To pick the right sand screen mesh size, you need to match the mesh openings to the material and how you will use it. This helps you get the best filtration. Research shows the right mesh lets small particles go through. Bigger particles stay on the screen. The screen moves to stop clogging. This keeps the process steady. If you know about mesh size, how to measure it, and particle size, you can make filtration and production better.

- Vibrating screens sort particles by size. This makes things work better.

- The right mesh count and pore size help the process stay steady and accurate.

Key Takeaways

- Pick the right sand screen mesh size for your material and use. This helps you get the best filtration.

- Mesh size shows how many openings are in one square inch. If the mesh number is higher, the openings are smaller.

- You can measure mesh size by counting the openings in one inch. Use rules like ASTM or ISO to be sure you are correct.

- There is an opposite link: higher mesh numbers stop bigger particles. They let smaller ones go through.

- Choose mesh size by the smallest particle you want to block. This makes your filtration work well.

- Think about flow rate. Finer mesh makes flow slower. You need to balance good filtration with how fast your process goes.

- Use a checklist to help you pick the mesh. Make sure you look at the material and what you need for your use.

- Try your mesh in your system. Change it if you need to keep things working well and stop clogs.

What Is Sand Screen Mesh Size?

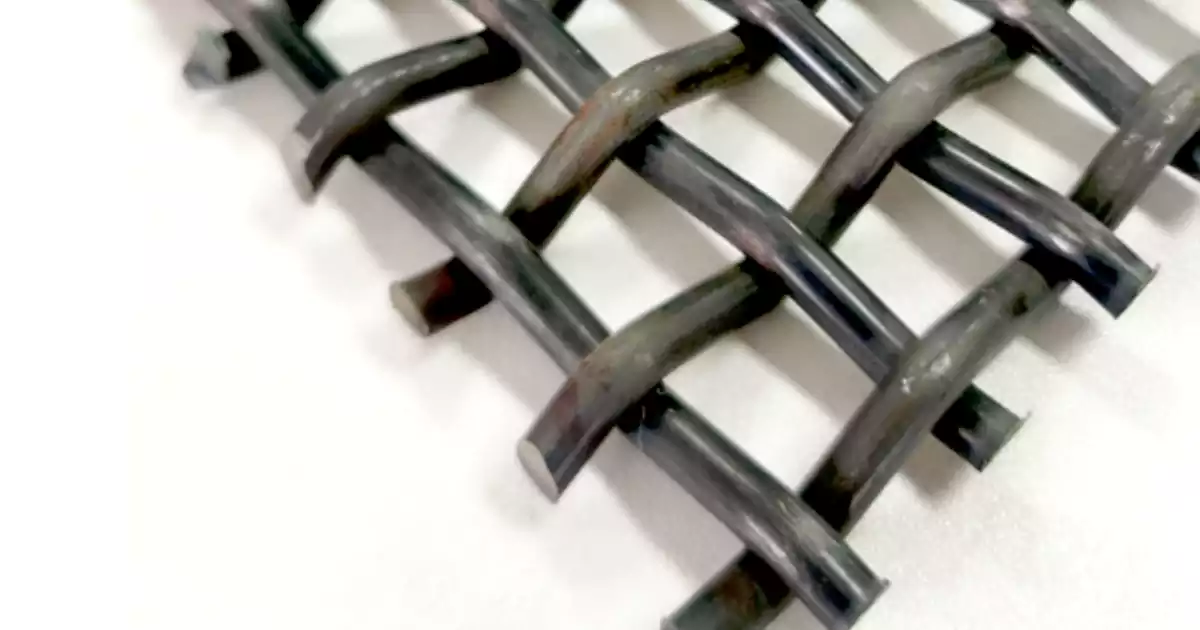

Mesh Size Definition

You need to understand what sand screen mesh size means before you can choose the right one. Sand screen mesh size tells you how many openings exist in one square inch of a screen. These openings let certain particles pass through while blocking others. The mesh count describes the number of spaces or holes in the screen. When you use a screen with a higher mesh count, you get smaller openings. This means only smaller particles can pass through. A lower mesh count gives you larger openings, so bigger particles can move through the mesh.

Mesh size plays a key role in many industries. You see it in oil and gas, construction, and water filtration. Each application needs a different mesh count to work well. If you pick the right mesh, you protect your equipment and improve your process.

Tip: Accurate mesh count selection helps you avoid clogs and keeps your system running smoothly.

How Mesh Size Is Measured

You measure mesh size by counting the number of openings in one linear inch of the screen. This is the mesh count. For example, if you have a mesh with 50 openings in one inch, the mesh count is 50. You can use different standards to measure mesh count and mesh size. The most common standards include:

- ASTM E2016: This standard covers wire mesh for screening materials and measuring particle size.

- ASTM E437: This standard sets grades for square mesh based on mesh count and wire diameter.

- ISO 9044:1999: This standard uses metric specifications for mesh aperture and grade tolerances.

You need to use the right standard for your industry. Accurate mesh count measurement ensures you get the right product quality and process efficiency. When you use the correct mesh size, you separate materials precisely and protect your machinery from debris. This is very important in chemical manufacturing, where you need specific particle sizes.

Mesh Size Numbering

The mesh size numbering system uses the mesh count to tell you how many openings are in one square inch of the screen. For example, a 36 mesh screen has 36 openings per inch. A 150 mesh screen has 150 openings per inch. As the mesh count increases, the openings get smaller. Only smaller particles can pass through a high mesh count screen. If you use a lower mesh count, you get larger openings, so bigger particles can pass.

You will find different mesh counts used for different jobs. Here is a table that shows common mesh sizes and where you might use them:

| Mesh Size | Application |

|---|---|

| 8×16 | Process water and wastewater systems |

| 12×20 | Drinking water filters |

| 16×30 | Industrial-scale water filters |

You should always match the mesh count to your material and your application. This helps you get the best results and keeps your process efficient.

Mesh Size vs Particle Size

Inverse Relationship

When you look at mesh size vs particle size, you see an important pattern. As the mesh number goes up, the openings in the screen get smaller. This means only smaller particles can pass through. Larger mesh numbers block bigger particles. If you use a lower mesh number, the openings are larger, so bigger particles can move through. You need to remember this inverse relationship when you choose a screen for your process.

Note: Mesh size vs particle size always works in opposite directions. A higher mesh number means a smaller particle size can pass.

Practical Implications

Understanding mesh size vs particle size helps you make better choices for your operation. If you pick the wrong mesh, you might let unwanted particles through or block too much material. The type of screen you use also matters. For example, wire-wrapped sand screens do not change much when you adjust the mesh size or particle size. Premium screens, on the other hand, react more to these changes. This means you must think about both the mesh size vs particle size and the type of screen you use.

A study shows that the range of particle sizes that can pass through a sand screen depends on the mesh size and the screen type. If you want to improve screening efficiency, you need to match the mesh size vs particle size to your material. This helps you get the best results and keeps your process running smoothly.

Mesh Size Examples

You can see how mesh size vs particle size works by looking at common mesh sizes. Here is a table that shows typical particle size ranges for two popular mesh sizes used in industry:

| Mesh Size | Particle Size Range (microns) | Median Diameter (microns) |

|---|---|---|

| 40/70 | 40 – 70 | 55 |

| 100 | 10 – 20 | N/A |

If you use a 40/70 mesh, you allow particles between 40 and 70 microns to pass through. If you use a 100 mesh, only particles between 10 and 20 microns can pass. This shows how mesh size vs particle size affects your results. You need to pick the right mesh for your material and your application.

Tip: Always check the mesh size vs particle size before you start your project. This helps you avoid problems and keeps your system efficient.

Mesh Size and Micron Measurement

What Is a Micron?

Before you compare mesh and micron sizes, you need to know what a micron is. A micron is also called a micrometer. It is one millionth of a meter. People use microns to show how big particles are that can go through screen openings. For example, a filter with a 150-micron rating stops particles bigger than 150 microns. Smaller particles can pass through. Picking the right micron size is very important for filtration systems. If you choose the right micron size, your equipment stays safe and your product stays clean. In oil filtration, a 100-micron strainer catches large dirt and keeps machines safe. This helps you save money on repairs. Micron size is also used in water treatment, food making, and medicine. Filters with a 1-micron rating catch harmful bacteria. This makes water safe to drink.

- Picking the right micron size keeps your product good in food and medicine.

- The right micron size stops contamination in sensitive places like semiconductors.

- You should match mesh size and micron size to your job for the best results.

Mesh Size to Micron Conversion

You may need to change mesh size to micron size when you pick a screen. Mesh size tells you how many holes are in one inch of the screen. Micron size tells you how big those holes are. There is no official formula to change mesh to micron, but you can use an estimate: Micron = 14900 / Mesh. For example, a 60 mesh screen has holes about 248 microns wide. This helps you pick the right screen for your needs. You use mesh and micron sizes together to get the best filtration.

Tip: Always check both mesh size and micron size before you buy a screen. This helps you keep your product good and your equipment safe.

Here is a table that shows common standards and ways to convert:

| Standard | Description |

|---|---|

| ASTM E11 | Standard Specification for Wire Cloth and Sieves for Testing Purposes |

| ISO 3310-1 | Test sieves – Technical requirements and testing Part 1: Metal wire cloth |

| ISO 565 | Test sieves — Nominal sizes of openings |

| Conversion Formula | Micron = 14900 / Mesh |

Industry Standards (ASTM, ISO)

You need to know the rules for mesh and micron measurement. ASTM standards use the American system. ISO standards use the metric system. The metric system is used more around the world. Both standards help you measure sieve openings and screen holes the right way. ASTM E11 and ISO 3310-1 give the rules for wire cloth and test sieves. USP and IP also give sieve numbers and mesh sizes for tests. The standards make sure you get the right opening size, wire thickness, and measurement limits.

| Standard | Aperture Size | Wire Diameter | Measurement Tolerances |

|---|---|---|---|

| ASTM | 3/8 in | Identical | Identical |

| ISO | 9.5 mm | Identical | Identical |

You should always use the right standard for your industry. This helps you get the best results and keeps your process working well.

How to Choose the Right Mesh Size

Identify Material and Application

First, you need to know what material you want to separate. You also need to know how you will use your filter. Different materials need different screens. For example, soil and rocks are heavy. They need strong screen decks or panels. Fine mesh is not good for heavy loads. If you work with coal, use polyurethane or rubber screen panels. These help particles bounce and leave the screen better. Wet or clay-rich materials can clog mesh or bar screens. Grates or tough panels work better for these. When you screen wood chips, you need very strong screen media. Good sealing helps stop blockages. If you have very large pieces, stepped hole plates stop blockages better than mesh.

You should also think about the environment and what you want to remove. Start by checking your material to see what contaminants are in it. Find out the size of these particles. Use a conversion chart to match particle sizes with the right sand screen mesh size. This helps you pick a filter that fits your needs and keeps your process working well.

Filtration Efficiency Needs

Filtration efficiency is important when you pick sand screen mesh size. The mesh size you choose decides what size particles your filter can catch. Finer screens trap smaller particles and make water cleaner. If you want to remove fine sand, silt, or organic debris, you need a finer mesh. In water treatment plants, the right mesh size helps clean water better.

| Aspect | Details |

|---|---|

| Filtration Efficiency | The mesh size determines the size of particles that can be effectively removed from water. |

| Particle Size Range | Finer screens capture smaller particles, enhancing water quality. |

| Problematic Particles | Fine sand, silt, and organic debris are effectively filtered out with appropriate mesh sizes. |

| Screen Construction | Multi-layer diffusion-bonded construction maintains pore geometry for optimal filtration. |

| Cleaning Process | Smooth surface design minimizes particle embedding, optimizing efficiency and facilitating cleaning. |

You should always balance filtration efficiency with flow rate. If you use a very fine mesh, you might block too many particles. This can slow down your process. The right filter mesh size lets you remove bad particles and keeps your system running well.

Flow Rate and Material Properties

Flow rate and material properties change your choice of sand screen mesh size. Mesh size affects how fast liquid or air moves through your filter. A finer mesh slows down the flow and raises pressure drop. If you use a mesh screen, you may get more sand production and higher pressure drop than with wire-wrapped screens. Slot width and fluid flow rate also change how much sand passes through. They also affect how particles bridge on slotted liners.

You need to think about your material’s properties. Abrasive materials need strong screens. High moisture can cause clogging. Fine particles may need a filter with a smaller micron rating. Always test your filter choice. Install the filter and watch how it works. Change it if you need to. Do regular maintenance to keep your filter working well.

Tip: Always match your filter mesh size to your material, application, and system needs. This helps you get the best filtration and keeps your process efficient.

Selection Checklist

A checklist helps you pick the right sand screen mesh size. It stops mistakes and keeps things working well. Use these steps each time you choose a mesh:

- Know Your Material

First, find out what kind of particles you want to filter. Check their size. If you can, do a particle size test. - Define Your Application

Decide if you want to separate, filter, or protect equipment. Each job may need a different mesh size. - Set Filtration Goals

Pick the smallest particle you want to remove. Match this to the mesh size and micron rating. - Check Flow Rate Needs

Make sure the mesh lets enough liquid or air pass. Finer mesh slows flow but catches smaller particles. - Consider Material Properties

Think about if your material is wet, sticky, or rough. Choose a mesh that will not clog or wear out fast. - Select Sieve Type for Accuracy

There are different sieve types. Each one gives a different accuracy. Use the table below to compare them:Sieve TypeDescriptionConfidence LevelCompliance SieveStandard sieves with measured openings; includes a certificate of conformance.66%Inspection SieveSpecified openings and wire diameters measured; statistical calculations confirm accuracy.99%Calibration SieveHighest accuracy with more openings measured; used for calibrating other sieves.99.73% - Verify Standards Compliance

Make sure your mesh meets rules like ASTM or ISO. This keeps quality and makes sure it works the same every time. - Test and Adjust

Put in the mesh and watch how it works. Change the mesh size if you see clogs, slow flow, or wrong particles getting through.

Tip: Always write down your mesh choices and results. This helps you get better at picking mesh over time.

Use this checklist every time you pick a sand screen mesh. It helps you make good choices and keeps your system working well.

Common Mesh Size Misconceptions

Understanding sand screen sizing can be confusing. Many people make mistakes when they choose or compare screens. You can avoid problems if you know the most common misconceptions.

Mesh vs Micron

You may think mesh size and micron rating mean the same thing. They do not. Mesh size tells you how many openings fit in one square inch of screen. Micron rating measures the distance between the wires or filter media. These two numbers do not always match up. Many people believe a certain mesh size will always filter out the same size particles as a certain micron rating. This is not true. The shape and weave of the screen can change the actual opening size. You need to check both numbers before you pick a screen.

Note: Confusing mesh size with micron rating can lead to poor filtration and equipment damage.

Mesh Number Meaning

You might think the mesh number always tells you the exact size of particles that can pass through. This is not always the case. The mesh number shows the number of openings per inch, but the actual opening size can change based on the wire thickness and screen design. Some manufacturers list a 50% cut size or median size. This number does not show the largest particle that can pass through. You should always ask for the maximum particle size if you need precise filtration.

Here are some common misunderstandings about mesh numbers:

- The mesh number always equals the opening size (it does not).

- All screens with the same mesh number have the same opening size (they can differ).

- The mesh number tells you the largest particle that will pass (it usually shows the median size).

One Size Fits All Myth

You may hear that one mesh size works for every job. This is not true. Each application needs a different screen. The type of material, the size of the particles, and the process all affect which screen you should use. Creative screen designs can also change how well a screen works. The API 13C scheme asks manufacturers to test screens with certain particles, but the results may not match your needs. You should always test screens in your own system.

Here is a simple checklist to avoid the “one size fits all” mistake:

- Check your material and particle size.

- Review your process needs.

- Compare both mesh size and micron rating.

- Test the screen before full use.

Tip: Always match your screen to your specific job for the best results.

Application Examples

Construction Sand

When you work with construction sand, you must pick the right screen. The mesh size depends on how big the sand pieces are and what you need to separate. If you use a coarse mesh like 14 mesh, it takes out big pieces of dirt or rocks. Medium mesh sizes, such as 28 or 60 mesh, help you get cleaner sand. Fine mesh sizes, like 100 mesh, are good for jobs that need very clean sand. The table below shows some common mesh sizes and what they are used for in construction sand:

| Sieve Mesh # | Inches | Microns | Typical Material |

|---|---|---|---|

| 14 | .0555 | 1400 | – |

| 28 | .028 | 700 | Beach Sand |

| 60 | .0098 | 250 | Fine Sand |

| 100 | .0059 | 150 | – |

| 200 | .0029 | 74 | Portland Cement |

| 325 | .0017 | 44 | Silt |

| 400 | .0015 | 37 | Plant Pollen |

You can see that big mesh sizes take out large pieces. Small mesh sizes catch tiny bits. This way, you can make sure your sand is good for concrete, mortar, or special sand jobs. Always pick the mesh size that fits your project to get the best results.

Water Filtration

You need to use the right screen in water filters to clean water well. Fine mesh filters with holes between 100 and 300 microns are good for catching small things in water. These screens are often made from 316 stainless steel, which is strong and does not rust. For big water filters that need fast flow, you can use mesh sizes between 500 and 1000 microns. The table below shows some common mesh sizes for water filters:

| Mesh Size (Microns) | Application | Material Used |

|---|---|---|

| 100 – 300 | Fine filtration for small particles | 316 Stainless Steel Fine Mesh |

| 500 – 1000 | Industrial filtration with higher flow | 500-Micron Stainless Steel Mesh |

Pick the mesh size by thinking about the smallest thing you want to remove. If you need to catch fine sand or silt, use a screen with a smaller micron number. If you want faster water flow and do not need to catch tiny things, use a bigger micron size. This helps your water filter work well and keeps other machines safe.

Custom Solutions

Sometimes, you have special problems and need custom mesh screens. Polyurethane screen mesh works well in mining, chemical, and sand plants. This kind of mesh does not wear out fast and can handle strong chemicals. It helps your machines last longer and saves money. You can also get custom mesh for jobs like making concrete, sorting rocks, or recycling. Companies like Anpeng make many types of screens to fit what you need.

- Polyurethane mesh works well in tough places and makes screening better.

- Custom mesh filters help fix special problems in mining, recycling, and making concrete.

Industry stories show you must look at how big the sand pieces are before you pick a screen. For example, a 200-micron wire-wrapped screen worked well in tests. It kept sand in and let water move through. Always check your material and how you use it to pick the best mesh size and type. This helps you get better results and stops machine problems.

Tip: Custom mesh screens help you follow rules and change when your project needs something new.

Conclusion

Picking the right sand screen mesh size means you must think about particle size, how fast things need to flow, and what your material is like. You should:

- Figure out what size particles you want to take out.

- Choose the biggest mesh that still works for your job.

- Try out the mesh and change it if it gets blocked or slows down.

- Ask experts for help if you need a special solution.

Knowing about mesh size, how to measure it, and how to use it helps you not make expensive mistakes. As a sand screen mesh maker, we have many mesh sizes and can give advice to help you get good, low-cost screening.

FAQ

What does mesh size mean for sand screens?

Mesh size tells you how many openings fit in one inch of the screen. A higher mesh number means smaller openings. You use mesh size to control what particles pass through and what stays out.

How do you convert mesh size to microns?

You can estimate using this formula:Micron = 14900 / Mesh Size

For example, a 100 mesh screen has openings about 149 microns wide.

Why does mesh size matter in filtration?

Mesh size controls what particles your filter removes. If you choose the right mesh, you protect equipment and improve product quality. The wrong mesh can cause clogs or let unwanted particles through.

Can one mesh size work for every application?

No, one mesh size does not fit all jobs. You must match mesh size to your material and process. Each application needs a different screen for best results.

How do you choose the right mesh size for sand?

You start by checking your material and the smallest particle you want to remove. Use a particle size test and a conversion chart. Test the mesh in your system and adjust if needed.

What is the difference between mesh and micron?

Mesh counts the number of openings per inch. Micron measures the actual size of each opening. Always check both numbers to make sure you get the right filter.

Do standards like ASTM or ISO matter when picking mesh?

Yes, you should always use mesh that meets industry standards like ASTM or ISO. These standards ensure quality and consistent performance.