Knowing trommel screen parts helps you do better in sorting materials. Every part, like the drum and mesh system, has its own job in screening. The drum’s shape and tilt change how well it works. The way the screen panels are made and set up also affects how they perform. You need to check and fix parts often and change the screening media to stop clogs and damage. When you understand how these parts work together, you can make more and use less energy.

Key Takeaways

- Knowing trommel screen parts helps sort materials better.

- The drum’s shape and angle change how well it sorts.

- You should check and change the mesh often to stop clogs and breaks.

- Picking the right mesh is important for sorting different things.

- Lifting bars and spiral shapes help move and sort materials faster.

- Grizzly bars take out big pieces and keep other machines safe.

- Water jets help with wet screening by washing sticky stuff away and stopping clogs.

- You need to pick a mobile or stationary trommel screen based on your job.

What Is a Trommel Screen?

Trommel Screen Definition

There are many machines for sorting materials. The trommel screen is special because of its design and how well it works. A trommel screen uses a spinning drum to separate things by size. As the drum turns, small pieces fall through holes. Big pieces keep moving down the drum. This way works well for sticky or wet stuff. The spinning drum helps stop clogs. It keeps the sorting smooth.

Tip: If you work with wet or sticky things, a trommel screen helps a lot. The drum spins and keeps things moving. This means fewer clogs and better sorting.

Some important parts of a trommel screen are:

- The spinning drum sorts things by size.

- The design works well with wet and sticky stuff.

- Small pieces fall through the mesh. Big pieces come out at the end.

This easy process makes the trommel screen popular in many jobs.

Main Uses and Applications

You see trommel screens used in many places. They can handle lots of different materials. Here are some common places where you find trommel screens:

- Ports & Terminals

- Quarry & Aggregates

- Mining

- Rail Loading & Unloading

- Demolition-Contractors

- Waste Transfer Stations

- Forestry

- Waste to Energy

People use trommel screens to sort soil, sand, mulch, wood pellets, compost, and home waste. The machine is great for sorting wet or sticky things. Small bits go through the mesh. Big bits move forward to be sorted more. In waste jobs, trommel screens help separate recycling from trash. In mining, they sort rocks and minerals by size. In forestry, they help with wood chips and mulch.

Note: When picking a trommel screen, think about what you need to sort. The machine’s design lets you work with many kinds of materials. This makes it useful for lots of jobs.

Trommel screens are reliable and flexible. They help you work faster and have less downtime. You get better sorting, which means cleaner results and more work done.

Key Trommel Screen Parts

Cylindrical Drum

Structure and Materials

The cylindrical drum is the main part of most trommel screen parts. You see it as a big cylinder that spins around. It is made from strong metals like steel. The drum’s surface uses plates with holes or mesh panels. These holes come in many shapes and sizes. The drum’s length and width decide how much material it can hold. This strong drum can handle heavy loads. It also stands up to rough materials.

Tip: Pick a drum made from tough materials if you work with rough or heavy stuff. This helps your trommel last longer and work better.

Role in Screening

The drum spins on its side. You put materials in at the higher end. Gravity and the tilt move them forward. Small pieces fall through the holes. Big pieces stay inside and move to the end. The tumbling action helps sort things by size. The drum’s design stops clogs, even with wet or sticky stuff. You get better sorting and more work done when you pick the right drum size.

| Component | Function |

|---|---|

| Rotating Drum | Lets materials tumble and get sorted by size. The drum’s size changes how much it can process. |

| Screen Panels/Mesh | Sorts materials by letting small pieces through. |

| Motor and Gearbox | Makes the drum spin and lets you change speed. |

| Support Structure | Keeps everything lined up and absorbs shaking. |

| Inlet/Outlet Points | Controls how materials go in and out for sorting. |

| Lifting Bars/Helix | Helps move materials inside the drum. |

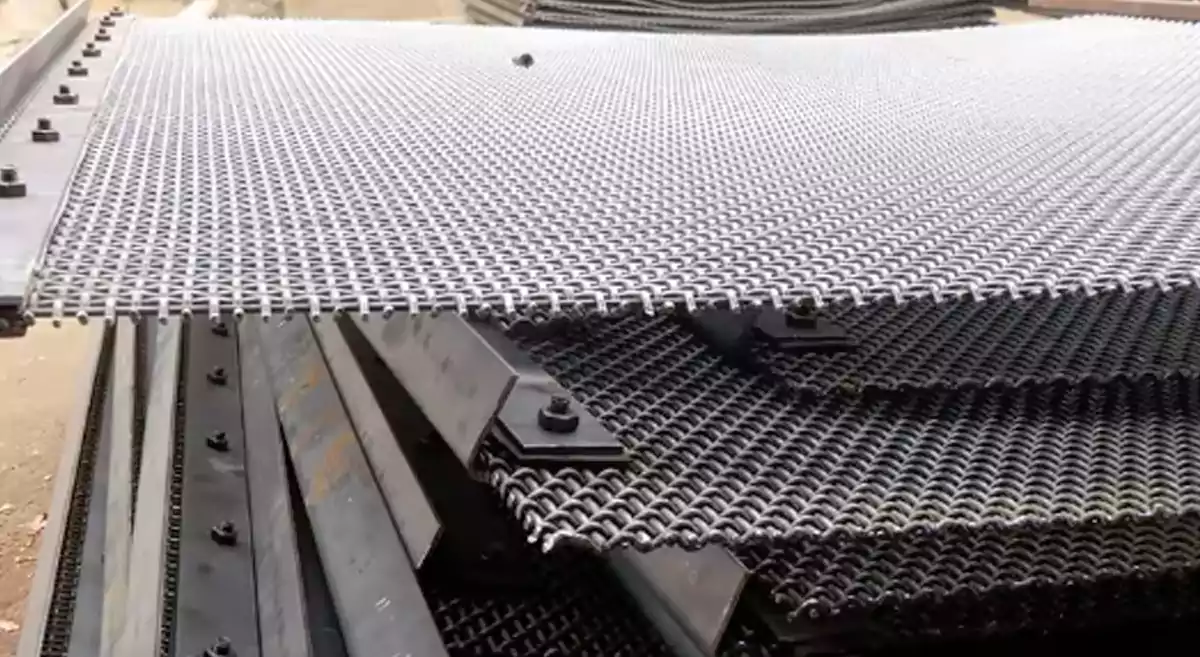

Trommel Screen Mesh

Mesh Types

You can pick from different mesh types for your trommel. Each type works best for certain materials and jobs. The table below shows some common choices:

| Mesh Type | Material Options | Advantages and Applications |

|---|---|---|

| Woven Wire Trommel Screen | High-strength carbon steel, spring steel, stainless steel | Has lots of open space, is light, good for dry stuff and small to medium pieces. |

| Perforated Trommel Screen | Low carbon steel, stainless steel | Very strong, best for tough jobs like building waste and raw ore. |

| Wedge Wire Trommel Screen | Stainless steel 304, 316L | Stops clogs, very strong, great for fine sorting and separating solids from liquids. |

| Polyurethane Trommel Screen | Polyurethane with steel frame | Lasts long, makes less noise, works well with wet stuff and draining water. |

Mesh Sizing

Mesh sizing is important for sorting materials well. You need to match the mesh hole size to the pieces you want to sort. Small holes let tiny pieces fall through. Big holes keep large pieces inside. The shape of the holes matters too. Round holes are best for even materials. Square or slotted holes work better for odd-shaped pieces. Longer drums give materials more time to separate. This helps the trommel sort better.

- Mesh hole size decides how many pieces can pass.

- Longer time in the drum helps sort better.

- Bigger screen area gives more chances for pieces to pass.

- Hole shape should fit your material type.

Replacement Media

You need to change old or broken mesh to keep your trommel working well. There are different types of replacement media. Each has good and bad points.

| Screening Media Type | Advantages | Disadvantages |

|---|---|---|

| Disc Screens | Clogs less, needs less fixing, is small | Not good for tiny pieces |

| Star Screens | Great for big stuff, works fast for large pieces | Not for tiny pieces, needs to tilt up |

| Self-Cleaning Screens | Needs less cleaning, good for sticky or wet stuff | Costs more, must fit the job, not as strong for rough use |

It is important to put new mesh in the right way. Make sure each piece sits flat and straight on the bars. This stops gaps and uneven wearing. Check the cross bars often, especially in wet jobs. Use liners to help your screen last longer.

Lifting Bars and Helix

Material Agitation

Lifting bars and helix shapes sit inside the drum. You use these trommel screen parts to move and mix materials as the drum spins. Lifting bars pick up materials and drop them down. This breaks up clumps and spreads them out. It helps sort sticky or wet stuff. Helix shapes move materials gently. They work well for organics or rooty topsoil.

- Lifting bars pick up and drop materials for better sorting.

- Helix shapes move materials softly, good for organics.

Screening Efficiency

Lifting bars help your trommel sort better. They run along the drum and keep materials moving. The lift-and-drop motion breaks up big pieces. It helps materials pass through the mesh. You get faster sorting and fewer clogs. When you sort wet or sticky stuff, lifting bars keep things moving smoothly. These parts help your trommel work better and make more.

Grizzly Bars

Oversized Material Removal

Grizzly bars help take out big pieces before the drum. You use these trommel screen parts to keep large, unwanted items away from your feed. This step keeps your equipment safe and helps things run well. Grizzly bars sit at the start of the trommel. They catch rocks and other big things. Only the right-sized material goes forward.

| Functionality | Description |

|---|---|

| Separation of oversized materials | Grizzly screens pull out big, unwanted pieces from smaller ones. This makes sure only the right size goes to the next machine. |

| Protection of downstream equipment | Grizzly screens stop big pieces from hurting crushers and other machines. |

| Customizable design | You can change the space between bars for different sizes. This makes the screen work better. |

You can move the grizzly bars closer or farther apart. This helps you sort your material the way you want.

Placement Options

You have a few ways to put grizzly bars on your trommel. Some trommel screen parts use bars that stay in one place at the hopper or feed chute. Others let you take off or move the bars for cleaning and fixing. You can set grizzly bars at different angles. Steep angles make material move fast. Flat angles slow it down for better sorting. Pick the spot and angle that works best for your job and material.

Tip: Check your grizzly bars often for damage or wear. Change or fix them when needed to keep your trommel working well.

Brushes and Cleaning Systems

Preventing Clogging

Brushes and cleaning systems help stop clogs in your trommel. You put brushes along the screen cloth to sweep off stuck stuff. When the drum spins, the brushes clean the mesh and stop buildup. You can move the brushes when they wear out to keep them working. This easy step keeps your trommel screen parts in good shape and cuts down on stops.

Cleaning Mechanisms

You can pick from different cleaning systems for your trommel. These systems make it easier to take care of your machine and stop big repairs.

- Quick-opening devices help you get into the drum fast for cleaning.

- Dust-proof devices make setup and fixing simple.

- Always check and clear out any junk from the drum before you start.

- Make sure the screen stays loose and adjust it if needed.

- Use calcium grease to oil the bearings.

- Oil the reducer with 45# oil at the right times.

- Check wires and tools to see if they work right.

- Tighten the drive chain so everything runs smooth.

Note: Cleaning your trommel often helps it last longer and sort better.

Tracks and Tires

Mobility Features

Tracks and tires help your trommel move where you need it. Tire-mounted carriers are good for roads and quick moves. Track-mounted carriers work well on rough ground and give better grip. You use these trommel screen parts to fit many places without building new roads.

- Tire-mounted carriers help you move fast and travel easily.

- Track-mounted carriers keep your trommel steady on bumpy ground.

- Flexible carriers let you use your trommel in lots of places.

Stationary vs. Mobile

You can pick stationary or mobile trommel screens for your job. Stationary ones stay in one spot and are good for long jobs. Mobile ones use tracks or tires to move around. Mobile trommel screens give you more choices, especially if you work in many places or need to move a lot.

Tip: Pick mobile trommel screen parts if you move your machine a lot. Use stationary parts for jobs where your trommel stays in one place.

How Trommel Screen Parts Work Together

Material Flow in the Drum

You control how materials move inside the drum by adjusting the design and setup of your trommel. The drum’s rotation, angle, and built-in parts all affect how well the trommel screening process works. If you set the drum at the wrong angle or use the wrong speed, you can slow down your screening efficiency. You want to keep materials moving smoothly from the feed end to the discharge end. The table below shows how different factors shape the flow of materials inside the drum:

| Evidence Description | Key Points |

|---|---|

| Structural Design Impact | The wrong design can lower performance. Drum angle, speed, and how long materials stay inside all matter. |

| Material Motion Analysis | Materials move in two ways: along the drum and across it. If too much piles up at the start, you get uneven flow. |

| Paving Components Role | Lifting bars and other built-in parts break up piles and spread materials out for better separation. |

You should check the drum’s speed and tilt often. This helps you avoid clogs and keeps the screen working well. When you use the right setup, you get even material flow and better results.

Separation Process

The trommel screening process uses several steps to sort materials by size. Each part of the trommel helps you get clean, sorted output. Here is how the separation works:

- You feed materials into the hopper. The hopper sends them into the drum to start the process.

- As the drum turns, materials tumble and mix with air. This helps dry wet materials and makes screening easier.

- The tumbling action breaks up clumps. Fine pieces fall through the screen mesh, while bigger pieces stay inside.

- You need to set the right drum speed. If the drum turns too slowly, materials can pile up and stick together, especially if they are wet.

- After screening, the sorted output drops onto a conveyor belt. Fines go into one pile, and larger pieces move to another area for more processing or disposal.

You can improve your results by watching each step. Make small changes to the drum speed or angle to get the best separation.

Interaction of Mesh, Lifting Bars, and Brushes

You get the best performance when the mesh, lifting bars, and brushes work together. The mesh lets small materials pass through while holding back larger pieces. Lifting bars pick up and drop materials as the drum spins. This action breaks up clumps and spreads materials across the screen. Brushes sweep the mesh clean, stopping clogs and keeping the holes open.

When you use all three parts together, you boost your screening efficiency. The lifting bars keep materials moving, the mesh sorts them by size, and the brushes keep the mesh clear. You get steady output and fewer stops for cleaning. This teamwork helps you handle wet, sticky, or mixed materials without losing speed or quality.

Tip: Check your brushes and lifting bars often. Replace worn parts to keep your trommel running smoothly.

Wet Screening with Water Jets

Wet screening with water jets is a strong way to deal with sticky or wet materials in your trommel screen. You use water jets to wash and separate things as they move inside the drum. This helps you keep your screening fast, even with clay or sludge.

Water jets do many helpful things in wet screening:

- Water works like a slippery layer and helps move small pieces. It stops fine bits from sticking to the mesh holes.

- You stop clogs, which keeps your work going without slowdowns.

- Spray bars or water jets are best for sticky stuff. You get better results with clay, compost, or sludge.

- Strong water sprays inside the drum wash big pieces. This helps you sort things better.

You put spray bars or water jets inside the drum. These jets spray water on the screen and the moving material. You can change the pressure and angle to fit your material. When you use water jets, you keep the mesh clean and open. This stops blockages and saves time.

| Feature | Benefit for Wet Screening |

|---|---|

| Water Lubrication | Stops fine particles from sticking |

| High-Pressure Showers | Washes large particles for better sorting |

| Adjustable Spray Bars | Lets you control water flow and pressure |

| Consistent Throughput | Keeps material moving and prevents clogs |

You notice a big difference when you screen wet stuff. Without water jets, sticky bits block the mesh. You lose time and have to clean more. With water jets, the screen stays clear. You can process more material faster.

Tip: Look at your spray bars and water jets often. Clean them to stop mineral buildup. Change old nozzles to keep the water strong.

You can use wet screening for many jobs. In mining, you wash ore and sort minerals. In waste jobs, you clean compost and sort organic stuff. In building, you handle wet soil and sand. Water jets help you get cleaner and more exact results.

You control the water amount for your material. Use more water for sticky or clay-rich feed. Use less water for sandy or loose stuff. Always check your water system for leaks or weak pressure.

Wet screening with water jets makes your trommel screen work for more jobs. You handle tough materials and keep things running well. You get better sorting, less downtime, and more work done.

Trommel Screen Mesh Systems

Choosing the Right Mesh

You have to pick the right mesh for your trommel. This helps you get the best results. The kind of material you use is important. How wet or sticky it is also matters a lot. Wet or sticky stuff can block the mesh. This makes your work slower. You should find mesh that can handle these problems. If you work with sticky things like clay, you need mesh that stops blinding. The right mesh keeps your screen clear. It helps you avoid stopping work.

Think about these things when you pick mesh:

- How wet your material is

- How sticky or thick your feed is

- The type and size of mesh holes

You can use different screens for different jobs. Vibrating screens are good for dry materials. Trommel screens are better for wet or sticky stuff because they tumble the material. Grizzly screens take out big pieces before the main job. Always match your mesh to your material. This keeps your work smooth.

Mesh Wear and Replacement

Mesh wear changes how well your trommel works. Over time, holes or tears can show up in the mesh. This makes sorting worse and causes more stops. You should check your mesh often. Look for tears, holes, or any buildup that blocks the screen. Listen for weird sounds or shaking. These signs mean your mesh needs help.

Polyurethane (PU) meshes last much longer than old types. They can last up to five times longer. This means you stop less and spend less money. Their strong surface helps your trommel run well. You should also check bolts and fasteners every week. A full check each month helps you find problems early.

Tip: Clean your mesh often to stop clogs and keep your screening working well.

Upgrading Mesh Media

Upgrading your mesh media gives you many good things. You get better results and your trommel lasts longer. New mesh types are stronger and work with many materials. You can make your trommel fit the exact material you use. This means you get cleaner results and stop less.

Here are some good things about upgrading mesh media:

- Better screening results

- Mesh lasts longer

- Works with many materials

- Best results for your needs

You should look at your mesh now and see if you need an upgrade. The right mesh upgrade can help you do more work and spend less on fixing things.

Trommel Screen Design and Performance

Drum Size and Length

You must pick the right drum size for your trommel. The drum size depends on what you want to sort. It also depends on how much material you have and if it is wet or sticky. A longer drum gives more time for sorting. This helps with wet or sticky materials. A wider drum means more space to work. You can sort more at once with a bigger drum. If you make the drum longer and wider, you get better sorting and more work done.

The drum’s diameter is important too. A bigger diameter gives more room for materials to move. This means you can sort more and do it better. But you need to balance the drum’s size with its speed and angle. If the drum spins too fast, sorting may not work well. If the slope is too steep, materials might leave before sorting is done. You should change these settings to fit your job.

Tip: Use a longer drum for wet or sticky stuff. This helps with sorting and stops clogs.

Mesh Opening Size

Mesh opening size tells you what can pass through the drum. You need to match the mesh size to your material size. Big holes let large pieces fall out. Small holes keep tiny pieces inside until they are ready. Picking the right mesh helps you get clean, sorted material.

If the mesh is too big, you lose small pieces you want. If the mesh is too small, it can clog and slow down your work. Always check your material size before picking the mesh. This makes sure your trommel works well and gives you good results.

Customization for Materials

You can change your trommel to fit your needs. Many features help you work with different jobs and materials. Heavy-duty steel makes the machine strong and last longer. Sub-frames give extra support for heavy loads. A loading hopper lets you put in raw materials easily. As the drum turns, it sorts the material. Finished pieces fall into a discharge hopper. Big pieces move forward for people to sort or for more work.

| Feature | Description |

|---|---|

| Heavy Duty Structural Steel | Strong frame holds the drum and drive parts for long use. |

| Sub-frame Assemblies | Extra support keeps the machine steady with heavy loads. |

| Loading Hopper | Puts raw materials into the drum for smooth work. |

| Screening Process | Drum turns and sorts materials, dropping finished pieces into the discharge hopper. |

| Discharge Mechanism | Moves finished pieces to the next step, like a conveyor or moving floor. |

| Handling Oversized Materials | Sends big pieces forward for people to sort or throw away. |

You can add lifter bars to help move things inside the drum. You can pick different screens for longer use. Drive systems like chains or gears help match the machine to your job. These choices let you build a trommel that fits your work and helps you do more.

Drive System Choices

You need to choose the right drive system for your trommel screen. The drive system powers the drum and controls how it spins. You see three main types: chain drive, gear drive, and hydraulic drive. Each system works best for certain jobs and materials.

| Drive System | How It Works | Advantages | Disadvantages |

|---|---|---|---|

| Chain Drive | Uses chains and sprockets | Simple, easy to fix, low cost | Needs regular oiling, can wear out faster |

| Gear Drive | Uses gears and shafts | Strong, handles heavy loads | Costs more, needs precise setup |

| Hydraulic Drive | Uses hydraulic motors | Smooth speed control, handles tough jobs | Needs more care, higher price |

Chain drives work well for light to medium jobs. You can fix them quickly and keep costs low. Gear drives give you more power. You use them for heavy materials or big drums. Hydraulic drives let you change speed easily. You use them for tough jobs or when you need to adjust the drum speed often.

Tip: Check your drive system every week. Oil chains and gears. Look for leaks in hydraulic lines. Fix problems early to avoid downtime.

You should match the drive system to your material and job size. If you process heavy rocks or wet soil, pick gear or hydraulic drive. For lighter jobs, chain drive saves money and works well.

Mobile vs. Stationary Trommels

You must decide if you need a mobile or stationary trommel screen. Mobile trommels move from site to site. Stationary trommels stay in one place and handle large, steady jobs.

Mobile Trommels:

- Mounted on tracks or tires

- Easy to move to new locations

- Good for short-term projects or changing job sites

- Set up quickly and start working fast

Stationary Trommels:

- Fixed in one spot

- Built for long-term use

- Handles high volumes every day

- Needs more setup but lasts longer

| Feature | Mobile Trommel | Stationary Trommel |

|---|---|---|

| Mobility | High | None |

| Setup Time | Fast | Slow |

| Job Flexibility | Very flexible | Best for fixed jobs |

| Capacity | Medium | High |

| Maintenance | Easier to access | Needs planned downtime |

You should pick a mobile trommel if you work at many sites or need to move often. Stationary trommels fit large plants or places where you sort materials every day. Mobile units help you save time and adjust to new jobs. Stationary units give you more power and handle bigger loads.

Note: Think about your job size, location, and how often you move. The right choice helps you work faster and keeps your costs low.

Selecting and Maintaining Trommel Screens

Choosing Trommel Screen Parts

When you pick a trommel screen, you need to think about many things. Your choice changes how much you can sort and how well your machine works. It also affects how long your machine will last. Each part should fit your job and the materials you use.

Here are some things to think about when picking trommel screen parts:

- Processing Requirements: Know what kind of material you want to sort. Think about how much you need to process. This helps you choose the right screen size and setup.

- Budget: Look at prices and see what you can spend. Try to find a good mix of price and quality. This helps your machine work well for a long time.

- Expected Lifespan: Check what the parts are made of. Stronger parts last longer and keep your trommel working better.

- Maintenance Requirements: Pick parts that are easy to clean and change. Easy maintenance keeps your machine running and stops long breaks.

- Customization Options: Some screens let you change mesh size or drum length. You can add special features too. Custom parts help you sort your own materials better.

- Manufacturer’s Experience: See if the company has a good history. Companies with more experience give better help and stronger parts.

- Manufacturer’s Support: Make sure you can get spare parts and help when you need it. Good support keeps your trommel working and protects your work.

You should also think about how much you want to make and how your machine is built. Where you put the conveyor matters for easy use. Custom parts help you sort special materials and get better results. If you are not sure which trommel to pick, ask about the best one for your job.

Tip: Always ask where to buy a trommel screen with strong manufacturer support. This helps you get good parts and quick help if you need repairs.

Maintenance Tips

Doing regular checks keeps your trommel screen working well. You want to keep your output high and stop breakdowns. Simple steps help your parts last longer and sort better.

Try these tips for good maintenance:

- Check the drum, mesh, and lifting bars every week. Look for cracks, wear, or stuff that blocks the screen.

- Clean the screen and brushes often. Take off stuck material to keep the mesh open.

- Oil moving parts like chains, gears, and bearings. Oil stops damage and keeps your trommel running smooth.

- Tighten bolts and fasteners. Loose parts can shake and make your machine work worse.

- Change old mesh and brushes fast. New parts keep your output high and stop long breaks.

- Look at the drive system for leaks or weak spots. Fix problems early to stop bigger repairs.

Keep a log of your checks and repairs. Write down each time you look at or fix something. This helps you see problems early and plan for new parts. Good care gives you better sorting and more from your trommel.

Note: Check all parts often. Preventive care saves money and keeps your screening working well.

Troubleshooting

If your trommel screen stops or sorts less, you need to find the problem fast. Troubleshooting helps you fix things and get your machine working again. Start with the most common problems and check each part.

Here is a simple troubleshooting guide:

| Problem | Possible Cause | Solution |

|---|---|---|

| Low output | Clogged mesh or worn parts | Clean mesh, replace worn components |

| Uneven separation | Drum speed or angle wrong | Adjust speed and tilt |

| Excess vibration | Loose bolts or damaged parts | Tighten bolts, replace damaged components |

| Frequent breakdowns | Poor maintenance | Improve inspection and cleaning |

| Material buildup | Weak brushes or water jets | Replace brushes, check water system |

If you cannot fix the problem, call the manufacturer for help. They can give you the right parts and advice. This keeps your trommel working well and protects your output.

Tip: Keep extra parts ready. Quick changes help you avoid long stops and keep your screening moving.

Optimizing Efficiency

You want your trommel screen to work at its best every day. To reach top efficiency, you must focus on a few key areas. Start with the basics. Keep your machine clean and free from blockages. Check the drum, mesh, and brushes before each shift. Remove any stuck material right away. This simple habit keeps your screen open and ready for work.

Set the drum speed and angle for your material. If you process wet or sticky feed, use a slower speed and a steeper angle. This helps materials move and sort better. For dry or loose material, a faster speed and a flatter angle work well. Adjust these settings as your material changes. You will see better sorting and less downtime.

Use the right mesh size for your job. If you use mesh that is too small, you will get clogs. If you use mesh that is too large, you will lose valuable fines. Match the mesh to your material size. Check the mesh often for wear or damage. Replace worn mesh quickly to keep your output high.

You should also use quality replacement parts. Cheap or poor-quality parts wear out fast. They cause more stops and lower your output. Buy parts from trusted suppliers. Ask for advice if you are not sure which part fits your job.

Train your team to spot problems early. Show them how to check for loose bolts, worn brushes, or weak water jets. A well-trained team keeps your trommel running smoothly.

Here is a quick checklist to help you optimize your trommel screen:

| Task | How Often | Why It Matters |

|---|---|---|

| Clean drum and mesh | Daily | Prevents clogs and keeps output high |

| Check drum speed and angle | Each shift | Matches settings to material type |

| Inspect mesh and brushes | Weekly | Stops wear from causing downtime |

| Lubricate moving parts | Weekly | Reduces friction and extends life |

| Replace worn parts | As needed | Keeps efficiency and output steady |

| Review team training | Monthly | Ensures everyone knows best practices |

Tip: Work with your equipment supplier for regular checkups. Professional support helps you spot issues early and keeps your trommel in top shape.

You can boost your efficiency by following these steps. Small changes make a big difference. Stay alert, use quality parts, and keep your team trained. Your trommel screen will reward you with steady, high-quality output.

Conclusion

You have learned how each trommel screen part—drum, mesh, lifting bars, grizzly bars, brushes, and drive system—plays a key role in sorting materials. When you know these parts, you can choose the right screen, keep it running, and get better results.

For the best performance, work directly with a professional screen manufacturer. We can help you choose the right mesh system and replacement screening media for your specific material and operating conditions.

FAQ

What materials can you process with a trommel screen?

You can use a trommel screen for many things. It works with soil, compost, sand, gravel, wood chips, and city waste. Trommel screens sort wet, sticky, or mixed stuff well. Many industries use them because they are reliable.

How often should you replace trommel screen mesh?

Check the mesh every week to look for damage. If you see holes, tears, or lots of wear, change it. Good mesh helps your machine work better and stops long breaks.

Can you use a trommel screen for wet materials?

Trommel screens work with wet materials too. Water jets and brushes help stop clogs. You get cleaner sorting when you use them for wet or sticky things.

What is the difference between mobile and stationary trommel screens?

Mobile trommel screens can move from place to place. Stationary trommel screens stay in one spot and handle more material. Pick mobile for moving jobs and stationary for big, long jobs.

How do you prevent clogging in a trommel screen?

Use brushes, cleaning systems, and water jets to keep mesh clear. Clean and check your machine often to stop clogs and keep it working well.

What maintenance does a trommel screen need?

Clean the drum and mesh often. Oil moving parts and check for loose bolts. Change old mesh and brushes fast. Regular checks help your trommel last longer.

Can you customize trommel screen parts for your job?

You can change drum size, mesh type, drive system, and how it moves. Custom parts help your trommel fit your job and the materials you use.