Stainless Steel Woven Wire Mesh

Anpeng manufactures Stainless Steel Woven Wire Mesh for screening media used on vibrating screens in mining, quarry, aggregate processing, and other harsh environments. Stainless steel mesh is commonly selected when corrosion resistance, heat resistance, or chemical exposure makes carbon steel less suitable. As a direct manufacturer, we supply custom apertures, wire diameters, weave styles, and panel sizes, including edge finishing to match your screen deck.

What Is Stainless Steel Woven Wire Mesh?

Stainless steel woven wire mesh is produced by weaving stainless steel wires into a stable screening cloth with consistent openings. In screening applications, it is installed on vibrating screens to separate material into size fractions. Compared with standard high-carbon steel mesh, stainless steel mesh is used when corrosion, moisture, or chemical exposure can shorten service life or affect screening stability.

When to Choose Stainless Steel Screen Mesh

Stainless steel woven wire mesh is often a practical choice when:

Screening is performed in wet conditions, washing lines, or coastal environments

Material or process exposure may cause corrosion

Cleanliness or contamination control is important in the process

Temperature or chemical conditions require a more resistant material

If your application is primarily high-abrasion and impact with limited corrosion risk, high-carbon steel or 65Mn may still be more economical. If corrosion is a recurring problem, stainless steel mesh can reduce replacement frequency and unexpected downtime.

How to Choose Stainless Steel Woven Wire Mesh

Start with your required cut size and screening duty, then select the appropriate stainless grade. 304 is commonly used for general corrosion resistance, while 316 is preferred when corrosion risk is higher (for example, more aggressive environments). Wire diameter and crimp structure are chosen based on aperture size, vibration duty, and the stability you need. Finally, confirm panel size and edge finishing to match your screen deck mounting system.

Tip: If you share your deck position, cut size, and whether the process is wet or corrosive, we can recommend a suitable grade and mesh specification.

Product Specifications

| Specification | Details |

|---|---|

| Product Name | Stainless Steel Woven Wire Mesh (Screen Mesh for Vibrating Screens) |

| Manufacturer | Anpeng (Direct Manufacturer) |

| Material Grade | 304 Stainless Steel, 316 Stainless Steel (other grades available upon request) |

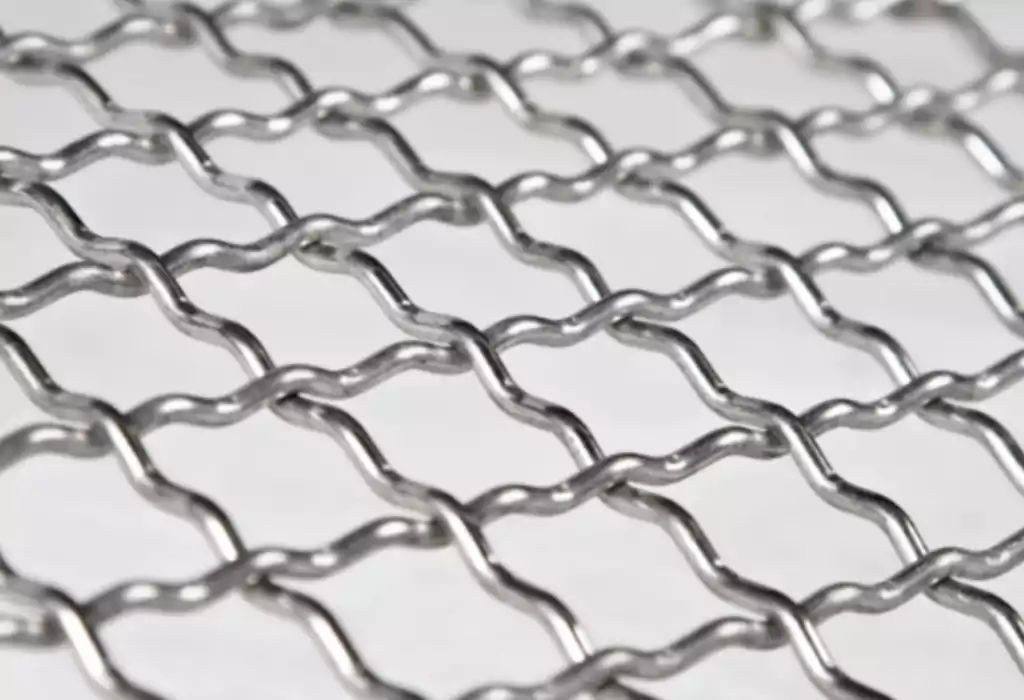

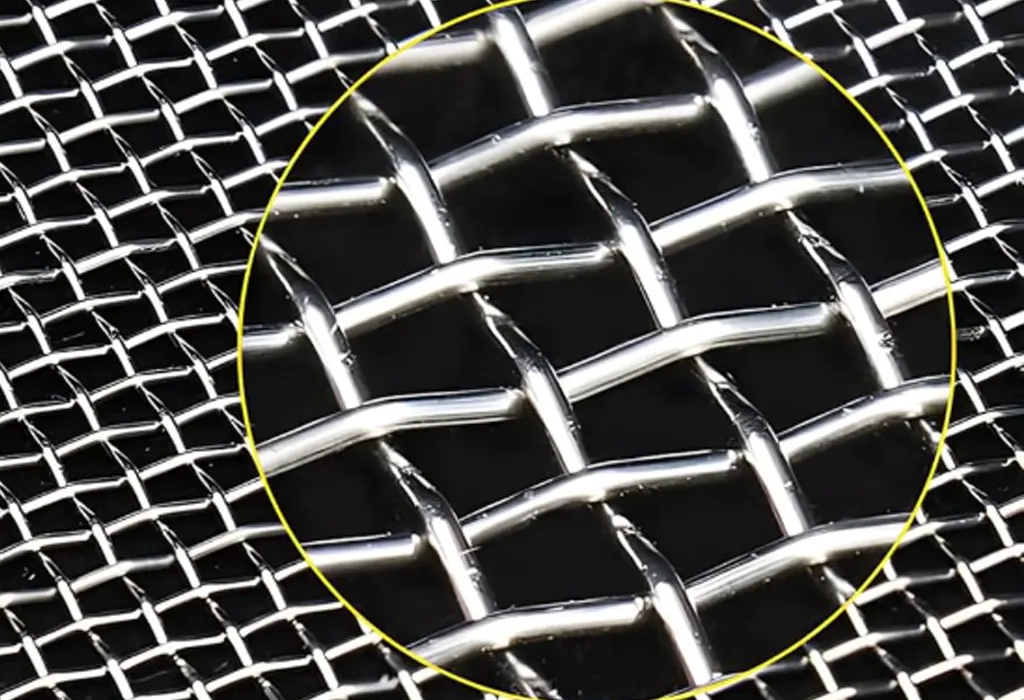

| Mesh Type | Crimped woven wire screen mesh; anti-clogging/self-cleaning options (optional) |

| Weave / Crimp Type | Pre-crimp, Intermediate Crimp, Lock Crimp (selected by aperture & duty) |

| Opening Size (Aperture) | 0.5–120 mm (custom available) |

| Wire Diameter | Custom based on screening duty and required stability |

| Open Area | Optimized by aperture & wire diameter to balance throughput and wear life |

| Panel / Sheet Size | Custom per screen deck layout (panel or full-sheet options) |

| Edge Finish | Plain edges, Hooked edges, Reinforced edges (match your tensioning system) |

| Mounting / Tensioning | Clamp bar tensioning; bolt-down or other fixing options (as required) |

| Recommended Applications | Wet screening, washing lines, corrosive environments, mining and aggregate screening media |

| Customization | Aperture, wire diameter, crimp type, panel size, edge finishing, and grade available upon request |

| Quotation Info Needed | Material grade, aperture (mm), wire diameter (mm), panel size (L×W), edge type, quantity, dry/wet condition |

| Packing | Bundles or export pallets with protective wrapping; labeled by specification & order ID |

Why Choose Anpeng

Anpeng offers high-quality stainless steel woven wire mesh with custom specifications, engineered for stability, durability, and efficient screening. As a direct manufacturer, we provide fast production and reliable delivery, making it easier for you to get the right mesh for your project.

We provide fully customizable stainless steel woven wire mesh to match your specific screen deck dimensions, edge types (hooked/plain/reinforced), and material requirements. This ensures a precise fit and optimized screening performance.

Our quality control processes ensure that every mesh is made to specification, with accurate apertures, wire diameters, and stable openings. This consistency helps maintain screening efficiency and product gradation.

As a direct manufacturer, we offer quicker lead times and reliable supply for your projects. Our packaging is designed for safe transport and easy handling on-site, ensuring that your mesh arrives ready for installation.

FAQs

What is stainless steel woven wire mesh used for in screening?

It is used as screen media on vibrating screens to separate material into size fractions, especially in wet or corrosive environments where carbon steel screens may rust or fail early.

304 vs 316 stainless—what’s the difference for screen mesh?

304 is commonly used for general corrosion resistance and many wet screening applications. 316 offers improved corrosion resistance in more aggressive conditions. The right choice depends on your environment and material exposure.

Can stainless steel mesh be made with hooked edges and custom panels?

Yes. We manufacture custom panel sizes and edge finishes (hooked/plain/reinforced) to match your deck and tensioning system.

Will stainless steel last longer than high-carbon steel?

In corrosive or wet environments, stainless steel can reduce corrosion-related failures and extend service life. In purely abrasive, high-impact duties, service life depends heavily on abrasion and impact, so wire selection and deck position matter.

What information do you need for a quotation?

Please provide grade (304/316), aperture, wire diameter (if known), panel size, edge type, quantity, and whether the screening condition is dry or wet.