You might ask, “What are polyurethane tension screens?” These screens utilize strong polyurethane instead of metal mesh to sort and filter materials. You get a tough screen that bends but does not break, ensuring durability. They last longer and fit your machines well. Many places experience significant improvements when they switch to polyurethane tension screens. For example:

- You can enhance screening efficiency by up to 30%.

- You will notice less clogging, which means you spend less time on repairs.

- You may reduce your replacement costs by 25%.

The smart design and excellent performance of polyurethane tension screens make them a great choice for demanding applications.

Key Takeaways

- Polyurethane tension screens last much longer than metal mesh. They can last up to 10 times more.

- These screens help sorting materials better by up to 30%. This means they make screening more efficient.

- You can install them fast and easily. You do not need special tools or new frames.

- Polyurethane screens stop clogging, so you fix them less often. This gives you more time to work and less time fixing.

- They also soak up vibration. This makes the machines quieter and lowers noise at work.

- If you check tension and clean screens often, they last up to 30% longer.

- Polyurethane screens work in many ways. You can change them for mining, recycling, or aggregate jobs.

- Picking the right screen size and material is very important. It helps your screens work well and last longer.

What Are Polyurethane Tension Screens

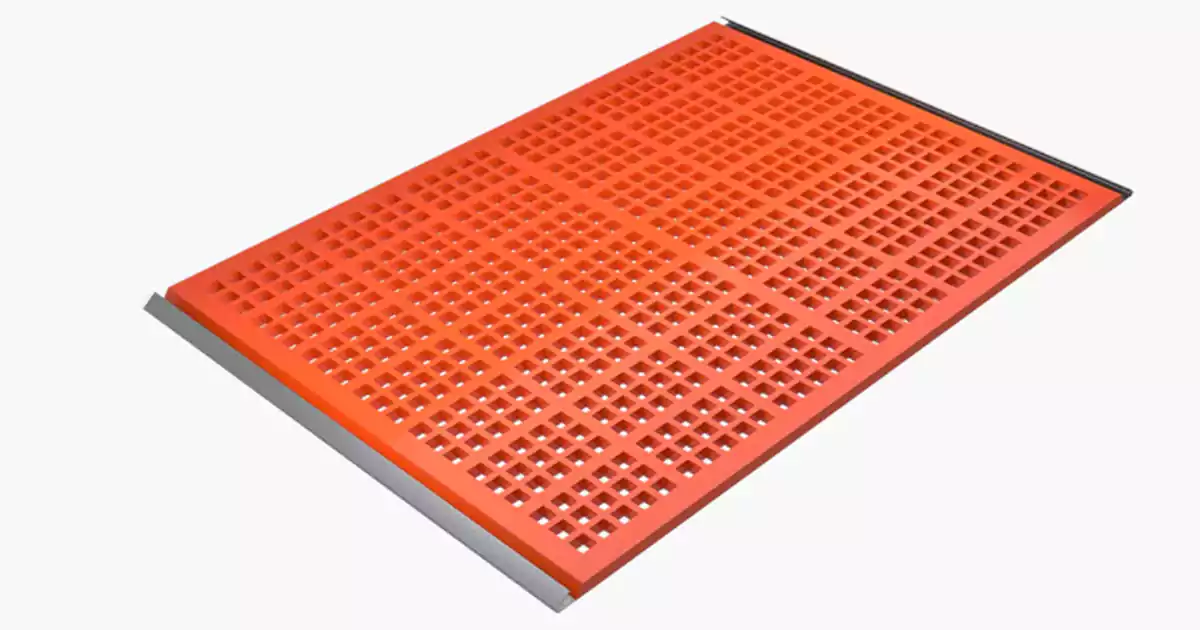

Definition and Structure

You may ask what polyurethane tension screens are. These screens are made in one piece. They replace old wire or plate panels. The mat is molded in big sections. It covers more space and handles more stuff. Hooks are on the edges. You can clamp them to the vibrating deck. This makes it easy to change panels fast. Your machine keeps working without long stops.

Reinforced Metallic Cables

Each urethane screen panel has strong metal cables inside. These cables, rods, or bars make the screen stronger. When you tighten the screen, the cables spread the tension. The screen stays in place, even if the machine shakes a lot. The metal inside takes the strain and heavy loads. You can use these screens for hard jobs. They work for sorting fine materials or big rocks.

High-Strength Polyurethane

The main part of the screen uses strong polyurethane. This material is tough and bends without breaking. Polyurethane tension screens have special additives. These help the screen bend, last longer, and resist wear. The screen keeps its shape and strength, even if it gets hot or cold. You can trust these panels in any condition.

Tip: If you install and take care of your urethane screen panels, they last longer and save you money.

Key Features

Anti-Abrasive Properties

Polyurethane tension screens are known for fighting wear. Polyurethane gets hard when it sets. It stands up to lots of use. These screens last longer than metal or rubber. You do not need to stop often to replace them. They also do not clog as much. You spend less time clearing blocked panels.

Flex and Wear Resistance

Urethane screen panels bend and resist damage well. The special additives help them stay strong and flexible. You can use them where there is lots of shaking. They keep working, even when the job is hard. Polyurethane tension screens also make less noise. If you work where it is quiet, you will notice this.

Here’s a quick look at what makes polyurethane tension screens special:

| Feature | Benefit for You |

|---|---|

| Durability | Lasts longer, needs less fixing |

| Reduced Noise Levels | Quieter, more work gets done |

| Resistance to Blinding | Works better, less clogging |

You get all these good things with polyurethane screen panels. Urethane screen panels help you work better, save money, and keep machines running.

How They Work in Screening Systems

When you use polyurethane tension screens, your machines work better and faster. These screens fit into your process easily and help you do more work.

Tensioning and Installation

Pre-Tensioned Design

You do not need to change your machines to use polyurethane tension screens. The pre-tensioned design lets you put them in like old metal mesh panels. You save time because you use the same clamps and fixings. Urethane screen panels come ready to use, so you do not spend hours setting up. You just hook them onto your vibrating screens and tighten them.

Here is why installation is simple:

- The pre-tensioned system means you do not need special tools.

- You can change panels fast, so you stop less.

- Urethane screen panels fit right into your old frames.

You get more work done because you do not stop for repairs or new parts as much.

Frame Compatibility

Polyurethane screen panels work with most screening machines. You do not have to buy new equipment. Urethane screen panels use the same hooks and clamps as metal mesh. You can put them on vibrating screens, scalping decks, or dewatering setups. The panels stay tight, even if your machine shakes a lot.

If you want the best results, follow these steps:

- Use a laser rangefinder to check the panel size. Make sure the size is within ±1.5mm and the flatness is less than 0.3mm per square meter.

- Fix the center first, then work out along a 45° angle. This keeps the panel flat.

- Set the hydraulic tension between 0.8 and 1.2 MPa. Tighten the panel in three steps: 60% at first, 80% after 24 hours, and 100% at the end.

- Run a vibration test with no load. The amplitude difference should be less than 15% of the design value.

- Check tension every shift, measure wear every week, and tighten connectors every month.

Tip: If you follow these steps, your polyurethane tension screens will last longer and work better.

Screening Process

Vibrational Energy Absorption

Polyurethane tension screens handle vibration very well. Urethane screen panels are stretchy, so they soak up shaking. When your vibrating screens run, the panels bend and bounce. This makes extra shaking that helps knock off stuck material. You get less clogging and more material moving through.

Here is why this helps you:

- Polyurethane screen panels make less noise, so your work area is quieter.

- Urethane screen panels stop material from sticking, so you clean less.

- The panels keep their shape, even after lots of shaking.

You see better results and smoother work.

Particle Separation Efficiency

You want your screens to sort things well. Polyurethane tension screens do this job fast and clean. Urethane screen panels help separate small and big pieces. You get sharp sorting and better filtering.

Let’s see how polyurethane tension screens last compared to others:

| Material | Average Lifespan (Months) |

|---|---|

| Polyurethane Screen Mesh | 12-18 |

| Rubber Screens | 3-4 |

| Steel Woven Mesh | 1.5-2.5 |

You can see polyurethane screen panels last much longer than rubber or steel mesh. Urethane screen panels keep working, so you do not need to replace them as often. You get more work time and fewer problems.

Note: If you use polyurethane tension screens, you work faster and sort better. Your machines run smoother, and you spend less on fixing them.

Polyurethane tension screens give you strong results, high efficiency, and easy setup. Urethane screen panels fit your machines, soak up vibration, and sort particles well. You get the best results in screening and separation every time.

Screen Media Comparison

Polyurethane vs. Metal Mesh

You may wonder how polyurethane screen panels compare to metal mesh screens. Polyurethane screen panels last much longer than metal mesh. They can work 8-10 times longer before wearing out. Urethane screen panels keep their shape, so sorting stays accurate. Metal mesh screens wear out fast and can bend. When they bend, sorting is not as good.

Here is a table to help you see the differences:

| Feature | Polyurethane Tension Screens | Metal Mesh Screens |

|---|---|---|

| Lifespan | 8-10 times longer than ordinary metal screens | Shorter lifespan due to wear and tear |

| Screening Efficiency | High efficiency with self-cleaning properties | Prone to clogging and lower efficiency |

| Screening Accuracy | Uniform pore size with small tolerance | Deformation leads to size deviations |

| Applicability | Suitable for various materials, wet and dry | Limited by material type and conditions |

Polyurethane screen panels are easier to take care of. You only need to check the tension often. You can use special meters to make sure they are tight. Metal mesh screens need more checks because damage is hard to see. You spend less time fixing polyurethane screen panels and more time working.

Tip: If you want less downtime and better results, try modular polyurethane screen panels for your next modular replacement.

Polyurethane vs. Rubber Screens

Let’s see how polyurethane screen panels do against rubber screens. Urethane screen panels are better for tough jobs. Polyurethane handles rough use and lasts longer. Rubber screens are good for big hits but wear out faster in harsh places. Urethane screen panels keep their holes the right size, so sorting is sharp. Rubber screens can stretch and lose shape, which makes sorting less accurate.

Look at this table to compare them:

| Material | Advantages | Disadvantages |

|---|---|---|

| Rubber | – Great at handling big impacts | – Wears out faster in rough jobs |

| – Costs less at first | – Does not last as long as polyurethane | |

| – Bends to fit more material in coarse sizing | ||

| Polyurethane | – Lasts longer in rough jobs | – Costs more at first |

| – Keeps holes the right size | – Not always best for very big pieces | |

| – Works well in wet jobs and cleans itself | ||

| – Panels last longer in rough jobs |

You get more work done with modular polyurethane screen panels. Urethane screen panels last longer and need fewer modular replacements. You save money over time, even if you pay more at first.

Pros and Cons

Durability

You want screens that last a long time. Polyurethane screen panels can last up to 10 times longer than woven wire screens. Urethane screen panels do not wear out fast, so you do not need to replace them often. This means you save money and do not stop work as much.

Cost

Polyurethane screen panels cost more at first. But you save money later. The cost per ton with polyurethane screen panels is about $2.10. Steel mesh costs $4.20, and rubber screens cost $3.75. Urethane screen panels help you save because you do not need to stop for modular replacement as often.

Throughput

You want your machines to handle more material. Urethane screen panels keep their shape, so you get high throughput. Polyurethane screen panels stop material from building up. You get better sorting and more product. Urethane screen panels also make less noise and use less energy, so your work area is safer and more comfortable.

Note: Modular polyurethane screen panels give you the best mix of long life, cost savings, and high throughput. You spend less time on modular replacement and more time getting results.

Applications

Mining & Quarrying

Mining and quarry jobs are very hard on equipment. Rocks and gravel can damage machines quickly. Urethane tension screens help your machines last longer. You do not need to fix them as much. Polyurethane screens can take heavy hits and big loads. Your machines do not stop for repairs as often.

Urethane panels fit easily into quarry setups. They sort rocks by size, so you get the right product. You can use them for mining and mineral jobs, too. The screens shake a lot, which helps move more material. You can increase how much you process by up to 40%. Urethane screens also stop clogging. You spend less time cleaning and more time working.

Here’s what you get with urethane screens in mining and quarry work:

- Less downtime because the screens last longer.

- More material processed every hour.

- Fewer problems with stuck rocks or gravel.

Your quarry and aggregate business runs smoother and gets better results.

Aggregate Processing

When you work with aggregate, you want speed and accuracy. Urethane tension screens give you both. Polyurethane panels are lighter than steel. You can move and install them safely. You do not need a big team or special tools. The panels keep their shape, so your product stays the same size.

Look at this table to see how urethane screens help with aggregate:

| Benefit | Description |

|---|---|

| Lower Maintenance and Safer Handling | Urethane panels are light and easy to move. |

| Improved Separation Accuracy | You get precise sizing because the holes stay the same. |

| Reduced Noise and Vibration | Polyurethane absorbs impact, so your work area is quieter. |

| Significantly Longer Wear Life | Urethane lasts 2–6 times longer than steel. |

| Superior Anti-Clogging Ability | The flexible mesh lets sticky material fall through, so you keep working. |

You can use urethane screens for all kinds of aggregate, like sand or crushed stone. The panels resist water and chemicals, so they work in wet or dry jobs. You get more product with less effort.

Recycling & Waste

Recycling plants and waste stations need strong screens. Urethane tension screens help sort glass, plastic, and scrap metal. Polyurethane mesh stands up to sharp edges and heavy loads. You get cleaner sorting and better recovery.

Urethane screens help lower moisture in recycled material. You can get moisture below 15%. This means you recover more usable product. Good dewatering also cuts landfill mass by up to 50%. You help the environment by reducing leachate and greenhouse gases.

Here’s how urethane screens help recycling:

- You sort more material with less waste.

- You save money on landfill costs.

- You help protect the environment.

Polyurethane tension screens work in many industries. You get strong screens, less downtime, and better results in every job.

Dewatering & Scalping

You may ask how urethane tension screens help with dewatering and scalping. These jobs are hard. You need to get water out fast or sort big pieces from small ones. If you pick the wrong screen, your work slows down. Your material stays wet, or the panels get blocked. Polyurethane and urethane screens are great for these jobs.

When you use urethane screens for dewatering, your material gets drier. The special design lets water drain out fast. You do not wait long for your product to dry. Polyurethane screens have tiny, exact holes. Water goes through, but the material stays on top. You get cleaner and drier results every time.

Scalping means you take out big pieces first. Urethane tension screens can handle heavy loads and sharp hits. You do not worry about the holes stretching or ripping. Polyurethane makes the screen strong. It bounces back after each hit. You keep working without stopping for repairs.

Here are some reasons to choose urethane screens for these jobs:

- Urethane screens do not blind easily. Wet or sticky stuff does not block the holes.

- Polyurethane screens last longer than metal or rubber. You save money on new parts.

- Urethane screens are light. You can put them in or change them without heavy tools.

- Polyurethane screens are quieter. Your work area is safer and more comfortable.

Tip: For the best results, check your urethane screens often. Clean them with water or air. Look for signs of damage. Change panels before they break. This keeps your system working well.

Let’s look at a table to compare how urethane screens do in dewatering and scalping:

| Feature | Urethane Screens | Metal Screens |

|---|---|---|

| Water Removal Speed | Fast | Moderate |

| Wear Resistance | Very High | Low |

| Noise Level | Low | High |

| Weight | Light | Heavy |

| Maintenance | Easy | Hard |

You can see that urethane and polyurethane screens give you big benefits. You get faster dewatering, better scalping, and less downtime. Your team works faster and safer. You spend less on repairs and new parts.

If you want to improve your dewatering or scalping, try urethane tension screens. You will see the difference right away. Your machines will work better, and your product will be higher quality.

Installation & Maintenance

Setup Guidelines

Tensioning Requirements

You want your polyurethane tension screens to last long. Start with a flat frame. Make sure it is not off by more than 3 mm per square meter. Use laser tools to check the tension. Try to keep the tension even, within 2 percent. Tighten bolts a little at a time, about 25 percent each step. This helps the screen settle flat. After two days, check and tighten the panels again. This is important because the screen can move a bit after use. Check the tension and bolts every 250 hours. These steps help your screens last up to 30 percent longer.

Tip: If you follow these steps, you can cut edge wear by 60 percent and stop early breaks.

Common Challenges

You might have some problems when you install the screens. If the tension is wrong, the screen can break early. Always check the tension before you start the machine. If you see big pieces stuck in the screen (pegging) or sticky stuff blocking holes (blinding), try high-vibration screen panels. These panels help shake loose the stuck material. If you still have trouble, check for broken parts or mistakes in how you set up the screen. You can also use different screen types together to get better results for each job.

Maintenance Tips

Cleaning & Inspection

You want your polyurethane screens to work well every day. Cleaning and checking them is important. Here is a simple table to help you remember what to do:

| Routine Type | Description |

|---|---|

| Daily Cleaning | Clean the screens after each shutdown. Take off debris to keep things balanced. |

| Regular Inspections | Look for signs of wear like thin spots, layers coming apart, or dents. |

If you clean and check your screens often, you will find problems early and avoid big repairs.

Repair & Replacement

When you see damage, fix it right away. Replace panels with cracks, holes, or lots of wear. If you see small problems, you can sometimes fix them with patch kits. Always use the right tools and follow the maker’s instructions. Doing repairs on time helps your polyurethane screens last longer.

Note: Regular care helps you avoid costly stops and keeps your screening system working well.

Equipment Compatibility

Before you put in polyurethane tension screens, check if they fit your machines. Make sure the screens are the right size and shape for your equipment. Polyurethane screens must handle the shaking and movement of your system. Sometimes, you may need to make small changes to your setup for the best results. If you do this, your screens will last longer and work better.

If you take time to check if the screens fit, you will get the most out of your polyurethane screens.

Choosing the Right Screen

Aperture & Size Selection

Picking the right screen starts with the aperture and size. You want your polyurethane screen to match your job. The holes, or apertures, decide what size material passes through. If you choose the wrong size, you might get too much waste or not enough product. Always check your installation structure. Larger apertures need bolt-type fixing. This keeps the screen from coming loose.

Think about your feeding design, too. If you drop material from too high, you can damage the screen. Try to keep the feeding height under 400mm. This helps your polyurethane screen last longer. Regularly tighten the bolts. Loose screens can hit the support bars and break.

Here’s a quick table to help you remember what to check:

| Factor | Description |

|---|---|

| Installation Structure | Match aperture size; large holes need bolt-type fixing |

| Material Type | Polyether for wet jobs, polyester for dry jobs |

| Maintenance | Tighten bolts often to stop damage |

| Feeding Design | Keep feed height under 400mm to protect the screen |

Material Grades

You have choices when it comes to material grades. Polyurethane screens come in different types for different jobs. If you work with wet material, pick polyether. For dry jobs, polyester works better. The right grade helps your screen last longer and work better.

Some screens need to be soft to handle sticky material. Others need to be hard for sharp rocks. You can talk to your supplier about what grade fits your job. The right choice means less downtime and more product.

Tip: Always match the material grade to your work environment. This keeps your polyurethane screen working at its best.

Customization Options

Every job is different. You might need a special screen size or shape. Polyurethane screens can be customized for your needs. You can pick the aperture size and shape. You can choose the panel thickness, from 5 mm up to 50 mm. This lets you use the screen in many places.

You can also pick between modular or tensioned designs. Some jobs need a harder screen, while others need a softer one. You can even get special sizes, like 305305mm or 610610mm. If you need something unique, just ask for a custom size.

Here’s a table of what you can customize:

| Customization Aspect | Details |

|---|---|

| Aperture sizes and shapes | Tailored for your job |

| Panel thickness and size | From 5 mm to 50 mm, many external sizes available |

| Modular or tensioned design | Pick what fits your machine |

| Material hardness | Choose soft or hard for your application |

With all these options, you can make sure your polyurethane screen fits your machine and your job. You get better results and save money in the long run.

Environmental Factors

When you pick a screen, think about where it will be used. Polyurethane tension screens can do hard jobs, but the environment can change how they work. There are some things you need to watch out for.

Temperature is important. If your work area gets very hot, polyurethane can get soft. This makes the screen weaker and it might stretch or lose its shape. If it gets very cold, the screen can turn stiff. When this happens, it could crack if you press on it too much. You want your screens to stay strong, so always check the temperature in your plant.

Chemicals are another thing to think about. Polyurethane does well with many chemicals. Oils, acids, and solvents usually do not hurt it. You can use these screens where other materials would break down. If you use strong chemicals, polyurethane is a smart choice.

Water and pH levels can also change how your screens work. Polyurethane does not like too much water, especially if the pH goes up and down a lot. Over time, water can break down the screen in a process called hydrolysis. This makes the screen weaker and less bendy. If your job uses lots of water or has changing pH, check your screens often.

Here is a short list of how the environment affects polyurethane tension screens:

- Polyurethane stays strong and keeps its shape under high pressure.

- It fights off damage from most chemicals, like oils, acids, and solvents.

- High heat can make polyurethane soft, but cold can make it stiff and easy to crack.

- Water and changing pH can cause hydrolysis, which makes the screen weaker over time.

You can use this table to help you decide if polyurethane is good for your job:

| Environmental Factor | Polyurethane Performance | What You Should Do |

|---|---|---|

| High Pressure | Stays strong and stable | Use for heavy-duty screening |

| Chemical Exposure | Resists most chemicals | Good for chemical plants |

| Extreme Heat | May soften and lose shape | Monitor temperature, use additives |

| Extreme Cold | Can become rigid and crack | Avoid sudden impacts |

| Water & pH Changes | May weaken from hydrolysis | Inspect screens regularly |

Tip: If you work in a place with changing temperatures or lots of chemicals, check your polyurethane screens often. Checking them helps you find problems early and keeps your system working well.

You want your screens to last and work right. By thinking about these things, you can pick the best polyurethane tension screen for your job. You get better results and spend less money fixing things.

Conclusion

When you pick polyurethane tension screens, your system works better. These screens are very tough and can bend without breaking. They also do not wear out fast. Urethane screen panels help you work with less stopping, sort things better, and use the screens longer. Custom polyurethane screens mix steel wire and resin. This makes them strong for hard jobs. Polyurethane screens fit many machines and can handle rough work. You get help from experts for design and setup.

| Service Type | Description |

|---|---|

| Customized Services | Polyurethane screens made just for your needs |

| Free Samples | You can test them before buying |

| Design and Drawings | Experts help you with special designs |

| Installation Guide | Simple steps to set up your screens |

| 24/7 Support | Get help any time you need it |

Want to make your work better? Contact us for custom polyurethane screens and expert help.

FAQ

What makes polyurethane tension screens better than metal mesh?

You get longer life and less clogging with polyurethane screens. They handle tough jobs and keep their shape. You spend less time on repairs and replacements.

Can I use polyurethane tension screens in wet environments?

Yes, you can. Polyurethane screens work well in wet or dry jobs. They resist water and chemicals. You get reliable performance in many conditions.

How do I know when to replace my screen panels?

Look for cracks, holes, or thin spots. If you see material leaking through or the screen looks worn, it is time to replace it. Regular checks help you catch problems early.

Are polyurethane screens hard to install?

No, you can install them easily. Most screens fit your current frames. You use the same hooks and clamps as before. You do not need special tools.

Do polyurethane screens reduce noise?

Yes, they do. Polyurethane absorbs vibration and impact. Your work area stays quieter. You and your team will notice the difference right away.

Can I get custom sizes or shapes?

Absolutely! You can order screens in many sizes, shapes, and thicknesses. Just tell us what you need. We help you find the perfect fit for your job.