When you look at metal screen mesh, each type has a special job. Some types, like gravity, vacuum, and pressurized, move big materials or filter liquids. They can also handle hard work. Choosing the right type of metal screen mesh is important. You should think about temperature, rust, and the size of things you want to catch. The best types of metal screen mesh work well and help your machines run smoothly.

Key Takeaways

- Metal screen mesh has many types. Each type is made for a special job like filtering or holding things up.

- Picking the right mesh depends on what it is made of, what you need it for, its size, and how strong it is. This helps make sure it works for your project.

- Woven wire mesh bends easily and is good for light work. Welded wire mesh is very strong and best for tough jobs.

- Expanded metal mesh is strong and lets air move through. It works well for security and machine guards.

- Perforated metal mesh can look different because of its many hole shapes. It is good for both looks and use.

- Self-cleaning screens shake off dirt by themselves. This makes them great for messy places.

- Cleaning and checking your wire mesh often can help it last longer. This keeps it working well.

- Talking to experts can help you pick the right mesh for your job.

What Are Metal Screen Meshes

Definition and Function

When you hear about metal screen mesh, you might picture a grid made from thin wires. That’s pretty close! Metal mesh is a material made by weaving or joining wires together. You often see it in construction, but it pops up in lots of other places too. You use mesh to separate, filter, or protect things. Some types of metal mesh work best for heavy-duty jobs, while others fit lighter tasks. Manufacturers design mesh with different strengths, so even if two pieces look the same, they might handle pressure or weight differently. You need to match the right mesh to your project for the best results.

Common Materials

You can find mesh made from several metals. Each one has its own strengths and weaknesses. Here are the most common choices:

- Plain carbon steel gives you strong mesh that can take a hit. It doesn’t fight off rust very well, but coatings help.

- Stainless steel stands up to rust and heat. You’ll see different grades:

- 304 works outside and in food factories because it resists corrosion.

- 316 handles salty air and water better than other types.

- 410 deals with high temperatures.

- 430 resists chemicals and heat.

- Aluminum is light and doesn’t rust easily, so it’s great for outdoor mesh.

- Copper and brass show up in decorative mesh because they look nice and resist corrosion.

When you pick from the types of metal mesh, you need to think about where you’ll use it. Some mesh needs to last in tough weather, while others just need to look good.

Key Features

You might wonder what sets metal mesh apart from other screen materials. Take a look at this table to compare some features:

| Feature | Aluminium Mesh | Fibreglass Mesh |

|---|---|---|

| Durability | Highly durable, resists rust and corrosion | Less durable, can tear or break |

| Maintenance | Easy to clean, needs little care | Needs more replacements |

| Installation | Harder to install, not very flexible | Simple to install, bends easily |

| Aesthetic Appeal | Looks sleek, almost invisible | Can block your view |

| Environmental Impact | Recyclable, good for the planet | Not as eco-friendly |

Metal mesh gives you strength and long life. You don’t have to replace it often, and it stands up to weather and wear. When you look at the types of metal mesh, you’ll notice each one has special features. Some mesh is tough and rigid, while others bend and flex. You get to choose the mesh that fits your needs, whether you want durability, easy cleaning, or a certain look.

If you want your project to last, pick the right mesh. Think about the job, the environment, and how much care you want to give it. The types of metal mesh let you match the perfect mesh to your task.

Main Types of Metal Screen Mesh

Woven Wire Mesh

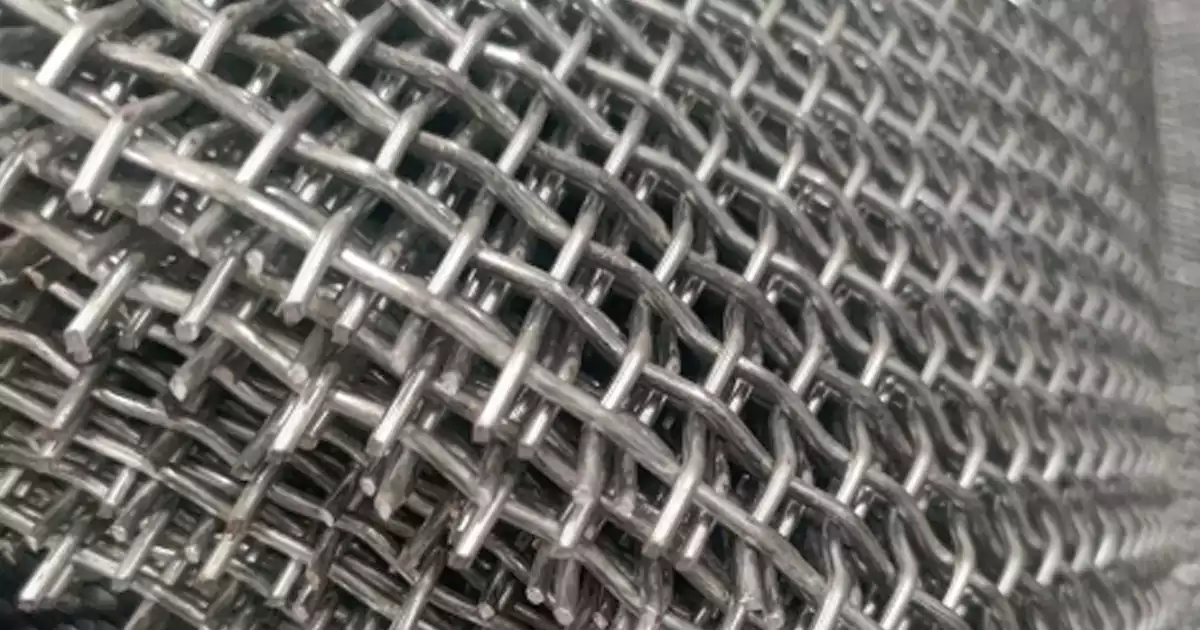

Woven wire mesh looks like cloth because of its pattern. Wires go over and under each other, just like threads in fabric. This makes the mesh bendy and easy to use. You can pick different patterns, such as plain weave or twill weave, for your needs.

This mesh bends without snapping. You can shape it for many jobs. People use it in railings for fences and panels in big buildings. Security teams use woven wire mesh for barriers and cages. If you need mesh that moves or shakes, this type is a good choice.

Woven wire mesh comes in many materials. Stainless steel wire mesh does not rust and lasts a long time. Aluminum wire mesh is light and simple to move. Copper and brass are used when you want the mesh to look nice. No matter what it is made of, woven wire mesh works for screens, filters, and guards.

Welded Wire Mesh

Welded wire mesh looks like a grid with neat squares or rectangles. Wires are welded together at every crossing point. This makes the mesh strong and stiff. The welded spots keep the shape even when it holds heavy things.

Here is how welded wire mesh is different from woven wire mesh:

- Welded wire mesh uses spot-welding, so it is stiff and strong.

- Woven wire mesh uses weaving, so it is more bendy and has different patterns.

Builders use welded wire mesh in construction. It makes concrete in floors, walls, and bases stronger. This helps buildings last longer. Welded wire mesh is also used for security fences. It makes strong barriers for homes, stores, and factories.

Look at this table to see how welded wire mesh compares to other types:

| Mesh Type | Strength and Durability Comparison |

|---|---|

| Welded Wire Mesh | High tensile strength, resistant to wear and tear, long lifespan, superior in harsh environments. |

| Chain-Link Fencing | Lighter and more flexible but offers less strength and durability in high-stress applications. |

| Wooden and Vinyl Fencing | Aesthetic appeal but lacks the strength and durability of welded wire mesh. |

| Rebar | Provides greater strength in specific heavy-duty applications but less evenly distributed support. |

Welded wire mesh is not just for concrete. It is used in bridges, roads, and walls that hold back dirt. For fences, you can see through it but still stay safe. Welded wire mesh is also great for animal cages and machine covers.

Stainless steel wire mesh and aluminum wire mesh are common for welded mesh. Stainless steel wire mesh fights off weather and chemicals. Aluminum wire mesh is lighter and easy to put up. Both types make strong and lasting screens.

Expanded Metal Mesh

Expanded metal mesh starts as a flat piece of metal. Machines cut and pull the metal to make diamond-shaped holes. This keeps the mesh in one piece and makes it strong. There are no loose wires or welds, so it stays tough.

How you make expanded metal mesh changes how it works:

| Manufacturing Stage | Impact on Performance |

|---|---|

| Sheet Metal Selection | Determines durability, lifespan, and suitability for applications like grating and fencing. |

| Dimensions of Metal Sheet | Influences final performance, layout options, and cost efficiency. |

| Cutting and Stretching Metal | Creates the mesh structure, affecting strength and uniformity of the final product. |

| Impact on Strength and Durability | Uneven stretching can lead to weak spots, while precision methods enhance strength and durability. |

Expanded metal mesh is used in many jobs. In cars and planes, it holds heavy parts during work. It supports parts during cleaning or making metal stronger. Expanded metal mesh also stands up to strong chemicals in cleaning. You can use it to sort and stack parts or keep things safe in fire safes.

Aluminum wire mesh is a top pick for expanded mesh because it is light and does not rust. Stainless steel wire mesh is good when you need more strength or heat resistance. Expanded metal mesh gives you a strong, one-piece screen that lasts a long time.

There are many kinds of wire mesh. Each one is best for certain jobs and places. If you pick the right mesh, your screens will work better and last longer.

Perforated Metal Mesh

Perforated metal mesh looks good and works well. It is a solid metal sheet with holes punched in it. The holes can be round, square, or special shapes. This mesh gives you more ways to design things than most other mesh.

Look at this table to see how perforated metal mesh is different from expanded metal and wire mesh:

| Characteristic | Perforated Metal Mesh | Expanded Metal | Wire Mesh |

|---|---|---|---|

| Versatility | Has the most choices for pattern, shape, and hole size. | Only has diamond shapes, but can change size. | Not as many design choices as perforated metal. |

| Strength | Can stand alone if it has solid edges, comes in many materials. | Made in one piece, strong but needs a frame. | Needs a frame to stay strong. |

| Weight | Lighter because of the holes, still strong. | Thinner but heavier than perforated metal for the same job. | Heavier and not as good for weight-to-strength. |

| Aesthetic Appeal | Many hole sizes and shapes, great for design. | Only diamond shapes, not as many looks. | Not as many looks as perforated metal. |

You can use perforated metal mesh in lots of ways. Some common uses are:

- Filtration systems: It keeps solids out of liquids or gases.

- Ventilation: It lets air move but stops dust or dirt.

- Sound absorption: It helps make loud places quieter.

- Architectural design: It makes buildings look cool and adds safety.

Perforated stainless steel mesh is very strong. It does not rust or wear out fast, so you can use it outside. You can pick the hole size and shape for your project. This helps you make buildings or machines look modern. If you want mesh that does more than just filter, perforated metal mesh lets you be creative.

You might see perforated metal mesh and welded wire mesh used together. Both are strong, but perforated mesh gives you more design choices. Welded wire mesh is good for support. Perforated mesh is best when you want both style and function.

Knitted and Specialty Meshes

Some jobs need special mesh types. Knitted and specialty meshes help with these jobs. They use different patterns and shapes to fix hard problems.

Here is a table that shows some specialty mesh types and what they do:

| Mesh Type | Characteristics | Applications |

|---|---|---|

| Bird’s Eye Mesh | Small, oval holes that look like a bird’s eye | Sportswear, baby clothes (lets air through) |

| Square Mesh | Even, square holes | Factories, farms, fencing |

| Small Hexagonal Mesh | Tiny hexagon holes, light and smooth | Thin clothes, lingerie, decorations |

| Large Hexagonal Mesh | Big hexagon holes for more air | Sports gear, backpacks, building materials |

| Diamond Mesh | Diamond holes for strength and looks | Fences, car seats, shoes |

| Irregular Hole Mesh | Odd shapes for cool looks | Fashion, factory screens, art |

Knitted mesh can stretch and bend. You see it in filters, gaskets, and car parts. Specialty meshes like diamond mesh or bird’s eye mesh look nice and work well. For example, diamond mesh makes fences strong and pretty.

Welded wire mesh is good for tough jobs. Specialty meshes are better when you need a certain look or feel. If you want mesh that stretches, breathes, or looks special, try these options.

Tip: Always pick the mesh that fits your project. Specialty meshes can do things regular mesh cannot.

Uses of Wire Mesh Screens

Industrial Applications

Wire mesh screens are used in many industries. They help filter, separate, and support materials. Look at the table to see where wire mesh screens are used and how:

| Industry | Main Uses |

|---|---|

| Pulp and Paper | Used for filtering during pulping, washing, bleaching, forming, and drying. |

| Mining | Used to separate and filter materials. |

| Agriculture | Used for support and filtering in irrigation systems. |

| Aquaculture | Used for filtering and support in fish farms. |

| Water Treatment | Used to filter out dirt from water. |

| Chemical | Used for support and filtering in chemical work. |

| Architecture | Used for support and decoration in buildings. |

| Food and Beverage | Used for filtering and support in food making and packing. |

| Sugar | Used for filtering and separating in sugar making. |

Wire mesh screens are strong and last a long time. In mining, they help sort rocks and minerals. In food factories, they filter liquids and keep things clean. Water treatment plants use wire mesh to clean water. You can find wire mesh screens in almost every factory.

Architectural and Decorative Uses

Wire mesh screens are not just for work. You can use them to make buildings look cool and modern. Here are some ways people use wire mesh in design:

- Space dividers and light walls in offices or homes

- Building fronts that add shine and texture

- Wall art and stair rails for a special look

- Stands for shows and events

- Sun shades and media walls with lights

- Sound panels that help control noise

Designers like wire mesh because it is flexible and shiny. You can shape it in many ways. It lasts a long time and keeps looking good. Wire mesh screens also protect windows and vents. You can choose from many metals and styles to fit your space. Wire mesh makes projects strong and beautiful.

Filtration, Sifting, and Ventilation

Wire mesh screens are great for filtering, sifting, and letting air through. How you use wire mesh depends on mesh count, wire thickness, and material. Mesh count means how many holes are in one inch. More holes mean smaller spaces, so you can catch tiny bits. If you need to filter small things, pick a screen with lots of holes.

Wire thickness is important too. Thick wires make the screen strong but block more air. Thin wires let more air or liquid pass. The right metal helps your screen last longer. Stainless steel does not rust and works well in wet places. Aluminum is light and easy to use.

Here are ways mesh details change how it works:

- Mesh density changes how well you filter or sift.

- Airflow changes with mesh density and wire thickness.

- Thick wires are strong but slow down air or liquid.

Wire mesh screens are used in air vents, dust catchers, and sieves. Factories use them to sift powders and grains. At home, window screens keep bugs out. Wire mesh helps you get the right mix of strength, airflow, and filtering.

Tip: Always pick the mesh type and size that fits your job. The right wire mesh screens make your work safer and easier.

Characteristics of Each Mesh Type

Woven Wire Screens

When you look at woven wire mesh, you notice its flexible design. You can bend it, roll it, or cut it to fit almost any shape. This makes woven wire mesh a top choice for projects that need to cover curved or uneven surfaces. You might use it for fine filtering, window screens, or even art projects.

Here’s a quick table to help you see how woven wire mesh compares to welded wire mesh:

| Feature | Woven Wire Mesh | Welded Wire Mesh |

|---|---|---|

| Flexibility | Highly flexible, fits odd shapes | Rigid, keeps its shape |

| Affordability | Usually more affordable | Costs more to make |

| Strength | Not as strong, best for light jobs | Very strong, great for heavy-duty work |

| Applications | Filtering, curved surfaces, screens | Security, fencing, support |

You can use woven wire mesh when you need something that adapts. It works well for sifting, filtering, and covering vents. You can also use it in places where you want to see through the mesh but still need protection. Woven wire mesh is easy to handle, so you can cut it with simple tools. You do not need special machines.

But woven wire mesh does have some limits. It is not the best choice if you need a lot of strength. It can bend under heavy weight. If you need a mesh that stands up to strong impacts, you might want welded wire mesh instead.

Tip: If you want a mesh that is easy to shape and install, woven wire mesh is your friend. For tough jobs, look at welded or expanded mesh.

Self-Cleaning Screens

Self-cleaning screens take wire mesh to the next level. You use these screens in places with lots of dirt, dust, or sticky stuff. The special design lets the mesh move a little, so debris falls off instead of clogging the openings. You spend less time cleaning and more time working.

Here are some big advantages of self-cleaning screens:

- Low maintenance: The mesh shakes off dirt, so you do not have to clean it often.

- Long life: The mesh resists wear and tear, even in rough conditions.

- Efficient separation: The mesh keeps working, so you get steady filtering or sorting.

| Advantage | Description |

|---|---|

| Low Maintenance | The self-cleaning action reduces the need for regular cleaning, saving time and labor costs. |

| Longevity and Durability | Highly resistant to wear and tear, designed to last longer and less prone to damage. |

| Efficient Separation | Ensures effective filtration, making it easier to separate solids from liquids or gases. |

You can use self-cleaning screens in mining, recycling, or any place with lots of debris. The mesh stands up to harsh chemicals and rough materials. You save money because you do not need to replace the mesh as often.

But self-cleaning screens can cost more at first. You might also need to pick the right type of wire mesh for your job. Some self-cleaning mesh works better with certain materials or machines.

Note: If you work in a tough environment, self-cleaning screens can make your life easier. You get less downtime and more reliable results.

When you choose wire mesh, think about what you need most. Do you want flexibility, strength, or easy cleaning? Each mesh type has its own strengths and weaknesses. Pick the mesh that matches your job, and you will get the best results.

Choosing the Right Mesh Type

Factors to Consider

When you pick wire mesh for your project, you want to make sure it fits your needs. Not all mesh works the same way. Here are some important things to think about:

- Material: You can choose from steel, stainless steel, or galvanized metal. Each one works best in certain places. Stainless steel stands up to rust, while galvanized mesh fights off corrosion.

- Purpose: Think about what you want the wire mesh to do. Some mesh is great for industrial jobs, while others work better for homes or design projects.

- Size, Thickness, and Pattern: Make sure the mesh size and thickness match your project. If you need a security barrier, pick a thicker mesh with a tight pattern.

- Durability: If your mesh will be outside or in wet places, choose a type that resists rust and damage.

Tip: Always match the mesh material to the environment. For example, stainless steel mesh lasts longer in wet or salty air.

Matching Mesh to Application

You want your wire mesh to do its job well. Start by thinking about where you will use it. Each mesh material has special strengths. Take a look at this table to see how different mesh types fit different applications:

| Mesh Type | Characteristics | Applications |

|---|---|---|

| Steel | High tensile strength | Tunnels, slopes, security |

| Galvanized Steel | Corrosion resistant | Outdoor screens, fencing |

| Aluminum | Lightweight | Temporary barriers, design panels |

In mining or construction, you need mesh that can handle heavy loads. For food processing, you want mesh that is easy to clean and safe for food. If you need a security mesh, pick one with small openings and strong wires. For ventilation, choose mesh with larger holes to let air flow. Always check the mesh count and wire diameter. These details change how well the mesh filters, protects, or supports.

Note: If you need a mesh for a security barrier, pick a type with high strength and a tight pattern. This keeps your space safe.

Maintenance Tips

You want your wire mesh to last as long as possible. Here are some easy ways to keep your mesh and screens in top shape:

- Clean your mesh often. Use mild soap and water to wash away dirt and dust.

- Check your mesh for damage. Look for broken wires or rust spots.

- Add a protective coating if needed. This helps your mesh fight off weather and chemicals.

- Fix small problems right away. This stops bigger issues and keeps your mesh strong.

Keeping your wire mesh clean and protected means you spend less time and money on repairs. Well-cared-for mesh works better and lasts longer, even in tough applications.

Choosing the right mesh makes your project safer and more reliable. Whether you need wire mesh for a security job, a barrier, or just to let air through, you have many options. Take your time, think about your needs, and pick the mesh that fits best.

Comparison Table: Types and Uses

Mesh Types Overview

You might ask which mesh is best for your project. Each mesh type has its own good points, price, and uses. Look at this table to see how the main types are different:

| Characteristic | Welded Wire Mesh | Woven Wire Mesh | Expanded Wire Mesh | Perforated Metal Mesh | Dutch Weave Wire Mesh |

|---|---|---|---|---|---|

| Strength & Durability | Strong and stiff, great for support | Very strong, stands up to hits | Strong but not heavy | Good strength, depends on thickness | Stable, keeps tiny bits out |

| Flexibility | Keeps its shape, not bendy | Very bendy, fits many shapes | Some bend, stays in one piece | Stiff, can be shaped with tools | Bendy, used for fine filtering |

| Best Use | Fences, concrete, safety walls | Filtering, sieving, decorations | Security fences, walkways, machine guards | Air vents, design, sound panels | Chemical and food filtering |

| Upfront Cost | Costs more | Costs less | Costs a medium amount | Medium to high cost | Costs more |

| Maintenance Cost | Costs less to keep up | Costs more to keep up | Costs little to keep up | Costs little to keep up | Costs a medium amount to keep up |

| Longevity | Lasts a long time | Does not last as long | Lasts a long time | Lasts a long time | Lasts a long time |

Tip: If you need strong support, welded wire mesh is a good pick. For shapes or fine filtering, woven wire mesh gives you more choices.

Application Summary

Mesh is used in many ways, like keeping things safe or letting air move. Here is a quick list to help you pick the right mesh for your job:

- Welded wire mesh: Used in fences, concrete, and safety walls. It holds heavy things and lasts a long time.

- Woven wire mesh: Used for filtering, sieving, and screens at home or work. It bends and fits odd shapes.

- Expanded wire mesh: Used in walkways, machine guards, and security fences. It is strong but light and lets air pass.

- Perforated metal mesh: Used for air vents, sound panels, and cool building looks. The holes can be any shape.

- Dutch weave wire mesh: Used for special filtering in chemical or food places. It keeps out tiny bits and stays steady.

When you choose mesh, think about these things:

| Consideration | What It Means for You |

|---|---|

| Application | What you want the mesh to do (screen, fence, filter) |

| Mesh Type | Pick square, rectangle, or special weaves |

| Mesh Size | How many holes per inch—changes what gets through |

| Opening Size | Space between wires—controls what is filtered |

| Wire Diameter | Thicker wires mean stronger mesh |

| Percent Open Area | More open space means better airflow |

| Surface Finishing | Pick the right metal for your place |

| Product Size | Get the right size and amount for your job |

| Accessories | You may need frames or bars for support |

Note: Always pick mesh that fits your needs. If you want screens to last, choose the right type, size, and metal.

Mesh helps you fix problems in many places. You can use wire mesh for safety, style, or to keep bugs out. When you know the differences, you can pick the best mesh for your project.

Conclusion

Knowing about metal screen mesh types helps you choose well. Each mesh has special features. These features change how it looks, feels, and works. Think about what you need. Think about your weather. Think about how you will use the mesh. Here’s a quick reminder:

- Each mesh type is best for certain jobs and places.

- Taking care of your mesh keeps it strong and working.

- Getting help from experts makes it easier to pick the right mesh.

If you want good choices, ANPENG has woven wire screens, self-cleaning screens, PU/urethane panels, rubber panels, and perforated plates for many jobs. If you are not sure, ask a supplier or expert. They can help you find the best mesh for your needs.

FAQ

What is the difference between woven and welded wire mesh?

Woven wire mesh looks like fabric. You can bend it easily. Welded wire mesh feels stiff and strong. You see it in fences and concrete work.

How do I choose the right mesh size?

Think about what you want to keep in or out. Small mesh keeps tiny things out. Large mesh lets more air or light through. Measure your needs first.

Can I use metal mesh outdoors?

Yes, you can! Stainless steel and galvanized mesh work best outside. They resist rust and last longer in rain or sun.

How do I clean metal screen mesh?

Use a soft brush or cloth. Warm, soapy water works well. Rinse and let it dry. For tough dirt, try a gentle spray.

Is metal mesh safe for food applications?

You can use stainless steel mesh for food. It does not rust or react with food. Always check for food-grade certification.

Can I cut metal mesh myself?

Yes, you can cut most mesh with wire cutters or tin snips. Wear gloves and eye protection. For thick mesh, ask a pro for help.

What are some creative uses for metal mesh?

You can use mesh for art, garden trellises, lamp covers, or even wall décor. Get creative—mesh is flexible and fun to work with!

Tip: Always check the mesh material before starting your project. The right choice makes your work easier and safer.