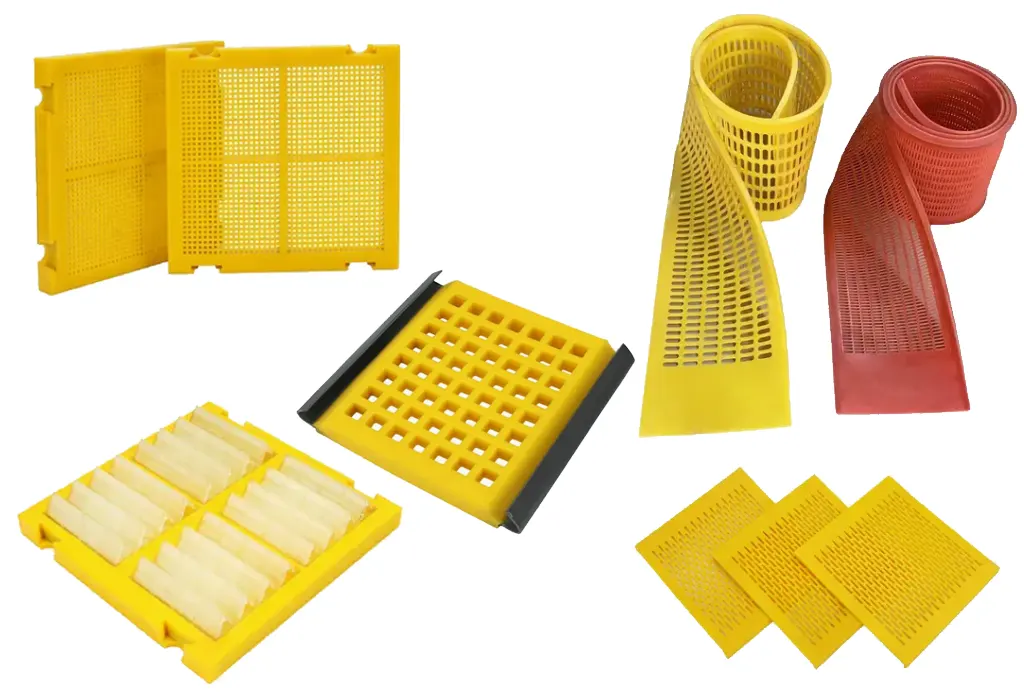

Vibrating Screen Panels

Anpeng manufactures durable Vibrating Screen Panels for vibrating screens used in quarrying, mining, sand & gravel, and aggregate processing. These modular screen media panels are designed for long wear life, reliable sizing, and faster maintenance. As a direct manufacturer, we provide custom apertures, opening patterns, panel thickness, module sizes, and fixing systems—so your panels fit your screen deck and perform steadily in demanding conditions.

What Are Vibrating Screen Panels?

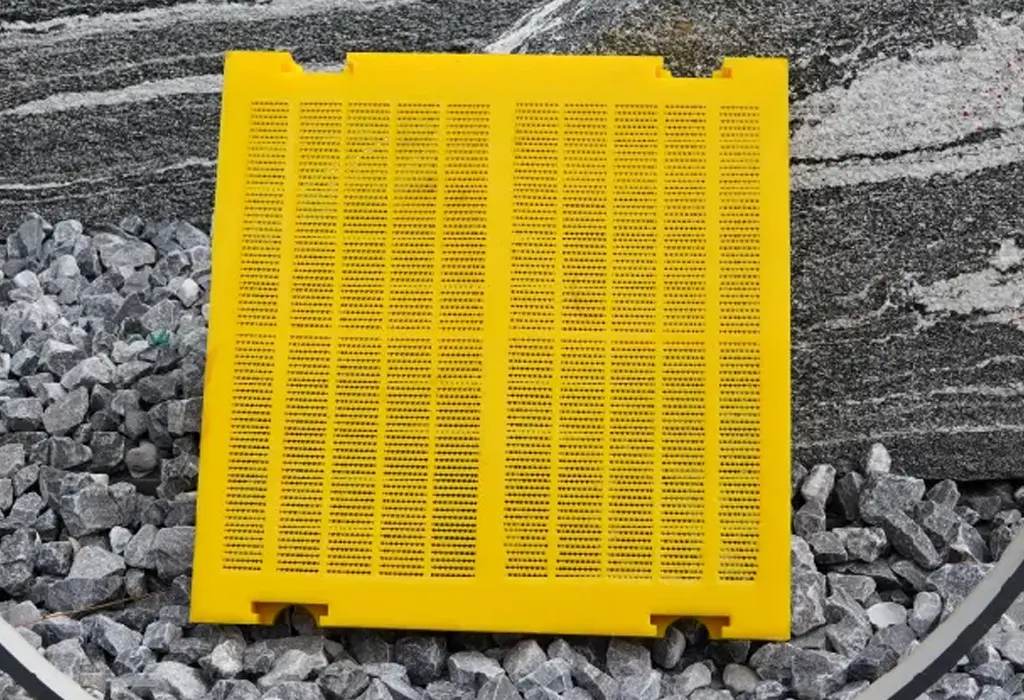

Vibrating screen panels are modular screen media installed on vibrating screens to separate material into different size ranges. Unlike woven wire mesh (screen cloth), panels are typically chosen when operations need better wear resistance, improved impact handling, reduced noise, or faster replacement. Panel selection depends on your target cut size, material condition (dry or wet/sticky), abrasion and impact level, and the fixing or tensioning system used on your screen deck.

Vibrating Screen Panel Options We Manufacture

Vibrating screen panels are available in multiple materials and fixing styles to match different duties and deck systems. Below are the common panel options we manufacture for quarry, mining, and aggregate screening.

Polyurethane (PU) Screen Panels

PU panels are a popular choice for abrasive screening and wet applications. They offer stable openings and can be produced with different hole patterns to match your cut size and screening behavior.

Common advantages

Long wear life in abrasive duties

Stable sizing performance with consistent openings

Suitable for wet screening environments

Round, square, or slotted openings available

Rubber Screen Panels

Rubber panels are often used where impact is high or where noise reduction is important. They can absorb vibration and help reduce damage caused by large lumps or heavy drop height.

Common advantages

Excellent impact resistance

Noise reduction compared with metal media

Suitable for heavy-duty scalping and harsh feed

Fixing & Mounting Systems

Fixing compatibility is critical for panel replacement projects. Vibrating screen panels are usually designed to match specific deck systems. We can manufacture panels to suit common fixing arrangements such as bolt-down, pin & clip, and rail/stringer systems (depending on your screen deck).

To confirm compatibility quickly, you can share:

A photo of your existing panels and deck fixing layout

Panel/module measurements (L × W × thickness)

Aperture and opening type (round/square/slot)

Screen model or deck drawing (if available)

Key Benefits of Vibrating Screen Panels

Faster maintenance: replace worn modules instead of changing a full deck

Wear resistance: material and thickness options matched to abrasion level

Stable sizing: consistent apertures help maintain product gradation

Impact handling: suitable choices for heavy feed zones

Noise reduction options: PU/rubber panels can help reduce operating noise

Where Vibrating Screen Panels Work Best

Vibrating screen panels are commonly selected when wear and impact are high or when maintenance time needs to be minimized. They are widely used on heavy-duty screening positions, abrasive material circuits, and wet screening lines where stable openings and predictable service life are important. Modular panels are also ideal when operators want faster maintenance—replacing only worn areas instead of removing and re-tensioning a full screen deck.

Product Specifications

| Specification | Details |

|---|---|

| Product Name | Vibrating Screen Panels (Modular Screen Media for Vibrating Screens) |

| Manufacturer | Anpeng (Direct Manufacturer) |

| Panel Material Options | Polyurethane (PU), Rubber (optional), Composite / reinforced options (upon request) |

| Opening Type | Round, Square, Slotted (custom patterns available) |

| Opening Size (Aperture) | 0.3–100 mm (custom available) |

| Panel Thickness | 10–60 mm (custom available) |

| Module / Panel Size | Custom per screen deck layout (modular panels to match your system) |

| Fixing / Mounting System | Bolt-down, Pin & Clip, Rail/Stringer system (match your existing deck) |

| Reinforcement | Steel inserts / reinforced frame (optional, based on duty and mounting) |

| Operating Condition | Suitable for dry or wet screening (selected by material, aperture, and duty) |

| Recommended Duty | Scalping, sizing, classification, and wet screening on vibrating screens (abrasion & impact duty) |

| Typical Industries | Quarry, sand & gravel plants, mining, aggregate processing, recycling |

| Customization | Opening pattern, aperture, thickness, module size, fixing method, reinforcement, and packing available upon request |

| Quotation Info Needed | Panel material, aperture, opening type, thickness, module size, fixing system, quantity, material condition (dry/wet/sticky) |

| Packing | Export pallets or cartons with protective wrapping; labeled by specification & order ID |

Why Choose Anpeng as Your Vibrating Screen Panels Manufacturer

Anpeng is a direct manufacturer, offering consistent quality, custom panel specs, and reliable delivery—backed by practical support to match your screen deck.

We control production to keep panel dimensions and openings consistent, helping ensure reliable fit and stable screening performance.

Panels can be made to match your fixing system and deck layout, reducing installation issues and improving on-screen stability.

Share your material type, cut size, and duty. We’ll recommend a suitable aperture, thickness, and panel option that fits your operating conditions.

FAQs

What are vibrating screen panels used for?

Vibrating screen panels are modular screening media used on vibrating screens to separate material into different size ranges. They are common in quarry, mining, sand & gravel, and recycling applications where wear resistance, impact handling, or faster maintenance is required.

What’s the difference between vibrating screen mesh and screen panels?

Vibrating screen mesh usually refers to woven wire screen cloth, which offers high open area and excellent screening efficiency. Screen panels are modular media (often PU or rubber) designed for longer wear life, impact resistance, and quick replacement. The best option depends on your duty, maintenance preference, and deck system.

PU vs rubber screen panels—how do I choose?

PU panels are often chosen for abrasive screening and stable sizing, especially in wet applications. Rubber panels are commonly selected for high-impact zones and noise reduction. If you share your material, moisture condition, and deck position, we can recommend a practical option.

Which fixing system do I need (bolt-down, pin & clip, rail)?

The fixing system should match your current screen deck design. The fastest replacement approach is to match your existing fixing style. If you’re upgrading or unsure, send photos of the deck and panel layout and we can confirm compatibility.

What affects panel wear life?

Wear life depends on abrasion level, impact load, deck position, moisture, and operating parameters. Panel thickness, opening shape, reinforcement, and material choice (PU/rubber) all influence service life.

What information do you need for a quotation?

For an accurate quote, provide panel material (PU/rubber), aperture and opening type, thickness, module size, fixing system, quantity, and material condition (dry/wet/sticky). Photos and measurements of existing panels are also helpful.