Screening Media

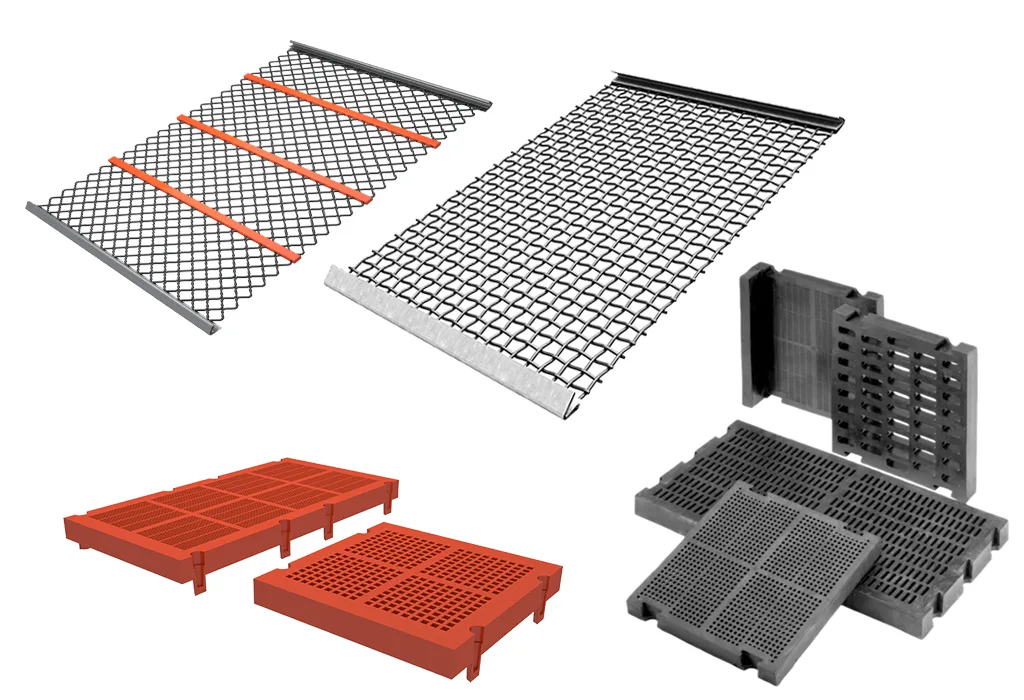

Woven Wire Mesh, Polyurethane Panels, Rubber Panels & Perforated Plates — Factory Direct

Screening media is the working surface of your vibrating screen. It determines capacity, cut accuracy, wear life, and downtime. As a direct manufacturer, Anpeng supplies a full range of screening media for aggregate, quarry, and mining—including woven wire screen mesh, polyurethane (PU) panels, rubber panels, perforated plates, and anti-blinding solutions—customized to your screen deck and operating conditions.

What Is Screening Media?

Screening media (also called screen media or screening surface) is the deck material installed on vibrating screens to separate rock, gravel, sand, ore, coal, and recycled aggregates into different size fractions. It is used for scalping (removing oversize and protecting downstream equipment), sizing (creating multiple grades), and final screening (controlling finished product specification). The right screening media improves throughput and grading accuracy while reducing plugging and maintenance.

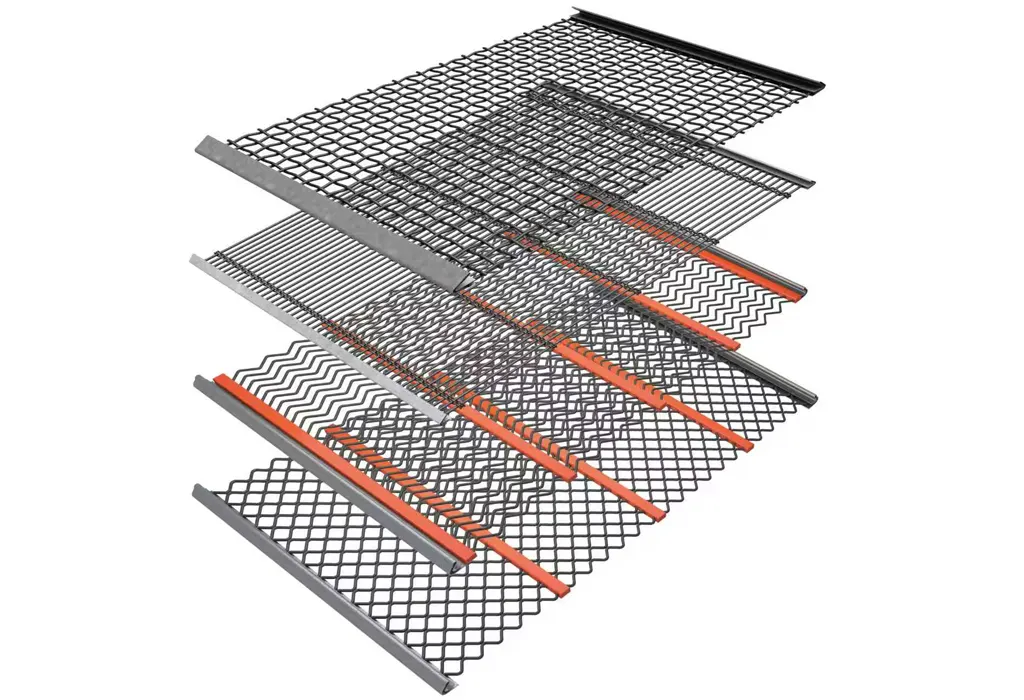

Screening Media Types We Manufacture

Below are the most common screening media options. Choose by feed condition, target cut size, impact level, and mounting system.

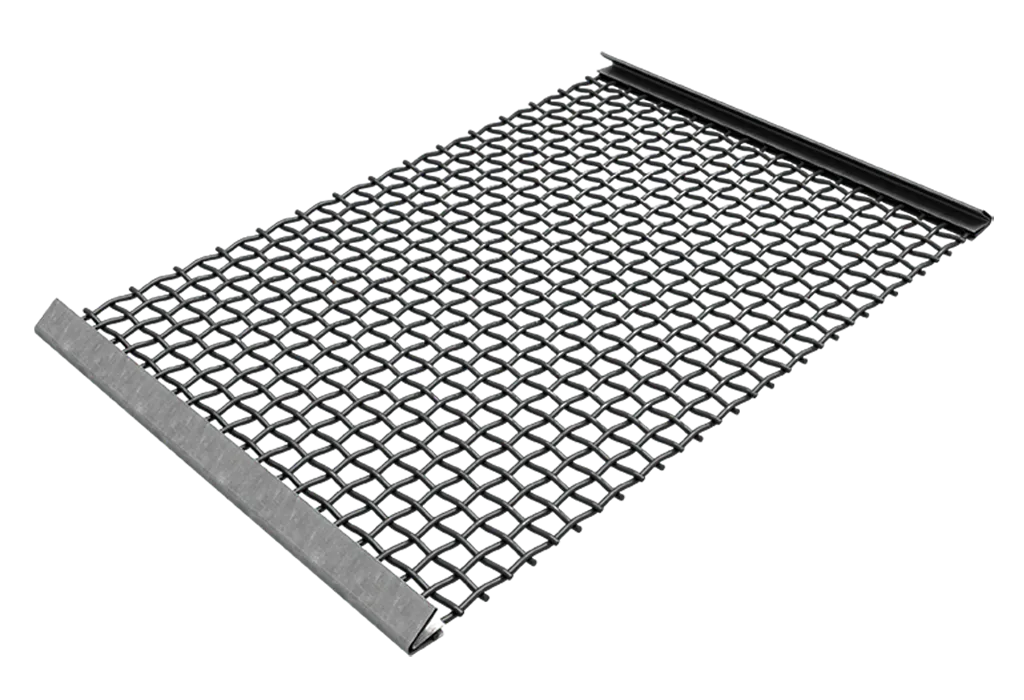

Woven Wire Screen Mesh

Best for: high open area, strong capacity, general aggregate and quarry screening

Woven wire screen mesh offers excellent throughput and is widely used for scalping, sizing, and finishing decks. We manufacture crimped wire mesh panels with multiple crimp styles to match duty and opening size.

Common options:

Crimp type: pre-crimp, intermediate crimp, lock crimp

Edge finish: plain edge, hooked edge, reinforced edge

Material: high-carbon steel, spring steel (65Mn), stainless 304/316 (optional)

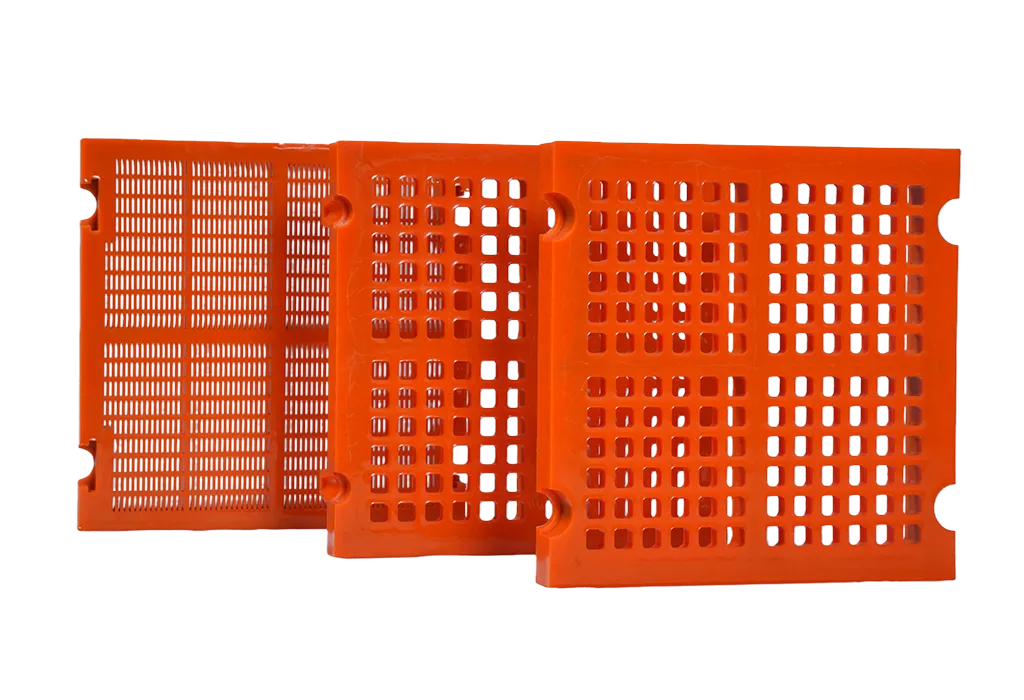

Polyurethane Screen Panels

Best for: abrasion resistance, consistent apertures, fine screening stability

PU panels are popular for applications where wear is high and sizing accuracy matters. Different panel designs support modular systems and tensioned decks.

Common options:

Modular PU panels, tensioned PU screens, flip-flow/high-frequency compatible designs (if applicable)

Aperture shapes and patterns customized to reduce plugging and improve efficiency

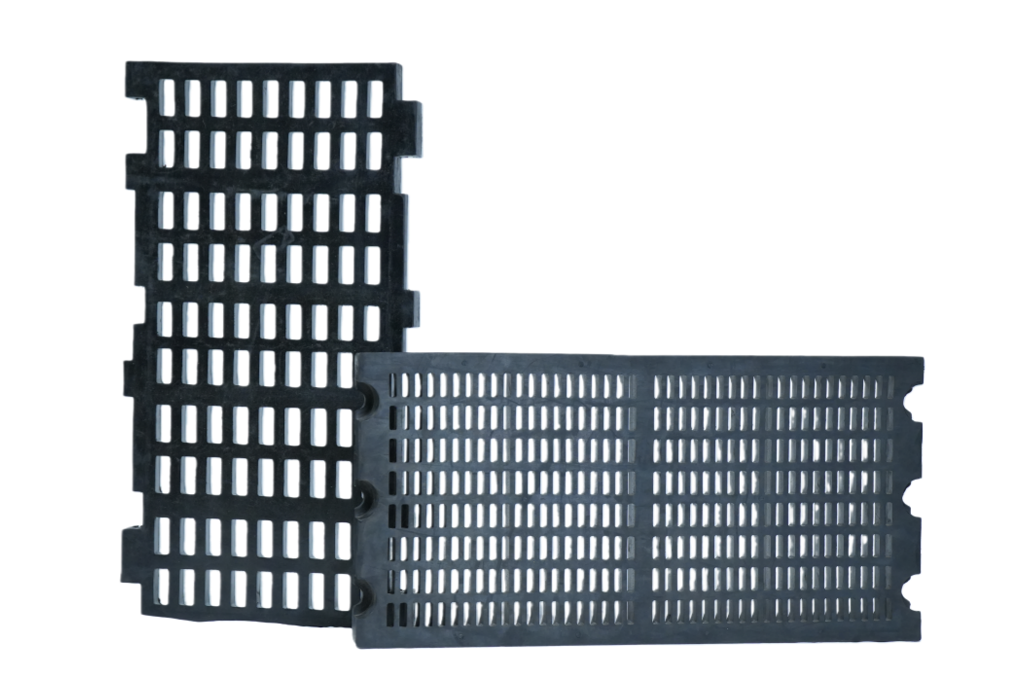

Rubber Screen Panels

Best for: impact absorption, noise reduction, heavy-duty zones

Rubber panels perform well in high-impact areas and can help reduce noise. They’re often used for heavy scalping or where comfort and safety matter.

Common options: modular rubber panels, bolt-down rubber panels, side tension rubber screens

Anti-Blinding / Self-Cleaning Screening Media

Best for: wet screening, sticky material, clay contamination, plugging/blinding issues

When standard media plugs, anti-blinding designs can maintain effective open area and reduce downtime.

Common options: self-cleaning wire screens, specialized aperture patterns, mixed media solutions

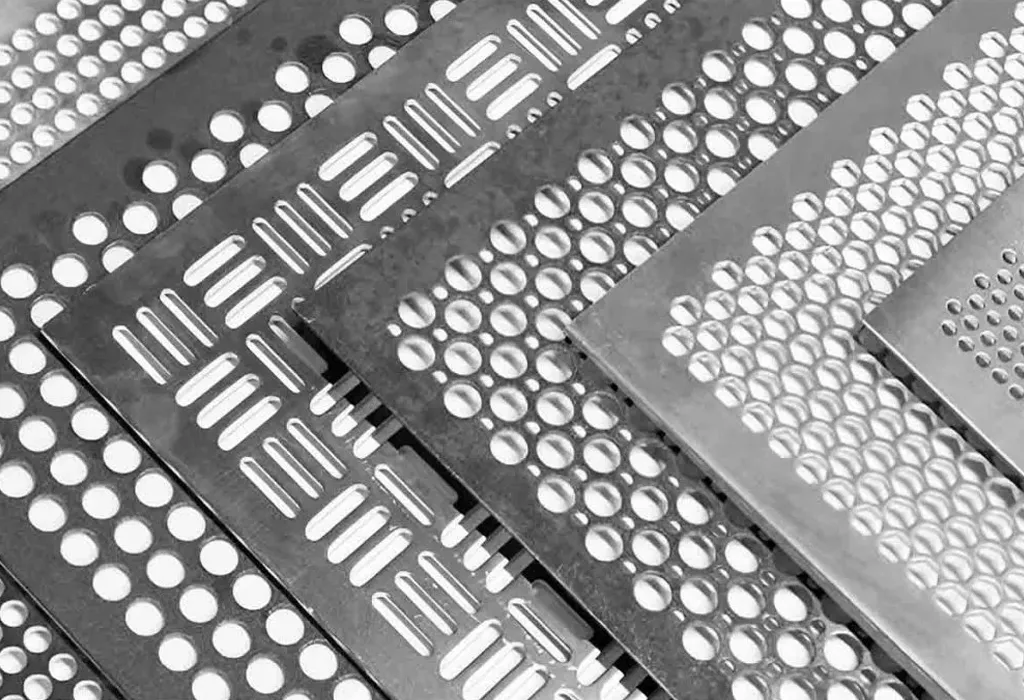

Perforated Plate Screens

Best for: heavy-duty scalping, large feed, strong structural support

Perforated plates are rigid and durable for coarse screening and high-impact loads, especially where maximum panel strength is required.

Common options: round/square/slot holes, thickness and open area customized

Applications

Our screening media is widely used in:

Aggregate & Quarry: crushed stone, gravel, sand, manufactured sand

Mining: ore screening in abrasive conditions

Coal & Power Plants: high-throughput screening

Washing Lines / Wet Screening: when moisture and clay increase blinding risk

Recycling: C&D waste, recycled aggregates with mixed feed

Quick Comparison Guide

Woven wire mesh: maximum open area and throughput; very common for aggregate sizing

PU panels: excellent abrasion resistance and stable apertures; good for fine screening

Rubber panels: strong impact absorption and lower noise; ideal for heavy impact zones

Perforated plates: rigid and strong; best for coarse scalping and heavy-duty loads

Anti-blinding solutions: reduce plugging in wet or sticky materials

Many plants use a mixed-deck solution—for example, tougher media on the top deck and higher-precision media on lower decks.

Manufacturer Capability & Quality Control

As a direct manufacturer, we control production from materials to final packing:

material inspection (wire grade / polymer compound)

aperture and tolerance checks

panel dimension verification and mounting compatibility checks

consistent forming/crimping and edge finishing

export packing with labels for size and order tracking

How to Choose the Right Screening Media

Choosing the right screening media is about matching material behavior + cut size + deck position + mounting system. Use the steps below to select a practical solution that balances throughput, wear life, and maintenance time.

1. Define Your Material and Feed Condition

Start with what you are screening and how it behaves:

Material type: granite, basalt, limestone, river gravel, ore, coal, recycled aggregate

Abrasiveness & impact: sharp crushed stone and high drop heights increase wear

Moisture & clay: wet, sticky fines often cause blinding and pegging

2. Confirm Your Target Cut Size and Product Requirements

Your separation size determines media type and opening design:

Target cut size (mm): the key number for choosing aperture size

Required grading stability: tighter specs usually need more consistent apertures

Throughput target: higher capacity may require higher open area or different media

3. Match the Media to Each Deck Position

Different decks do different jobs—don’t treat them the same:

Top deck (scalping): needs strong impact resistance and durability

Middle deck (sizing): balances capacity and accuracy

Final deck (finish screening): focuses on cut accuracy and stable grading

4. Identify Your Mounting / Fixing System

Media must fit your deck system, otherwise installation and life suffer:

Tensioned (hook/rail): requires correct tension dimensions and edge style

Modular panels: confirm module size, pin/lock pattern, and support frame

Bolt-down: confirm bolt layout, thickness, and reinforcement needs

Rail system: confirm rail spacing and panel interface

5. Decide the Best Performance Priority

Be clear about what matters most for your operation:

Maximum throughput: higher open area and correct aperture design

Longest wear life: thicker/stronger media and abrasion-resistant material

Lowest downtime: modular replacement or mixed-deck strategies

Best cut accuracy: consistent apertures and stable screening surface

6. Control Blinding and Pegging (If It’s a Problem)

If you screen wet or sticky material, include an anti-blinding plan:

choose self-cleaning / anti-clogging designs when fines stick

adjust aperture shape (slot vs square) where plugging is common

consider mixed media (e.g., more resistant media in problem zones)

Quick Tip for Faster Selection

If you share deck drawing (or photos + measurements), your cut size (mm), and wet/dry condition, we can recommend the most suitable screening media type and a practical deck layout—optimized for wear life and capacity.

FAQs

What does “screening media” mean?

Screening media is the screening surface installed on vibrating screens to separate material into different size fractions.

What are the main types of screening media?

Common types include woven wire mesh, polyurethane panels, rubber panels, perforated plates, and anti-blinding/self-cleaning designs.

Which screening media is best for aggregate?

Woven wire mesh is widely used due to high open area and throughput. For high abrasion or fine screening, PU panels are often preferred. For heavy impact and noise reduction, rubber panels are common.

How do I reduce blinding or pegging?

Choose anti-blinding designs (self-cleaning screens or optimized aperture patterns), and match aperture shape/open area to your wet/sticky material conditions.

What information do you need to recommend the right media?

Material type, wet/dry condition, target cut size, deck layout/mounting system, and deck position are the most important.

Can you customize screening media to my screen deck?

Yes. We manufacture screening media to match your deck dimensions, fixing system, and operating conditions.

Do you offer mixed-deck solutions?

Yes. Many operations combine different media types across decks to balance wear life, accuracy, and throughput.

What’s the typical lead time?

Lead time depends on media type and customization. Send your specs and quantity for a quick confirmation.