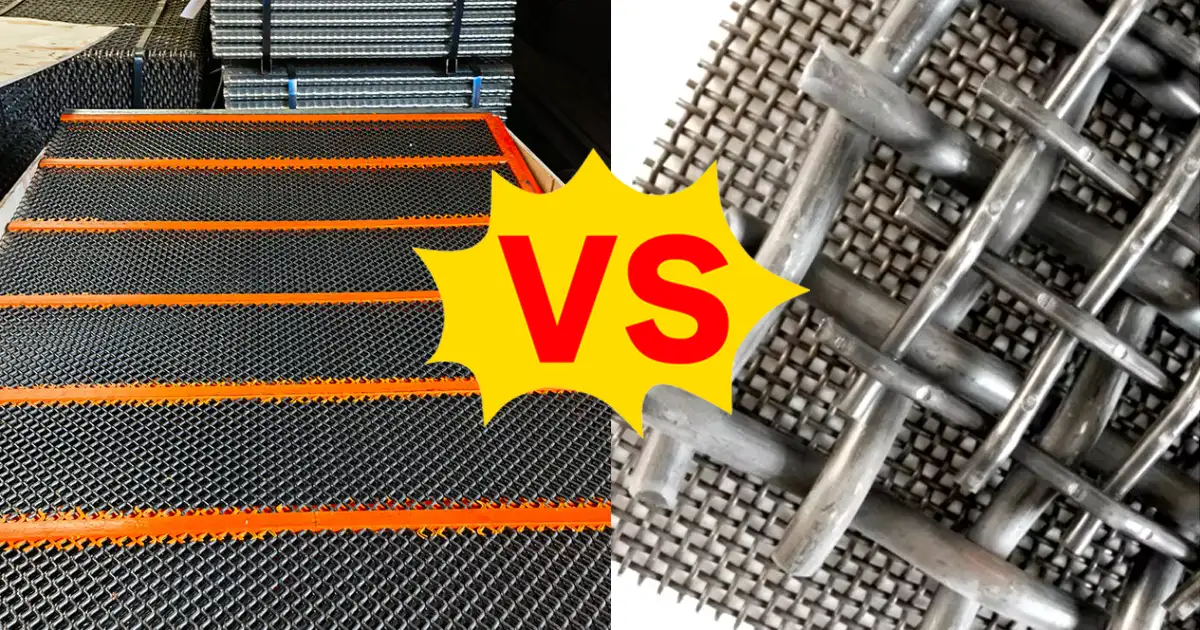

When you compare self-cleaning screens vs woven wire screens, you’ll notice that they serve different purposes effectively. Woven wire screens are commonly utilized in mining and the process of crushing rocks. They allow a significant amount of material to pass through and assist in sorting by size. On the other hand, self-cleaning screens feature unique designs that prevent blockages, making them particularly useful for handling wet or sticky materials like recycled asphalt pavement.

Tip: Consider the moisture content of your material and its potential to block screens. Choosing the right type of screen can enhance your efficiency and reduce complications.

Key Takeaways

- Self-cleaning screens work best with wet or sticky stuff. They help cut down on machine stops and repairs.

- Woven wire screens are great for sorting dry and loose things. They let a lot of material through and sort it well.

- Pick self-cleaning screens if you want less clogging and less cleaning. They are good for hard jobs.

- Woven wire screens cost less for simple work. But, you have to fix them more often.

- Think about what you are sorting and how wet it is. This helps you pick the best screen for the job.

- Self-cleaning screens last longer and are stronger. They are a good choice for tough work.

- Check your screens often and take care of them. This stops problems like blinding and pegging. It keeps things running smoothly.

- Talk to suppliers to get screens made just for you. This can help your machines work better.

Self-Cleaning Screens vs Woven Wire Screens Overview

Quick Comparison Table

When you compare self-cleaning screens and woven wire screens, you notice they work in different ways. Woven wire screens have wires that cross each other. This makes a surface that is both bendy and strong for sorting things. But, this kind of screen can get blocked if the material is wet or sticky. Self-cleaning screens, also called wedge wire screens, use wires shaped like a V and have special slots. These shapes help stop things from getting stuck and mean you do not need to clean them as much.

Here is a table that shows the main differences:

| Feature | Self-Cleaning Screens (Wedge Wire) | Woven Wire Screens |

|---|---|---|

| Slot Shape | V-shaped, widens inward | Uniform or narrowing |

| Blinding Resistance | High | Low |

| Particle Lodging | Rare | Common |

| Cleaning Frequency | Infrequent | Frequent |

| Structural Strength | High | Moderate |

| Service Life | Long | Shorter |

| Open Area | Moderate to High | High |

| Cost | Higher upfront | Lower upfront |

Note: Self-cleaning screens keep working well with sticky or wet stuff. Woven wire screens are best for dry and loose materials.

Selection Checklist

Picking between self-cleaning screens and woven wire screens depends on what you need to sort and what problems you have. Use this list to help you choose the right screen:

- Do you sort wet, sticky, or clay-heavy stuff?

- If yes, self-cleaning screens might be better.

- Do you want less clogging and less cleaning time?

- Self-cleaning screens help with this.

- Is your goal to get more open space and move lots of dry, easy stuff?

- Woven wire screens could be best.

- Do you want a screen that lasts longer and is stronger?

- Self-cleaning screens give you these things.

- Are you trying to save money and want a cheaper screen at first?

- Woven wire screens usually cost less to start.

- Do you need a screen that fits your frame or has a special finish to stop rust?

- Both types can be changed, but ask your supplier for details.

Tip: Always pick a screen that matches your material and your plant’s needs. The right screen can help you save time and money.

By using this table and list, you can compare self-cleaning screens and woven wire screens. This helps you make a smart choice for your work.

What Are Self-Cleaning Screens?

Definition and Function

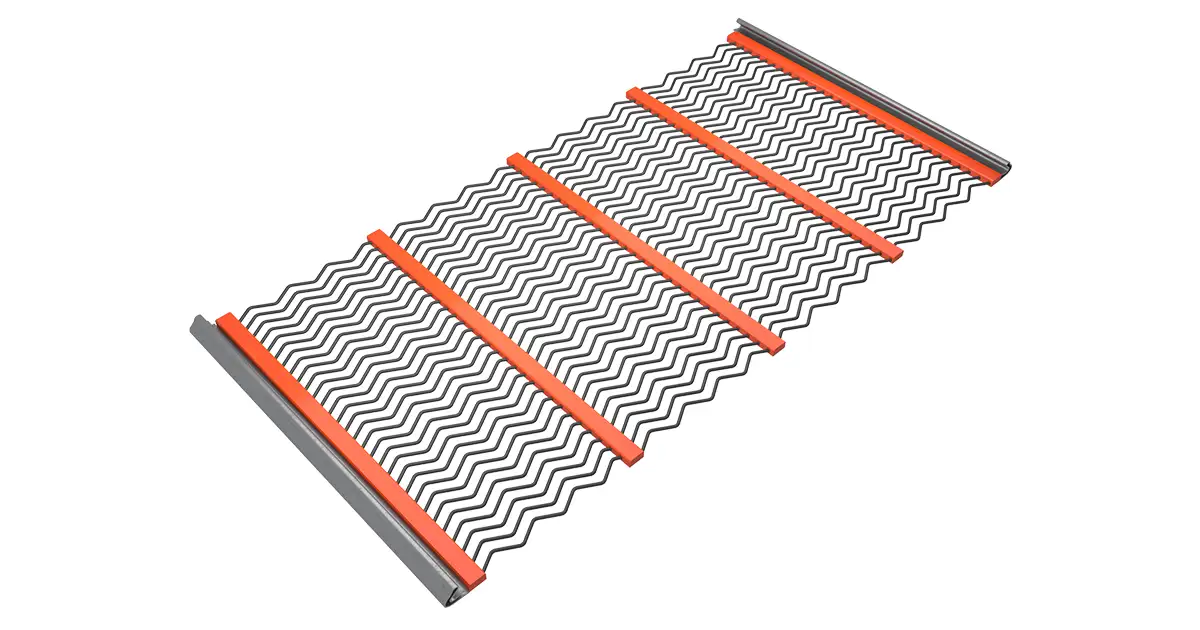

Self-cleaning screens help when materials are wet or sticky. These screens have wires that move by themselves. The movement keeps holes open. It stops things from blocking the screen. You spend less time fixing them. They last longer than woven wire mesh.

The idea is easy to understand:

Bulk material falls onto a moving screen. Rotating shafts push the material forward. Small pieces drop through the holes. Scrapers under each shaft clean off anything stuck. This keeps the screen working well.

Here is how it works:

- You put bulk material on the moving screen.

- Rotating shafts push the material ahead.

- Small pieces fall through the holes.

- Scrapers under the shafts clean stuck stuff.

- The screen stays open and works well.

Types of Self-Cleaning Mesh

Self-cleaning screens come in different types. Each type uses a special wire shape or pattern. This helps keep the screen clear.

Slotted/Harps

- Harp screens have straight wires one way and crimped wires the other way. This lets wires move and shake off sticky stuff.

- Piano wire screens use thin, straight wires. These wires vibrate and stop clogging.

- Both types are good for wet or sticky materials.

D-Shaped/W-Shaped

- D-shaped and W-shaped screens use wires bent into special shapes. These shapes help wires bend and move.

- The movement keeps holes clear.

- You see these screens where material sticks or blinds the screen.

| Type | Material | Main Feature | Application |

|---|---|---|---|

| Flex Anti Clogging Screen Mesh | 65Mn High Carbon Steel Wire | Stops clogging and cleans itself | Aggregate Processing, Washing |

| Woven Wire Mesh | Special wire patterns | Keeps holes clear | Wet or sticky materials |

| Metal Anti-Clogging Screen | Different hole shapes | Stops clogging | Mining, Quarry, Recycling |

Common Applications

Self-cleaning screens are used in many industries. They help with tough materials and keep things running well.

| Industry/Application | Performance Benefits |

|---|---|

| Mining | More uptime and steady work. |

| Crushing Circuits | Handles hard materials well. |

| Dewatering Processes | Better screening and less fixing needed. |

| Final Sizing Operations | Lower costs and safer work. |

| Wastewater Treatment | Helps with more people and changing water flow. |

| Food Processing | Makes work faster and more accurate. |

| Chemicals | Less downtime and fixing. |

| Oil and Gas | Safer and cheaper work. |

| Pharmaceuticals | Good for new and upgraded setups. |

When you look at self-cleaning screens vs woven wire screens, self-cleaning screens are best for sticky or wet materials. They help you avoid problems like blinding and pegging. This keeps your work running smoothly.

What Are Woven Wire Screens?

Definition and Construction

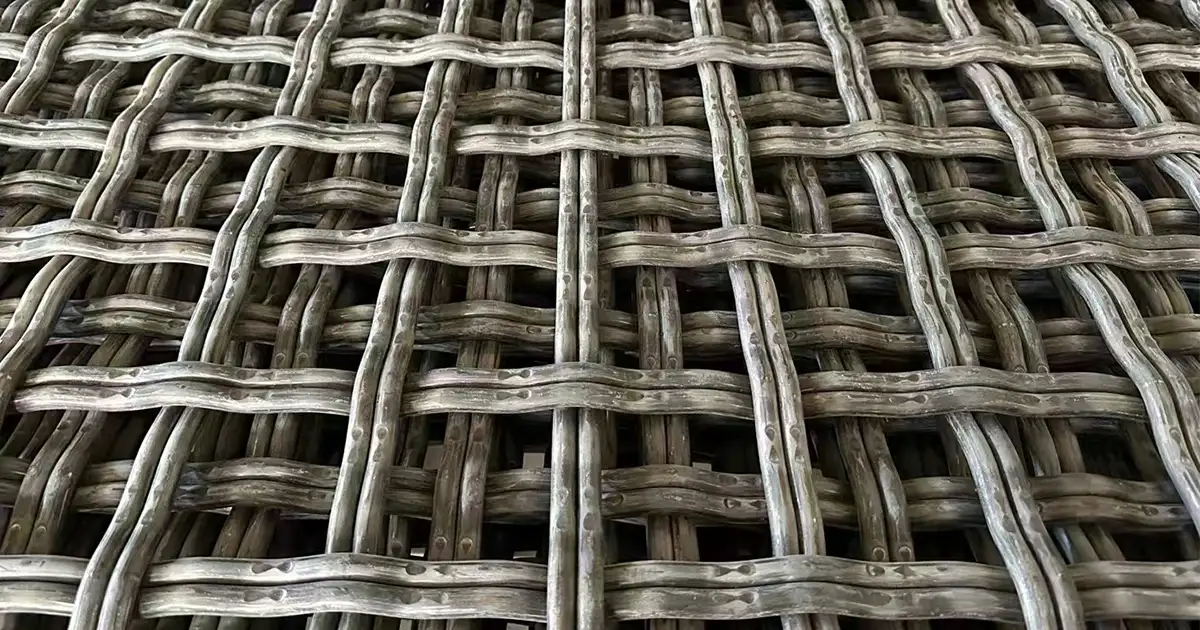

Woven wire screens are used to sort things in many places. These screens are made by weaving metal wires together. The way they are built changes how well they work and how long they last.

Here is how woven wire screens are made and used:

- Material Selection: You pick a metal, like stainless steel, if you want it to resist rust.

- Design & Configuration: You choose the mesh size, weave style, and thickness for your job.

- Installation: You put the mesh in your machine. Make sure it is tight and straight.

- Operation: Material moves over the mesh. Big pieces stay on top. Small pieces fall through the holes.

- Maintenance & Cleaning: You check and clean the mesh often. This helps it work well. Some screens are simple to clean or change.

- Performance Monitoring: You watch how much material goes through. You check how fast the mesh wears out. You see how well it sorts things.

Tip: Clean and check your woven wire screens often. This helps them last longer and work better.

Types of Woven Wire

Woven wire screens come in different styles. Each style helps with sorting materials in its own way.

| Screen Type | Description | Efficiency Impact |

|---|---|---|

| Plain Weave | Simple weave with even holes. | Good for most jobs. Gives steady sorting. |

| Inter Crimp | Wires are bent for extra strength. | Lasts longer in hard jobs. Handles heavy hits well. |

| Lock Crimp | Wires are locked together tightly. | Mesh stays strong. Less downtime and better sorting. |

| Flat Top | Flat surface helps material move and makes cleaning easy. | Great for fast flow and less clogging. |

- Tensioning Hook Style: How you attach the mesh helps it stay in place and last longer.

- Tension Hook Orientation: The right direction keeps the mesh tight. This stops clogging and breaking.

Square Opening

Square mesh has even holes both ways. It sorts particles very well. This is good when you need to control the size of what goes through. Square mesh works for most screening jobs.

Slotted Opening

Slotted mesh has long holes in one direction. This lets more material pass and helps stop clogging. Use slotted mesh when you need to move lots of material fast or when your material sticks.

Common Applications

Woven wire screens are strong and flexible. Many industries use them for different jobs. They do more than just sort rocks or minerals.

| Application | Advantages |

|---|---|

| Screening | Strong, does not rust, and sorts particles well. |

| Filtering | Small holes clean liquids and gases. |

| Printing | Makes printing easy, costs less, and works well. |

| Shielding | Blocks waves in electronics and medical tools. |

| Others | Used for insect screens, grills, and fuel cells. |

When you look at self-cleaning screens vs woven wire screens, woven wire screens are best for dry, loose materials. They are good for jobs that need steady and accurate sorting. You can pick the type and design that fits your plant. This helps your work run smoothly.

Performance Comparison

Blinding and Pegging Resistance

You often face problems with blinding and pegging when you screen wet, sticky, or clay-rich materials. Blinding happens when fine particles block the screen openings. Pegging means larger pieces get stuck in the holes. These issues slow down your work and increase cleaning time.

Self-cleaning screens help you avoid these problems. Their wires move and vibrate on their own. This action shakes off stuck material and keeps the holes open. Woven wire screens do not have this feature. They can clog more easily, especially with tough materials.

Here is a quick comparison:

| Feature | Self-Cleaning Screens (MAX Kleen) | Woven Wire Screens |

|---|---|---|

| Resistance to Blinding | High | Moderate |

| Resistance to Pegging | High | Low |

| Maintenance Costs | Lower (less manual cleaning) | Higher (more cleaning) |

| Wear Life | Longer | Shorter |

- Self-cleaning screens are made for materials that peg and blind. You get longer wear life and less downtime.

- Woven wire screens may cost you more in maintenance if you handle sticky or wet materials.

Tip: If you see frequent plugging or blinding, try self-cleaning screens. Their flexible wires, like those in harp or piano wire screens, vibrate and shed near-size particles. This keeps your operation running smoothly.

Open Area and Throughput

Open area means the total space in the screen where material can pass through. Throughput is how much material moves through the screen in a set time. Both matter when you want fast and efficient screening.

Woven wire screens usually offer a high open area. This lets you move a lot of dry, free-flowing material quickly. You get good throughput with less resistance. However, if the screen blinds or pegs, the open area drops fast. You then lose efficiency and must stop for cleaning.

Self-cleaning screens may have a slightly lower open area at first. But their design keeps the holes clear, even with sticky or damp material. You keep a steady flow and avoid sudden drops in throughput. Over time, you may process more material because you do not need to stop as often.

- Choose woven wire screens for dry, loose materials where blinding is not a problem.

- Pick self-cleaning screens if you want steady throughput with tough or wet materials.

Note: The right screen keeps your plant running longer and helps you meet your production goals.

Cut Accuracy

Cut accuracy means how well your screen separates material by size. You want each particle to go to the right place. This helps you get a clean product and reduces waste.

Woven wire screens give you sharp cut accuracy when they stay clean. The even holes sort particles by size with little error. But if the screen blinds or pegs, the accuracy drops. You may get mixed sizes and need to reprocess material.

Self-cleaning screens keep their holes open, so you get more consistent cut accuracy over time. The wires move and clear out stuck pieces. This means you get the right size product, even with sticky or hard-to-screen material.

- For the best cut accuracy, keep your screens clean and well-tensioned.

- Self-cleaning screens help you maintain accuracy in tough conditions.

When you compare self-cleaning screens vs woven wire screens, you see that each has strengths. Your choice depends on your material and your plant’s needs.

Wear Life and Durability

You want your screens to last a long time. Wear life means how many weeks a screen works before you change it. Durability is how well a screen handles tough jobs like sorting rocks or minerals.

Self-cleaning screens use special materials like polyurethane. These screens can last much longer than woven wire screens. In places with lots of wear, you see a big difference. For example, NexGen Polyurethane screens last about 10 weeks. This is twice as long as regular polyurethane screens, which last around 5 weeks.

Here is a table that shows how the screen types compare:

| Screen Type | Wear Life (Weeks) | Comparison to Standard |

|---|---|---|

| NexGen Polyurethane | 10 | 2 times longer |

| Standard Polyurethane | 5 | – |

| Rubber | N/A | – |

| Other Polyurethane | N/A | – |

Tip: If you work with sharp or heavy materials, pick screens with longer wear life. This saves money and cuts down on downtime.

Self-cleaning screens also do not bend or break easily. You spend less time fixing or changing them. Woven wire screens can wear out faster, especially with hard or rough materials. You need to check them often and replace them more.

Vibration and Material Carryover

Vibration helps screens shake off stuck material. It keeps the holes open so more material can fall through. Material carryover means how much stuff stays on the screen instead of going through.

Self-cleaning screens have special wire shapes and flexible designs. These features help the screen vibrate more. The vibration stops blinding and pegging. You see less material carryover, especially with sticky or wet materials.

Woven wire screens work well with dry and rough materials. They let dry material pass quickly. But they do not vibrate as much. Sticky or wet material may stay on the screen, causing more carryover.

Here is a table that compares these features:

| Feature | Self-Cleaning Screens | Woven Wire Screens |

|---|---|---|

| Vibration Characteristics | Prevents blinding and pegging | Best for dry and coarse materials |

| Material Carryover Rates | Effective for sticky or damp materials | Fast passage for dry materials |

| Maintenance Needs | Less manual cleaning and downtime | More frequent cleaning needed |

Note: If you screen wet or sticky material, self-cleaning screens help your plant keep running. You spend less time cleaning and more time working.

Noise and Comfort

Noise can make your job uncomfortable. Loud screens can distract you or hurt your ears over time. Comfort is important when you work near screens every day.

Self-cleaning screens are usually quieter than woven wire screens. Their flexible wires and shapes soak up some vibration. This lowers noise and makes your work area nicer.

Woven wire screens can be louder, especially with heavy or rough material. The metal wires hit each other and make more sound. You might need ear protection in these spots.

- Pick self-cleaning screens if you want a quieter place to work.

- Use woven wire screens if noise is not a big problem.

Tip: A quieter plant helps you focus and keeps your team safe. Always think about comfort when you choose your screens.

Maintenance and Downtime

You want your screening equipment to run as much as possible. Less downtime means more production and fewer headaches. The type of screen you choose affects how often you need to stop for cleaning or repairs.

Self-cleaning screens help you reduce maintenance. These screens use flexible materials like polyurethane or rubber. The wires move and flex as material passes over them. This action shakes off stuck particles. You do not need to stop as often to clear blockages. This design works well with wet or sticky materials.

Woven wire screens have a different story. These screens use rigid metal wires. The open area is high, so you can move a lot of material. However, the wires do not flex. When you run sticky or damp material, the holes can clog. You may see pegging or blinding. You must stop the machine to clean the screen. This increases downtime and lowers your output.

Here is a quick look at how each screen type affects your maintenance routine:

- Self-Cleaning Screens

- Flexible wires shake off stuck material.

- Less manual cleaning needed.

- Fewer shutdowns for maintenance.

- Stay efficient in tough conditions.

- Woven Wire Screens

- Rigid wires do not flex.

- More likely to clog with sticky or wet material.

- Require frequent cleaning.

- More downtime for maintenance.

| Screen Type | Cleaning Frequency | Downtime Risk | Maintenance Needs |

|---|---|---|---|

| Self-Cleaning | Low | Low | Minimal |

| Woven Wire | High | High | Frequent |

Tip: If you want to keep your plant running longer with less effort, self-cleaning screens offer a clear advantage. You spend less time fixing problems and more time producing.

Best Use Cases

Wet and Sticky Materials

You often face problems when you screen wet or sticky materials. These materials can clog your screens and slow down your work. Self-cleaning screens help you solve this problem. Their special wire shapes and flexible designs keep the openings clear. The wires move and shake off sticky particles. You spend less time cleaning and more time working.

Here is a table that shows which screen types work best for moist and viscous materials:

| Screen Type | Recommended Use Case | Self-Cleaning Effect |

|---|---|---|

| PM-Grade (Piano Mesh) | Moist and viscous materials | Yes |

| RM-Grade (Rectangle Mesh) | Moist and viscous materials | Yes |

| DM-Grade (Diamond Mesh) | Moist and viscous materials | Yes |

| TM-Grade (Triangle Mesh) | Moist and viscous materials | Yes |

| Woven Square Mesh | Wet and dry materials, not viscous | No |

| W-Harp | Increased throughput, self-cleaning | Yes |

| G-Harp | Wet, viscous materials | Yes |

| S-Harp | Moist, wet, slimy, loamy, or dry | Yes |

Self-cleaning screens are very effective for wet, sticky, or clogging materials. You see them used in construction, mining, and recycling. Their design gives you more open area, so you get better performance with tough materials.

Clay-Rich and Near-Size Screening

Clay-rich materials and near-size particles can cause big problems in screening. Clay sticks to the wires and blocks the holes. Near-size particles are almost the same size as the screen openings, so they get stuck easily. You need a screen that can handle these challenges.

Many producers have improved their results by switching to the right screen type. For example, an asphalt plant in Ohio changed its setup for sand screening. The old screen only recovered 72% of the fine sand because of blinding. After upgrading to a new screen and adding a pre-wash, recovery jumped to 94.3%. The plant also saw less clogging and used less water. This shows how important it is to match your screen to your material.

A recent survey found that most early screen failures happen because the screen type does not fit the material. When you choose the right screen for clay-rich or near-size screening, you get better results and fewer problems.

Dry Abrasive Stone

Dry, abrasive stone needs a strong and durable screen. Woven wire screens work well for this job. They have a high open area, so you can move a lot of material quickly. The wires are tough and can handle sharp rocks without wearing out too fast.

You should use woven wire screens when you process dry gravel, crushed stone, or other hard materials. These screens give you steady performance and sharp cut accuracy. You do not need the self-cleaning feature because dry materials do not stick or clog the openings.

When you compare self-cleaning screens vs woven wire screens, you see that each type has its place. Self-cleaning screens work best for sticky, wet, or clay-rich materials. Woven wire screens are better for dry, abrasive stone. Picking the right screen helps you get the best results for your plant.

Scalping, Sizing, and Final Decks

You need to choose the right screen for each deck in your screening plant. Each deck has a special job. The scalping deck removes big, unwanted rocks. The sizing deck sorts material by size. The final deck gives you the finished product. Your choice between self-cleaning screens and woven wire screens affects how well each deck works.

Scalping Decks:

You use the scalping deck to protect your equipment. It takes out large rocks and debris before they reach the next step. Woven wire screens work well here. They have many holes and let smaller material pass through. You can change them quickly if they wear out. These screens cost less, so you can replace them often. However, they do not last as long as other types. You need to check them often for wear.

Sizing Decks:

The sizing deck sorts your material into different sizes. Woven wire screens give you the most exact sizing. They have a high open area, so you get good sorting and fast processing. You can trust them for most jobs. If you work with wet or sticky material, you may see blockages. Self-cleaning screens help here. They keep the holes open and reduce downtime. You spend less time cleaning and more time working.

Final Decks:

The final deck gives you your finished product. You want clean, accurate sizing. Woven wire screens provide sharp cut accuracy. They are easy to change when needed. If your material is sticky or damp, self-cleaning screens help prevent blockages. You get steady performance and less waste.

Here is a table to help you compare both screen types for these applications:

| Screen Type | Advantages | Disadvantages |

|---|---|---|

| Woven Wire Screens | – Trusted by most in the industry | – Do not last as long |

| – High open area for better sorting | – Need frequent checks and changes | |

| – Lowest cost for many jobs | ||

| – Easy to replace | ||

| – Most accurate sizing | ||

| Self-Cleaning Screens | – Prevent blockages from wet or sticky materials | – Higher initial cost |

| – Reduce downtime and maintenance | ||

| – Improve sorting efficiency with high open area | ||

| – Allow faster processing and less waste |

Tip: For dry, easy-to-screen material, woven wire screens work best. For sticky or wet material, self-cleaning screens keep your plant running smoothly.

You should match your screen type to your material and the job of each deck. This helps you get the best results and keeps your plant working with less trouble.

Troubleshooting Screening Issues

Common Symptoms

You might see some signs when your screening does not work well. The most common problems are:

- Blinding: Fine or sticky stuff covers the screen holes. This means less material goes through.

- Pegging: Big pieces get stuck in the holes. This blocks the screen and slows things down.

- Reduced Throughput: Not as much material comes out as you expect.

- Frequent Cleaning: You have to stop often to clean the screens.

- Uneven Wear: Some parts of the screen wear out faster.

Check your screens often to find problems early. If you spot issues soon, you can fix them before they get worse.

Likely Causes

Many things can cause these screening problems. Look for these reasons:

- High Moisture: Wet material sticks to wires. This makes a crust and causes blinding.

- Near-Size Particles: Pieces almost as big as the holes can get stuck and plug the screen.

- Improper Vibration: Not enough shaking lets material pile up. Too much shaking can make material bounce off.

- Screen Flexibility: If the screen is too stiff, it blinds more. If it is too soft, it wears out fast.

- Screen Load: Heavy loads with little flex can blind some spots.

You need to balance strength and flexibility. This helps stop blinding and keeps screens from failing early.

Solutions and Fixes

You can fix most screening problems by making smart changes. Try these solutions:

Switch to Self-Cleaning

If you work with wet or sticky stuff, try self-cleaning screens. These screens have wires that move and shake off stuck pieces. You will see less blinding and pegging. Self-cleaning screens are best for tough materials that clog woven wire screens.

Adjust Aperture or Angle

Change the size of the screen holes to help. Bigger holes let more material pass and stop plugging. Change the angle of your screen deck to help material move faster. A steeper angle stops buildup.

Improve Tensioning

Good tension keeps your screen flat and strong. If it is too loose, material piles up and can hurt the screen. If it is too tight, the screen wears out faster. Check tension often and fix it when needed.

| Problem | Solution |

|---|---|

| Poor quality mining screens | Use manganese steel screens with high elasticity and wear resistance for longer life. |

| Insufficient tension of the screen | Ensure proper tensioning to prevent screen damage and material buildup. |

- Use a soft nylon brush to clean stuck pieces.

- Try a pressure washer for deep cleaning, but be careful not to damage the screen.

- Check and clean your screens often to keep them working well.

- Use sensors or alarms to warn you when screens get clogged.

Tip: Make a cleaning plan and watch your screens. This helps you find problems early and keeps your plant working well.

When Not to Use Self-Cleaning Screens

Picking the right screen for your plant matters a lot. Self-cleaning screens are great for sticky or wet stuff. But sometimes, other screens work better. Using standard woven wire or polyurethane and rubber screens can save you money. It can also make your work easier.

Standard Woven Wire Applications

Standard woven wire screens fit many common jobs. These screens are very accurate and simple to put in. They cost less when you use them for easy materials. Here are some times when woven wire screens are the best pick:

- You work with dry, non-sticky stuff.

- You want sharp, exact sizing.

- You need a screen that is fast to change.

- You want to spend less on simple jobs.

- Your material does not block or clog the screen.

Woven wire screens are best when you do not have blinding or pegging. You get steady work and do not pay extra for self-cleaning.

If your plant sorts dry gravel, sand, or crushed stone, woven wire screens are a good choice. They sort things fast and last long if you take care of them. You can tighten them easily and fit them in most machines.

Polyurethane or Rubber Alternatives

Sometimes, you need a screen for tough jobs or special needs. Polyurethane and rubber screens give you special benefits. Pick these screens if you want them to last longer or make less noise.

| Screen Type | Best For | Key Benefit |

|---|---|---|

| Polyurethane | High-wear, abrasive materials | Long wear life |

| Rubber | Impact-heavy, noisy environments | Noise reduction, flexibility |

Polyurethane screens are good for sharp or rough rocks. They last longer than metal and do not break easily. Rubber screens help make your plant quieter. They also soak up hard hits.

Tip: Polyurethane and rubber screens cost more at first. But they last longer and need fewer changes, so you save money later.

Self-cleaning screens are not always as tough as polyurethane or as quiet as rubber. If you want less wear or noise, try these other screens. You get smoother work and less time fixing things.

Why Choose Anpeng

When you pick a screening media supplier, you want a partner who understands your needs. Anpeng stands out because you get high-quality products, flexible solutions, and expert support. Here’s why you should consider Anpeng for your next screen order.

Manufacturing Quality

Anpeng uses strict quality control at every step. You get screens made from top-grade materials like high-carbon steel, stainless steel, and polyurethane. Each screen goes through careful checks for strength, accuracy, and finish. This means you receive products that last longer and work better in tough conditions.

- Consistent Mesh Openings: You get precise sizing for every job.

- Strong Welds and Joints: Your screens resist wear and tear.

- Smooth Surfaces: Material moves easily, so you see less blinding.

Tip: High-quality screens help you avoid downtime and keep your plant running smoothly.

Customization

Every plant is different. You need screens that fit your machines and your material. Anpeng offers many ways to customize your order.

- Mesh Size and Shape: Choose from square, slotted, harp, or specialty patterns.

- Material Options: Pick the best wire or polymer for your job.

- Screen Dimensions: Get screens cut to fit your frame exactly.

- Surface Treatments: Ask for coatings that resist rust or abrasion.

| Custom Option | Benefit |

|---|---|

| Mesh pattern | Better fit for your material |

| Wire thickness | Longer wear life |

| Special coatings | Less corrosion and sticking |

You can talk to Anpeng’s team about your plant, your material, and your goals. They help you design a screen that works best for you.

Technical Support

You may have questions about screen selection, installation, or troubleshooting. Anpeng gives you access to technical experts who know screening inside and out.

- Fast Response: Get answers when you need them.

- On-Site Help: Arrange visits for setup or problem-solving.

- Training: Learn how to install, tension, and maintain your screens.

- Troubleshooting Guides: Solve common issues with easy tips.

Note: Good support means you spend less time fixing problems and more time producing.

When you choose Anpeng, you get more than a screen. You get a partner who helps you succeed.

Conclusion

When you look at self-cleaning screens and woven wire screens, you notice they are not the same. Self-cleaning screens are better for sticky or wet stuff. Woven wire screens are good for dry and loose things. Anpeng can help you pick the best screen for your plant. Tell Anpeng what kind of material you have and what problems you face. Picking the right screen helps you work faster and stop your machine less.

FAQ

What is the main advantage of self-cleaning screens?

You get less downtime because self-cleaning screens resist blinding and pegging. The wires move and clear stuck material. This keeps your plant running and reduces cleaning time.

Can you use woven wire screens for wet materials?

You can use woven wire screens, but they clog easily with wet or sticky materials. You may need to clean them often. For wet jobs, self-cleaning screens work better.

How do you know when to replace your screen?

You should check for uneven wear, broken wires, or reduced throughput. If you see more blinding or pegging, it is time to replace your screen.

Are self-cleaning screens more expensive?

Self-cleaning screens cost more at first. You save money over time because you spend less on cleaning and replacements. You also get more uptime.

Can you mix screen types in one plant?

Yes, you can use different screens on each deck. For example, use woven wire for dry scalping and self-cleaning screens for sticky sizing decks.

How do you clean a clogged woven wire screen?

You can use a nylon brush or a pressure washer. Always check the tension and look for damage. Clean screens often to keep them working well.

Which screen lasts longer?

Self-cleaning screens usually last longer, especially with tough or sticky materials. Woven wire screens wear out faster with abrasive or heavy loads.

Do you need special tools to install these screens?

You do not need special tools for most installations. You should follow the supplier’s instructions and check the tension for best results.