You use screening equipment to sort materials by size. This helps you get the right product for each job. Screens are used in mining, construction, recycling, and food processing. You can pick woven wire mesh, self-cleaning screens, or polyurethane screens to work better. Screens make sorting materials faster and easier for any job. When you look at Types of Screening Equipment, you see many choices. Screens can fit your equipment and needs.

Key Takeaways

- Screening equipment separates materials by size. This helps industries work better, like mining, construction, recycling, and food processing.

- Picking the right screening equipment, like vibrating, trommel, or disc screens, can help you work faster. It also helps you waste less.

- It is important to take care of screening equipment. Check screens often to find damage early. This saves you time and money.

- Mesh types, like woven wire and polyurethane, change how well sorting works. Pick the best mesh for your material to get good results.

- Self-cleaning screens work well with sticky materials. They stop clogging and keep things moving. This means less time fixing problems.

- Screening equipment keeps products good by taking out unwanted bits. This is very important in food processing and making things.

- Knowing your material and how much you need to sort helps you pick the best screening equipment for your job.

- Digital tools can help you watch how equipment works. They also help you plan when to fix things.

What Is Screening Equipment?

Definition and Function

Screening equipment is used in many places where materials are handled. It helps sort things by size, grade, or what they are made of. This equipment splits materials into groups based on how big or small they are. Only the right materials move on to the next step or get sold. If something does not match, it goes back for more work or gets thrown away.

Screening machines use easy but clever technology. You put materials on a mesh or screen. The mesh shakes, so small pieces fall through. Bigger pieces stay on top. This gives you sorted materials for the next step. There are many kinds of screening machines. Some are vibratory screens, rotary screens, flip-flop screens, gyro screens, and air classifiers. Each one is good for different jobs.

Tip: Picking the right screening equipment can help you work faster.

Here is what screening machines do for you:

- They split materials into different sizes and grades.

- Vibrating screen mesh lets small pieces go through.

- Big pieces stay on top for more work.

- There are different machines for different jobs in many industries.

Industrial Roles

Screening equipment is very important in many industries. It helps your work go smoothly and saves time. Here is how screening machines help in different areas.

Mining

In mining, screening equipment handles lots of rocks and minerals. These machines sort out what is valuable fast. Some systems can process up to 850 tons each hour. This means fewer slowdowns and faster work. You get better products and save money on materials.

Construction

In construction, you need screening equipment to sort sand, gravel, and crushed stone. These machines make sure you get the right size for each job. This helps keep workers safe and cuts down on waste.

Recycling

Screening equipment is very important in recycling. These machines sort materials and help you get back useful things. For example, a recycling plant in Germany worked 20% faster and got 95% pure lithium from batteries. This makes recycling better and helps the environment.

Food Processing

In food processing, screening equipment helps sift powders and grains. Machines with special screens keep food safe and clean. A bakery in Europe worked 20% faster when processing cocoa powder. This means cleaner products and better quality.

| Industry | Role of Screening Equipment | Benefits |

|---|---|---|

| Food Processing | Sifts powders and grains with special screens to keep things clean and safe. | A bakery in Europe worked 20% faster with cocoa powder. |

| Recycling | Sorts materials to get back useful things and makes recycling better. | A German plant worked 20% faster and got 95% pure lithium from batteries. |

| Mining | Handles lots of materials, making work faster and easier. | Some systems can process up to 850 tons each hour, making work much better. |

| General Benefits | Makes products better, cuts waste, keeps people safe, and saves money. | Food powders can be 99% pure; saves up to 15% on materials; lowers injury risks. |

Screening equipment helps you handle materials and do better in many jobs. You get better results, save money, and keep your workplace safer.

Types of Screening Equipment

When you check out screening equipment, you find many choices. Each type uses its own technology to help you get the right size material. Let’s look at the main types of screening machines used in factories.

Vibrating Screens

Vibrating screens are very common. You see them in mining, construction, food, and chemical plants. They use vibration to sort things by size and shape.

How They Work

You put your material on a screen deck. The deck is tilted. A special system or shaft makes the deck shake. This shaking bounces the material up and down. Small pieces fall through the mesh. Big pieces stay on top. This sorting is called stratification. It helps you separate things fast and well.

Screen decks can be flat or slanted. Flat decks move back and forth. Slanted decks move in circles. Both use vibration to help materials touch the screen and get sorted.

Here’s how screens work in simple steps: 1. The screen deck is set at an angle. 2. Vibration starts with a special system or shaft. 3. Materials bounce and move around. 4. Small pieces drop through the mesh. 5. Big pieces stay for more sorting.

You use vibrating screens for: – Mining, to sort rocks and minerals. – Construction, to process sand, gravel, and other materials. – Food processing, to keep products clean and safe. – Chemical plants, for separating materials.

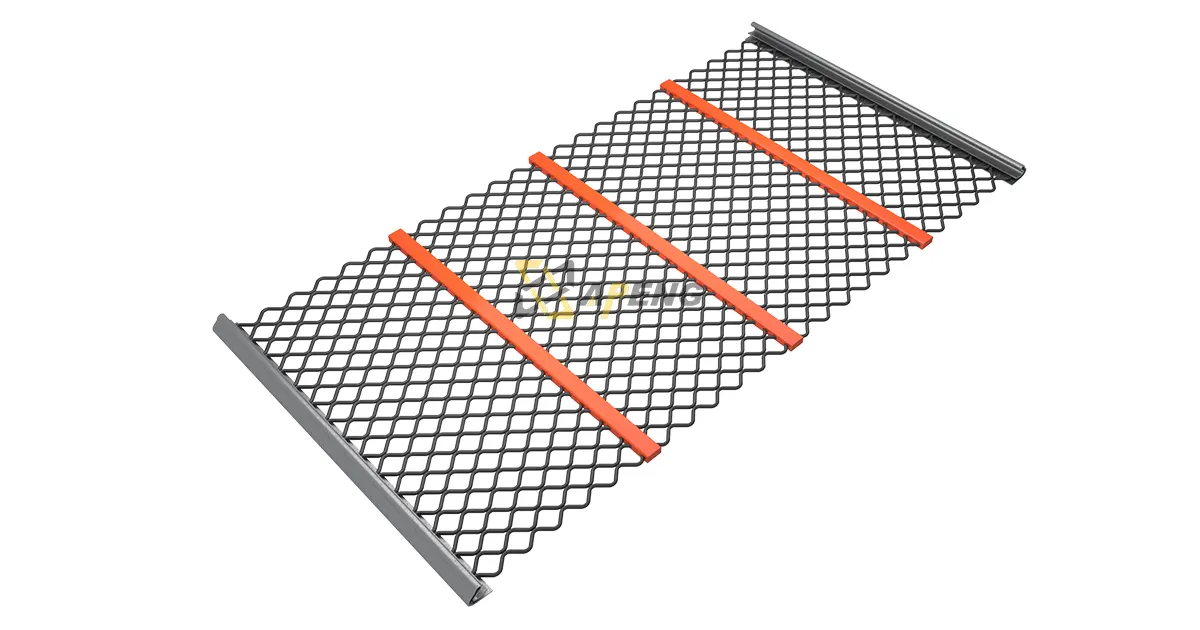

Common Mesh Types

The mesh you pick changes how well your machine works. Here are the most common mesh types:

- Woven Wire Mesh: You can change the size and thickness. This mesh works for many jobs.

- Perforated Plate: Metal sheets with holes in special shapes. You use these for certain tasks.

- Polyurethane Screen Mesh: This mesh lasts long and does not wear out fast. It is good for tough jobs.

- Rubber Screen Mesh: This mesh is quiet and handles hits well.

Mesh design affects how well your screening works. You want the right mesh for good sorting, strength, and to last longer. Make sure the mesh is tight. This helps your screens last longer, even in wet or rough places.

Trommel Screens

Trommel screens use spinning drums to separate materials. You see these machines in waste, mining, and composting. They use a turning drum to sort by size.

Operation

A trommel screen has a big round drum. The drum spins. When materials go in, they tumble inside. Small pieces fall through holes in the drum. Big pieces move to the end and come out. This sorting uses stratification.

| Working Principle | Industries Applied |

|---|---|

| Trommel screens use a spinning drum to separate materials by size. | Waste management, mining, composting |

Trommel screens are easy to use. You load the material, and the drum does the work. The spinning helps break up clumps and keeps things moving.

Applications

You use trommel screens for: – Sorting waste in recycling plants. – Separating minerals in mining. – Screening compost for gardens and farms.

Trommel screens are good for wet or sticky materials. The spinning drum helps stop clogging and keeps the machine working well.

Disc Screens

Disc screens use spinning discs to sort materials. This technology is fast and works well with sticky or clumped materials.

Separation by Size and Shape

Disc screens have discs set at different angles. As materials move over the discs, small pieces fall through gaps. Big or odd-shaped pieces move forward. This sorting uses stratification by size and shape.

| Feature | Disc Screens | Trommels and Star Screens |

|---|---|---|

| Efficiency | Higher efficiency | Less efficient, can clog |

| Maintenance | Needs less maintenance | Needs more maintenance |

| Footprint | Smaller size | Bigger size |

| Performance with clumped materials | Works better with clumped materials | Not as good with clumped materials |

Disc screens work better with clumped materials. They need less fixing and take up less space than other screening machines.

Typical Uses

You use disc screens in: – Waste management, to sort trash and recyclables. – Biomass processing, to separate wood chips and plant matter. – Factories, where you need fast and reliable sorting.

Disc screens help you get clean, sorted materials with less waiting. Their design makes them a smart pick for many jobs.

Tip: When picking screening equipment, think about your material, if it is wet or sticky, and how much you need to sort. The right machine can save you time and money.

Now you know the main types of screening equipment: vibrating screens, trommel screens, and disc screens. Each one uses different technology and sorting methods to help you get the best results for your job.

Static Screens

Static screens are a simple way to separate things. They do not shake or move. You see these machines where solids need to be taken out of liquids. They also help sort waste. The screens stay still while water or slurry flows over them. Small bits go through the screen. Big pieces stay on top. This gives you clean water and sorted solids.

Non-Vibrating Applications

Static screens are used in many places. These machines work best when you want easy care and steady work. You do not need motors or moving parts. The screens use gravity and flow. Here are some common uses: * Paper mills — get fibers back and remove solids. * Tanneries — take out fur, grease, and other stuff. * Slaughterhouses — remove pouches, fur, grease, and waste. * Municipal wastewater — treat sewage before it goes on. * Starch, alcohol, sugar, beer, and malt factories — remove plant shells, fiber, and malt skins. * Pharmaceutical and food processing — separate waste. * Poultry and livestock farms — remove animal hair, manure, and trash. * Fish and meat processing — take out offal, scales, minced meat, and grease. * Textile mills, chemical plants, plastic factories, big workshops, hotels, and homes.

Static screens help keep your work clean and running well. You get good separation with very little work needed.

Self-Cleaning Screens

Some static screens can clean themselves. These machines have special mesh that shakes or bends when water flows over. This movement stops clogging and keeps the screen clear. You spend less time cleaning and more time working.

Self-cleaning screens are great for sticky or stringy stuff. You see them in food processing, recycling, and cleaning dirty water. The mesh design helps you separate better and makes screens last longer. You do not need to stop your machines to clean as much.

Tip: If you work with sticky or stringy stuff, self-cleaning screens help save time and money.

Aggregate Screening Equipment

Aggregate screening equipment helps you sort and size rocks and sand. These machines make sure you get the right size for your job. There are two main types: inclined screens and horizontal screens. Each type has its own design and use.

Inclined Screens

Inclined screens are the most common type. You set these machines at an angle, from 5 to 45 degrees. The angle helps things move down the screen using gravity. The screen shakes in a circle. This helps separate and keeps things moving.

You use inclined screens for sorting, sizing, and separating rocks and sand. These machines work well for big jobs and tough stuff. The screens help sort before separating. You get better sorting and less clogging.

Inclined screens are important in many plants. You see them in mining, digging, and building. They handle sand, gravel, crushed stone, and other rocks. The design lets you work fast and well.

Horizontal Screens

Horizontal screens are another type. You set these machines flat or with a small tilt, up to 10 degrees. They use strong shaking to move things across the screen. The motion helps separate and gives you more exact sizing.

Horizontal screens work best for low setups and final sorting. You use them when you need exact separation and less clogging. These machines handle smaller rocks and give you clean, sorted stuff.

Here is a table to compare inclined screens and horizontal screens:

| Feature | Inclined Screens | Horizontal Screens |

|---|---|---|

| Angle of Installation | Between 5 and 45 degrees | Operate at zero degrees, can incline up to 10 degrees |

| Material Movement | Relies on gravity, low stroke, low G-force | Requires high G-force for material conveyance |

| Motion Type | Circular vibratory motion | Motion of the machine conveys material |

| Applications | Used throughout material processing, scalping, and sizing | Best for low-profile applications and final screening |

| Efficiency | Stratifies material before separation | More accurate particle sizing, less plugging |

Pick inclined screens for fast work and tough jobs. Choose horizontal screens for exact sorting and clean results. Both types help you get the right rocks and sand for your job.

Note: When you pick screening machines, think about your material, the size you need, and how much you want to sort. The right machine makes your work easier and faster.

Screening Media and Mesh Types

When you pick screening equipment, the mesh type matters a lot. The right mesh gives you cleaner results. It saves time and helps your equipment last longer. Let’s look at the main mesh types you will see.

Woven Wire Mesh

Woven wire mesh is used for many screening jobs. You see it in mining and food processing. This mesh is strong and very exact. Here is why it is special:

- Dual lock woven wire screens are extra stiff. They keep the opening size fixed. You get better control with big openings over 25mm (1 inch).

- Woven wire mesh is used in mining and aggregate work. It has lots of open space and tight weaving. This helps you sort things more accurately.

- The mesh holes are very close to the right size, within ±3%. You can trust the holes for good sorting.

- Metal wires are heated to make them stronger and more bendable. This helps the mesh last longer.

- Woven wire screens do not wear out fast. They last up to 40% longer than regular screens.

- You use this mesh in many places: mining, cement, asphalt, flour mills, fertilizer, food, and chemicals.

Woven wire mesh gives you great separation. The regular shape and small holes help you sort by size or density. You can even use magnets for special jobs. This mesh is best when you need accurate and reliable screening.

Self-Cleaning Screens

If you work with sticky or wet stuff, self-cleaning screens help a lot. These screens use smart designs and bendy materials to keep things moving. Here is how they help:

| Benefit/Mechanism | Description |

|---|---|

| Reduced Clogging | Self-cleaning screens stop clogging. You do not need to replace them as much. |

| Continuous Material Movement | They keep things moving and shake off sticky bits. This cuts downtime. |

| Vibration Mechanism | The screens vibrate to knock off stuck pieces. This keeps flow steady. |

| Flexible Materials | Made from polyurethane or similar stuff. These screens bend, not break. |

| Special Patterns | Triangle or other shapes spread force. This stops worn-out spots. |

| Long-term Cost Efficiency | They are tough and need less fixing. You save money over time. |

Self-cleaning screens give you more working time and less trouble. They are great for recycling, food processing, and any job where clogging is a problem.

Tip: If you want to clean less and screen more, self-cleaning screens are a good choice.

Polyurethane Screens

Polyurethane screens are tough and last a long time. You use them for hard jobs. Here is why they are good:

- Polyurethane mesh is very strong. It works well in rough places and tough jobs.

- These screens do not wear out from rubbing, chemicals, or weather. They last a long time, even outside.

- Polyurethane screens are better than woven wire screens for sun resistance. They keep working after years in the sun.

- They cost more at first, but you save money because they last longer and need less fixing.

- The panels can be made in many shapes and sizes. You get good screening for fine, rough, or corrosive stuff.

- High strength means these screens handle stress during work.

- Chemical resistance helps in water treatment and other tough jobs.

- The design stops clogging and pegging. You get steady results.

You see polyurethane screens in places with rough materials, water treatment, and jobs that need strong screening. Their toughness and flexibility make them a top pick for many uses.

Note: Picking the right mesh helps you get better results and keeps your equipment working longer.

Screening Equipment Applications

Mining and Quarrying

Screening machines are used a lot in mining and quarrying. These machines help sort rocks, minerals, and aggregates by size or weight. Vibrating screening machines separate small pieces from big chunks. Stationary screening machines are good for taking out large pieces first.

Here are some ways screening is used in mining and quarrying: – You get rocks ready for making roads. – You process salt for icy roads in winter. – You prepare lime for factories.

Screening equipment helps you work faster and keeps you safe. You can move large amounts and get the right size for each job. Using screening machines saves time and money. It also makes your final products better.

Construction and Aggregates

Screening machines are important in construction and for making aggregates. You need different sizes of sand, gravel, and crushed stone for each project. Screening equipment sorts these materials so you get the best results.

Aggregate screens use mesh to separate big rocks from small ones. You can run the materials through different screens more than once. This helps you get more valuable material and meet project needs.

Here’s why screening is important in construction: – You sort materials for concrete, asphalt, and roads. – You make sure every batch is good quality. – You keep your work steady and dependable.

Screening machines give you choices. You can change the screen size and setup for each job. This helps you get the right mix for any project, like building a road or making a foundation.

Tip: If you want the best concrete or gravel, use screening machines to sort your materials first.

Recycling and Waste

Screening machines are needed in recycling and waste management. These machines sort and separate materials to make your work easier. You can use screening equipment to pull out plastics, compost, and glass from mixed trash.

Screening machines help your recycling center run well. You can set up the machines for each job. As technology gets better, you get more ways to sort and better results.

Here’s how screening helps with recycling: – You pull out valuable things from trash. – You make recycled products cleaner. – You send less waste to landfills.

Screening equipment makes recycling faster and cleaner. You can handle more material and get back more useful things. This helps the planet and saves you money.

Note: If you want to recycle more, get screening machines that fit your needs.

Food Processing

You may not notice screening equipment when you eat snacks or drink soda. But it helps keep your food safe and tasty. In food factories, screens check every ingredient and product. They make sure everything meets strict quality rules. Screens keep out things like dust, stones, or packaging bits. Screening equipment does this job at every step.

Let’s see how screening works in food factories:

- Inbound Material Screening: Trucks bring flour, sugar, or cocoa powder. Cyclone screeners catch and remove dirty stuff. This happens before ingredients go into storage silos. You do not want dirty things mixing with food supplies.

- Quality Control Process Integration: Before making cookies or bread, you check again. Cyclone screeners make sure only clean ingredients move forward. This step helps avoid problems and keeps recipes the same.

- Final Product Verification: Before packaging, cyclone screeners check one last time. They make sure finished products meet all quality and purity rules. You can trust what goes into the bag or box is safe to eat.

Screening technology does more than catch big pieces. It also controls how small or big particles are. You want flour to be fine and sugar to be even. Same-sized particles help machines work well and make food taste better.

Here’s what screening equipment does in food processing:

- Takes out bad stuff from raw materials.

- Keeps production lines moving without jams.

- Makes sure every batch is safe and good quality.

- Cuts waste by finding problems early.

- Helps you follow food safety laws and pass checks.

| Screening Stage | What Happens | Why It Matters |

|---|---|---|

| Ingredient Unloading | Cyclone screeners remove dirty things | Keeps storage clean |

| Before Production | Screens check ingredient quality | Only best ingredients used |

| Before Packaging | Final screeners check product purity | Safe, high-quality food |

You find screening equipment in bakeries, snack factories, and places that make spices or sauces. If you want faster production and less waste, you need good screens. They help you follow strict rules and keep customers happy.

Tip: If you work in food processing, check screens often. Clean screens mean cleaner food and fewer problems later.

Screening equipment makes your job easier. You get safer food, better taste, and happy customers. Next time you eat a snack, remember—screens helped make it great!

Choosing Screening Equipment

Material and Throughput

When you pick screening equipment, you need to think about your material and how much you want to process. Every application is different. Some materials are wet or sticky. Others are dry and dusty. The type of material changes how your screen works. If you have a high feed rate, your screen must handle the load. Too much material can overload the machine and slow down your process.

Here are some things you should check before you choose:

- Feed rate: Make sure your screen can handle the amount of material you plan to run.

- Material characteristics: Wet, sticky, or abrasive materials need special screens for an efficient screening process.

- Layer height: If the material piles up too high on the screen, it will not separate well.

If you want to know how to choose a screen, always match your equipment to your material and your daily needs. This helps you get the best results for your application.

Mesh Selection

Mesh selection is a big part of getting good results from your screening. The mesh size must fit the size of the particles you want to separate. If you use the wrong mesh, you might miss small pieces or clog the screen. In mining, you need the right mesh for ore. In food or chemical plants, you want a mesh that gives you even, clean products.

Mesh selection depends on several things:

- Mesh count and aperture size: Higher mesh counts let you screen smaller particles, but they can block more easily.

- Mesh material: Stainless steel lasts longer and works for tough jobs. Polyester is cheaper and works for lighter tasks.

- Mesh shape and weave: The shape of the holes and the way the mesh is woven change how fast material moves through.

- Mesh tension: Tight mesh gives you even results. Loose mesh can cause uneven screening.

A good mesh choice helps you get clean, sorted material for any application. It also keeps your equipment running longer.

Durability and Maintenance

You want your screening equipment to last. Regular care makes a big difference. If you check your screens often, you can spot problems early. Fixing small issues before they get big saves you time and money.

Here are some tips to keep your equipment in top shape:

- Inspect your screens regularly to catch wear and tear.

- Use preventive maintenance to fix small problems before they stop your process.

- In cold weather, winterize your equipment. Drain water lines and use the right grease to stop freezing.

A little care goes a long way. When you keep up with maintenance, your screens last longer and your application runs smoother. You spend less on repairs and get more from your screening.

Tip: Make a checklist for your maintenance routine. This helps you remember every step and keeps your equipment ready for any job.

Practical Tips

Choosing the right screening equipment can feel tricky. You want your machines to work well and last a long time. Here are some practical tips to help you get the best results from your screens.

- Check Your Needs First

Start by looking at your whole operation. Think about what you want to screen, how much material you have, and the space you have for equipment. Ask yourself about the maximum feed size and the type of separation you need. This helps you pick the right screen for your job. - Pick the Right Media

Modular media makes changing and adjusting screens easy. If you work with different types of ore or materials, modular panels save you time. You can swap them out fast and keep your process moving. - Secure Your Screen Media

Make sure you attach synthetic media tightly. Loose panels can cause problems and slow down your work. Double-check the fit before you start your machine. - Keep Tension Tight

Proper tensioning stops your screens from wearing out too soon. If the mesh is loose, it can break or clog. Tight screens give you better results and last longer. - Schedule Regular Maintenance

Set up a routine to check your equipment. Look for signs of wear, damage, or anything unusual. Regular care helps you avoid breakdowns and keeps your workplace safe. - Use Digital Tools

Remote monitoring lets you see how your equipment is working in real time. You can spot problems early and plan repairs before something breaks. Digital tools also help you track maintenance schedules. - Try Vibration Analysis

Vibration analysis helps you find issues before they get serious. If your machine shakes in a strange way, it might need fixing. Catching these problems early saves you money and time. - Work With Experts

Team up with screen media manufacturers for performance checks. They know the best ways to keep your screens working well. You can ask for advice or get help with upgrades. - Sample and Test Often

Take samples from your screens and check them for quality. If you see changes, you might need to adjust your mesh or replace panels. Regular testing keeps your products clean and your process smooth.

Tip: Use a simple checklist for daily and weekly tasks. This helps you remember what to check and keeps your equipment running strong.

| Task | Why It Matters | How Often? |

|---|---|---|

| Check screen tension | Prevents early wear | Weekly |

| Inspect attachments | Stops panels from coming loose | Before startup |

| Monitor vibrations | Finds problems early | Monthly |

| Sample screen output | Keeps quality high | Every batch |

| Review digital data | Tracks health and performance | Daily |

If you follow these tips, you can keep your screening equipment working well. You save time, cut costs, and get better results for every job.

Benefits and Challenges of Screens

Efficiency and Consistency

You want your work to go well every time. Screens help you do this. Carrier Vibrating’s screening technology lets you control how particles are separated. You can change the settings for your material. This gives you the same results for each job. Picking the right mesh size keeps out things you do not want. You get good quality and use your resources wisely.

Here’s how screens help you:

- You take out unwanted bits and dirt.

- Your products pass strict quality checks.

- Food and drug companies get purer products.

- Good screening helps you work faster and waste less.

- Automation makes your process steady and easy.

If you want great products, screens are important for every job.

Common Issues

Screens work hard but face problems. Shock can hurt screens when big or odd things hit them. Corrosion happens at the edges where stuff builds up. Abrasion comes from fast feed or rough handling.

Other problems are:

- Screen meshes get blocked, slowing down work.

- Fine or sticky stuff clogs screens.

- Dust can spread and cause health risks.

- Bad screening makes product quality change.

- Some equipment does not work well for special jobs.

- Plugging happens when particles block holes and slow things down.

If you see these problems, your screens may not work right. You could lose time and money if you do not fix them fast.

Solutions and Best Practices

You can fix most problems with smart steps. Preventative maintenance is important. Check for strange sounds and wear on vibrating screens often. Make a schedule to keep things working well. Work with an OEM for regular check-ups to find issues early.

Here’s a table with a helpful solution:

| Solution Type | Description | Benefits |

|---|---|---|

| OCC Auger Screen | Anti-wrapping and anti-jamming screen that separates mid to large sized OCC | No need for presort, safer for workers, less downtime and damage risks |

You can also:

- Check your screening technology for care needs.

- Use anti-wrapping screens or ballistic separators for tough jobs.

- Think about future material changes when picking new equipment.

If you follow these tips, your screens will last longer and work better. You will spend less time fixing and more time getting good results.

Tip: Watch your screens and plan upgrades early. Small steps now save you trouble later!

Conclusion

You want your project to go well and get good results. Choosing the right screening equipment and mesh is important. Think about these things: – What is your material like? – How exact do you need to sort? – How much do you want to get out? – What is your work site like? ANPENG has many kinds of screening media for you:

| Type of Screening Media | Description |

|---|---|

| Woven Wire Screens | Classic screens for many jobs |

| Self-Cleaning Screens | Made to stop clogging |

| PU-Mesh Screens | Bendable and strong for many uses |

If you ask experts, they can give you advice that fits your job. This helps you work better and makes your equipment last longer.

FAQ

What is the main job of screening equipment?

Screening equipment helps you separate materials by size. You can sort rocks, sand, or food ingredients. This makes your work faster and your products better.

How do I choose the right mesh for my screen?

Think about your material and the size you want. Fine mesh works for small particles. Strong mesh lasts longer with rough materials. Ask an expert if you are not sure.

Can I use the same screen for wet and dry materials?

You can, but some screens work better for wet or sticky stuff. Self-cleaning screens help stop clogging. Polyurethane screens last longer in wet jobs.

How often should I check or clean my screens?

Check your screens every week. Clean them if you see clogging or slow flow. Regular care keeps your equipment working well and saves you money.

What are the signs that my screen needs replacing?

Look for holes, tears, or loose mesh. If you see uneven sorting or hear strange noises, it is time to replace your screen.

Are there screens that help reduce downtime?

Yes! Self-cleaning screens and modular panels make maintenance easy. You can swap them out fast and keep your process moving.

Why does screen tension matter?

Tight screens give you better sorting and last longer. Loose screens can break or clog. Always check tension before you start your machine.