You might wonder, what are flip-flow screens? These special machines, also called flip flop screens or elastic mesh screens, help you separate tricky materials. They work best when you deal with sticky, wet, or tough stuff that clogs regular screens. If you want to know how these screens handle the messiest jobs, you’re in the right place. Let’s keep things simple and easy to follow!

Key Takeaways

- Flip-flow screens, also called flip flop screens, help separate sticky or wet materials that block normal screens.

- These screens move in a wave-like way to keep materials moving and stop clogging. This makes them great for messy work.

- Recycling, waste management, and biomass processing use flip-flow screens because they can handle tough materials.

- The flexible polyurethane mesh in flip-flow screens is strong and stops clogging. This helps separate materials well.

- Flip-flow screens can work very well, handling up to 92.45% of materials without needing to be cleaned often.

- These machines clean themselves and do not need much manual care, so they can run all the time.

- When picking a flip-flow screen, you should think about things like amplitude, screen width, and how much it can process to fit your needs.

- You can also get custom flip-flow screens to match your material types and how you want to use them.

What Are Flip-Flow Screens?

Simple Definition

So, what are flip-flow screens? You might hear people call them flip flop screens or elastic mesh screens. These are special screening machines that help you separate materials that regular screens just can’t handle. When you work with sticky, wet, or fine stuff, these screens step in to do the job. They use a flexible mesh that moves in a unique way, making sure nothing gets stuck.

Here’s a quick look at the most common names you’ll see for this type of screening equipment:

| Alternative Name |

|---|

| Flip-Flow Screen |

| Flip-Flop Screener |

You can see that people use different names, but they all mean the same thing. When someone asks, “what are flip-flow screens,” they’re talking about these clever machines that make tough screening jobs much easier.

Main Uses

You might wonder why you need flip-flow screens. The answer is simple. These screens help you sort out materials that are hard to separate with regular screening equipment. If you deal with things like wet soil, compost, or sticky waste, you know how quickly normal screens can clog up. Flip-flow screens solve this problem.

They work best when you need to screen materials with lots of moisture or things that tend to stick together. For example, you can use them to separate organic matter, fine soil, and even viscous substances. In recycling, these screens help you clean up construction waste by removing dust, clay, and small particles. You get cleaner, more valuable materials at the end.

Where Flip-Flow Screens Are Used

You’ll find flip-flow screens in many places. They show up wherever you need to handle tricky materials. Here’s a table that shows some of the main industries and what they use these screens for:

| Industry | Typical Applications |

|---|---|

| Recycling | Various recycled materials, glass recycling |

| Biomass | Biomass processing |

| Waste Management | Commercial & industrial waste, compost, construction & demolition |

If you work in recycling, you might use flip-flow screens to sort glass or other recyclables. In waste management, these screens help you process compost or separate out fine materials from demolition debris. Biomass plants also use them to handle organic matter with lots of moisture.

When you ask, “what are flip-flow screens,” remember that they’re the go-to solution for screening jobs that regular screens just can’t handle. They keep your process moving, even when things get sticky.

How Flip-Flow Screens Work

It helps to know how flip-flow screens work. These machines are different from other screening machines. Let’s look at what makes them special and why they work so well.

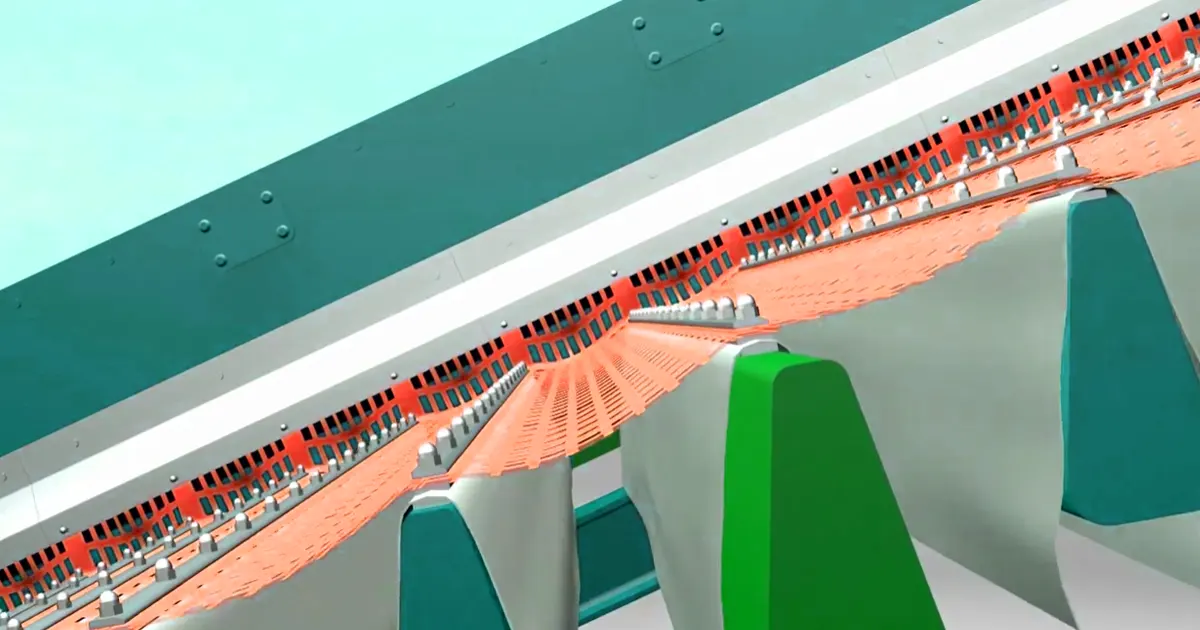

Flip-Flow Principle

Wave-Like Motion

Think about a trampoline. When you jump, it bends and then goes back. Flip-flow screens use this idea. The mesh moves in waves. This shakes and tosses the materials. Sticky or wet things do not stay on the mesh. The movement keeps everything moving and loose.

Opposite Frame Movement

Flip-flow screens have two frames. One frame does not move. The other frame moves the opposite way. This makes a double vibration. The shaking helps separate tough materials. The mesh stretches and relaxes again and again. Sticky stuff gets thrown off the screen. The holes stay clear.

Tip: Double vibration is what makes flip-flow screens special. Regular screens move in a line or a circle. Flip-flow screens use this motion to handle hard jobs.

Here’s a quick comparison:

| Feature | Flip-Flow Screens | Other Screening Technologies |

|---|---|---|

| Operating Principle | Utilizes a unique dual vibration mechanism to effectively screen tough materials. | Typically rely on linear or circular motion. |

| Advantages | Handles high-moisture and sticky materials without clogging. | May struggle with sticky materials. |

Screen Mesh and Materials

Polyurethane Mesh

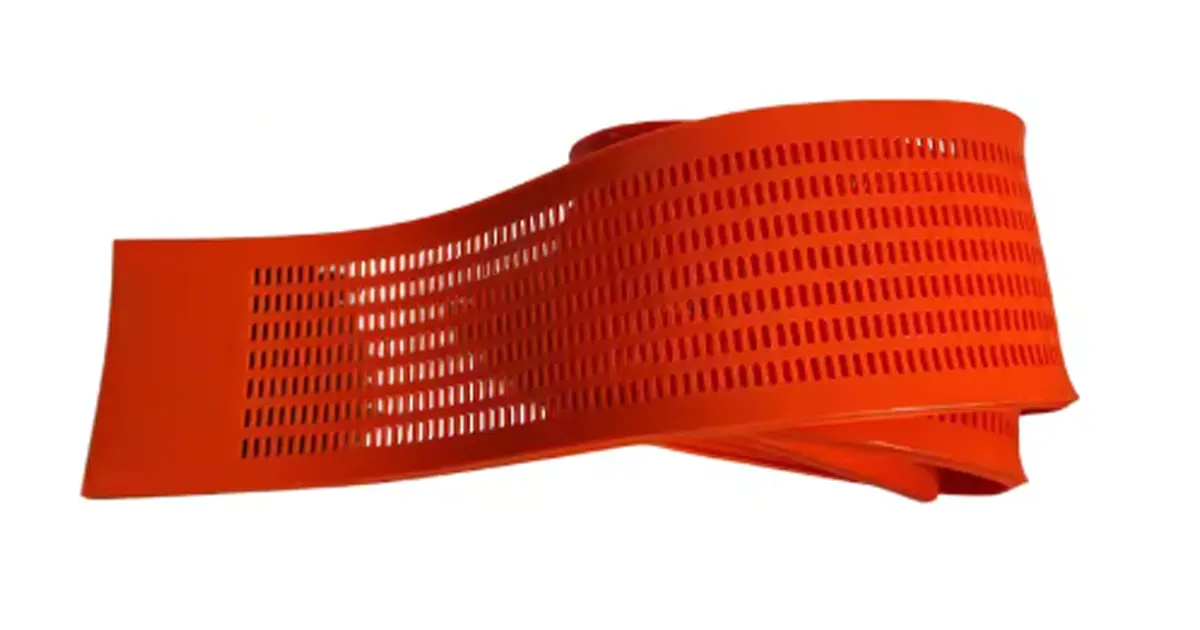

You might wonder why the mesh is important. Most flip-flow screens use polyurethane mesh. Polyurethane is stretchy and strong. It does not wear out fast. It bends and snaps back easily. This helps with sticky and wet materials. The mesh does not clog or stick much. Some machines use rubber or metal mesh. These do not work as well for sticky jobs.

Here’s a look at the common mesh materials:

| Material | Advantages |

|---|---|

| Polyurethane | Good elasticity, wear resistance, long life, great for sticky and wet materials, no clogging. |

| Rubber | Less durable, not as good for sticky materials. |

| Metal | Rigid, can clog with sticky materials, less flexible. |

Frequency and Motion

Flip-flow screens vibrate very fast. The mesh stretches and relaxes quickly. Sometimes it moves up to 50 times the force of gravity. This fast motion makes materials jump and separate. Fine and sticky particles cannot stick to the mesh. The screen stays clear. You get better results. The double vibration makes the mesh move in a special way. It stretches and relaxes every cycle. This keeps the screening smooth and easy.

Note: The special motion is important. The mesh never stops moving. Sticky materials do not block the holes.

Material Separation Process

When you put material on flip-flow screens, the action starts right away. The mesh moves in waves. The frames shake in opposite ways. Sticky, wet, or fine materials bounce and tumble. The mesh stretches and snaps back. Anything that tries to stick gets thrown off. You get clean separation, even with tough materials.

Here’s how the process works in simple steps:

- You put the material on the screening machines.

- The mesh starts to vibrate and stretch.

- Sticky or wet particles bounce and move along the mesh.

- The mesh throws off anything that blocks the holes.

- Clean, separated material comes out the other side.

Flip-flow screens make screening easy. They work even with the messiest materials. You spend less time cleaning and more time working.

Key Features of Flip-Flow Screens

Flexible Mesh Design

Flip-flow screens have a special mesh. The mesh is flexible and made from materials like polyurethane. This lets the mesh stretch and snap back easily. It can handle sticky or wet materials without trouble. Regular screens do not bend like this. The mesh moves in waves to help separate different particles. This wave motion stops clogging. Your machines keep working and do not stop often.

Here’s a quick table showing what makes the mesh so special:

| Feature | Benefit |

|---|---|

| Flexible materials (e.g., polyurethane) | Allows handling of wet, sticky, or fine materials effectively. |

| Unique design | Enables efficient separation of particles of different sizes. |

| Clogging prevention | Reduces the common issue of clogging found in traditional screens. |

The mesh design helps with tough jobs. The mesh keeps moving, so sticky stuff does not get stuck.

High Efficiency for Wet/Sticky Materials

You want machines that work fast and do not waste time. Flip-flow screens are very good at screening wet or sticky materials. Studies show they can reach up to 92.45% efficiency with the right settings. This means you get more clean material and less waste. Changing the tension can make them work even better. Researchers found that adjusting tension improved efficiency by 9.17%. You get better results by changing the settings.

Tip: If you need to screen sticky or wet material, flip-flow screens help a lot. You spend less time cleaning and more time screening.

These machines can handle messy jobs. The flexible mesh and strong vibration keep things moving. You get great performance every time.

Prevents Blinding and Blockage

Blinding and blockage slow down screening equipment. Flip-flow screens stop this problem with smart design. The dual-mass drive system uses changing tension to keep the mesh moving. Elastic screen panels shake off trapped particles. The screen holes change shape all the time. This stops particles from getting stuck. The mesh cleans itself, so you do not need to stop and clean.

Here’s a table that shows how flip-flow screens prevent blinding and blockage:

| Feature | Description |

|---|---|

| Dual-mass drive system | Utilizes alternating tension to prevent blinding and blockage. |

| Elastic screen panels | Help dislodge trapped particles, ensuring consistent material flow. |

| High resistance to clogging | Constantly changes screen opening geometry to prevent particles from lodging. |

| Self-cleaning action | Virtually eliminates downtime for manual cleaning, enhancing operational efficiency. |

Your machines run longer without stopping. You do not have to clean the screens all the time. This means you get more work done and less trouble.

Benefits of Flip-Flow Screens

Handles Difficult Materials

Some materials are hard to separate. Flip-flow screens help with these tough jobs. They work well with things like auto shredder residue and compost. Even if the material is wet or sticky, these machines keep working. Other screens might stop, but flip-flow screens do not.

- You can use them for compost that is wet or light.

- High-frequency vibrations help sort out small pieces.

- These screens stop clogging by reducing blinding and pegging.

- You can screen compost down to 1/8 inch if needed.

Tip: Some materials can still be tricky. If the moisture or mix changes a lot, check your material first.

Reduces Downtime

No one wants to stop work for cleaning or repairs. Flip-flow screens help you keep working. They are made to handle wet and sticky stuff without getting blocked all the time. You spend less time fixing and more time screening.

- The FlipWave™ screen helps stop blockages and cuts downtime.

- Old screens clog up fast, so you have to stop and clean them.

- Many recycling plants use systems to watch flip-flow screens. These systems find problems like wear or blockages right away.

- You get alerts so you can fix small issues before they get worse.

You also save time on maintenance. Most flip-flow screens use panels you can swap out fast. You can change these panels in less than two hours. Polyurethane panels last longer than rubber ones. You do not need to change them as often. Quick fixes help you save money.

Improves Screening Quality

You want your material clean and sorted at the end. Flip-flow screens help you do this. They make sure more material goes through the screen plates.

- The mesh jumps to help the screen work better.

- You can get up to 11.01% better efficiency than other screens.

- The vibration can reach 27.81, which helps sort even tiny pieces.

- These screens can handle 278 tons per hour. The error rate is as low as 0.057 grams per cubic centimeter.

Note: Better screening means more good material and less waste. Your process works better, and your final product looks cleaner.

Flip-flow screens help you with hard materials, cut downtime, and make your screening better. These benefits make your work easier and more productive.

Applications of Flip-Flow Screens

You may ask where flip-flow screening machines are used. These machines work in lots of industries. They help with tough materials that other screens cannot handle. Let’s see some main places where you find these machines.

Industries Using Flip-Flow Screens

Recycling

Recycling can be messy work. Flip-flow screening machines help sort glass, scrap, and fine minerals. You can use them for municipal solid waste, wood, and organic biomass. The machines keep things running smoothly. You get cleaner products at the end.

Mining

Mining sites use flip-flow screening machines for heavy and sticky stuff. You can screen coal, gold ore, and slag with them. They work well with fine and wet particles. The screens do not clog or blind easily. This gives you better results.

Waste Management

Waste management needs strong screening equipment. Flip-flow screening machines help process compost, construction debris, and waste. You can separate sand, concrete, and glass. The machines keep working, so you do not stop for cleaning often.

Quarrying

Quarrying deals with sand, gravel, and rocks. Flip-flow screening machines sort natural riverbed sand and manufactured sand. They handle wet and sticky materials that regular screens cannot. You get more usable material and less waste.

Tip: If you work in these industries, flip-flow screens make your job easier and faster.

Types of Materials Screened

Flip-flow screening machines work with many materials. Here are some common examples:

- Municipal solid waste

- Wood

- Organic biomass

- Sand

- Concrete

- Compost

- Coal

- Gold ore

- Natural riverbed sand

- Manufactured sand

- Glass

- Scrap

- Fine-grained minerals

- Slag

These machines handle big and small particles. You can screen wet, sticky, or fine materials with no problem. The machines keep the process moving. You get clean, sorted products every time.

If you need screening equipment for tough jobs, flip-flow screens are a smart choice. You can use them in many industries and for many materials. The right machines help you save time and get better results.

Flip-Flow Screens vs. Traditional Screens

Key Differences

You might wonder how flip-flow screens stack up against traditional screening equipment. The differences show up in both design and performance. Flip-flow screens use a two-body system that creates strong vibrations. This helps you handle sticky and wet materials with ease. Traditional screens, like circular vibrating screens, use a single-body design. They often struggle when you try to screen tough materials.

Take a look at this table to see how the two compare:

| Feature | Flip-Flow Screen (VFFS) | Circular Vibrating Screen (CVS) |

|---|---|---|

| Vibration Intensity | High | Standard |

| Efficiency for Sticky Particles | 77.62% | 61.99% |

| Total Misplaced Materials | 5.76% | 9.82% |

| Design Type | Two-body system | Single-body system |

| Handling of Sticky Materials | Excellent | Poor |

Flip-flow screens give you higher vibration intensity. This means you get better screening results, especially with sticky particles. You also see fewer misplaced materials, so your final product looks cleaner. The two-body design lets the mesh stretch and snap back, which keeps the holes clear. Traditional screens can’t do this, so they clog more often.

Note: Flip-flow screens use less energy, too. You can save 30-50% on energy costs compared to older screening equipment. That’s a big win for your budget and the environment.

When to Choose Flip-Flow Screens

You don’t always need flip-flow screens, but some jobs make them the best choice. Here’s when you should pick them over traditional screens:

- You need to screen fine-grained minerals, especially if they’re sticky or wet.

- Your materials tend to clog or cluster because of moisture or clay.

- You want to avoid downtime from cleaning blocked screens.

- You need strong ejection power and high screening efficiency for tough jobs.

- You want to lower your energy use during screening.

Flip-flow screens shine in challenging conditions. If you work with compost, wet sand, or sticky waste, these machines keep your process moving. You spend less time fixing problems and more time getting clean, sorted material.

Tip: If you notice your old screens clogging up or slowing down, it’s time to think about switching. Flip-flow screens handle messy jobs with ease and help you get better results.

You can trust flip-flow screens to tackle the toughest screening tasks. They work fast, use less energy, and keep your operation running smoothly.

Choosing Flip-Flow Screens

If you want the best results, picking the right flip-flow screens is important. You should think about what materials you have and what you want to do. Your site setup also matters. Let’s look at what you need to check so you get screens that work for you.

Selection Factors

There are a few things to think about before you pick your screening equipment. Each thing can change how well your flip-flow screens work.

- Amplitude: This means how much the mesh moves up and down. More movement helps shake off sticky stuff.

- Screen surface width: A wider screen lets you sort more material at once.

- Screen surface tension: The right tension keeps the mesh tight. This helps with tough materials.

- Speed: Faster shaking helps with fine or wet particles.

You should also think about:

- Classification accuracy: How well do you want to sort different sizes?

- Processing capacity: How much material do you need to screen each hour?

- Operational stability: Will your screens run smoothly without stopping a lot?

- Maintenance costs: Can you keep your equipment running without spending too much money?

- Smooth progress of subsequent processes: Will your screening help the next steps go better?

Tip: If you get these things right, your screening will be faster and cleaner. It will also be easier to manage.

Customization Options

Every job is different. You might need special features to get the best results from your flip-flow screens. The good news is there are many ways to change your equipment.

| Customization Type | Description |

|---|---|

| Custom Fabrication | You can get screens made to your exact size and shape. |

| Custom Formulation | Experts help you pick the right material for your job. |

| Material Quality | Pick natural rubber or imported polyurethane for better performance and longer life. |

You can also ask for:

- Custom setups for each type of material, so you always get the best screening.

- Choices for hardness, thickness, or hole size in polyurethane panels.

Polyurethane flip-flow panels work well for vibratory screens. You can pick the panel size, the shape, and the size of the holes. These panels handle tough materials and stop blinding, so your screening stays efficient.

Sometimes, you might have problems during installation or maintenance. Here’s a quick look at what you might face:

| Challenge | Description |

|---|---|

| Installation and Integration | You need to install your screens the right way for the best performance. |

| Maintenance and Troubleshooting | Regular checks and quick fixes help prevent downtime. |

Note: If you plan ahead and pick the right options, you can avoid most problems. Your screening process will run smoothly.

Picking the right flip-flow screens and changing them for your needs will help you get the most out of your screening process. You will save time, reduce waste, and keep your operation moving.

Conclusion

You have learned that flip-flow screens use a special flip-flop motion. This motion helps tough materials keep moving and stops clogging. These screens are different because they clean themselves. They work very well and are easy to take care of. Here are the main benefits:

| Feature | What It Means for You |

|---|---|

| Self-cleaning motion | Less clogging, more uptime |

| High adaptability | Handles many types of materials |

| Quick maintenance | Fast screen changes, less downtime |

If you need to screen sticky or wet material, try flip-flow screens. We make custom solutions for every industry. Contact us today if you want more details or a price!

FAQ

What makes flip-flow screens different from regular screens?

Flip-flow screens use a flexible mesh that moves in waves. This motion helps you screen sticky or wet materials. Regular screens often clog or block when you try to screen tough stuff.

Can you use flip-flow screens for dry materials?

Yes, you can use flip-flow screens for dry materials. They work best with sticky or wet stuff, but they also handle dry particles without trouble.

How do you clean flip-flow screens?

You do not need to clean flip-flow screens often. The mesh moves and shakes off stuck material by itself. This self-cleaning action saves you time.

What materials can you screen with flip-flow screens?

You can screen compost, sand, glass, coal, minerals, and waste. Flip-flow screens handle fine, wet, or sticky materials that regular screens cannot process well.

Do flip-flow screens need a lot of maintenance?

No, you do not need much maintenance. The panels last a long time. You can swap them out quickly if needed. Most users spend less time fixing these screens.

How do you choose the right flip-flow screen?

Check your material type, moisture level, and how much you need to screen. You can ask for custom sizes or mesh types. Experts help you pick the best option.

Are flip-flow screens energy efficient?

Yes, flip-flow screens use less energy than traditional screens. You can save up to 50% on energy costs. This helps your budget and the environment.

Can you customize flip-flow screens for your job?

Absolutely! You can choose mesh size, panel thickness, and material type. Custom screens fit your needs and help you get better results.