How does a trommel screen work? You feed material into a rotating drum with mesh panels and lift bars. The trommel lifts and tumbles the mix. Smaller pieces fall through the mesh while larger ones move forward and exit. The trommel screen working principle uses drum movement to keep material flowing and sort by size.

Why should you care about the trommel screen working principle?

- The trommel keeps material moving for nonstop separation.

- You can change drum speed and angle to boost performance and stop clogs.

- The trommel screen working principle works well with wet, sticky materials.

Key Takeaways

- Trommel screens have a drum that spins to sort materials by size. Smaller pieces fall through the mesh panels.

- You can change the drum speed and angle to make it work better. This also helps stop clogs and makes screening more efficient.

- The mesh size is very important. It should fit the material size so blockages do not happen and separation works well.

- Lift bars inside the drum break up clumps. They also help materials move easily, even if they are wet or sticky.

- Cleaning systems like brushes or spray bars are used for maintenance. Regular cleaning keeps the trommel working well and stops long breaks.

- Trommel screens can be used for many things. They can handle compost, gravel, and waste, so they are good for different jobs.

- If you take care of a trommel screen, it can work very well. It can reach high efficiency, usually between 85% and 95%. This saves time and money on labor.

- Knowing the trommel’s parts and what they do helps you use it better and get good results.

Trommel Screen Working Principle

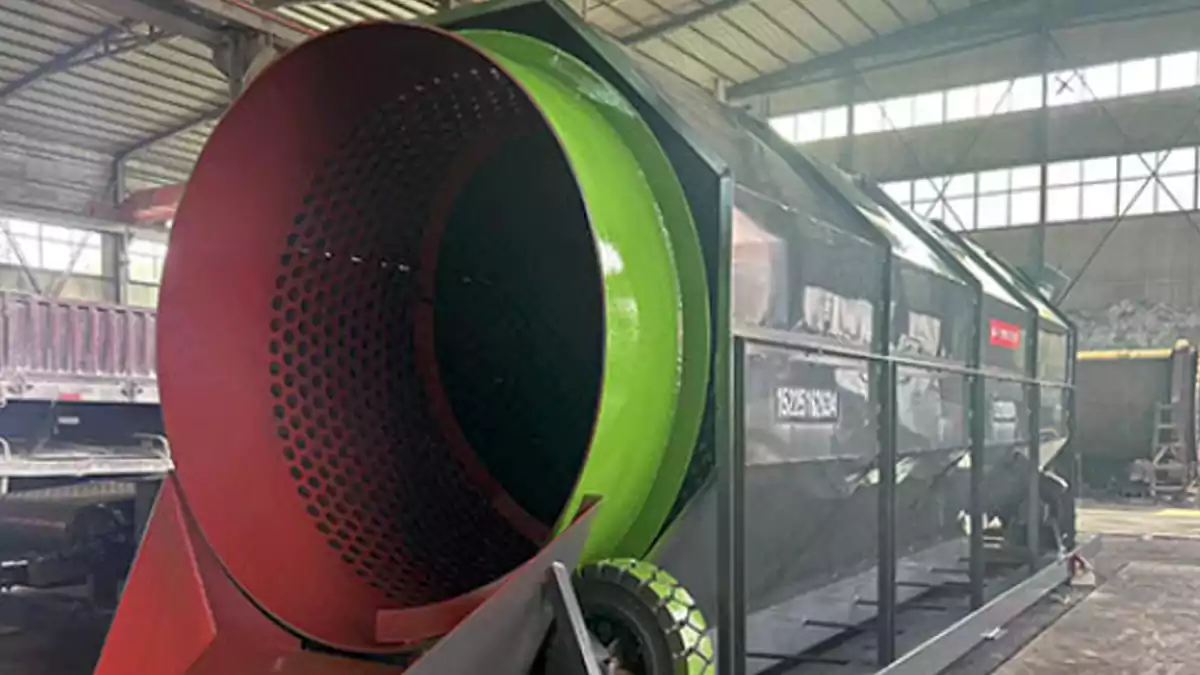

Rotating Drum Mechanism

Picture a large, tilted drum spinning slowly. That’s the heart of a trommel. You feed material into one end of the drum. The motor turns the drum, and lift bars inside scoop up the material as it rotates. These lift bars do more than just move things around—they break up clumps and keep everything loose. This helps wet or sticky stuff move smoothly, so you don’t get jams. If you work with compost or mulch, you might want taller lift bars. For dry rocks or sand, shorter bars work better.

Here’s how the main steps of the trommel screen work:

- The drum starts to rotate, and the lift bars pick up the material.

- As the drum turns, the material falls and spreads out, letting smaller pieces reach the mesh.

- Fine particles drop through the holes in the mesh panels.

- Larger pieces keep moving forward until they reach the end and exit.

- You can adjust the speed and angle of the drum to get the best screening results.

The speed of the drum matters a lot. If you set it too slow, the material just slides along, and only the smallest bits get screened. If you find the right speed, the material tumbles and spreads out, so more of it touches the mesh. This boosts your screening efficiency. But if you go too fast, everything sticks to the drum wall, and screening drops off.

Material Separation by Size

The trommel screen sorts material by size. The mesh panels have holes that let only small particles pass through. Bigger pieces stay inside and move toward the exit. The size of the mesh controls what gets through. If you use a mesh with big holes, only the smallest pieces fall out. If the mesh holes are almost the same size as your material, you might get clogs, and screening slows down.

Here’s a quick look at how mesh size affects separation:

| Key Concept | Explanation |

|---|---|

| Mesh Size vs. Particle Size | When the mesh size is larger than the particulate size, smaller particles can escape through the holes, leading to effective size separation. |

If your material is close in size to the mesh holes, you might see more blockages. This means less screening area and lower efficiency.

You want to match the mesh size to your material for the best separation. That way, you get clean piles of screened material, ready for the next step.

Role of Downward Incline

The angle of the trommel drum makes a big difference. Most trommel screens sit at a slight downward tilt. This incline helps move material from the feed end to the discharge end. If you work with dry material, a steeper angle moves things faster and helps with quick screening. For wet or sticky material, a shallower angle keeps the material inside longer, giving it more time to separate.

Here’s a handy table for incline angles:

| Material Type | Optimal Incline Angle |

|---|---|

| Dry Materials | Steeper angles for faster separation |

| Wet Materials | Shallower angles for longer residence time |

| General Use | 5° to 8° incline |

You can adjust the angle to fit your material and your screening goals. A good setup means you get steady flow, less clogging, and better separation.

Tip: If you want to boost your screening efficiency, play with the drum speed and incline. Small changes can make a big difference in how well your trommel screen works.

By understanding these key parts—the rotating drum, the mesh size, and the drum’s angle—you can get the most out of your trommel screen. You’ll see better screening, less downtime, and cleaner separation every time.

Trommel Screen Components

Drum and Mesh

When you look at a trommel, the drum stands out first. This drum is a big, round cylinder that rotates slowly. You feed material into one end. The drum has mesh panels with holes all over its surface. These holes decide what size of material can pass through. If you want to separate fine sand from rocks, you pick a mesh with small holes. For bigger pieces, you choose larger holes.

The mesh does more than just let small pieces fall through. It also helps keep the larger chunks moving forward. As the drum turns, the mesh lifts and drops the material. This action spreads everything out, so more of it touches the mesh. You get better separation and less waste. If you work with sticky or wet material, you might see the mesh clog up. That’s where cleaning systems come in, but more on that soon.

Lift Bars

Inside the trommel drum, you find lift bars. These bars run along the inside wall. They do an important job. As the drum rotates, the lift bars scoop up clumps of material and drop them back down. This movement breaks up sticky lumps and keeps everything loose. You don’t want blockages in your trommel. Lift bars help prevent that, especially with wet or sticky loads. They make sure the material keeps moving and gets plenty of chances to touch the mesh.

Lifting bars within the trommel drum are designed to elevate clumps of material, which helps to prevent blockages in the screen. This function is crucial, especially when dealing with wet or sticky materials, as it enhances the overall movement and separation of materials.

You can change the size and shape of the lift bars. Taller bars work well for compost or mulch. Shorter bars fit dry gravel or sand. If you notice your trommel isn’t separating material well, check the lift bars. Sometimes, a small change makes a big difference.

Cleaning Systems

Every trommel needs a way to stay clean. When you screen wet or sticky material, the mesh can clog up fast. That’s where cleaning systems help. Some trommels use brushes, others use spray bars or even rubber balls.

A heavy-duty nylon brush system is an effective cleaning system for preventing mesh clogging in trommel screens, particularly when handling wet and sticky materials.

You want to keep the mesh clear so the trommel works at its best. If you see the screen slowing down, check the cleaning system. A good brush or spray keeps the holes open and the material moving. This means less downtime and more clean, separated product for you.

If you set up your trommel with the right drum, mesh, lift bars, and cleaning system, you get smooth operation and great results. Each part plays a role in making sure your material gets sorted quickly and efficiently.

Drive and Frame

When you look at a trommel screen, you see a big drum, but the real magic happens with the drive and frame. These parts keep everything moving and steady. The drive system powers the drum, making sure it spins at the right speed. The frame holds the whole machine together, giving it strength and stability.

Let’s talk about the drive first. You have a few options for how the drum gets its power. Each type of drive has its own strengths and weaknesses. Here’s a quick table to help you see the differences:

| Drive Mechanism | Description | Impact on Reliability |

|---|---|---|

| Gear Drive | Uses gears to turn the drum. | Very efficient and reliable. Gears give strong, steady power. |

| Chain Drive | Uses chains to move the drum. | Reliable, but you need to check for wear and keep it oiled. |

| Belt Drive | Uses belts to spin the drum. | Works well, but belts can slip if the load gets heavy. |

| Friction Drive | Uses wheels that press against the drum to make it turn. | Simple design, but can slip and lose power, especially with heavy loads. |

You might wonder why there are so many choices. Sometimes, you need a tough drive for heavy rocks. Other times, you want something simple for lighter jobs. Many trommel screens use a mix of gear, chain, and friction drives. If you use a friction drive, the wheels have a rough surface. This helps them grip the drum better and stops slipping. Still, friction drives can struggle if the drum gets too heavy with material.

Here are some things you should know about drive designs:

- Gear and chain drives work best when you need strong, steady power.

- Belt drives run quietly, but you need to watch for slipping.

- Friction drives keep the design simple, but they can fail if the drum is overloaded.

- The weight of the drum and the material inside can make friction drives less reliable.

- Rough-surfaced friction wheels help prevent slippage and keep things running smoothly.

Now, let’s look at the frame. The frame is the backbone of your trommel screen. It holds the drum, the drive system, and all the other parts. A strong frame keeps everything lined up and stops the machine from shaking or moving. If the frame is weak, you get more wear and tear, and your screen won’t last as long.

You want a frame made from heavy-duty steel. This gives you the strength to handle big loads and tough jobs. The frame also needs to support the drum at the right angle. If the angle is off, material won’t move right, and you lose efficiency.

Tip: Always check the frame and drive system before you start screening. Tighten bolts, look for worn parts, and make sure everything is lined up. A little maintenance goes a long way!

When you pick a trommel screen, pay close attention to the drive and frame. These parts decide how well your machine runs and how long it lasts. With the right setup, you get smooth operation, less downtime, and better results every time.

Trommel Screening Process

The trommel screening process helps you separate materials quickly and efficiently. You can break it down into three main steps: feeding the material, screening and separation, and finally, collecting the sorted products.

Material Feeding

You want to start with even and steady feeding. If you feed the trommel too fast or too slow, you might get clogs or uneven separation. Most people use conveyor belts or hoppers to load material into the trommel. These tools spread the material out and help you avoid blockages. You can also use a manual feed system for smaller jobs, but conveyors work best for big loads.

Before you start, make sure you remove any oversized or non-processable items. This keeps the trommel running smoothly. Always check that the machine sits on level ground and that all safety covers are in place. When you turn on the trommel, let it reach a steady speed before you feed in the material. This way, you get a consistent flow and better results.

Tip: Consistent feeding means better screening. Try to keep the material moving at the same rate for the best performance.

Screening and Separation

Once the material enters the trommel, the real action begins. The drum rotates and lifts the material with its internal bars. As the material tumbles, smaller pieces fall through the mesh panels. Larger pieces stay inside and move toward the end of the drum.

You might wonder how well a trommel works compared to other screens. Here’s a quick look:

| Screen Type | Efficiency in Coarse Materials | Efficiency in Fine Materials | Notes |

|---|---|---|---|

| Trommel Screen | High | Low | Great for big pieces, but not as accurate for fine particles. |

| Vibrating Screen | High | High | Works well for both coarse and fine materials. |

Trommels shine when you need to sort coarse materials. If you work with fine particles, you might see better results with a vibrating screen. Still, the trommel handles wet, sticky, or bulky loads with ease.

Discharge and Collection

After screening, you need to collect the separated materials. Fine materials drop below the trommel and land on collection conveyors or bins. Larger pieces exit at the end of the drum. You can adjust the drum speed and angle to get the best separation for your material.

Here are some best practices for this stage:

- Pick the right mesh size for your material.

- Clean the mesh regularly to prevent clogs.

- Check the drum speed and angle often.

- Do routine maintenance to keep your trommel in top shape.

If you follow these steps, you’ll get clean, sorted piles ready for the next process. The trommel screening process gives you control and flexibility, making it a smart choice for many jobs.

Design Features for Efficient Separation

Drum Incline and Speed

You can boost your trommel screen’s performance by adjusting the drum’s incline and speed. The drum sits at a slight angle, which helps move material from one end to the other. When you set the right incline, fine materials sift through the mesh faster, while larger pieces stay inside longer. If you work with sticky or wet material, a gentle incline keeps everything inside the drum for more time. For dry, coarse material, a steeper angle moves things along quickly.

Drum speed matters, too. If you turn the drum too slowly, material just slides and doesn’t separate well. If you go too fast, everything sticks to the drum wall and skips the mesh. You want to find the sweet spot. Most trommel screens let you change the speed. This helps you match the drum’s movement to your material.

Tip: Start with a slow speed and a gentle incline. Watch how your material moves. Then, make small changes until you see the best separation.

The right combination of drum incline and speed lets you separate fine and coarse materials with less effort. You get cleaner piles and less waste.

Mesh Size Selection

Picking the right mesh size is key for efficient screening. The mesh panels have holes that decide what size of material can pass through. If you choose a mesh that’s too small, you might get clogs. If it’s too big, you lose valuable fine material.

Here’s a table to help you see what matters when choosing mesh size:

| Criteria | Description |

|---|---|

| Specifications, Standards & Compliance | Make sure your mesh meets safety and quality standards like ISO 9001 or CE. |

| Performance & Quality Validation | Look for screens that give you over 90% efficiency and cut downtime by at least 25%. |

| Cost-Efficiency Analysis | Think about the total cost, including energy and maintenance, over five years. |

| Wear Resistance & Longevity | For tough jobs, pick polyurethane-coated drums or stainless steel mesh that lasts over 5,000 hours. |

You want a mesh that matches your material and your job. If you screen sand, go for a fine mesh. For rocks or wood chips, pick something larger. Always check the mesh for wear and replace it when needed.

Internal Lifters

Internal lifters, or lift bars, play a big role in how well your trommel screen works. These bars run along the inside of the drum. As the drum turns, the lifters scoop up material and drop it back down. This action breaks up clumps and spreads everything out. You get more contact with the mesh, which means better separation.

You can change the size and shape of the lifters to fit your material. Tall lifters work well for sticky or wet loads. Shorter lifters fit dry, loose material. If you notice your trommel isn’t separating material well, try adjusting the lifters.

Note: Internal lifters help prevent blockages and keep your trommel running smoothly, even with tough materials.

When you combine the right drum incline, speed, mesh size, and lifter design, you get a trommel screen that works hard and lasts long. These features make your job easier and your results cleaner.

Cleaning Mechanisms

You want your trommel screen to keep working without stops. That means you need a good cleaning system. If you let the mesh get clogged, your screening slows down. You might even have to shut down the machine to clean it by hand. No one wants that.

Let’s talk about what works best. The most common cleaning mechanism is the self-cleaning brush. This brush sits right against the mesh panels. As the drum turns, the brush sweeps over the holes. It pushes out any particles that try to stick. You get steady material flow and less downtime. The brush does the hard work for you.

You also get help from the drum itself. The trommel drum spins and rolls the material inside. This rolling motion knocks loose any bits that might block the holes. The material tumbles and slides, so clogs don’t have a chance to build up. You keep your throughput high and your operation smooth.

Here’s a quick list of cleaning mechanisms you might find on a trommel screen:

- Self-cleaning brushes: These brushes sweep the mesh clean as the drum rotates. They work well for wet or sticky materials.

- Spray bars: Water jets spray the mesh to wash away fine particles. You see these on trommels that handle soil or compost.

- Rubber or plastic balls: These bounce inside the drum and knock loose any stuck material. They work best for dry loads.

- Continuous rolling motion: The drum’s movement helps clear the mesh by itself. You get fewer blockages and more uptime.

Tip: Check your cleaning system every day. A worn-out brush or blocked spray bar can slow you down. Replace parts before they fail to keep your trommel running strong.

You can mix and match cleaning systems. For example, you might use both brushes and spray bars if you handle tough, sticky loads. If you mostly screen dry gravel, the drum’s rolling action might be enough.

Cleaning mechanisms do more than just keep the mesh open. They help you get better separation and cleaner products. You spend less time on maintenance and more time getting work done. If you want your trommel screen to last, don’t skip on cleaning systems. They make your job easier and your results better.

Advantages of Trommel Screens

Screening Efficiency

You want a machine that gets the job done fast and right. Trommels deliver high screening efficiency, usually between 85% and 95%. That means you can separate most of your material in one pass. You save time and cut down on labor. The tumbling action inside the drum gives every piece a chance to touch the mesh. Smaller bits fall through, while bigger chunks move forward. You can adjust the drum speed and angle to match your material. When you set things up well, you get clean piles with very little waste.

Did you know? The best screening efficiency happens when you run the drum at 30% to 40% of its critical speed and keep the feed rate at about 70% to 80% of what the machine can handle.

Here’s a quick look at how trommels stack up against other screens:

| Advantage | Description |

|---|---|

| Increased Efficiency | Trommels can process large volumes quickly, saving time and reducing labor costs. |

| Reduced Downtime | Durable design and simple maintenance lead to minimal operational interruptions. |

You get more work done with less hassle. That’s a win for any job site.

Versatility

Trommels shine when you need to handle different materials. You can use them for wet, sticky loads or dry, loose stuff. They work in many industries, from mining to landscaping. You can even screen compost, mulch, or wood chips. The drum and mesh come in many sizes, so you can pick what fits your job.

Check out how versatile trommels are:

| Industry | Application Description |

|---|---|

| Mining/Aggregate | Sorts minerals and ores by size, keeping oversized rocks out. |

| Construction | Separates sand and gravel, making sure you meet project specs. |

| Landscaping | Screens topsoil and mulch, giving you clean, high-quality soil. |

| Hemp/Cannabis | Removes unwanted plant material for better extraction. |

| Compost | Separates organic waste, so you get pure compost. |

| Lumber Mill By-Products | Classifies sawdust and wood chips for new products. |

| Municipal Solid Waste | Sorts trash to help with recycling and cut down on landfill waste. |

You can switch out drums or mesh panels to handle new jobs. That flexibility makes trommels a smart choice for many businesses.

Low Maintenance

You want equipment that keeps running with little fuss. Trommels have a simple, tough design. They use fewer moving parts than other screens. That means less can go wrong. You spend less time fixing things and more time working. The drum and mesh last a long time, even with heavy use. Cleaning systems like brushes or spray bars keep the mesh clear, so you don’t have to stop for clogs.

Here’s why you’ll love the low maintenance:

- Handles wet and sticky materials without clogging.

- Simple design means fewer breakdowns.

- Easy to swap out drums or mesh for different jobs.

- Cleaning systems keep things running smoothly.

Tip: Regular checks and quick cleaning help your trommel last even longer.

When you look at the advantages of using a trommel screen, you see why so many industries trust this tool. You get high screening efficiency, the ability to handle almost any material, and a machine that keeps working with little downtime.

Applications in Industry

Trommel screens are used in many industries. These machines help sort materials fast. Let’s see where trommel screens make work easier.

Mining and Aggregates

If you work in mining, you need to sort rocks by size. Trommel screens can handle tough jobs like sorting stone, gravel, and sand. You put raw material into the drum. The trommel spins and sorts by size. Big rocks move out one end. Small pieces fall through the mesh. This keeps your work running smoothly.

You can use trommel screens for topsoil, sand, and wood chips. These uses help you get clean piles for your next step. Many mining sites pick trommel screens because they work well with wet or sticky loads. You can change drum speed and mesh size to fit your needs.

Here’s a quick look at throughput rates for different jobs:

| Application | Typical Throughput Rates |

|---|---|

| Sizing crushed aggregate | Varies by material |

| Sand | Varies by material |

| Topsoil | Varies by material |

Waste Management

Trommel screens are important in waste management. You can use them to sort solid waste, compost, and organics. The drum separates materials by size. You get clean streams for recycling or disposal. If you handle compost or mulch, a trommel helps remove big debris and gives you a fine product.

You might see trommel screens at recycling centers. They sort plastics, metals, and glass. This makes recycling faster and easier. You can also use them for organics processing. The drum keeps things moving, so you don’t get clogs.

Here are some common jobs in waste management:

- Compost

- Mulch

- Municipal solid waste

- Organics processing

Trommel screens give you flexibility. You can switch between materials with little downtime.

Concrete and Recycling

In concrete and recycling, you want to sort materials quickly. Trommel screens help sort concrete rubble, asphalt, and debris. The drum removes fines and separates bigger pieces. This makes it easier to recycle and reuse materials.

You can use trommel screens for sizing mulch, wood chips, and glass. These uses help keep your work clean and organized. You get more value from waste and less goes to the landfill.

Here’s a list of materials you can process with a trommel:

- Concrete rubble

- Asphalt

- Wood chips

- Glass

Trommel screens work in many jobs. You can find them in mining, waste management, and recycling. They help you save time, cut waste, and get work done right.

Common Challenges and Solutions

When you use a trommel, you want it to run smoothly. Sometimes, you face problems that slow you down. Let’s look at the most common issues and how you can fix them.

Clogging and Cleaning

Clogging happens when material gets stuck in the screen holes. Wet or sticky loads can cause this. You might see the screen plug up with big pieces or blind over with fine, wet material. This stops the trommel from sorting well. You spend more time cleaning and less time working.

Here’s a quick table of common challenges and what they mean for your trommel:

| Challenge | Description |

|---|---|

| Screen Plugging | Large pieces get stuck in the mesh, stopping the flow. |

| Screen Blinding | Wet or sticky material covers the holes, blocking separation. |

| Energy Use | Clogs make the drum work harder, using more power and raising costs. |

You can fight clogging with good cleaning systems. Self-cleaning brushes or spray bars help keep the mesh clear. If you handle wet loads, check your cleaning system every day. You can also slow the drum or use a mesh with bigger holes for tough jobs. Some screens, like the BIVITEC® flip-flow, use a different motion to stop clogging, but most trommel screens do well with regular cleaning.

Tip: Clean your trommel after each shift. This keeps the mesh open and your work on track.

Wear and Durability

Trommel screens work hard. Over time, the drum and mesh can wear out. Rocks, sand, and debris hit the mesh again and again. If you see holes or tears, it’s time to replace the mesh. Drum damage can cost a lot to fix, so check for cracks or dents often.

You can make your trommel last longer by picking strong materials. Stainless steel mesh and heavy-duty drums stand up to tough jobs. Keep the frame tight and the drive system oiled. If you spot a problem early, you can fix it before it gets worse.

- Check the mesh for wear every week.

- Tighten bolts and oil moving parts.

- Replace worn parts before they break.

Note: A well-maintained trommel runs longer and saves you money.

Throughput Optimization

You want your trommel to sort as much material as possible. If you feed it too fast, you get clogs. If you go too slow, you waste time. The right speed and angle help you get the best results.

Try these steps for better throughput:

- Start with a slow feed and watch the material move.

- Adjust the drum speed until you see steady flow.

- Change the incline if material moves too fast or too slow.

- Pick the right mesh size for your job.

If you work in a small space, remember that trommel screens can be big. Plan your setup so you have room to feed and collect material. With the right setup, you get more done and keep your trommel running strong.

Keep an eye on your trommel. Small changes can make a big difference in how much you sort each day.

By knowing these common challenges and using smart solutions, you keep your trommel working its best. You save time, cut costs, and get cleaner results.

Conclusion

Now you understand how a trommel works. The rotating drum, lift bars, and mesh panels sort material by size. You can process lots of material quickly. Trommel screens help stop clogs and save energy. They are used in mining, aggregate, concrete, and recycling jobs. You can choose mesh sizes that fit your needs. The strong design means less downtime and lower costs. Anpeng Wire Mesh Filter Equipment Co., Ltd. makes tough screening tools like woven wire screens, self-cleaning screens, and PU-mesh screens. If you want clean results and better work, a trommel is a smart pick.

- High capacity helps you handle more material.

- Less clogging keeps your trommel working well.

- Custom mesh sizes match your job.

- Energy efficiency saves money.

- Durability means fewer fixes.

Want to improve your work? Try a trommel for your next material sorting job.

FAQ

What materials can you process with a trommel screen?

You can use trommel screen sifters for soil, gravel, compost, sand, and even waste. They handle wet, sticky, or dry materials. You get clean separation for many jobs.

How do you choose the right mesh size?

You should match mesh size to your material. Smaller holes catch fine particles. Larger holes let bigger pieces pass. Selecting the right trommel screen helps you get the best results for your project.

Can a trommel screen handle composting?

Yes! Trommel screens work great for composting. They separate finished compost from larger debris. You get a fine product ready for gardens or farms.

What is the main advantage of using trommel screens?

You get easy breakdown and separation of materials. The rotating drum keeps everything moving. This means less clogging and more efficient sorting.

How do you keep your trommel screen clean?

Most screening equipment uses brushes or spray bars. These systems clear the mesh as the drum turns. You spend less time on maintenance and more time working.

Are trommel screens easy to maintain?

Yes, they are. Trommel screens have simple designs. You can check parts quickly. Regular cleaning and inspections help your machine last longer.

What industries use trommel screens?

You find trommel screens in mining, recycling, landscaping, and waste management. They also help with soil and compost jobs. Many industries trust them for fast, reliable sorting.