If you work with hard materials that often clog or stick, you might ask, “What are piano wire screens?” and why they are important. These screens utilize strong wires that are pulled tight and set side by side, allowing them to perform tasks that regular woven screens cannot accomplish. You often see them used to sort various materials, including:

- Clumpy materials

- Sticky materials

- Fine materials

- Cubical materials

- Damp sand

- Top soil

Understanding what piano wire screens are and how they work can help you achieve better results when you need careful and accurate screening.

Key Takeaways

- Piano wire screens use strong wires that bend easily. These wires stop clogging. This makes them good for wet or sticky stuff.

- These screens work fast and well. More material goes through quickly. This helps people get more work done.

- You can change things like wire thickness and hole size. This helps the screen fit different materials.

- Piano wire screens last a long time. They can handle hard jobs. But you might need to replace them more often than other screens.

- Cleaning and checking the screens often helps them last longer. It also keeps them working well.

- Piano wire screens clean themselves as they work. This means less stopping and faster screening.

- Many industries use these screens. Mining, recycling, and construction use them to sort materials.

- Picking the right screen is important. You need to think about the material and how wet it is. This helps you get the best results.

What Are Piano Wire Screens

Definition and Structure

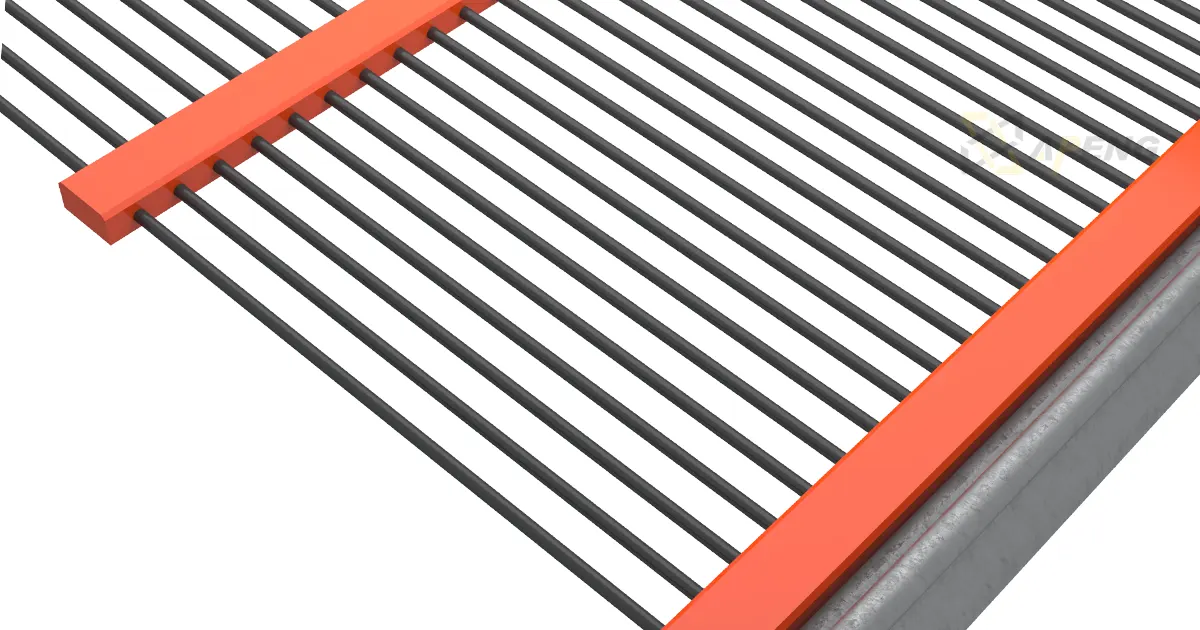

If you ask, “what are piano wire screens,” you want a simple answer. These screens use high-tensile steel or stainless steel wires. The wires run next to each other and are pulled tight across the frame. Plastic profiles keep the wires straight and locked in place. This setup makes the screen strong and bendable for tough jobs.

Here’s a quick look at the main properties:

| Property | Description |

|---|---|

| Composition | Made from high-tensile steel or stainless steel, arranged vertically and held by plastic profiles. |

| Anti-Clogging | Flexible wires vibrate independently, preventing clogging and maintaining a clean screening surface. |

| High Screening Efficiency | Higher open area than conventional screens, allowing more material to pass through. |

| Durability | Withstands abrasive conditions, offering a longer lifespan. |

| Customization | Can be tailored with variable spacing and wire diameters for specific needs. |

Some piano wire screens have tension folds and bindings. These parts make it easy to install and help the screen fit tightly. Some screens use straight wires. Others use waved wires for better sorting.

Primary Function

Piano wire screens separate materials fast and accurately. You use them when you need to screen a lot and want to stop clogging. These screens work well with wet, sticky, or fine materials. The wires move by themselves and shake off anything stuck.

Here’s what you get from using piano wire screens:

| Feature | Description |

|---|---|

| High-Volume Screening | Designed for high throughput, capable of handling various materials efficiently. |

| High Precision | Provides accurate product separation, enhancing overall processing efficiency. |

| Minimal Clogging | Engineered to reduce clogging and blinding, ensuring consistent performance. |

| Flexibility | Offers opening sizes from 1mm to 19mm for optimal material flow. |

If you need to screen lots of material and want a clean screen, piano wire screens are a good choice. You can change them to fit your needs, like wire spacing or thickness.

Tip: If you work with damp sand or sticky soil, piano wire screens help your screening process stay smooth.

Comparison to Woven Screens

You might wonder how piano wire screens compare to woven wire mesh. Both help sort materials, but they work differently.

- Woven wire mesh bends and twists easily. You can use it on curved surfaces or when you need a flexible screen.

- Piano wire screens stay stiff and strong. They are best for heavy jobs where you need the screen to last.

Piano wire screens have more open space than woven wire mesh. This lets more material pass through and gives better screening. The wires in piano wire screens vibrate alone, which helps shake off fine particles and stops clogging. Woven wire mesh does not do this, so it can get blocked, especially with wet or sticky stuff.

If you want a screen that lasts and handles tough jobs, piano wire screens are a smart pick. They can be a little fragile sometimes, but their high-precision screening makes them popular in many industries.

Screen Construction and Materials

High-Tensile Steel and Stainless Steel

When you look at a piano wire screen, you might wonder what makes it so strong. The answer comes from the type of steel used in the screen. Manufacturers use special steel to make sure your screen can handle tough jobs and last a long time. Here’s a simple table to show you the most common types of steel you’ll find in a piano wire screen:

| Type of Steel | Description |

|---|---|

| High Tensile Spring Steel | Used for its strength and durability in manufacturing piano wire screens. |

| Manganese Steel Wire | Provides extra strength and resists wear, making your screen last longer. |

| Stainless Steel Wire | Known for corrosion resistance and durability, great for wet or harsh jobs. |

| Stainless Steel 304 | Offers a good mix of strength and corrosion resistance for your screen. |

| Stainless Steel 316 | Gives even better corrosion resistance, perfect for tough environments. |

You can pick a screen made from high tensile spring steel if you need something that won’t bend or break easily. If you work with wet or sticky materials, a stainless steel screen helps prevent rust and keeps your screen working longer. Some screens use manganese steel wire for extra toughness, especially if you deal with sharp or abrasive materials.

Tip: If you want your screen to last, always choose the right steel for your job.

Parallel Wire Design

The way the wires sit in a piano wire screen makes a big difference. In this screen, the wires run side by side in a straight line. This parallel wire design gives your screen a bigger open area. That means more space for material to pass through the screen. You get better self-cleaning because the wires can move and shake off anything that tries to stick. This design helps your screen stay clear, even when you work with fine, wet, or sticky materials. You spend less time cleaning your screen and more time getting the job done.

When you use a screen with parallel wires, you notice fewer clogs. The screen works faster and keeps your material moving. You don’t have to stop as often to fix problems. This makes your whole screening process smoother and more efficient.

Profile Bar Options

Profile bars hold the wires in place on your screen. You can choose different profile bar shapes and materials to match your needs. Here are some common options you might see in a piano wire screen:

- Plastic Profile Bars: These bars keep the wires straight and help reduce noise. They also protect the wires from wearing out too fast.

- Rubber Profile Bars: If you want a quieter screen, rubber bars help absorb sound and vibration.

- Steel Profile Bars: For heavy-duty jobs, steel bars give your screen extra strength and support.

You can pick the profile bar that fits your screen best. If you want less noise, go for plastic or rubber. If you need a tough screen, steel bars are the way to go.

No matter which options you choose, the right construction and materials make your screen last longer and work better. When you understand how each part of the screen works, you can pick the best screen for your job and keep your screening process running smoothly.

Key Screen Features

Anti-Clogging and Blinding Prevention

If you use a screen for hard jobs, you want it to stay clear. Piano wire screens help stop clogging and blinding. The wires move by themselves, so sticky or wet stuff does not block the holes. You get a clean screen and do not need to stop often. Special profiles help keep things moving. Here is how these profiles work:

| Mechanism Type | Description |

|---|---|

| Crowned profiles | These have curved tops. They change tension and help particles move. |

| U-shaped profiles | These shapes help material flow better and stop clogging. |

| Piano-wire profiles | Fewer contact points mean less plugging and more material passes. |

You will see the screen keeps working with fine or sticky stuff. The wires shake off anything that tries to stick. You spend less time cleaning and more time working. If you compare this screen to others, you will notice you stop less for repairs.

High Open Area

The open area in a screen is important. Piano wire screens give you more space for material to go through. The wires sit next to each other, leaving bigger gaps. This design lets more material move and stops blocking. You can see your screening goes faster. Here are some facts about open area and throughput:

- Wires that move alone can boost product flow by up to 40% compared to woven wire or polyurethane panels.

- Special wire patterns, like the MAXKleen system, make open area bigger for better screening.

- FLEX-MAT screens run at high speeds, which sorts material faster and increases flow.

- Double-wire woven screens can handle up to 50% more material than perforated plate screens because they have bigger openings.

If you want to finish faster, pick a screen with high open area. You will get quicker results and fewer clogs.

Screening Efficiency

You want your screen to sort things fast and right. Piano wire screens give high screening efficiency. The wires shake quickly, which helps separate material better. You get clean products and less waste. In some jobs, like sludge dewatering, these screens reach efficiency rates of 85% or more. That means you get more good material and less mess.

Let’s compare piano wire screens to regular woven wire screens:

| Feature | Piano Wire Screens | Traditional Woven Wire Screens |

|---|---|---|

| Open Area | More open space for better flow | Less open space, gets clogged |

| Anti-Clogging Properties | Wires move alone and stop clogging | Gets blocked with fine or wet stuff |

| Screening Efficiency | Screens more material | Works slower because of clogging |

| Durability | Made from strong steel, lasts longer | Wears out faster with rough jobs |

You get better results with piano wire screens. The screen keeps working, even with tough materials. You do not need to worry about clogging or blinding. The screen gives you high flow and top sorting power. If you want a screen that works hard and lasts long, piano wire screens are a smart choice.

Tip: If you need a screen for wet, sticky, or fine materials, piano wire screens help you finish faster and cleaner.

Durability

When you choose a screen for your job, you want it to last. Durability matters because you do not want to stop work just to fix or replace your screen. Piano wire screens give you strong performance, but you should know how they stack up against other screen types.

Let’s look at how piano wire screens compare to polyurethane and hybrid screens:

| Screen Type | Durability | Effectiveness in Heavy Use | Self-Cleaning Properties |

|---|---|---|---|

| Piano Wire Screens | Shorter wear life | Effective | Yes |

| Polyurethane Screens | Longer wear life | Effective | No |

| Hybrid Designs | Varies | Effective | Yes |

You can see that piano wire screens do not last as long as polyurethane screens. Polyurethane screens have a longer wear life, so you might not need to replace them as often. Hybrid screens can last longer or shorter, depending on how they are made. But here’s the thing—piano wire screens work really well in tough jobs, especially when you deal with sticky or wet materials.

Here are some things you should know about piano wire screens and their durability:

- Piano wire screens have a shorter lifespan compared to polyurethane and hybrid screens.

- They do a great job at stopping blinding and pegging because the wires move and clean themselves.

- Even though you might need to replace them more often, you get better productivity. The screen stays clear, so you do not lose time fixing clogs.

- The self-cleaning action means you spend less time on maintenance and more time getting work done.

Note: If you work in a place where screens wear out fast, you might need to change piano wire screens more often. But the boost in productivity can make up for the cost of replacing them.

You should think about what matters most for your job. If you want a screen that keeps working without clogging, piano wire screens are a smart choice. If you need something that lasts a very long time, you might look at polyurethane screens. But for many jobs, the balance of performance and easy cleaning makes piano wire screens a favorite.

So, when you pick a screen, remember to check how long it will last and how well it works with your material. The right choice helps you keep your operation running smoothly.

Benefits in Screening Applications

Handling Wet and Sticky Materials

You know how tough it can be to keep your screen clear when you work with wet or sticky materials. Piano wire screens make this job much easier. The wires move on their own, so the screen shakes off anything that tries to stick. You get a clean screen, even when you deal with sand, compost, or topsoil. The screen does not clog, so you spend less time cleaning and more time screening.

Here’s a quick look at why piano wire screens work so well for wet and sticky materials:

| Feature | Benefit |

|---|---|

| Self-Cleaning | Reduces clogging, ideal for wet and sticky materials |

| Longer Service Life | Outlasts conventional screens, maintaining material specifications |

| Largest Screening Area | Facilitates rapid removal of fines, enhancing efficiency |

You can use these screens for hard-to-screen materials. The screen keeps working, even when things get messy. You do not need to stop your screening process to fix blockages. The screen helps you finish your job faster and with less effort.

- Suitable for wet, sticky, hard-to-screen materials

- Ideal for screening sand, compost, and topsoil

If you want a screen that stays clear, piano wire screens are the way to go. The screen gives you better results and saves you time.

Improved Throughput

When you use a piano wire screen, you notice your screening speed goes up. The screen has a large open area, so more material passes through. You do not have to wait for the screen to clear itself. The screen keeps moving, and your screening process does not slow down.

You get higher throughput because the screen does not clog. The screen lets fines drop through quickly. You can handle more material in less time. The screen helps you reach your production goals without extra effort.

If you want to boost your screening output, choose a piano wire screen. The screen works fast and keeps your operation running smoothly.

Consistent Stratification

Stratification means sorting material into layers. Piano wire screens help you get consistent stratification. The screen vibrates and moves material across the surface. You see fine particles drop through first, then larger pieces stay on top. The screen keeps the layers separate, so your screening results stay accurate.

You do not have to worry about uneven sorting. The screen does the work for you. You get clean, sorted material every time you use the screen. The screen helps you keep your product quality high.

If you want reliable screening, piano wire screens give you the consistency you need. The screen makes your job easier and your results better.

Customization for Specific Needs

Every screening job is different. You might work with sand one day and crushed rock the next. Sometimes, you need to screen wet soil. Other times, you want to sort dry gravel. That’s why you need a screen that fits your exact needs. Piano wire screens give you lots of ways to customize. You can pick the right setup for your job, so you get the best results every time.

Here’s how you can customize your piano wire screen:

- Wire Diameter: Choose thin wires for fine materials or thicker wires for heavy, rough stuff.

- Opening Size: Pick small openings for tiny particles or larger ones for bigger chunks.

- Wire Material: Go with stainless steel if you deal with moisture or chemicals. Use high-tensile steel for tough, dry jobs.

- Profile Bars: Select plastic for less noise, rubber for extra quiet, or steel for strength.

- Screen Length and Width: Order screens that fit your machine perfectly, so you don’t waste space or time.

Tip: If you’re not sure what you need, talk to your screen supplier. They can help you pick the right options for your material and machine.

Let’s look at a quick table to see how you might choose different features:

| Your Material | Best Wire Type | Opening Size | Profile Bar |

|---|---|---|---|

| Wet sand | Stainless steel | Small | Plastic |

| Crushed stone | High-tensile steel | Medium | Steel |

| Compost or soil | Stainless steel | Medium | Rubber |

| Fine gravel | High-tensile steel | Small | Plastic |

You can also ask for special features. Maybe you want extra reinforcement for heavy loads. Maybe you need a special tension system for quick changes. Some screens even come with color-coded edges, so you know which one to use at a glance.

Customizing your screen helps you:

- Get better screening results

- Reduce downtime from clogs or breaks

- Make your machine last longer

- Save money by only replacing what you need

You don’t have to settle for a “one size fits all” screen. With piano wire screens, you get a solution that matches your job. You work faster, cleaner, and with less hassle.

Note: The right customization can make a big difference in your daily work. Take a little time to choose the best options, and you’ll see better results on every job.

Choosing Piano Wire Screens

When you want the best results from your screening process, you need to choose the right screen. Picking the right screen can feel tricky, but you can break it down into a few simple steps. Let’s look at what you should think about before you pick your screen.

Material Type

Start by thinking about what you want to screen. The type of material you use changes the kind of screen you need. If you work with soft soil, you need a different screen than if you handle sharp rocks. Some screens work better with fine sand, while others handle big stones. You want your screen to match your material, so you get the best screening every time.

- For soft or wet materials, pick a screen with thin wires. This helps the screen move and shake off sticky bits.

- For hard or sharp materials, choose a screen with thicker wires. This makes your screen last longer.

- If you use the screen for many types of material, ask your supplier for advice. They can help you find a screen that works for everything you need.

Tip: Always tell your supplier what you plan to screen. This helps them suggest the best screen for your job.

Moisture and Cut Size

Next, think about how wet your material is. Wet material can clog your screen fast. If you deal with damp sand or sticky soil, you need a screen that can clean itself. Piano wire screens do this well. The wires move and shake, so the screen stays clear.

Cut size means the size of the holes in your screen. If you want to catch small pieces, pick a screen with small holes. If you want to let bigger pieces through, choose a screen with larger holes. The right cut size helps you get the exact product you want.

Here’s a quick table to help you decide:

| Material Moisture | Best Screen Type | Cut Size Suggestion |

|---|---|---|

| Dry | Standard screen | Any size |

| Damp | Self-cleaning screen | Medium to large |

| Wet/Sticky | Piano wire screen | Small to medium |

If you are not sure about the right cut size, try a few screens and see which one gives you the best screening.

Throughput and Screen Model

Now, think about how much material you want to screen. Throughput means how much you can screen in a set time. If you need to screen a lot, you want a screen with a big open area. This lets more material pass through the screen. Piano wire screens are great for high throughput because they do not clog.

You also need to match your screen to your machine. Every screen model fits a certain deck or frame. If you use the wrong screen, it might not fit or work right. Always check your machine’s manual or ask your supplier for the right screen model.

Here are some things to remember:

- High throughput needs a screen with a large open area.

- Make sure your screen fits your machine’s deck.

- If you change your screening needs, you might need a new screen model.

Note: If you want help picking the right screen, talk to your supplier. They can help you match your screen to your material, moisture, cut size, and machine.

Choosing the right screen makes your screening job easier. You get better results, less downtime, and a smoother process. Take your time, ask questions, and pick the screen that fits your needs.

Common Uses and Industries

Mining and Aggregates

You see the screen in action every day in the mining and aggregates industry. When you work at a quarry or a mine, you need to separate rocks, gravel, and sand. The screen helps you sort these materials by size. You pour the raw material onto the screen. The screen shakes and moves, letting smaller pieces fall through while bigger chunks stay on top. This process makes your job easier and faster.

You might use the screen to sort crushed stone for road building. You can also use the screen to separate sand from gravel. The screen works well with wet or sticky material, so you do not have to stop your work to clean it. The screen keeps your operation running smoothly. If you want to boost your production, you should use the right screen for your job.

Tip: If you notice your screen getting clogged, try a piano wire screen. It cleans itself and keeps your screening process moving.

Recycling

You help the planet when you use the screen in recycling. The screen sorts glass, plastic, and metal pieces by size. You feed the mixed material onto the screen. The screen shakes and moves, letting small bits drop through. Larger items stay on top for easy removal. This makes recycling faster and more efficient.

The screen handles tough jobs, like sorting shredded tires or broken glass. You do not have to worry about the screen getting blocked. The screen keeps working, even with sticky or wet waste. You can use the screen to separate compost, mulch, or even electronic parts. The screen helps you get clean, sorted material ready for reuse.

A quick list of recycling jobs where the screen shines:

- Sorting glass and plastic

- Separating metal scraps

- Screening compost and mulch

- Handling electronic waste

If you want to make your recycling process better, choose a screen that fits your needs.

Construction Materials

You use the screen every day in construction. The screen helps you sort sand, gravel, and crushed stone for building roads, bridges, and houses. You pour the raw material onto the screen. The screen shakes and moves, letting fine sand fall through while larger stones stay on top. This gives you the right material for your project.

The screen works well with both dry and wet materials. You do not have to stop to clean the screen. The screen keeps your screening process fast and smooth. You can use the screen to prepare topsoil for landscaping or to sort gravel for concrete. The screen helps you get the best results for your job.

Here’s a table showing how you might use the screen in construction:

| Material | Use Case | Best Screen Type |

|---|---|---|

| Sand | Concrete, mortar | Piano wire screen |

| Gravel | Road base, drainage | Piano wire screen |

| Crushed stone | Asphalt, foundations | Piano wire screen |

| Topsoil | Landscaping, gardens | Piano wire screen |

If you want your construction project to go smoothly, pick the right screen for your material. The screen saves you time and gives you better results.

Soil and Sand Screening

If you work with soil or sand, you know how tricky screening can get. Wet soil sticks together. Damp sand clogs up screens. You want a screen that keeps working, even when things get messy. That’s where piano wire screens come in.

Piano wire screens make your job easier. The wires move on their own. They shake off sticky bits of soil and sand. You don’t have to stop and clean the screen every few minutes. You keep working and finish faster.

Why do piano wire screens work so well for soil and sand?

- Self-cleaning action: The wires vibrate and flex. They knock off clumps of dirt or wet sand. You see fewer blockages.

- High open area: More space between wires means more soil or sand passes through. You get better results in less time.

- Custom fit: You can pick the right wire size and spacing for your soil or sand. This helps you get the exact product you want.

Tip: If you screen topsoil for landscaping or sand for playgrounds, piano wire screens help you get a clean, even product.

Let’s look at some common jobs where you might use these screens:

| Application | Benefit of Piano Wire Screens |

|---|---|

| Topsoil screening | Removes rocks and roots, keeps soil loose |

| Sand production | Stops wet sand from clogging the screen |

| Compost processing | Separates fine compost from larger debris |

| Sports field prep | Delivers clean, even sand for surfaces |

You might run a landscaping business. You want to sell topsoil that looks good and feels soft. Piano wire screens help you remove rocks, sticks, and clumps. Your customers get better soil, and you get fewer complaints.

Maybe you work at a sand pit. Wet sand can slow you down. Regular screens clog up fast. Piano wire screens keep the sand moving. You don’t waste time cleaning or fixing the screen.

Here’s what you’ll notice when you switch to piano wire screens:

- Less downtime for cleaning

- More material screened each hour

- Fewer problems with wet or sticky soil

- Better quality soil and sand for your customers

Note: If you’re not sure which screen to pick, talk to your supplier. Tell them about your soil or sand. They can help you choose the best wire size and spacing.

You want your screening job to go smoothly. Piano wire screens help you get there. You spend less time fighting clogs and more time getting the job done.

Maintenance and Care

Cleaning Procedures

You want your screen to work well every day. Cleaning helps you keep your screening process smooth. Start by turning off your machine. Use a soft brush or air hose to remove dirt and stuck material from the screen. For wet jobs, rinse the screen with water. Dry the screen before you use it again. If you see tough spots, use a plastic scraper. Never use metal tools because they can damage the wires.

Here’s a simple cleaning checklist for your screen:

- Turn off the machine and lock it out.

- Brush or blow off loose material.

- Rinse with water if needed.

- Scrape gently with plastic tools.

- Let the screen dry before starting screening again.

Tip: Clean your screen after each shift. This keeps your screening results strong and helps your screen last longer.

Inspection and Replacement

You need to check your screen often. Look for broken wires, loose parts, or worn spots. If you see holes or tears, stop screening and fix the problem. Small problems can turn into big ones if you ignore them. Use a flashlight to see every part of the screen. Check the tension of the wires. If the screen feels loose, tighten it before you start screening again.

Here’s what you should look for during inspection:

| What to Check | What to Do If You Find a Problem |

|---|---|

| Broken wires | Replace the screen right away |

| Loose wires | Tighten or adjust before screening |

| Worn profile bars | Change them to keep the screen safe |

| Holes or tears | Stop screening and replace the screen |

If you need to replace the screen, follow your machine’s manual. Always use the right size and type for your screening job.

Extending Service Life

You want your screen to last as long as possible. Good care helps you get more screening hours from each screen. Clean the screen often. Check for problems before each screening shift. Use the right screen for your material. Do not overload the screen with too much material at once. If you use the screen for wet or sticky jobs, let it dry between shifts.

Here are some easy ways to make your screen last longer:

- Clean and inspect the screen every day.

- Use the right screen for each screening job.

- Do not push the screen past its limits.

- Store extra screens in a dry, safe place.

Note: A little care goes a long way. You save money and time when you keep your screen in top shape. If you ever have questions about your screening setup, ask your supplier for help.

Conclusion

Piano wire screens use strong wires that bend easily. These wires help your screening job go smoothly. The screens do not clog up fast. They have lots of open space for material to pass through. You can change them to fit your needs. They work well with wet or sticky stuff. When you choose a screen, think about what you are screening. Also, think about how wet it is and the size you want to catch.

ANPENG makes industrial screening media. They can help you pick the right piano wire screen. Tell them about your material, how wet it is, the size you want, how much you need to screen, and your machine setup.

FAQ

What makes piano wire screens different from regular screens?

You get flexible wires that move on their own. This helps stop clogging and keeps your screen clear. Regular screens often block up with wet or sticky stuff.

Can I use piano wire screens for wet materials?

Yes! Piano wire screens work great with wet or sticky materials. The wires shake off clumps, so you spend less time cleaning and more time working.

How do I know which wire size to choose?

Think about your material. Fine sand needs thin wires. Big rocks need thicker wires. If you feel unsure, ask your supplier for advice.

How often should I clean my piano wire screen?

You should clean your screen after every shift. Use a soft brush or water. This keeps your screen working well and helps it last longer.

Will piano wire screens fit my current screening machine?

Most piano wire screens come in custom sizes. You can order one that fits your machine. Just check your machine’s deck size before you buy.

Are piano wire screens expensive to replace?

They cost more than some regular screens, but you save money on downtime and cleaning. You also get better results with less hassle.

What industries use piano wire screens the most?

You see these screens in mining, recycling, construction, and soil screening. They help sort rocks, sand, compost, and more.