Woven Wire Mesh

Industrial woven wire mesh screens for aggregate, mining and recycling. Square and slotted apertures, double‑weave, flat‑top, rolls, and hook systems. Custom sizes and quick lead times.

the longest-lasting woven wire screens available

Woven wire mesh are made with either longest-lasting high carbon steel wire or stainless steel with an industry-leading stringent opening tolerance of ± 3% with range of opening sizes, wire diameters, and patterns.

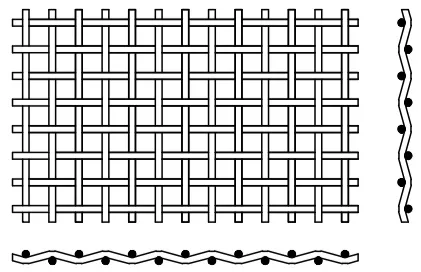

WEAVE STYLES

Square

- For general applications

- Provides precise passing

Opening Sizes:

- 0.093” – 6”

- 2.36 mm – 152.4 mm

Double-Weave

- An alternative to large diameter wire or punch plate, Double-Weave is designed for high-impact top deck applications

- Greater durability while maintaining maximum open area

Opening Sizes:

- 1.125” – 4”

- 31.75 mm – 127.0 mm

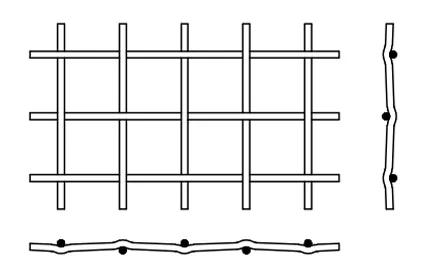

Slotted

- Single or triple shute

- Removes fines

- Provides more open area than square openings

- Use with round or cubical-shaped material or when precise passing is not required

- Customized to specific applications

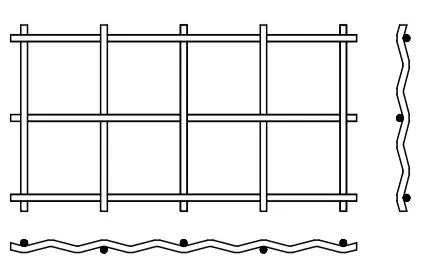

Flat Meshes

- Opening with square and slotted

- Customized to specific requirements

Opening Sizes:

- Wire diameters : 1.25 mm – 12.5 mm

- Opening sizes : 2.36mm – 120 mm

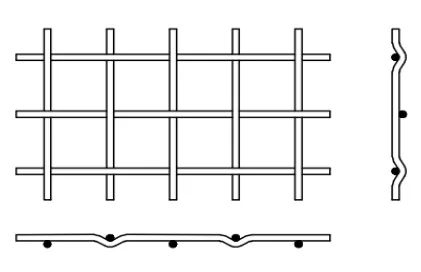

Rolls

- Opening with square and slotted

- Customized to specific requirements

Opening Sizes:

- Wire diameters : 1.25 mm – 5 mm

- Opening sizes : 2.36 mm – 50 mm

Overlaps

Used to prevent product contamination at junction points where cross-members are absent, on screens featuring openings of 3⁄8 inch (9.5 mm) or less.

HOOKS

Anpeng provides tailored hooks for end and side-tensioned screens, ensuring a perfect fit for diverse manufacturer specifications.

Why Choose Us

We don't keep our customers waiting. Our usual callback time is within 30 minutes of your message. At the very least we'll be in touch within one working day.

Quality is our cornerstone. Every product is engineered for long-term durability, and your complete satisfaction is guaranteed—if anything falls short, we’ll resolve it immediately.

With two decades of manufacturing behind us, we build every product—and every accessory—to exacting specs and long-haul durability.

FAQs

What is Woven Wire Mesh?

Woven wire mesh is widely used across various industrial sectors as the most common type of screen made by weaving metal wires. It screens materials using a mesh formed by weaving wires such as high-carbon steel or stainless steel. Common weave patterns for vibrating screen meshes include plain weave, inter crimp, lock crimp, and flat top. We also offer edge hook processing for vibrating screens. Depending on the particle size, throughput, and vibrating screen type, we provide the optimal solution.

The advantages of Anpeng's Woven Wire Mesh

Our advanced wire-drawing process produces steel wire with significantly higher tensile strength and improved ductility. The tougher, more ductile wire resists impact and vibration fatigue, which reduces damage in service and extends the wear life.

How do I choose the right Woven Wire Mesh for my application?

Consider: particle size to be retained/passed, abrasion level, moisture/plugging risk, chemical exposure, temperature and required open area. Tell us these conditions and we will recommend a suitable weave/material.

What affects the service life of the Woven Wire Mesh?

Service life depends on material choice, wire diameter, weave, operating conditions (abrasion, impact, chemical exposure), and maintenance frequency.

Can Woven Wire Mesh be customized?

Yes, woven wire mesh can be customized to meet specific requirements. We can offer various sizes, wire gauges, and aperture designs.