You need to pick a vibrating screen mesh size that matches your material and process. Mesh size is important because it decides which particles can go through. This affects both quality and how well things work. Many industries need the right vibrating screen mesh size. These include food processing, mining, construction, and pharmaceuticals. You should think about what your material is like. You also need to know how much material you want to move. The type of vibrating screen and mesh rules also matter. Choosing the best vibrating screen size means you must know what you need.

| Application | Description |

|---|---|

| Food Processing | Keeps products safe and follows health rules. |

| Mining | Sorts materials well by particle size. |

| Construction | Filters rocks for good building materials. |

| Pharmaceuticals | Makes sure medicine stays pure and works well. |

Key Takeaways

- Pick the right mesh size by looking at your material’s particle size. This helps you screen better.

- If the mesh count is higher, the holes are smaller. Only tiny particles can go through small holes.

- Think about your material’s features, like if it is wet or rough, before you pick a mesh.

- Use anti-clog mesh for wet or sticky stuff. This stops blockages and keeps things moving.

- Check and take care of your mesh often. This makes it last longer and work better.

- Look at mesh size charts to find the best mesh for your material. This gives you the best results.

- Try out your mesh in real situations. Make sure it works well for your needs.

- Write down any changes you make to your mesh setup. This helps you choose better next time.

Vibrating Screen Mesh Size Basics

Mesh Size and Particle Size

When you look at vibrating screen mesh, you might wonder what mesh size really means. Mesh size tells you how many holes sit in one square inch of the screen. For example, a 200 mesh screen has 200 holes in each square inch. This number is called the mesh count. The higher the mesh count, the smaller the holes. That means only tiny particles can pass through. If you use a lower mesh count, the holes get bigger, and larger particles can go through.

Minimum and Maximum Particle Size

You need to match the mesh size to the particle size of your material. If your particles are too big, they will not pass through the screen. If they are too small, they might slip through when you do not want them to. The relationship is simple: as the mesh number goes up, the opening size goes down. So, you can control what stays on top of the screen and what falls through by picking the right mesh size.

Mesh Count Explained

Mesh count is just the number of openings per square inch. You can think of it as a way to measure how fine or coarse your vibrating screen mesh is. Here’s a quick look at how mesh count affects particle size:

| Mesh Count | Opening Size | Particle Size Allowed |

|---|---|---|

| Low (20-50) | Large | Big particles |

| Medium (60-150) | Medium | Medium particles |

| High (200-300) | Small | Fine particles |

You can see that a higher mesh count means smaller openings. This helps you choose the best vibrating screen mesh for your needs.

Standard Mesh Sizes

Common Ranges (20-300 mesh)

You will find that the most common vibrating screen mesh sizes range from 20 mesh up to 300 mesh. Here’s a table to help you see how these ranges work in real life:

| Mesh Size Range | Opening Size (mm) | Typical Uses |

|---|---|---|

| Coarse (3½-30) | 5.6 mm to 0.6 mm | Gravel, rocks, construction screening |

| Medium (35-100) | 0.5 mm to 0.15 mm | Sands, soils, foundry work |

| Fine (120-400) | 0.125 mm to 0.038 mm | Fine chemicals, pharmaceuticals |

If you work in mining or construction, you will probably use coarse or medium mesh. For food or pharmaceuticals, you might need a fine mesh. Picking the appropriate mesh size range helps you get the results you want.

Industry Standards

You want your vibrating screen mesh to meet industry standards. This ensures quality and consistency. Here are some of the main standards you should know:

| Standard | Description |

|---|---|

| ISO 3310-1 | Sets rules for metal wire mesh test sieves, making sure the aperture size and mesh quality are right. |

| ASTM E11 | Defines mesh sizes and tolerances for wire cloth and sieves in the U.S. |

| BS 410-1:2000 | Covers sizes of openings for test sieves, including both wire mesh and perforated plate sieves. |

When you follow these standards, you know your vibrating screen mesh will perform as expected. You also make it easier to compare different types of vibrating screen meshes and find the standard mesh size for vibrating screens that fits your job.

Tip: Always check the mesh count and the standard before you buy. This helps you avoid problems and keeps your process running smoothly.

Choosing the right vibrating screen mesh size is not just about numbers. You need to think about your material, your process, and the types of vibrating screen meshes available. This way, you can pick the best vibrating screen mesh for your application.

Key Factors for Choosing Vibrating Screen Mesh Size

Material Type and Properties

You should think about your material first. Different materials act in different ways on screens. Some materials are soft and move easily. Others are hard, sticky, or sharp. These things change how you pick the best mesh for your job.

Abrasiveness and Hardness

Hard or rough materials can damage your mesh fast. Sharp particles can break the mesh and make it wear out sooner. Here are some things to remember:

- Rough materials can hurt the mesh and make it work less well.

- Big or sharp particles can break the mesh more easily.

- Strong mesh and special coatings help your screen last longer.

If you want your screen to last, match the mesh to your material’s hardness. This helps you use your mesh longer and not replace it often.

Moisture Content

Water can change how your mesh works. Wet or sticky stuff can block the mesh holes. When this happens, your screen slows down and does not work as well. If you work with wet things like sludge, use anti-clog mesh like polyurethane screen media. These help stop blockages and keep things moving.

- Wet or sticky stuff needs anti-clog mesh to stop blocking.

- Polyurethane mesh is good for jobs with lots of water.

Picking the right mesh for wet materials saves you time and money.

Throughput and Tonnage

Throughput means how much stuff you want to move. If you need to move a lot, use a bigger screen and bigger mesh holes. This helps your screen handle more material. But bigger holes can make your sorting less exact. You need to balance speed and quality when you pick your mesh.

Screen Type: Horizontal vs Inclined

The kind of screen you use matters too. Horizontal and inclined screens work in different ways. Here is a table to show the main differences:

| Screen Type | Energy Requirement | Stroke Size | Use of Gravity |

|---|---|---|---|

| Horizontal Screen | Higher | Larger | No |

| Inclined Screen | Lower | Smaller | Yes |

- Horizontal screens lay flat and need more power and a bigger shake to move stuff.

- Inclined screens use gravity to help move stuff, so they need less power and a smaller shake.

When you know your screen type, you can pick the right mesh and screen media for your setup. This helps you get the best results from your screen.

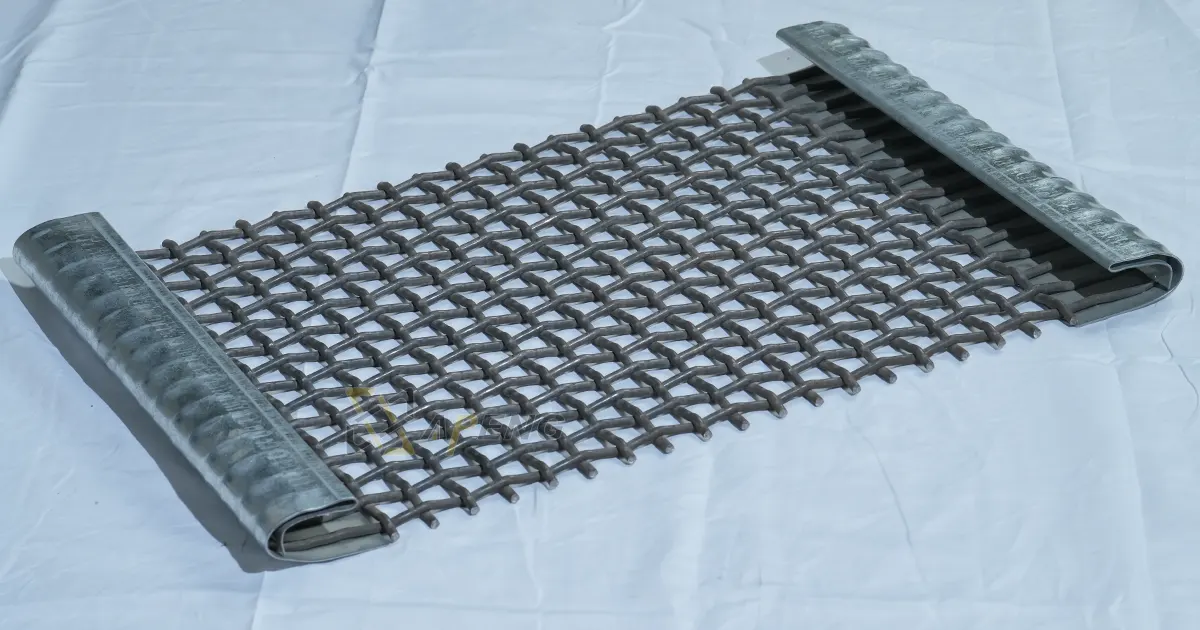

Wire Material Selection

Picking the right wire material is important for your vibrating screen mesh. The wire material you choose can change how well your screen works. It also affects how long your screen will last. You want a mesh that is strong enough for your material. It should also handle your work amount and not cost too much. Let’s look at some common wire materials for vibrating screen mesh. Each one has something special about it.

Here is a table to help you see the differences:

| Wire Material | Advantages | Disadvantages |

|---|---|---|

| Polyurethane | High wear resistance, high elasticity, sound absorption, long service life | Product dimensions are not flexible, high production cost |

| Woven Mesh | Light weight, high opening rate, improves screening efficiency | Shorter life span |

| Stainless Steel Polyurethane Composite | High overall rigidity, sound absorption, easy to disassemble | Complex production process, high production cost, quality assurance issues |

| Welded Slotted Screen | High rigidity, flexible size change, easy processing | High noise, poor surface abrasion resistance, not easy to disassemble |

| Bar Sieve Plate | Suitable for coarse-grained materials | Limited to fixed screens, not suitable for fine materials |

| Polyurethane Composite | High opening rate, sound absorption, easy to assemble | N/A |

Every wire material has good and bad points. Polyurethane is good if you want your mesh to last a long time. It also works well for tough jobs. Woven mesh is light and helps your screen work better. But it does not last as long as some other types. Stainless steel polyurethane composite is strong and easy to take apart. But it costs more and is harder to make.

When you pick a wire material, think about what you need most. Do you want your mesh to last a long time? Do you need it for heavy or sharp materials? Or do you want something easy to put in and take out? Your answers will help you pick the best wire material for your job.

High-Carbon Steel Wire

High-carbon steel wire is used a lot for vibrating screen mesh. You might pick this wire if you need something strong. It can handle rough materials without breaking. High-carbon steel wire is good for heavy loads and sharp rocks. It also costs less than stainless steel. This helps if you want to save money.

Here are some reasons to pick high-carbon steel wire:

- It is strong and does not break easily.

- It works well for rocks, gravel, and hard stuff.

- It gives you good value for your money.

But there are some problems with high-carbon steel wire. It can rust if you use it in wet or damp places. If you need a mesh for food or chemicals, try stainless steel or polyurethane instead.

Tip: Always pick a wire material that matches your work place. If you use the wrong wire, your mesh may break too soon or not work well.

When you know your choices, you can pick the right vibrating screen mesh. This helps you get better results and save money over time.

Calculating Screen Area and Mesh Size

Choosing the right vibrating screen mesh for your application requirements means you need to know both the mesh size and the screen area. These two factors work together to help you reach your required separation and get the product sizes you want. Let’s break down how you can figure out what you need for your screening equipment.

Required Screen Area

You want your screening equipment to handle your material flow without clogging or slowing down. The screen area is the total surface where your material meets the vibrating screen mesh. If you pick a screen that’s too small, you won’t meet your application requirements. If it’s too big, you waste space and money.

Material Properties Impact

Material properties change how you pick your screen area. Sticky or wet materials need more open space so they don’t block the mesh. Heavy or abrasive materials might need stronger screen media. You should always look at your material’s size, shape, and moisture. These details help you decide how much screen area you need.

Throughput Capacity

Throughput is the amount of material you want to process in a set time. If you need high throughput, you need a larger screen area or a mesh with bigger openings. But bigger openings can let unwanted particles through. You must balance throughput with your application requirements for product sizes.

Tip: Always check your material flow rate and match it with the screen area. This helps you avoid bottlenecks and keeps your screening equipment running smoothly.

Matching Mesh Size to Application

Mesh size is the number of openings per inch in your vibrating screen mesh. The mesh size you choose controls the screen opening size, which decides what particles pass through. You want to match the mesh size to your application requirements so you get the right product sizes and meet your required separation.

Separation Goals

Your separation goals guide your mesh size choice. The screen opening size sets the cut-off point for what stays on top and what falls through. If you want fine product sizes, pick a higher mesh size with smaller openings. If you want coarse product sizes, use a lower mesh size with bigger openings. The mesh size directly affects your screening equipment’s ability to meet your required separation.

Product Quality

Product quality depends on picking the right mesh size and screen media. If your mesh size is too big, you get oversized particles in your final product sizes. If it’s too small, you lose throughput and slow down your process. You can use these simple formulas to help:

- Particle size (μm) = 15000 / mesh size

- Opening size in mm = 25.4 / mesh size

- Opening size in microns = 25,400 / mesh size

You can also count the number of openings per inch to find your mesh size:

- Measure a 1-inch line across the mesh.

- Count both the wires and openings.

- The total number is your mesh size.

Note: Always match your mesh size and screen opening size to your application requirements. This helps you get the best product sizes and keeps your screening equipment working at its best.

Choosing the right vibrating screen mesh and screen media for your application requirements takes a little math and a lot of attention to your material and process needs. When you get it right, you’ll see better product sizes, higher quality, and smoother operation.

How to Choose Vibrating Screen Mesh Size: Step-by-Step

Gather Material Data

You need to start by collecting all the details about your material. This step helps you avoid mistakes later. Ask yourself these questions:

- What is the particle size range of your material?

- Is your material dry, wet, sticky, or abrasive?

- How much material do you want to process each hour?

- Do you need to separate fine powders or larger chunks?

Write down the answers. If you work with sand, gravel, or chemicals, you might see big differences in how each material moves across the screen. Sticky or wet materials can clog the mesh. Hard or sharp particles can wear out the mesh faster. When you know your material, you can pick the right vibrating screen mesh size for your job.

Tip: Take a sample of your material and measure the largest and smallest particles. This helps you set your screening goals.

Consult Mesh Size Charts

Once you have your material data, you need to look at mesh size charts. These charts show you the number of openings per inch and the wire diameter. You can use them to match your material to the right mesh. Mesh size is a critical measurement in the screening industry. It tells you which particles will pass through and which will stay on top.

Here’s a table showing some common mesh types and their differences:

| Mesh Type | Openings per Inch | Wire Diameter Differences |

|---|---|---|

| Market Grade | Varies | Varies |

| U.S. Standard | Varies | Varies |

If you work in pharmaceuticals, you’ll see mesh sizes from 40 to 400 used for shifting and milling raw materials. These sizes help you get the right product quality.

| Mesh Size | Application |

|---|---|

| 40-400 | Pharmaceutical manufacturing |

Mesh size charts help you compare options quickly. You can see which mesh will work best for your material and process. If you need to choose vibrating screen mesh size for a new job, always check these charts first.

Note: Mesh sizes commonly used in pharmaceuticals range from 40 to 400. These sizes are crucial for shifting and milling raw materials.

Test and Evaluate Performance

After you pick a mesh size, you need to test it. Testing helps you see if your choice works in real life. You can use different methods to check how well your vibrating screen mesh size performs.

Here’s a table with some common testing methods:

| Testing Method | Description |

|---|---|

| Pressure Testing | Seal the mesh in a chamber and increase pressure. Look for leaks to find weak spots or holes. |

| Particle Testing | Pass a known amount of particles through the mesh. Check if larger particles slip through. This shows if the mesh is damaged or installed wrong. |

| Ultrasonic Testing | Use high-frequency sound waves to find cracks or voids inside the mesh. This helps you spot problems you can’t see from the outside. |

| Electrical Conductivity Testing | Measure how well the mesh conducts electricity. Compare the result to the expected value. This shows if there is corrosion or physical damage. |

You should run these tests before you start full production. If you see problems, you can adjust the mesh size or try a different wire material. Testing helps you avoid costly mistakes and keeps your process running smoothly.

Tip: Always test your mesh with your actual material. Lab tests may not show real-world problems like clogging or wear.

If you follow these steps, you can find the best vibrating screen mesh size for your needs. You’ll get better results, higher product quality, and fewer breakdowns.

Final Selection and Adjustment

You have gathered your material data, checked mesh size charts, and tested your screen. Now comes the most important part—making your final choice and adjusting for the best results. This step helps you get the most out of your vibrating screen and avoid problems down the road.

Here’s a simple process you can follow:

- Install and Monitor

Put your chosen mesh on the vibrating screen. Watch how it works with your actual material. Look for signs like clogging, slow flow, or pressure drops. These signs tell you if the mesh size fits your needs. - Adjust if Needed

If you see problems, don’t worry. You can change the mesh size or try a different wire material. For example, if the mesh clogs too fast, pick a larger opening or a mesh with anti-clog features. If you notice too many fine particles slipping through, switch to a finer mesh. Always use feedback from your tests and daily operation to guide your changes. - Set Up Regular Maintenance

Make a schedule to check, clean, or replace your mesh. Regular care keeps your screen working well and helps you spot issues early. Clean mesh lasts longer and gives you better results.

Tip: Keep a log of any changes you make and the results you see. This record helps you make smarter choices next time you need to adjust your mesh.

You might need to repeat these steps a few times. Each adjustment brings you closer to the perfect setup for your material and process. Stay flexible and open to change. Your screening process will run smoother, and you’ll get the quality you want.

Vibrating Screen Mesh Issues and Solutions

Clogging and Blinding

Clogging can slow down your screening and hurt product quality. This happens when sticky or wet materials block the mesh holes. Sometimes, particles stick together or cling to the mesh. Light or weird-shaped particles can also block the screen. Using the wrong mesh type or wire thickness can make clogging worse.

Here’s a table showing the most common causes:

| Cause | Description |

|---|---|

| Excessive Material Moisture | High moisture makes material clump and stick to the screen. |

| Material Adhesiveness or Static Charge | Particles stick together and to the mesh surface. |

| Lightweight or Irregularly Shaped Material | Light or flaky particles block openings easily. |

| Poor Particle Size Distribution | Too many particles close to the mesh size block the screen. |

| Incorrect Screen Selection | Thick wires or wrong mesh shape reduce open area. |

| Lack of Cleaning Devices | No automatic cleaning means blockages stay longer. |

Prevention Methods

You can stop clogging by lowering moisture and cleaning your mesh. If your material has more than 5% moisture, use wet screening. Wet screening washes away sticky particles. Tightening the mesh helps too. It adds small shakes that knock loose stuck bits.

Try these tips for better results:

- Use wet screening for materials with lots of moisture.

- Tighten the mesh to add extra shakes.

- Clean your mesh often to get rid of stuck particles.

Tip: If you see clogging a lot, check your material’s moisture and shape. Small changes can help your screen work better.

Mesh Type Solutions

Picking the right mesh type helps a lot. For wet or sticky stuff, use anti-clog mesh. Polyurethane screens are good for these jobs. For flaky particles, match the mesh shape to the particle size. You can also change how you crush things to get better shapes.

Here’s what you can do:

- Pick mesh types that fit your material’s moisture.

- Use polyurethane mesh for sticky or wet jobs.

- Match mesh shape to particle size for flaky materials.

Inefficiency and Wear

Screening does not work well if you ignore mesh problems. You might see slow flow or bad separation. Sometimes, the mesh wears out too fast. Moisture and stickiness can stop materials from spreading on the screen. Low shaking or the wrong screen angle can also make things worse.

Common factors that cause inefficiency and wear include:

- Too much moisture and stickiness slow down movement.

- Weak shaking and wrong angle lower accuracy.

- Damaged mesh makes screening worse.

- Blocked mesh shrinks the working area.

- Deck setup and motion settings change how materials move.

- Uneven feeding spreads materials badly.

- Wrong screen settings lower speed and accuracy.

Adjusting Mesh Size

You can make screening better by changing mesh size. Small mesh sizes work best for tiny particles. Big mesh sizes are good for large particles. Always think about your material’s size, wetness, and stickiness before picking mesh size. Try different screen setups and test to see what works.

- Change mesh size to fit your material’s size.

- Use small mesh for fine particles, big mesh for coarse ones.

- Test different setups for better results.

Wire Diameter Choices

Wire thickness changes mesh strength and open space. Thick wires last longer but have less open area. Thin wires give more open space but wear out faster. Pick wire thickness that fits your material’s hardness and how much you want to move.

- Use thick wires for rough or heavy materials.

- Pick thin wires for light or fine materials.

- Balance strength and open space for the best results.

Note: If you want your screen to last longer, check wire thickness and mesh size often. Small changes can help you stop clogging and keep your screen working well.

As a maker of industrial screening media, ANPENG can help you pick the right mesh. They look at your material, moisture, cut size, how much you want to move, and your screen setup.

Best Practices for Vibrating Screen Mesh

Keeping your screening process running smoothly means you need to follow some best practices. If you want the best vibrating screen mesh for your operation, you should focus on regular maintenance, smart supplier relationships, and ongoing performance checks. Let’s break down what you can do to get the most out of your mesh.

Maintenance and Inspection

You want your mesh to last as long as possible. Regular care helps you spot problems early and keeps your screen working at its best. Here are some simple steps you can follow:

- Inspect the mesh and screen panels for any tears or holes. Small damage can turn into big trouble if you ignore it.

- Check for loose bolts or parts. Tighten anything that feels wobbly.

- Lubricate bearings and moving parts as the manufacturer suggests. This keeps everything running smoothly.

- Clean the screen surface often. Remove any material buildup or debris to prevent clogging.

- Listen for strange noises or check for odd vibrations. These signs can mean something is wrong.

Tip: Make a habit of checking your vibrating screen mesh every week. Regular inspections help you catch wear and tear before it leads to downtime.

Working with Suppliers

Choosing the right supplier makes a big difference. Good suppliers help you find the best vibrating screen mesh for your needs. They can also give you advice on new materials or designs that might work better for your process.

- Ask your supplier about mesh options for your material type.

- Share details about your process, like moisture levels and throughput.

- Request samples or small test runs before you buy in bulk.

- Keep an open line of communication. If you have issues, let your supplier know right away.

A strong partnership with your supplier means you get quick answers and better support. You can also stay updated on the latest mesh technology.

Performance Review

You should always check how your mesh is performing. This helps you know if you have the best vibrating screen mesh for your job. Here are some things to watch:

- Track screening efficiency. This tells you how well your mesh separates materials.

- Watch for changes in vibration or noise. These can signal problems with the mesh or machine.

- Review your product quality. If you see more oversized or undersized particles, it might be time to adjust your mesh size.

- Try new setups, like adding a ball tray deck, to prevent blockages and improve flow.

Note: Regular audits and routine maintenance help you keep your screening process efficient. When you review your mesh performance, you can make smart changes and avoid costly mistakes.

If you follow these best practices, you will get longer mesh life, better product quality, and fewer breakdowns. As a manufacturer of industrial screening media, ANPENG can recommend the right mesh specification based on your material, moisture, cut size, throughput, and screen model or deck layout.

Conclusion

You now know the key steps for picking the right vibrating screen mesh size. Start by checking your material’s particle size, then match it to the right mesh opening. Always think about your process needs and keep up with regular checks. If you want the best results, test and review your setup often. Need help? As a manufacturer of screen mesh, ANPENG can recommend the right mesh size and specification based on your material, moisture, target cut size, throughput, and screen model/deck layout.

FAQ

What does mesh size mean on a vibrating screen?

Mesh size tells you how many holes sit in one square inch of the screen. A higher mesh number means smaller holes. You use mesh size to control which particles pass through.

How do I know which mesh size to choose?

You look at your material’s particle size. Check mesh size charts. Test with your actual material. Adjust until you get the results you want. Always match mesh size to your process needs.

Can I use the same mesh for wet and dry materials?

No, you need different mesh types. Wet or sticky materials work better with anti-clog mesh like polyurethane. Dry materials can use woven wire mesh. Pick the mesh that fits your material’s moisture.

Why does my screen mesh wear out so fast?

Hard, abrasive, or sharp materials can damage mesh quickly. Thin wires wear out faster. You can switch to thicker wires or stronger materials like high-carbon steel to make your mesh last longer.

What is the difference between woven mesh and polyurethane mesh?

Woven mesh is light and gives high screening efficiency. Polyurethane mesh lasts longer and resists wear. You pick woven mesh for speed and polyurethane for tough jobs or sticky materials.

How often should I inspect my vibrating screen mesh?

You should check your mesh every week. Look for tears, holes, or loose parts. Clean the mesh often. Regular inspections help you catch problems early and keep your screen working well.

Can I change mesh size after installation?

Yes, you can swap out mesh panels if you need a different size. Watch your results and adjust as needed. Keep a log of changes to help you make better choices next time.

Do industry standards matter when buying mesh?

Yes, standards like ISO 3310-1 and ASTM E11 make sure your mesh meets quality and size rules. Following standards helps you get reliable results and compare different mesh options easily.