final decks. - Pick the right hardness.

Softer screens bend and flex. Harder screens last longer and fight wear. - Think about maintenance.

If you want fast changes and easy handling, rubber screens help. If you want less downtime and longer life, polyurethane screens work better.

Tip: Write down your plant’s needs before you choose. Match your screen type to your job for the best results.

Quick Questions to Ask Yourself:

- Do you need to handle big impacts or heavy loads?

- Is your material wet, sticky, or dry?

- Do you want longer screen life or easier maintenance?

- Are you screening coarse or fine material?

You can use this checklist to make a smart choice. The right screen helps your plant run better and saves you money.

Quick Selection Guide

Selection Checklist

You need to pick the best screen for your plant. This checklist helps you choose between rubber and polyurethane screens:

- Look at your material’s size and weight. Rubber screens are good for big, heavy pieces. Polyurethane works well with smaller materials.

- Think about how rough your material is. If it is very rough, you need screens that last longer. Polyurethane screens fight wear very well.

- Check how often you want to do maintenance. Rubber screens do not need fixing as much, so you save time. Polyurethane screens last longer, so you change them less.

- Decide what size openings you need. Rubber screens are best for holes bigger than 4 inches. Polyurethane screens can fit many different sizes.

- Think about your budget. Rubber screens cost less at first. Polyurethane costs more but lasts longer, so you save money later.

- Plan how you will install your screens. Both types are easy to put in. Setting them up right helps them work better.

Tip: Write down what your plant needs before you pick a screen. The right choice saves money and keeps your plant working well.

Comparison Table

This table helps you compare rubber and polyurethane screens. It makes it easy to see which one is best for you.

| Criteria | Rubber Screen Media | Polyurethane Screen Media |

|---|---|---|

| Impact Resistance | Excellent | Good |

| Abrasion Resistance | Good | Excellent |

| Noise Reduction | Very high | Moderate to high |

| Wet Applications | Limited effectiveness | Excellent |

| Throughput | Higher for coarse sizing | Better for fines and sticky feed |

| Cost | Lower upfront | Higher upfront, longer ROI |

| Maintenance | Moderate replacement frequency | Fewer replacements required |

| Customization | Flexible (hooks, bolt-down mats) | Wide modular and hybrid options |

Polyurethane screens fight wear better and work great when things are wet. Rubber screens take hard hits and make less noise. Pick the one that matches your material, your plant, and your budget.

Why Choose Anpeng

Three Key Benefits

When you choose Anpeng for your screening media, you get more than just a product. You get a partner who helps your plant work better and faster. Anpeng stands out because of three main benefits. You can see these benefits in the table below:

| Benefit | Description |

|---|---|

| Scale & Capacity | 345,000 sq ft facility with 35 production lines for rapid delivery. |

| Diverse Innovation | Cross-industry expertise drives continuous advancement in screen design and materials. |

| Stringent QC | ISO-certified. ±3% aperture tolerance (tighter than industry norm) ensures consistency. |

1. Scale & Capacity

You want your screens delivered on time. Anpeng has a huge facility, covering 345,000 square feet. With 35 production lines, you get your order quickly. You do not have to wait long for new screens. This helps you keep your plant running without delays.

Tip: Fast delivery means less downtime for your plant. You can plan your work better and avoid waiting for parts.

2. Diverse Innovation

You need screens that fit your job. Anpeng uses knowledge from many industries. This helps them create new designs and better materials. You get screens that work well for mining, aggregates, and other tough jobs. Anpeng always looks for ways to improve, so you get the latest technology.

- You get access to new screen shapes and materials.

- Your plant can handle more types of material with fewer problems.

3. Stringent Quality Control

You want screens that work the same every time. Anpeng uses strict quality checks. Their screens meet ISO standards. The holes in the screens stay within ±3% of the size you need. This is tighter than most other companies. You get screens that sort your material right every time.

Note: Consistent quality means you get the same results every day. You do not have to worry about mistakes or poor sorting.

Choosing Anpeng gives you fast delivery, new ideas, and reliable quality. You can trust your screens to last longer and work better. Your plant stays productive, and you save money over time.

Request a Quote

If you want the best screen for your plant, you need to give the right details. This helps Anpeng give you a fast and accurate quote. You can follow the steps below to make the process easy.

What to Provide

You should collect some key facts before you ask for a quote. These details help Anpeng understand your needs and suggest the best screen for your job. You can use the table below as a checklist:

| Requirement | Description |

|---|---|

| Panel Material | Choose PU (polyurethane) or rubber |

| Aperture | Tell the size of the openings in the screen |

| Opening Type | Pick the type (square, round, etc.) |

| Thickness | Give the thickness of the screen material |

| Module Size | Share the size of the screen module |

| Fixing System | Explain how you will secure the screen |

| Quantity | State how many screens you need |

| Material Condition | Describe if your material is dry, wet, or sticky |

| Additional Info | Add photos or measurements of old panels |

Tip: Take clear photos of your current screens. Write down all measurements. This helps Anpeng match your needs and avoid mistakes.You should also think about your plant’s working conditions. If you screen wet or sticky material, let Anpeng know. If you have special needs, add them in your message.

Conclusion

You can see clear differences between rubber and polyurethane screens. The table below shows how each type fits different jobs:

| Criteria | Rubber Screen Panels | Polyurethane Screen Panels |

|---|---|---|

| Best Use | Medium-hard, dry or slightly wet materials | High-hardness, wet or sticky materials |

| Wear Life | 3–6 months | 6–12 months |

| Cost | Lower upfront | Lower long-term |

You should match your screen to your plant’s needs. Anpeng helps you choose the right panel design and wire mesh for better results. Send your screen deck details to Anpeng for a fast quote and expert advice.

FAQ

What is the main difference between rubber and polyurethane screens?

Rubber screens absorb impacts well. Polyurethane screens resist abrasion better. You should choose rubber for heavy hits. You should pick polyurethane for longer wear life.

Can I use polyurethane screens for wet materials?

Yes, you can use polyurethane screens for wet or sticky materials. The smooth surface helps prevent clogging. You get better performance with less cleaning.

How often should I inspect my screen panels?

You should inspect your screen panels every week. Look for tears, cracks, or loose bolts. Early checks help you avoid bigger problems.

Which screen type is easier to install?

Rubber screens are lighter and easier to handle. You can install them quickly without special tools. Polyurethane screens also offer modular designs for fast setup.

Do rubber screens reduce noise in my plant?

Yes, rubber screens lower noise levels. You get a quieter work environment. Your team feels less stress and stays safer.

How do I choose the right screen for my application?

Write down your material type, deck position, and maintenance needs. Use the selection checklist in this guide. Match your screen to your plant’s job for best results.