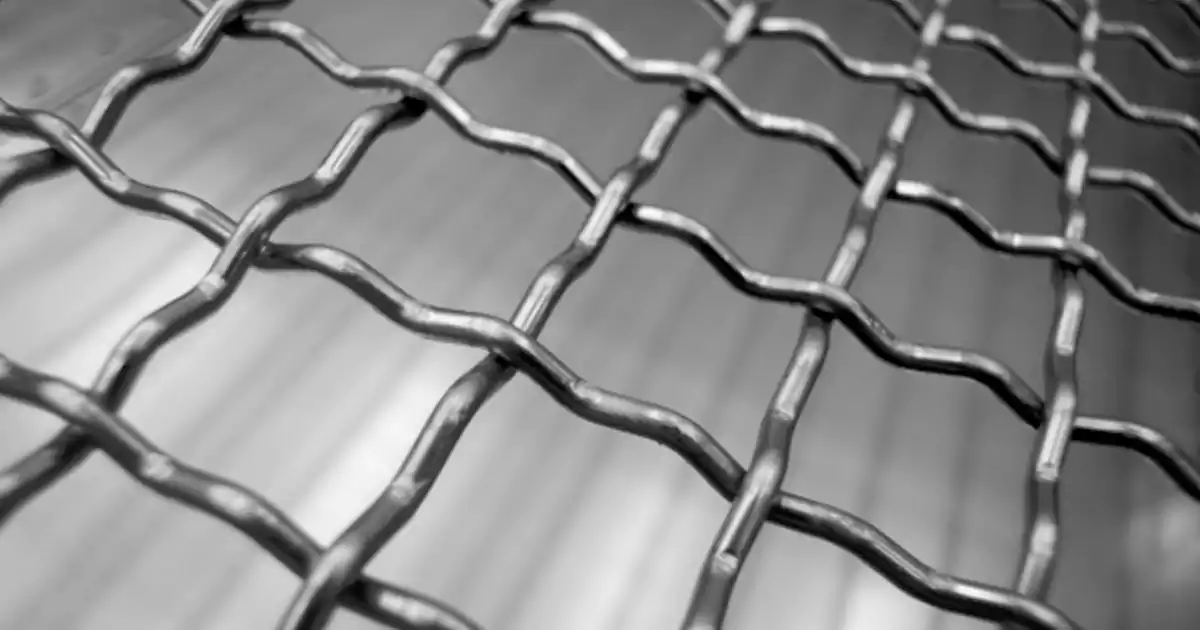

You might wonder what is the woven wire mesh intercrimp and why it stands out. Intercrimp uses a zig-zag crimp pattern that helps wires lock together at intervals. This design gives the mesh extra grip and rigidity. You’ll notice pre-crimped wires and intersections spaced apart, which make the mesh stronger. Here’s a quick look at common sizes you’ll find:

| Wire Diameter | Width of Opening |

|---|---|

| 0.177 in | 0.823 in |

| 0.105 in | 0.645 in |

If you want woven wire mesh with reliable structure, intercrimp is a smart choice.

Key Takeaways

- Intercrimp mesh has a zig-zag shape for more strength.

- The way the wires cross makes the mesh strong and open.

- Intercrimp mesh is stiffer than plain crimp mesh.

- Pick intercrimp mesh if you need strength and bigger spaces.

- People use steel, stainless steel, and aluminum to make it.

- Wires are bent first to help make intercrimp mesh.

- Intercrimp mesh is good for factories and building designs.

- You can change intercrimp mesh for special needs.

What Is the Woven Wire Mesh Intercrimp

Intercrimp Wire Mesh Definition

You might ask, what is the woven wire mesh intercrimp? This type of mesh uses wires that bend in a zig-zag shape. The wires cross each other at set points. These crossings do not happen at every single spot, but at intervals. This design gives the mesh a unique look and feel. When you touch it, you notice the mesh feels firm and strong. You see the wires hold together well. If you want to know what is the woven wire mesh intercrimp, just look for the crimped wires and the spaces between the crossings.

Tip: If you need a mesh that stays in shape and does not sag, you should consider this style.

Zig-Zag Crimp Pattern

The zig-zag crimp pattern is easy to spot. Each wire bends up and down, making a wave. When you look at the mesh, you see these waves line up with each other. This pattern helps the wires grip each other. The wires do not slip or move out of place. You get a mesh that holds its form, even if you push or pull on it. If you wonder what is the woven wire mesh intercrimp, remember the zig-zag pattern is the key feature.

- The zig-zag shape adds strength.

- The pattern keeps the mesh from stretching.

- You get a sturdy and reliable product.

Interval Intersections

Interval intersections set this mesh apart from others. The wires do not cross at every wave. Instead, they meet at certain points. These points are spaced out, not crowded together. This design lets you have bigger openings in the mesh. You can see through it more easily. The mesh stays strong because the wires lock at each intersection. If you ask what is the woven wire mesh intercrimp, you will find that interval intersections make it special.

You can use this mesh for many jobs. It works well in places where you need both strength and open space. The interval intersections give you both.

Intercrimp vs. Other Crimp Styles

Crimp Style Overview

When you look at woven wire mesh, you will notice different crimp styles. Each style changes how the wires fit together and how the mesh performs. The three most common crimp styles are plain crimp, lock crimp, and intercrimp. You might wonder why these styles matter. The answer is simple. The crimp style affects the strength, stability, and look of your mesh.

Here is a quick table to help you see the main differences:

| Crimp Style | Wire Crossing Points | Mesh Stability | Opening Size |

|---|---|---|---|

| Plain Crimp | Every intersection | Moderate | Small |

| Lock Crimp | Every intersection | High | Small |

| Intercrimp | At intervals | High | Large |

Note: The right crimp style depends on your project needs. Some jobs need more strength. Others need bigger openings.

Intercrimp vs. Plain Crimp

You may have seen plain crimp mesh before. It uses straight wires that bend only at the crossing points. The wires cross at every spot, so the mesh feels flat and simple. This style works well for light-duty jobs. If you need a mesh that holds its shape under pressure, plain crimp may not be enough.

Intercrimp mesh stands out because it uses a zig-zag pattern. The wires bend up and down, then cross at set intervals. This design gives you two big benefits:

- The mesh feels much stiffer and stronger.

- You get larger openings without losing stability.

If you want a mesh that does not sag or shift, intercrimp is a better choice than plain crimp. You can use it for screens, guards, or panels where you need both strength and open space.

Intercrimp vs. Lock Crimp

Lock crimp mesh uses wires that bend at every crossing. The wires lock tightly together, so the mesh feels very rigid. This style works best when you need a flat, tight mesh with small openings. You often see lock crimp in heavy-duty screens or security panels.

Intercrimp mesh offers a different advantage. The wires only cross at intervals, not every spot. This lets you have bigger openings while keeping the mesh strong. You get a lighter mesh that is still sturdy. If you need airflow, visibility, or a lighter weight, intercrimp mesh is a smart pick.

Tip: Choose lock crimp for maximum rigidity and small openings. Pick intercrimp when you want strength plus larger gaps.

You now know how each crimp style works. This knowledge helps you pick the right mesh for your next project.

Structural Differences

When you compare intercrimp mesh to plain crimp and lock crimp, you notice some big differences in how they look and work. Each style has its own way of holding wires together. Let’s break down what sets them apart.

1. Wire Crossing Points

You see the first difference at the wire crossings. In plain crimp and lock crimp, the wires cross at every single point. This means the mesh has a tight, even pattern. The wires touch each other at every intersection, so the mesh feels flat and uniform.

Intercrimp mesh does something different. The wires only cross at certain intervals. You get spaces between the crossings. This creates a more open look and lets you see through the mesh more easily. The wires still hold tight at each crossing, but you get bigger gaps between them.

2. Crimp Pattern

Plain crimp mesh uses simple bends. The wires bend just enough to go over and under each other. You get a basic, flat pattern.

Lock crimp mesh takes it a step further. The wires bend sharply at every crossing. This locks the wires in place and makes the mesh very stiff.

Intercrimp mesh uses a zig-zag or wave pattern. The wires bend up and down in a repeating shape. These waves line up with each other, and the wires cross at set points. This pattern gives the mesh extra grip and keeps it from stretching out.

3. Mesh Rigidity and Strength

You might think more crossings mean more strength. That’s true for lock crimp, which feels very rigid. Plain crimp is less stiff, so it can sag if you use it for heavy jobs.

Intercrimp mesh finds a balance. The zig-zag pattern and spaced crossings give you both strength and flexibility. The mesh holds its shape well, but it’s not as heavy as lock crimp. You get a sturdy product that’s easier to handle.

4. Opening Size

If you need bigger openings, intercrimp mesh is your best bet. The interval crossings let you have larger gaps without losing strength. You get more airflow and better visibility. Plain and lock crimp meshes have smaller openings because the wires cross more often.

Tip: Choose intercrimp mesh when you want a strong mesh with large, open spaces. Pick lock crimp for maximum rigidity and small gaps. Use plain crimp for light-duty jobs where you don’t need much strength.

Quick Comparison Table

| Feature | Plain Crimp | Lock Crimp | Intercrimp |

|---|---|---|---|

| Crossing Points | Every spot | Every spot | At intervals |

| Crimp Pattern | Simple bends | Sharp bends | Zig-zag waves |

| Rigidity | Moderate | Very high | High |

| Opening Size | Small | Small | Large |

You now know how the structure of each mesh style changes how it works. When you pick a mesh, think about how much strength, rigidity, and open space you need. Intercrimp mesh gives you a unique mix of all three.

Intercrimp Wire Mesh Manufacturing

Material Selection

You want your intercrimp wire mesh to last and perform well. That starts with picking the right material. You can choose from several options. Each one has its own strengths.

- Steel: This is a popular choice. Steel gives you toughness and good value.

- Stainless Steel: You get extra resistance to rust and corrosion. This works well outdoors or in wet places.

- Brass: Brass looks great and resists corrosion. You might pick this for decorative uses.

- Aluminum: This metal feels light but stays strong. It also resists rust.

Tip: Think about where you will use your mesh. If you need strength, go with steel. If you want something that looks nice and will not rust, try stainless steel or brass.

You can see that the right material makes a big difference. It affects how your mesh looks, how long it lasts, and how well it works.

Pre-Crimping Process

Before weaving starts, you need to shape the wires. This step is called the pre-crimping process. You run each wire through special rollers. These rollers bend the wire into a zig-zag shape. This is the key to making intercrimp wire mesh.

The wire crimping process does more than just make waves. It helps the wires grip each other when you weave them together. The crimps keep the wires from sliding out of place. You get a mesh that stays tight and strong.

Here’s what happens in this step:

- Feed straight wire into the crimping machine.

- Rollers press the wire into a zig-zag pattern.

- Check the crimps to make sure they are even and match the mesh design.

Note: If you skip pre-crimping, your mesh will not have the same strength or shape. This step is very important for intercrimp wire mesh.

Weaving Equipment

Now you need the right tools to weave your mesh. You cannot do this by hand. You use special weaving machines. These machines line up the pre-crimped wires and weave them together at set intervals.

A typical weaving machine for intercrimp wire mesh has these features:

| Feature | Purpose |

|---|---|

| Crimped Wire Feeders | Hold and guide the wires |

| Weaving Loom | Interlaces the wires |

| Tension Controls | Keep wires tight and straight |

| Mesh Size Adjustments | Set the opening size |

You control the machine to match your mesh design. The machine weaves the wires together, locking them at each intersection. This gives you a strong and even mesh.

If you want high-quality intercrimp wire mesh, you need skilled workers and good equipment. The right tools make the process smooth and the product reliable.

Step-by-Step Weaving

You might wonder how intercrimp wire mesh comes together. The weaving process is where the magic happens. You start with pre-crimped wires and use a weaving machine to lock them into place. Let’s walk through each step so you know exactly what happens.

- Set Up the Machine

You place the pre-crimped wires into the machine. The machine lines up the wires so they stay straight and even. You check the settings to match your mesh design. - Feed the Wires

The machine pulls in the wires one by one. Each wire follows the zig-zag pattern made during pre-crimping. You make sure the wires stay in the right order. - Weave the Wires Together

The machine weaves the wires over and under each other. The zig-zag shapes fit together like puzzle pieces. At each interval, the wires cross and lock in place. You watch the process to catch any mistakes early. - Adjust Tension

You use tension controls to keep the wires tight. If the wires get loose, the mesh will not hold its shape. You check the tension often to make sure the mesh stays strong. - Check the Openings

You measure the gaps between the wires. The openings must match your design. If the openings are too big or too small, you adjust the machine. - Cut the Mesh to Size

When the weaving finishes, you cut the mesh to the size you need. You use special tools to make clean edges. You remove any sharp ends for safety.

Tip: Always check the mesh as you weave. Small problems are easier to fix right away.

Here’s a quick look at the weaving process:

| Step | What You Do |

|---|---|

| Set Up | Load wires and set machine |

| Feed Wires | Guide wires into the loom |

| Weave | Interlace wires at intervals |

| Adjust Tension | Keep wires tight and straight |

| Check Openings | Measure gaps for accuracy |

| Cut to Size | Trim mesh to final dimensions |

You can see that weaving intercrimp wire mesh takes skill and attention. Each step matters. If you follow these steps, you get a mesh that is strong, even, and ready for any job.

Woven Wire Mesh Advantages

Rigidity and Grip

You want a mesh that stays firm and does not sag. Intercrimp woven wire mesh gives you just that. The zig-zag pattern and interval intersections lock the wires together. You get a mesh that feels solid when you touch it. The wires grip each other tightly, so the mesh holds its shape even if you push or pull on it.

- The mesh resists bending and stretching.

- You can use it for screens, guards, or panels that need to stay in place.

- The grip between wires adds extra strength.

Tip: If you need a product that stands up to heavy use, choose intercrimp mesh for its reliable rigidity.

Versatility

You might wonder where you can use this mesh. The answer is almost anywhere. Intercrimp mesh works in many settings because it balances strength and open space. You can pick different materials, wire diameters, and opening sizes to match your needs.

Here are some ways you can use it:

- Industrial screens for sorting or filtering.

- Safety guards around machines.

- Fencing for outdoor areas.

- Decorative panels in buildings.

The mesh adapts to your project. You can order custom sizes or shapes. If you need something special, manufacturers can help you design the perfect mesh.

| Application | Benefit |

|---|---|

| Industrial | Handles tough jobs |

| Architectural | Adds style and safety |

| Custom Solutions | Fits your requirements |

Note: You get flexibility with intercrimp mesh. It fits many uses and can be tailored to your project.

Aesthetic Value

You may not think of mesh as stylish, but intercrimp woven wire mesh looks great. The zig-zag pattern creates a unique visual effect. You see clean lines and open spaces. The mesh adds texture and interest to any space.

- Use it in building facades for a modern look.

- Add it to railings or partitions for a sleek finish.

- Choose brass or stainless steel for extra shine.

The mesh does more than just work hard. It also makes your project stand out. You get both function and style in one product.

If you want your design to catch the eye, consider intercrimp mesh for its attractive pattern and finish.

Woven Wire Mesh Applications

Industrial Uses

You will find woven wire mesh in many factories and work sites. It helps you sort, filter, and protect. You might see it in machines that separate rocks or grains. Workers use it for safety guards around moving parts. The mesh keeps hands and tools safe from danger. You can also use it for drying racks or trays in food processing. The open spaces let air flow while holding items in place.

Here are some common industrial uses:

- Machine guards

- Conveyor belts

- Sieves and screens

- Drying racks

- Fencing for equipment

Tip: If you need something strong and reliable for your factory, this mesh is a great choice.

Architectural Uses

You can use woven wire mesh to make buildings look modern and stylish. Architects love it for its clean lines and open design. You might see it on building facades, stair railings, or even ceilings. The mesh adds texture and lets light pass through. It also works well for privacy screens or room dividers. You get both beauty and function in one product.

Check out these popular architectural uses:

| Application | Benefit |

|---|---|

| Facades | Modern look, airflow |

| Railings | Safety, style |

| Ceilings | Unique texture, light |

| Room Dividers | Privacy, open feel |

Note: You can pick different metals and finishes to match your design.

Custom Solutions

Sometimes you need something special. You can order woven wire mesh in custom sizes, shapes, or patterns. Maybe you want a certain color or a unique opening size. Manufacturers can help you design the perfect mesh for your project. You just tell them what you need, and they make it happen.

Custom solutions work well for:

- Art installations

- Special machine parts

- Unique building features

- Custom fencing or gates

If you have a creative idea, this mesh can bring it to life. You get a product that fits your needs exactly.

If you want something one-of-a-kind, ask about custom woven wire mesh options.

Choosing Intercrimp Wire Mesh

Selection Factors

You want to pick the right intercrimp wire mesh for your project. You might feel unsure about where to start. Don’t worry. You can break the process into a few simple steps.

Here are the main things you should look at:

- Purpose

Think about what you need the mesh to do. Do you want it for safety, decoration, or filtering? Your answer will help you narrow down your choices. - Material

You can choose from steel, stainless steel, brass, or aluminum. If you need something strong, go with steel. If you want a mesh that will not rust, pick stainless steel or aluminum. Brass works well for a fancy look. - Wire Diameter

Thicker wires give you more strength. Thinner wires let you have bigger openings. You should match the wire size to your job. - Opening Size

Do you need large gaps for airflow or small gaps for filtering? Measure the space you want between the wires. You can ask for a sample if you are not sure. - Mesh Size

You can order mesh in sheets or rolls. Think about how much you need and what size fits your space.

Tip: Write down your needs before you shop. This makes it easier to talk with a supplier.

Quick Selection Table

| Factor | What to Consider |

|---|---|

| Purpose | Safety, decoration, filtering |

| Material | Steel, stainless, brass, aluminum |

| Wire Diameter | Thick for strength, thin for open space |

| Opening Size | Large for airflow, small for filtering |

| Mesh Size | Sheets or rolls, custom sizes |

Customization Options

You might want something special for your project. Good news! You can customize almost every part of your intercrimp wire mesh.

Here’s what you can change:

- Material Type

You can pick the metal that works best for your job. - Wire Thickness

You can ask for thicker or thinner wires. - Opening Shape and Size

You can choose square or rectangular openings. You can also set the size of each opening. - Sheet Size

You can order mesh in large sheets, small panels, or even rolls. - Finish

You can pick a shiny, matte, or colored finish. Some suppliers offer powder coating or special treatments.

Note: Custom mesh takes a little more time to make. You should plan ahead if you need a special order.

Why customize?

- You get a mesh that fits your project perfectly.

- You can match your design style.

- You can solve unique problems, like odd shapes or special safety needs.

If you have an idea, just ask your supplier. Most companies love to help you create the perfect mesh. You can even send a sketch or photo to show what you want.

In short:

You have lots of choices when you pick intercrimp wire mesh. You can select the right material, size, and look. You can also ask for custom options. This way, you get a mesh that works just right for you.

Conclusion

Now you can see why intercrimp woven wire mesh is unique. The zig-zag pattern and spaced crossings make it strong and flexible. This mesh has bigger gaps than plain or lock crimp styles. It also stays sturdy and holds its shape well. Good materials, pre-crimping, and careful weaving are used to make it.

- Holds tight and stays firm

- Works for lots of jobs

- Can be made to fit what you want

Want a special mesh? We can help you create the right one for you.

FAQ

What makes intercrimp wire mesh different from other mesh types?

You get a unique zig-zag crimp pattern with intercrimp mesh. The wires cross at intervals, not every spot. This gives you bigger openings and strong grip. You will notice the mesh feels sturdy and holds its shape well.

Can I use intercrimp mesh outdoors?

Yes, you can. If you pick stainless steel or aluminum, your mesh will resist rust and weather. These materials work great for outdoor fences, screens, or guards. Just choose the right metal for your climate.

How do I choose the right opening size?

Think about your project needs. If you want more airflow or visibility, go with larger openings. For filtering or safety, pick smaller gaps. You can always ask for a sample to see what fits best.

Is intercrimp mesh easy to cut or shape?

You can cut intercrimp mesh with the right tools, like wire cutters or a saw. For best results, measure first and use safety gloves. If you need special shapes, you can order custom sizes from the manufacturer.

What finishes are available for intercrimp mesh?

You can choose from shiny, matte, or colored finishes. Some suppliers offer powder coating or special treatments. These finishes help match your style or add extra protection.

Can I order custom designs or patterns?

Absolutely! You can ask for custom wire thickness, opening size, sheet size, or even special shapes. Just share your idea or drawing with the supplier. They will help you create the perfect mesh for your project.

Where can I use intercrimp mesh in my home?

You can use it for cabinet doors, room dividers, stair railings, or garden fences. The mesh adds style and strength to many spaces. You get both function and a modern look.

How do I clean and maintain intercrimp mesh?

You can wipe the mesh with a damp cloth or use mild soap and water. For outdoor mesh, rinse with a hose. Stainless steel and aluminum need less care, while steel may need extra protection from rust.