If you work with industrial screening, it helps to know your vibrating screen parts. This can save you time and money. Every part, like the drive motor and the screen mesh, helps the machine work well. Picking the right screen media, such as woven wire mesh screens, self-cleaning screens, or urethane panels, makes the machine work better. It also helps you avoid long stops that cost a lot. Checking the parts often, using the right oil, and tightening things keeps the machine working longer. This also helps you find problems before they get worse.

Key Takeaways

- Knowing vibrating screen parts helps save time and money. It is important in industrial screening.

- Picking the right screen media, like woven wire mesh or polyurethane, makes work faster. It also helps stop delays.

- Checking and fixing your screen often keeps it working well. This also helps it last longer.

- The vibration mechanism is very important for separating materials. You should change the settings to get the best results.

- Strong screen body and side plates make the machine tough. This lets it carry heavy things.

- Self-cleaning screens stop clogging. They work well with wet or sticky stuff.

- Oiling bearings the right way stops damage. It helps the machine run smoothly.

- Picking the best parts for your job helps you work better. It also helps you spend less money.

What Is a Vibrating Screen?

Definition and Function

You might wonder what a vibrating screen does in an industrial setting. A vibrating screen is a piece of equipment that uses vibration to sort, classify, and clean materials. It works by shaking materials so that particles move along a set path. This movement helps separate items based on their size. You can find different types of vibrating screens, such as mining vibrating screens, linear vibrating screens, high-frequency vibrating screens, and circular vibrating screens. Each type has its own way of moving and sorting materials.

Tip: If you want to get the best results, you should choose the right vibrating screen for your material and job. The design and type of screen can change how well it works and how long it lasts.

The main job of a vibrating screen is to make sure that only the right-sized particles pass through. Larger pieces stay on top, while smaller ones fall through the mesh or panel. This process helps you get cleaner and more uniform materials for your next steps.

Basic Operation in Industry

When you use a vibrating screen in your plant, you make your workflow smoother. The screen sorts materials by size. It does this by shaking the particles, which lowers the surface tension between them. As the material moves down the screen, smaller particles have a chance to pass through the mesh. Larger pieces keep moving until they reach the end or get removed.

Here’s how a vibrating screen fits into your daily operations:

- You feed raw material onto the screen.

- The vibration starts, making the particles move and separate.

- Smaller particles drop through the mesh or panel.

- Larger particles stay on top and move off the screen.

- You collect the sorted material for further use.

You can use vibrating screens in many industries, like mining, mineral processing, recycling, and construction. The screens can be set up with one motor for elliptical motion or two motors for straight motion. You can place them flat or at an angle, depending on your needs. The screen itself can be made from wire mesh, steel, or polyurethane. The choice of material affects how much you can process and how often you need to clean or replace the screen.

Note: Picking the right screen media, such as woven wire mesh, self-cleaning screens, or urethane panels, helps you get better results and longer life from your vibrating screen.

A vibrating screen helps you control particle size and improve the quality of your products. It keeps your process efficient and reduces waste. If you pay attention to how your vibrating screen works, you can spot problems early and keep your operation running smoothly.

Key Vibrating Screen Parts

Screen Body and Side Plates

When you look at vibrating screen parts, you start with the screen body and side plates. These are the main components of a vibrating screen. The screen body acts as the backbone. It holds everything together and gives the machine its shape. The side plates attach to the body and help keep the whole structure strong. If you want your vibrating screen to last, you need a solid screen body and tough side plates.

Here’s a quick look at how each part helps with durability:

| Component | Contribution to Durability |

|---|---|

| Screen Body | Serves as a supporting base for the screen mesh, ensuring stability. |

| Supporting Structure | Provides stability and support, preventing excessive vibration. |

| Isolation Springs | Absorb vibrations, ensuring smooth operation and reducing wear. |

You can see that each part works together. The screen body supports the screen mesh and deck. The supporting structure keeps the machine steady. Isolation springs help the machine run smoothly by soaking up extra movement. When you have strong screen body parts, your vibrating screen can handle heavy loads and tough jobs.

Screen Mesh and Deck

The screen mesh and deck are where the real action happens. The screen deck holds the mesh or panels in place. The mesh is what separates your material by size. If you want good results, you need to pick the right mesh and deck for your job.

The design of the screen mesh and deck affects how well your machine works. The size and shape of the holes in the mesh decide how much material passes through. If you have more open area, you can process more material. The spacing between the holes and the thickness of the wires also matter. When you get this right, you boost your screening efficiency and get better product quality.

Screening efficiency means how much of the right-sized material passes through the mesh. If your screen works at 75% efficiency, you lose 25% of your good product with the bigger pieces. That’s why you need to choose the right mesh size. It helps you separate the material you want and keeps out the stuff you don’t.

Woven Wire Mesh Screens

Woven wire mesh screens are a popular choice for many jobs. They use wires woven together to make a grid. You can pick different wire sizes and hole shapes. These screens give you sharp cuts and good accuracy. They work well when you need to separate small particles.

But there are some trade-offs. Woven wire mesh screens have a shorter lifespan, usually about 1.5 to 2.5 months. They can get noisy and may clog up if you screen sticky material. The good news is that they cost less up front. You can change them out quickly when you need to.

Self-Cleaning Screens

If you deal with wet or sticky material, self-cleaning screens can help. These screens use special wires or flexible panels that move as the machine vibrates. This action shakes off any material that tries to stick or block the holes. You get less clogging and more uptime.

Self-cleaning screens last longer than woven wire mesh screens, usually 6 to 10 months. They make less noise and need less maintenance. You pay a bit more at first, but you save time and money because you don’t have to stop as often to clean or replace them.

Polyurethane Screens and Urethane Panels

Polyurethane screens and urethane panels are tough and long-lasting. They use strong plastic material that stands up to wear and tear. These panels work well for heavy-duty jobs and rough materials. You can use them in mining, quarrying, or recycling.

These screens last the longest—up to 12 to 18 months. They run quietly and rarely clog. The upfront cost is higher, but you save money over time because you don’t have to change them as often. Maintenance is easy because you can swap out modular panels when needed.

Here’s a quick table to compare the three types:

| Feature | Woven Wire Screens | Self-Cleaning Screens | PU Mesh Screens |

|---|---|---|---|

| Lifespan | Short (1.5–2.5 months) | Medium (6–10 months) | Long (12–18 months) |

| Noise Level | High | Medium | Low |

| Clogging/Blinding | Common | Rare | Rare |

| Upfront Cost | Low | Medium | High |

| Maintenance | Frequent | Moderate | Easy (modular) |

Tip: If you want less downtime and longer life, try polyurethane screens or urethane panels for your screen deck.

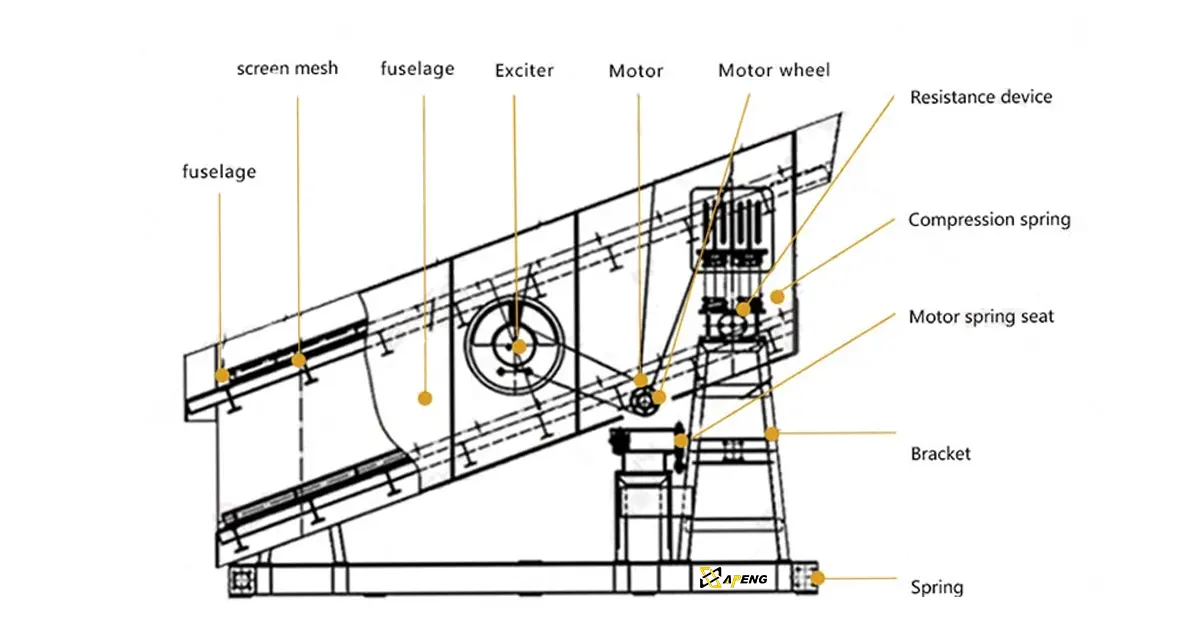

Vibration Mechanism and Exciter

The vibration mechanism is the heart of your vibrating screen. This part makes the machine shake and move the material across the screen mesh. The exciter is the device that creates the vibration. It uses motors, gears, or eccentric blocks to make the screen body move.

You can adjust the vibration mechanism to fit your needs. Change the speed or the size of the movement to match your material. The right settings help you get better separation and higher efficiency. The elliptical motion spreads the material out and helps it move across the screen deck. This action increases the contact between the particles and the mesh, so you get more of the right-sized product.

Here’s how the vibration mechanism helps you:

- The elliptical motion spreads material evenly and boosts separation.

- Eccentric blocks on the exciter shaft create strong, steady vibrations.

- Gyratory motion keeps material moving and stops it from piling up in one spot.

When you use the right vibration mechanism, you get better screening and less waste. You also protect your screen body and mesh from too much wear. The role of key components like the vibration mechanism and exciter is to keep your machine running smoothly and your product quality high.

Drive Motor and Power System

The drive motor is the powerhouse of your vibrating screen. It gives the energy needed to shake the screen and move material across the deck. When you turn on your machine, the drive system starts working right away. This system includes the drive motor, belts, pulleys, and sometimes a gearbox. Each part works together to keep your screen running smoothly.

You want to pick the right drive motor for your job. If you use a motor that is too small, your screen will not move enough material. If you use one that is too big, you waste energy and money. The drive system also affects how much power your machine uses. Here are some things that change how much energy your vibrating screen needs:

- Motor size and capacity – Bigger motors use more power to make stronger vibrations.

- Frequency and amplitude – Higher speeds and bigger shakes need more energy, especially for tough jobs.

- Duty cycle – If you run your screen all day without breaks, the drive motor uses more power and wears out faster.

- Load demands – Heavy or sticky materials make the drive system work harder and use more energy.

- System efficiency – If your drive system is old or not set up right, you lose energy and pay more for power.

If you want your vibrating screen to work well, keep your drive system in good shape. Check the drive motor often. Make sure the belts and pulleys are tight and not worn out. When you use the right drive motor and keep your drive system clean, you save energy and get better results.

Tip: A well-matched drive system helps you lower your energy bills and keeps your screen running longer.

Springs and Suspensions

Springs and suspensions are like the legs of your vibrating screen. They hold up the machine and let it move without shaking the whole building. Good springs help your screen work quietly and last longer. You can find different types of springs, such as steel coil springs and rubber isolators. Each type has its own job.

Springs do more than just hold up the screen. They also soak up shocks and stop too much vibration from reaching the floor. This keeps your machine steady and your work area safe. Here is a table that shows what good springs and suspensions can do for you:

| Advantage | Description |

|---|---|

| Shape flexibility | You can pick the shape and stiffness you need for your screen. |

| Elastic deformation | Springs can stretch and bend a lot, which helps with tough jobs. |

| Vibration absorption | They soak up shocks and keep things quiet. |

| Multidirectional load | Springs can handle pushes and pulls from many directions at once. |

| Maintenance | Easy to install and remove, no oil needed, so you save time on upkeep. |

You might see systems with high damping, like in sports cars. These give you a stable ride but do not block all the shaking. Steel coil springs need extra dampers to keep things steady. Rubber isolators have built-in damping, so you do not need extra parts, but they do not block as much vibration.

If you want your vibrating screen to last, check your springs often. Look for cracks or wear. Replace them if they look tired. Good springs keep your machine safe and help you get the best results.

Beams and Damping Elements

Beams and damping elements are the bones and muscles of your vibrating screen. The beams hold up the screen deck and spread out the weight. Damping elements help control how much the screen shakes. When you use strong beams and good damping, your screen lasts longer and makes less noise.

Damping elements are special parts that soak up extra movement. They help stop cracks from spreading in the beams. This keeps your screen safe and working well. Here is a table that shows how beams and damping elements help your vibrating screen:

| Effect | Description |

|---|---|

| Vibration Amplitude | More damping means less shaking, even if a beam has a crack. |

| Stress Distribution | Damping spreads out the stress, so no one spot gets too weak. |

| Service Life | Good damping means less bending and a longer life for your screen. |

If you want a quiet and strong vibrating screen, pay attention to the beams and damping elements. Check them for signs of wear or damage. Replace them if needed. When you keep these parts in good shape, your screen runs better and lasts longer.

Note: Strong beams and good damping help your screen handle heavy loads, reduce noise, and keep your operation safe.

Clamps, Seals, and Fasteners

You might not think much about clamps, seals, and fasteners, but these small parts do a big job on your vibrating screen. They hold everything together and keep your machine running smoothly. If you want your screen to work well, you need to make sure these parts are in good shape.

Clamps lock the screen mesh or panels tightly onto the deck. When you use woven wire mesh screens, self-cleaning screens, or urethane panels, clamps keep them from shifting or coming loose during operation. This means your screening media stays flat and secure, so you get accurate separation every time

Seals stop dust, water, and fine particles from leaking out of the screen. Good seals help you keep your work area clean and safe. They also protect the inside of your machine from dirt and moisture, which can cause damage over time.

Fasteners, like bolts and nuts, connect the different parts of your vibrating screen. They hold the side plates, beams, and other components together. If a fastener comes loose, your machine can shake too much or even break.

Rubber hose clamps play a key role in keeping everything tight. They make sure hoses and connectors stay sealed, even when the machine vibrates or the pressure changes. This helps prevent leaks, which can waste energy and create safety risks. Clamps made from corrosion-resistant materials last longer and protect both your equipment and your team.

Here’s a quick list of what happens when you take care of your clamps, seals, and fasteners:

- You stop material from leaking out.

- You keep your screening media in place.

- You avoid unplanned shutdowns.

- You protect your machine from damage.

- You make your work area safer.

Tip: Check your clamps, seals, and fasteners often. Tighten or replace them if you see any wear or damage. This simple step can save you a lot of trouble down the road.

Bearings and Lubrication

Bearings help your vibrating screen move smoothly. They let the screen body and deck shake back and forth without too much friction. If your bearings work well, your machine runs quietly and lasts longer.

Lubrication is just as important. Grease or oil keeps the bearings from wearing out too fast. If you forget to check the lubricant, your bearings can overheat or break. That means more downtime and higher repair costs.

You can make your bearings last longer by following a few simple steps:

- Check the lubrication often. Look at the amount, color, and thickness of the grease or oil.

- Add or change the lubricant on schedule. Follow the instructions from your equipment maker.

- Pick the right type of grease or oil. Some machines need special lubricants to handle tough jobs.

Here’s an easy way to remember what to do:

- Every two weeks, add lithium-based grease (like ZL-3) to the motor’s bearings.

- Use the oil cup to add grease, unless your bearings are sealed. Sealed bearings don’t need extra grease.

If you keep up with these steps, your bearings will last longer and your screen will work better. You’ll also avoid sudden breakdowns that can stop your whole operation.

Note: Good bearings and the right lubrication help your vibrating screen handle heavy loads, reduce noise, and keep your process running smoothly. Don’t skip this part of your maintenance routine!

Screen Efficiency and Parts

If you want your vibrating screen to work well, you need to check every part. Each part, like the screen mesh and bearings, helps the machine separate materials and meet your needs.

Material Separation and Throughput

Good material separation gives you cleaner products and less waste. The screen media you pick changes how well your screen works and how much you can process.

Role of Woven Wire Mesh

Woven wire mesh screens help you cut and separate materials fast. You can choose different wire sizes and hole shapes for your job. Small holes are best for fine materials. Big holes let larger pieces pass through. This choice changes how much you can process and how well you sort things.

Benefits of Self-Cleaning Screens

Self-cleaning screens stop clogging, even with wet or sticky stuff. These screens move as the machine shakes, so they clear out anything blocking the holes. You get steady separation and less time cleaning. This keeps your screen working well and lets you process more without stopping.

Durability of Polyurethane and Urethane Panels

Polyurethane screens and urethane panels last a long time, even with hard jobs. They can handle heavy loads and rough materials without wearing out quickly. When you use these panels, you do not have to change screens often. This helps you run your machine longer and keep your separation on track.

Here is a table that shows what affects how well your screen separates materials:

| Factor | Effect on Separation Effectiveness |

|---|---|

| Screen Aperture | Bigger holes work better for large materials. |

| Angle of Inclination | Works best up to 15°, then gets worse at higher angles. |

| Feed Rate | Lower feed rates work better. |

| Frequency of Vibration | Helps up to a point, but too much can make it worse. |

Tip: The right screen media and settings help you get the best separation and keep your screen working well.

Vibration and Material Flow

Vibration moves your material across the screen. If you set the vibration just right, small pieces fall through the mesh and big pieces move along the deck. At first, strong vibration keeps particles from piling up. As the material moves down, less vibration helps sort the pieces better.

The right vibration makes your screening smoother. High vibration at the start keeps material loose and moving. Lower vibration at the end helps sort and stops big pieces from building up.

Structural Stability

You want your vibrating screen to last, even with heavy use. Strong side plates, good welding, and the right materials keep your machine steady. Thick side plates and rubber bars stop extra shaking and protect your screen. Good stress spread means your screen can handle big loads without breaking.

| Design Feature | Description |

|---|---|

| Heavy gauge side plates | Make the screen strong and steady under heavy loads. |

| Rubber-cushioned camber bars | Lower vibration and stop damage. |

| High strength materials | Hold up the weight and force of the screening process. |

| Stress distribution | Helps the frame handle big vibration forces. |

Do not forget about your bearings. They help the screen move smoothly and stop wear. If you keep your bearings in good shape, your machine works better and lasts longer. This keeps your screen working well and your material separation steady.

Maintaining Vibrating Screen Parts

Routine Inspection and Cleaning

You want your vibrating screen to run smoothly every day. Routine inspection and cleaning help you catch problems early and keep your machine in top shape. If you check your screen often, you can spot loose bolts, worn parts, or buildup before they cause trouble.

Here’s a simple table to help you remember what to check and when:

| Interval | Task Description |

|---|---|

| Daily | Inspect cleanliness, greasing, loose parts, and oscillating behavior. |

| Weekly | Inspect structural components and screen media installation. |

| Monthly | Check motor mount, belt tension, and wear components. |

| Annually | Examine rubber mounts or springs and suspensions. |

You should also lock out and tag out the vibrating screen before any maintenance. This keeps you safe while you work. Each week, look for material buildup and clean the screen, especially in spots where material likes to stick. If you see tears or worn areas on the screen media, plan to replace them soon.

Tip: A quick daily check can save you from long downtime later.

Replacing Screening Media

Screening media wears out over time. If you want to keep your screening performance steady, you need to replace it before it fails. The right media helps you get the best separation and keeps your process running.

- Choose the correct screen media for your material. This boosts throughput and efficiency.

- Use self-cleaning or polyurethane screens if you handle wet or sticky materials. These options help prevent clogging.

- Match the aperture size and shape to your desired product size.

- Check your screen media often and swap it out before it gets too worn.

When to Replace Woven Wire Mesh

Woven wire mesh screens work well for many jobs, but they don’t last forever. You should replace them if you see:

- Tears or holes in the mesh.

- Wires that look thin or bent.

- More blinding or clogging than usual.

- Lower screening efficiency.

Regular inspection helps you spot these signs early. If you wait too long, you risk poor separation and more downtime.

Upgrading to Urethane Panels

If you want longer life and less maintenance, think about upgrading to urethane panels. These panels last much longer than woven wire mesh and handle tough jobs with ease. They also resist clogging and run quietly. When you switch, make sure the panels fit your deck and match your material needs.

Lubrication and Bearings Care

Bearings keep your vibrating screen moving. If you take care of them, your machine runs better and lasts longer. Regular lubrication makes a big difference. It helps prevent about 40% of bearing damage, which means fewer breakdowns and less lost time.

- Check the grease or oil level often.

- Use the right lubricant for your bearings.

- Stick to a schedule for adding or changing lubricant.

If you keep your bearings in good shape, you avoid costly repairs and keep your screen working hard.

Checking Springs and Fasteners

You want your vibrating screen to stay safe and steady. Springs and fasteners play a big role in this. If you check them often, you can stop problems before they start.

Here’s what you should do:

- Look at your vibrating screen every day. Watch how it runs and listen for strange sounds.

- Check the screen mesh for any damage or blockages. If you see a problem, fix it right away.

- Inspect all bolts and nuts. Use a wrench to tighten any that feel loose.

- Press down on the screen frame to test the springs. If a spring feels weak or does not bounce back, replace it.

- Look at rubber springs for cracks or wear. Swap them out if they look damaged.

- Each week, check the screen mesh for wear. If it looks thin or worn out, put in a new one.

- Make sure you tighten all bolts, especially those on the vibrator and screen box.

- Check the bearings and add grease if needed. If a bearing looks bad, replace it.

Tip: Springs and fasteners keep your screen running smoothly. If you take care of them, you avoid big repairs and keep your machine safe.

Preventing Common Issues

You might run into problems with your vibrating screen. The good news is you can stop most issues with simple checks and the right habits. Here’s a table that shows common problems and how you can prevent them:

| Common Issue | What Happens | How to Prevent It |

|---|---|---|

| Screen or Mesh Fatigue | The mesh bends and breaks from too much shaking. | Install the mesh the right way and keep it tight. Check anti-clogging devices often. |

| Improper Screen Installation | The screen gets damaged if you miss washers or set it up wrong. | Make sure you use all washers and put the screen in the right way. |

| Shock | Heavy objects can hit and break the screen. | Keep heavy things away from the screen. Have spare screens ready just in case. |

| Corrosion | The wires get thin from rust or chemicals. | Use the right materials for your job. Check for rust or damage often. |

| Wear and Tear | Rough materials or harsh cleaning can wear out the screen faster. | Clean with soft brushes, mild soap, and low-pressure water. Use special cleaners if you need to. |

Note: If you check your screen often and use the right cleaning tools, you can stop most problems before they start. This keeps your machine working longer and saves you money.

Choosing Vibrating Screen Parts

When you pick parts for your vibrating screen, you need to make sure they fit your job. The right parts can help your machine work better and save you money. Let’s see how you can choose the best screen media for your work and what you should think about before making a choice.

Matching Media to Application

Every industry needs something different. You can’t use the same screen for mining and recycling. Here’s how you can match your screen media to your job:

Mining and Heavy-Duty Use

Mining is a tough job. You have to deal with big rocks and heavy loads. You need screens that last a long time and don’t wear out fast. Polyurethane panels or strong woven wire mesh are good choices. They can handle sharp and rough materials and keep your screening going.

If you pick the right screen media and mix them well, you can save a lot of money in mining or aggregates. It is not always easy to find the best mix of long life and high wear.

Aggregate and Quarry

If you work with gravel, sand, or crushed stone, your screens need to be strong. These materials can be rough on your screens. Self-cleaning screens stop clogging, and wire mesh helps you size things just right. You want a screen that can take a lot of use and still give you clean results.

Recycling and Construction

Recycling and construction jobs have many types of materials. You might see wood, metal, plastic, and more. You need screens that can handle mixed loads and don’t get blocked. Urethane panels or self-cleaning screens are smart picks. They keep your screening moving, even with sticky or weird-shaped stuff.

Here’s an easy way to pick your screen media:

- Figure out what material you are working with.

- Check how long your current screen media lasts.

- Think about any problems you have with your screens now.

- Look at the size, weight, and roughness of your material.

- Do a vibration check on your vibrating screen.

Factors to Consider

You want your screen to last and do a good job. Think about these things before you choose:

- Material Characteristics: Check the size, density, wetness, and roughness of your material.

- Screening Purpose: Decide if you need to sort, scalp, or remove water.

- Operating Environment: See if there is heat, wetness, or chemicals.

- Load and Capacity: Make sure your screen can handle the weight and amount you need.

- Maintenance Needs: Pick parts that are easy to clean and change.

Choosing the right parts helps your screening process work better and keeps downtime low.

Custom Solutions from ANPENG

Sometimes, you need something special for your job. ANPENG makes custom vibrating screen solutions just for you. Here’s what you get with ANPENG:

| Advantage | Description |

|---|---|

| Scale & Capacity | Big factory with 35 lines for fast delivery. |

| Diverse Innovation | Experts from many fields keep making better screens and materials. |

| Stringent Quality Control | ISO-certified with tight checks, so you get the same quality every time. |

| Cost Efficiency | You get top quality like big brands but pay less. |

You get fast shipping, new ideas, and great quality for a good price. If you want your screening to work better, ANPENG can help you find the right fit.

Trends in Vibrating Screen Components

Advances in Screening Media

Screening media keeps getting better each year. New materials and smart designs help your vibrating screen work better. Polyurethane screens now last much longer than old ones. They are great for tough jobs like mining and mineral processing. Modular media systems let you change broken panels quickly. This means you fix things faster and work more. Better fastening systems also help your screens last longer and make repairs easier.

Here’s a quick look at some of the newest advances:

| Advancement Type | Benefit Description |

|---|---|

| Polyurethane Media | Gives you better screening efficiency and longer life in tough jobs. |

| Modular Media Systems | Lets you replace panels quickly and adjust your setup for better results. |

| Improved Fastening Systems | Makes your screens last longer and cuts down on downtime during repairs. |

- Polyurethane screens can help your screens last longer in many jobs.

- Modular media lets you change panels fast, but it may not work for every job.

Tip: If you want less downtime and more work done, try modular or polyurethane screens for your next upgrade.

Wear Life and Sustainability

You want your equipment to last and be good for the planet. New vibrating screen parts help with both. Modern parts use strong materials that last longer. This means you throw away less and save money. These parts also help you use less energy and lower pollution.

- You use less energy, so you make less pollution.

- You make less waste, so more things stay out of landfills.

- You separate materials better, so you can reuse and recycle more.

- You do not over-process, which saves energy and money.

- You help the circular economy by keeping materials in use longer.

Note: Picking the right screen parts helps you run a greener business and gets you ready for the future.

Digital Monitoring

Digital tools now help you keep your vibrating screen working well. Wireless sensors watch how your machine shakes and find problems early. You can see if something is wrong before it gets worse. This means you plan repairs, avoid surprise breakdowns, and save money.

- Sensors watch your screen’s vibration all the time.

- You find problems early and fix them before they get big.

- You do maintenance when it is needed, not just by the calendar.

- Wireless sensors are easy to put in and do not cost much to use.

With digital monitoring, you worry less about breakdowns and keep your work going. You spend more time working and less time fixing problems.

Conclusion

You want your vibrating screen to work hard and last long. Picking the right parts makes your job easier and saves money. Polyurethane screens last up to three times longer than wire mesh, cut noise, and help you process more material. You also spend less per ton over time. Regular checks and the right screen media—like woven wire mesh, self-cleaning screens, or urethane panels—keep your machine running strong. Need help? ANPENG offers custom solutions and expert advice. Reach out for a fast quote today!

FAQ

What is the most common reason for screen failure?

You usually see screen failure because of wear and tear. Sharp or heavy materials can damage the mesh or panels. If you check your screens often, you can spot problems early and avoid sudden breakdowns.

How often should you replace vibrating screen media?

You should check your screen media every week. Replace woven wire mesh every 1–3 months. Self-cleaning screens last 6–10 months. Polyurethane panels can last up to 18 months. Your material and workload affect how often you need to change them.

Can you mix different types of screen media on one deck?

Yes, you can! Mixing woven wire mesh, self-cleaning screens, and urethane panels helps you handle different materials. You get better performance and longer life. Just make sure the panels fit your deck and match your screening needs.

Why does my vibrating screen make loud noises?

Loud noises often mean loose bolts, worn bearings, or damaged springs. Check these parts first. Tighten bolts, grease bearings, and replace any broken springs. Quiet screens usually work better and last longer.

How do you prevent screen blinding or clogging?

You can use self-cleaning screens or polyurethane panels to stop clogging. Keep your screen clean and check for buildup every day. If you see sticky material, clean it right away. This keeps your screening smooth.

What should you do if your screen vibrates unevenly?

Uneven vibration can mean broken springs, loose fasteners, or a problem with the drive motor.

Check these parts and fix or replace them as needed. Balanced vibration helps your screen work well and last longer.

Is it hard to switch from wire mesh to urethane panels?

Switching is easy if your deck supports modular panels. You just remove the old mesh and snap in the new urethane panels. You get less noise, longer life, and less maintenance. Always check the fit before you start.