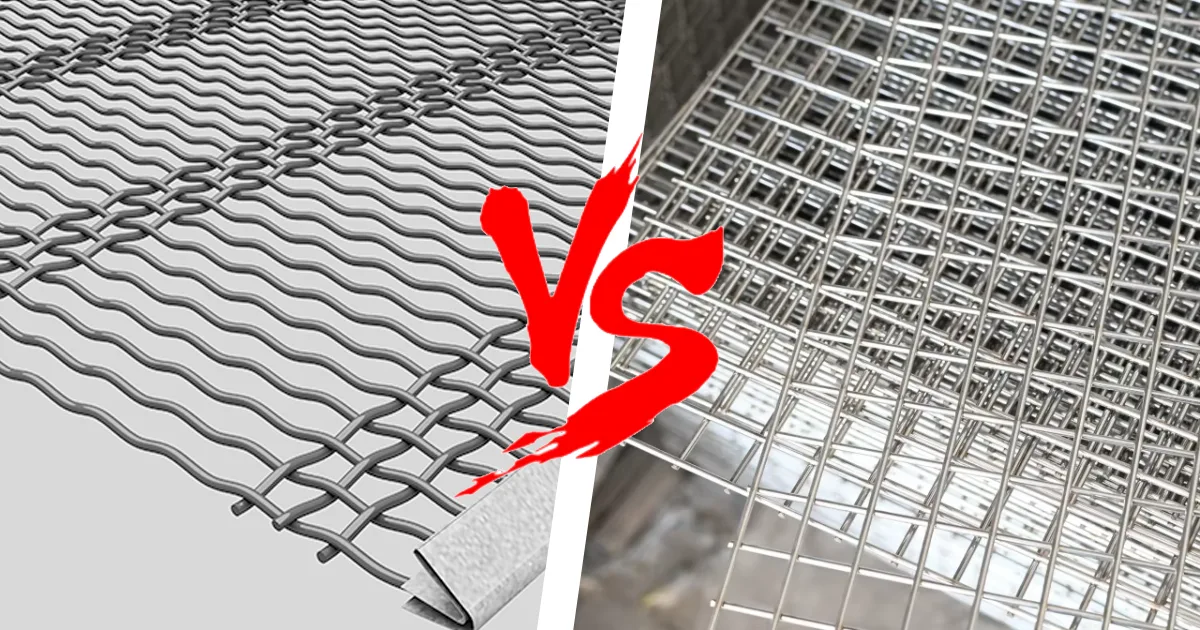

When you compare woven wire mesh vs welded wire mesh, you notice significant differences. Woven wire mesh bends easily and adapts to odd shapes, while welded wire mesh is stiff and strong. If you need to support heavy items, welded wire mesh is more stable. Woven wire mesh is suitable for specialized tasks, but it often comes at a higher cost. Here is a simple table to illustrate how they compare:

| Feature | Woven Wire Mesh | Welded Wire Mesh |

|---|---|---|

| Construction | Flexible, fits many wire sizes | Stiff, very strong |

| Strength | Not as strong | Very strong |

| Flexibility | Bends and adapts | Stays firm, not bendy |

| Cost | Usually costs more | Costs less |

Are you ready to choose your mesh? Let’s consider what matters most for your project.

Key Takeaways

- Woven wire mesh bends easily and fits many shapes. This makes it good for custom jobs.

- Welded wire mesh is tough and does not bend. It works well for strong jobs like fences and concrete.

- Think about where you will use the mesh.

- Pick galvanized or stainless steel for outside use. This helps stop rust.

- Woven wire mesh usually costs less for short or light jobs.

- Welded wire mesh is better if you need it to last longer.

- Woven wire mesh lets you control the size of the openings. This makes it good for filtering and sorting things.

- Welded wire mesh is even and strong. It stays steady when holding heavy things or in tough spots.

- Look at what your project needs.

- Choose the right mesh for its main job, like support, decoration, or filtering.

- Think about how much it costs to put in and take care of.

- Woven wire mesh may cost less at first.

- Welded wire mesh often needs less work later.

Woven Wire Mesh Overview

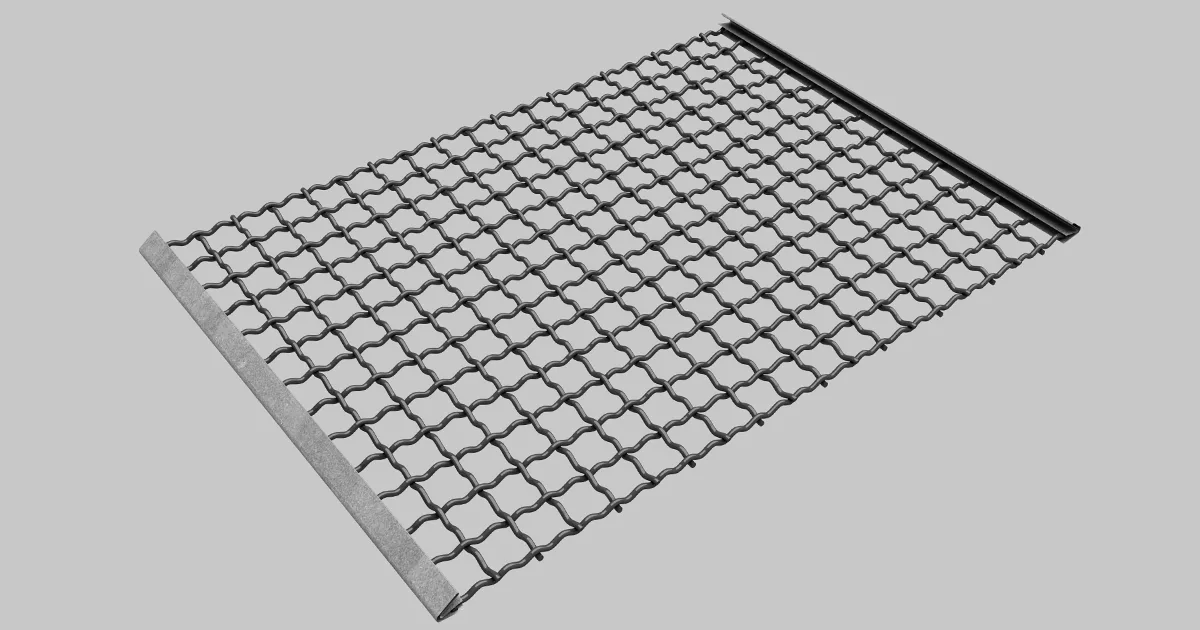

What Is Woven Wire Mesh

When you look at woven wire mesh, you see a grid made by weaving wires over and under each other. This creates a pattern that looks like fabric, but it is made from metal. You can find woven wire mesh in many places, from factories to your own kitchen. People use it for things like screens, filters, and even for making woven mesh baskets. The mesh comes in different shapes and sizes, so you can pick what fits your needs best.

Woven wire mesh stands out because it is flexible and easy to shape. You can bend it or cut it without much trouble. This makes it perfect for projects where you need the mesh to fit into tight or odd spaces. You also get a lot of choices in mesh size and wire thickness. Some woven wire mesh has tiny openings for fine filtering, while others have bigger gaps for more airflow.

Here’s a quick look at the materials used to make woven wire mesh and how they affect performance:

| Material Type | Properties | Applications |

|---|---|---|

| Stainless Steel | Resists heat and corrosion, very durable | High-impact, food, and chemical uses |

| Low Carbon Steel | Strong, but needs coating to avoid rust | Industrial screens, general use |

| High Carbon Steel | Handles abrasion and impact well | Mining, farming, sorting |

| Oil Tempered Steel | Strong and tough, but less impact resistance | Heavy-duty jobs |

| Aluminum | Light, naturally resists rust | Lightweight projects |

| Copper and Brass | Good for looks, conducts heat and electricity | Decoration, electronics |

| 300-series Stainless | Handles heat and corrosion, keeps shape at high temperatures | General-purpose |

| 400-series Stainless | Tougher, works in harsh places | Marine, chemical |

How Woven Wire Mesh Is Made

You might wonder how woven wire mesh gets its shape. The process starts with picking the right metal wires. Factories check each wire to make sure it is strong and the right thickness. Workers then weave the wires together, crossing them over and under to form the mesh. Machines keep the spacing between wires even, which is important for things like woven mesh baskets and woven wire cloth.

Here’s what happens during production:

- Workers check the metal to make sure it is high quality.

- Machines watch the wire thickness to keep it even.

- The mesh gets woven with careful spacing for each opening.

- Inspectors test the mesh for strength and look for any problems.

This careful process means you get woven wire mesh that is strong, reliable, and ready for many uses.

Key Features of Woven Wire Mesh

Flexibility

One of the biggest advantages of woven wire mesh is how flexible it is. You can bend it, twist it, or cut it to fit almost any shape. This makes it great for projects where you need the mesh to wrap around something or fit into a small space. Woven mesh baskets use this feature to hold items of different shapes and sizes. You can also use woven wire cloth for screens or filters that need to move or flex.

Precision

Woven wire mesh gives you precise control over the size of each opening. This is a huge advantage when you need to filter out tiny particles or let air flow through. You can choose mesh with very small or very large openings, depending on your project. Woven wire cloth and woven mesh baskets both benefit from this precision, making them useful in labs, kitchens, and factories.

You will notice that woven wire mesh comes in different weave patterns. Square weaves work well for most jobs, while Dutch weaves are better for filtering air or water. The many options and the ability to customize make woven wire mesh a top choice for many people.

Tip: If you need a mesh that bends easily and fits odd shapes, woven wire mesh is the way to go. Its flexibility and precision are two of the main advantages of woven wire mesh.

Pros of Woven Wire Mesh

Customization

Woven wire mesh gives you many choices. You can pick how thick the wire is. You can choose the size of the holes. You can also pick what the mesh is made from. This helps you get the right mesh for your job. It works for filters, screens, or even for decoration. Woven wire mesh can fit many shapes and sizes. You can use it for big or small projects. If you want something special, you can ask for a custom look. This makes woven wire mesh popular in food, building, and factories.

Tip: Woven wire mesh lets you match your project better than most other mesh.

Cost-Effectiveness

Woven wire mesh can help you save money. It lasts a long time and does not break easily. It stands up to heat, chemicals, and water. It is also easy to put in place, so you pay less for work. Many companies pick woven wire mesh to keep costs low and still get good results.

Here’s why woven wire mesh is a smart buy:

| Advantage | Description |

|---|---|

| Strength | Handles heavy loads and tough conditions. |

| Versatility | Works for many jobs and can be tailored to your needs. |

| Durability | Stands up to harsh environments, including chemicals and moisture. |

| Cost-effectiveness | Needs little upkeep and installs easily, saving you money. |

| Environmental | Offers a sustainable choice that helps reduce your carbon footprint. |

Cons of Woven Wire Mesh

Lower Strength

Woven wire mesh bends and moves, but it is not as strong as welded wire mesh. If you need to protect something heavy, woven wire mesh might not work well. It is good for light and medium jobs. It may not last if you use it for rough work or strong hits.

| Disadvantage | Description |

|---|---|

| Less Robust | Woven wire mesh is usually not as tough as welded metal, so it does not protect as well. |

| Flexibility | Small things can fall out because the mesh is bendy. |

Unraveling Risk

Woven wire mesh can come apart if you cut it or hurt the edges. The wires may start to come loose. This can make holes or gaps in the mesh. You can fix this by using a frame or sealing the edges. You should remember this when you plan your project.

| Disadvantage | Description |

|---|---|

| Item Loss | Small things can fall out of the mesh or through the holes. |

| Coating Support | The mesh might be too thin to hold a coating. |

Common Uses for Woven Wire Mesh

Filtration

Woven wire mesh is used for filtering in many places. Factories use it to clean liquids and gases. You might see it in water plants, chemical plants, or even in your kitchen sink. The mesh lets water or air go through but catches dirt.

Sieving

Woven wire mesh is great for sorting things. Farmers use it to separate grains like corn and wheat. Builders use it to sort sand and gravel. The mesh helps you sort things by size and makes work faster.

- Industrial: Used for sorting, filtering, machine guards, letting air in, and keeping things safe.

- Agricultural: Used for animal floors, fences, bug control, and sorting crops.

Decorative Applications

Woven wire mesh can make buildings and homes look nice. Builders use it for handrails, panels, and lights. The mesh gives a modern look and can be shaped in cool ways. You also see it in art and sculptures.

| Industry/Application | Description |

|---|---|

| Decorative/Architectural | Used in handrails and building details to make spaces look better. |

| Protection | Used for window grills, cages, and gates to keep things safe and look good. |

Note: Woven wire mesh can do many jobs, from keeping bugs out to making your house look special. It gives you both use and style in one product.

Welded Wire Mesh Overview

What Is Welded Wire Mesh

When you look at welded wire mesh, you see a grid made by joining metal wires together at every crossing point. You get a strong, stiff sheet that holds its shape. Welded wire mesh works well for heavy-duty jobs, like fencing, safety barriers, and even welded wire mesh baskets. You can use it indoors or outdoors because it stands up to tough conditions.

Welded wire mesh comes in different types. You can pick stainless steel for extra strength, galvanized mesh for rust protection, or PVC-coated mesh for a colorful look. Here’s a quick table to help you see the options:

| Type of Welded Wire Mesh | Description | Applications |

|---|---|---|

| Stainless Steel Welded Mesh | High-quality stainless steel wires in a grid pattern | Fencing, construction, marine |

| Hot-Dipped Galvanized Welded Mesh | Thick zinc coating for corrosion resistance | Outdoor, long-term use |

| Galvanized Welded Mesh | Thin zinc layer on mild steel | Industrial, gardening, DIY |

| PVC-Coated Welded Mesh | Mild steel with PVC coating | Landscaping, gardening, aesthetics |

| Powdered Welded Mesh | Polyester powder coating | Landscaping, architecture |

You can use welded wire mesh for welded wire mesh baskets, welded wire cloth screens, and even animal cages. The design makes it easy to cut into panels or shapes for your project.

How Welded Wire Mesh Is Made

Factories make welded wire mesh using a step-by-step process. You get a product that is strong and reliable because each step adds to its durability. Here’s how it works:

- Workers pick high-quality steel wire for the job.

- Machines draw the wire through dies to make it strong and even.

- Wires are lined up and welded together to form the mesh pattern.

- Electric resistance welding melts the wire surfaces and presses them together for solid joints.

- The mesh gets trimmed and straightened so every piece looks uniform.

- Surface treatments like galvanization or PVC coating protect against rust and wear.

- Inspectors check the mesh for quality and strength.

- The finished welded wire mesh is packed and shipped to you.

This process gives you welded wire mesh that lasts a long time. You can trust it for welded wire mesh baskets, welded wire cloth screens, and fencing.

Key Features of Welded Wire Mesh

Rigidity

You will notice welded wire mesh feels stiff and solid. It does not bend easily. This rigidity helps when you need a fence that stands tall or a barrier that does not sag. Welded wire mesh baskets keep their shape, even when you fill them with heavy items. Welded wire cloth panels stay flat and strong, making them perfect for safety screens.

Uniformity

Welded wire mesh gives you even spacing and a neat look. Every wire is welded at the same spot, so you get a grid that looks perfect. Welded wire cloth panels have the same size openings all over, which helps with security and sorting. You can rely on welded wire mesh for projects where you need everything to line up just right.

Here’s a table showing why welded wire mesh stands out:

| Feature | Description |

|---|---|

| Strength and Durability | Welded construction gives you long-lasting performance, even in tough places. |

| Versatility | You can use welded wire mesh for fencing, baskets, and building support. |

| Customization | Pick your wire thickness and opening size for your project. |

| Cost-Effectiveness | Welded wire mesh lasts a long time, so you save money on repairs. |

| Corrosion Resistance | Galvanized and stainless steel options protect against rust and weather. |

Tip: If you want a mesh that stays firm and looks neat, welded wire mesh is your best choice. You get strength, uniformity, and lots of options for your project.

Pros of Welded Wire Mesh

High Strength

You want something tough for your project. Welded wire mesh gives you that strength. Each wire is welded at every crossing point, so the whole sheet holds together tightly. You can count on it to handle heavy loads without bending or breaking. This makes it perfect for construction, security, and industrial jobs.

- Welded wire mesh stands up to harsh weather and strong impacts.

- The rigid structure keeps intruders out and protects your property.

- You get a solid barrier that is hard to climb or cut through.

If you need a fence or a safety screen, welded wire mesh is a smart choice. It keeps things safe and secure.

Durability

Durability matters when you want something to last. Welded wire mesh resists wear and tear, even in tough environments. You can use it outside, in factories, or anywhere you need a strong barrier. The mesh does not rust easily if you pick galvanized or stainless steel options.

- Welded wire mesh lasts longer than many other materials.

- You save money on repairs because it needs little maintenance.

- The mesh keeps its shape and strength over time.

Tip: If you want a solution that works for years, welded wire mesh is a reliable pick.

Cons of Welded Wire Mesh

Limited Flexibility

Welded wire mesh is strong, but it does not bend much. You might find it hard to fit around corners or uneven ground. If your project needs a mesh that wraps or twists, you may want to look at other options.

- The rigid design makes it tough to shape or modify after installation.

- You need special tools and skills to cut or adjust the mesh.

- It does not work well for decorative jobs where you want curves or soft edges.

Higher Cost

You might notice welded wire mesh costs more at first. The price comes from the strong materials and the welding process. If you have a tight budget, this can be a challenge.

- Welded wire mesh is heavier, so it costs more to transport and handle.

- You may need to pay extra for coatings to prevent rust.

- The industrial look does not suit every project, especially if you want something stylish.

Note: Welded wire mesh saves money in the long run because it lasts, but the upfront cost is higher than some alternatives.

Common Uses for Welded Wire Mesh

Fencing

You see welded wire mesh used for fences in cities, farms, and factories. It creates a strong barrier that keeps people and animals safe. The mesh lets you see through, so you get security without blocking your view. Maintenance costs drop by 25% compared to other fencing types.

Concrete Reinforcement

Builders use welded wire mesh to make concrete stronger. The mesh spreads out the load, so walls and floors do not crack as easily. Concrete structures last up to 30% longer and show 40% fewer cracks when reinforced with welded wire mesh.

Safety Barriers

Welded wire mesh works well for safety barriers in warehouses, playgrounds, and construction sites. The rigid design stops people from entering dangerous areas. You get a secure space that protects workers and equipment.

| Application | Description | Benefit |

|---|---|---|

| Fencing | Security and visibility for property and livestock | Lower maintenance, strong barrier |

| Concrete Reinforcement | Strengthens slabs, walls, and foundations | Longer lifespan, fewer cracks |

| Safety Barriers | Prevents access to restricted or hazardous zones | Improved safety, reliable protection |

Welded wire mesh gives you strength, durability, and security for many jobs. You can trust it for tough tasks where safety and long life matter.

Woven Wire Mesh vs Welded Wire Mesh Comparison

Construction Differences

When you look at woven wire mesh vs welded wire mesh, you notice big differences in how each one is made. Woven wire mesh is created by weaving metal wires over and under each other, almost like making fabric. This weaving process lets you pick from many wire sizes and patterns. You can even get woven mesh with up to 500 wires per inch. That means you can use it for very fine filtering or delicate jobs.

Welded wire mesh is made in a different way. Factories use machines to weld steel wires together at every crossing point. This creates a strong and uniform grid. The spacing between wires stays the same across the whole sheet. Because of this, welded wire mesh is perfect when you need something stiff and sturdy. You usually see it with bigger openings, like 1/4 inch or more.

Here’s a quick table to help you see the construction differences:

| Feature | Woven Wire Mesh | Welded Wire Mesh |

|---|---|---|

| How It’s Made | Wires woven over and under each other | Wires welded together at intersections |

| Customization | Many weave patterns and wire sizes available | Limited to standard grid patterns |

| Fineness | Can be made with very fine wires | Usually has larger openings |

| Structure | Flexible, like fabric | Rigid, holds its shape |

Tip: If you need a mesh that bends or fits odd shapes, woven wire mesh gives you more options. For a mesh that stays firm and strong, welded wire mesh is the way to go.

Strength and Stability

Now, let’s talk about the comparison of strength and durability. When you compare woven wire mesh vs welded wire mesh, you see that welded wire mesh stands out for strength and stability. The welded joints make the whole sheet very rigid. You can use it for heavy-duty jobs, like fences or concrete support. It keeps its shape, even under a lot of weight.

Woven wire mesh is strong in its own way. It has great tensile strength, so it can handle pulling and stretching. But it is less rigid than welded wire mesh. If you put it under a lot of pressure, it might move or bend. That means it works best for lighter jobs or where you need some give.

Here’s a table to show you how they compare:

| Characteristic | Welded Wire Mesh | Woven Wire Mesh |

|---|---|---|

| Strength and Durability | Strong and rigid, ideal for structural support. | Excellent tensile strength, resistant to impact. |

| Stability | Holds shape under heavy loads | May shift or bend under pressure |

| Best Use | Fencing, concrete, safety barriers | Filtration, sieving, decorative uses |

You might want to remember these points:

- Welded wire mesh keeps its shape and stays stable, even with heavy loads.

- Woven wire mesh can move or shift if you use it for tough jobs.

- Welded wire mesh is more durable in high-stress places.

If you need a mesh for industrial applications where safety and support matter, welded wire mesh is usually the better choice.

Flexibility and Adaptability

Flexibility is another big difference in the woven wire mesh vs welded wire mesh debate. Woven wire mesh bends and twists easily. You can shape it to fit around corners, curves, or uneven ground. This makes it perfect for custom jobs, like curved filters or decorative screens. You can even use it for projects where you need to change the shape often.

Welded wire mesh is much more rigid. It does not bend or flex much. If you try to shape it, you might break the welds or damage the mesh. That means it works best for flat surfaces or places where you want the mesh to stay put.

Here’s a table to help you compare their flexibility and adaptability:

| Type of Mesh | Flexibility and Adaptability |

|---|---|

| Woven Wire Mesh | Flexible; conforms to uneven terrain and curved surfaces. |

| Welded Wire Mesh | Rigid; limited ability to adapt to irregular surfaces. |

You should also know:

- Woven wire mesh is great for bending, shaping, or wrapping around objects.

- Welded wire mesh gives you a stable structure but does not work well for curves or frequent changes.

Note: If your project needs a mesh that can flex or fit into tricky spots, woven wire mesh is the winner. For projects that need a firm, steady barrier, welded wire mesh is your best bet.

This comparison of flexibility and versatility helps you pick the right mesh for your needs. Whether you want strength and durability or easy shaping, you can find the best fit by looking at these key differences in woven wire mesh vs welded wire mesh.

Cost Comparison

When you look at wire mesh options, cost is often the first thing you notice. You want to know which mesh fits your budget and lasts the longest. Woven wire mesh usually costs less upfront. You can buy it for temporary projects or lighter jobs without spending much. If you need a quick fix or a small screen, woven wire mesh saves you money at the start.

Welded wire mesh costs more when you buy it. The production process is more complex, and the materials are heavier. You pay extra for the strength and stability welded mesh provides. However, you get what you pay for. Welded wire mesh lasts longer and needs less maintenance. Over time, you spend less fixing or replacing it. If you want a fence or barrier that stands strong for years, welded wire mesh is a smart investment.

Here’s a table to help you compare the costs:

| Mesh Type | Upfront Cost | Maintenance Cost | Longevity | Best For |

|---|---|---|---|---|

| Woven Wire Mesh | Lower | Higher | Shorter-term | Temporary, light jobs |

| Welded Wire Mesh | Higher | Lower | Long-term | Permanent, heavy-duty |

Tip: If you need a mesh for a short project or light use, woven wire mesh keeps costs low. For long-term jobs, welded wire mesh saves you money in the end because it lasts and needs less care.

You also need to think about installation. Woven wire mesh is easier to shape and install, but it may need more repairs later. Welded wire mesh takes more effort to put in place, but you won’t have to worry about it much after that. You spend less time and money on maintenance with welded wire mesh.

Application Suitability

Choosing the right mesh depends on your project. You want to match the mesh to your needs so you get the best results. Woven wire mesh works well for jobs that need flexibility. You can use it for screens, filters, and decorative panels. It bends and shapes easily, so you can fit it into tight spaces or wrap it around objects.

Welded wire mesh is best for projects that need strength and stability. You see it in fences, safety barriers, and concrete reinforcement. It stays firm and holds up under pressure. If you need a barrier that won’t bend or break, welded wire mesh is the way to go.

Here are some common uses for each type:

- Woven Wire Mesh

- Filtration systems in factories

- Protective screens for windows or vents

- Decorative panels in buildings

- Sieving and sorting in agriculture

- Welded Wire Mesh

- Fencing for gardens, farms, and playgrounds

- Reinforcing concrete in construction

- Safety barriers in warehouses

- Animal enclosures for larger animals

You should also consider the environment and stress your mesh will face. Welded wire mesh handles heavy loads and tough weather. Woven wire mesh adapts to changing shapes and lighter tasks. If you want a mesh for a custom project, woven wire mesh gives you more options. If you need a strong, permanent solution, welded wire mesh is your best choice.

Note: Always think about how much strength, flexibility, and durability your project needs. Pick the mesh that matches your goals and budget. This way, you get the best performance and value.

How to Choose the Right Wire Mesh

Assessing Project Needs

Before you pick a wire mesh, think about what you want it to do. Do you need something strong for security? Maybe you want a mesh that bends for a custom shape. Start by asking yourself what the main job of the mesh will be. If you need support or safety, welded wire mesh often works best. For filtering or a unique look, woven wire mesh might be the right choice. Always match the mesh type to your project’s main goal.

Tip: Write down your project’s needs. This helps you compare options and avoid mistakes.

Key Factors to Consider

Environment

Look at where you plan to use the mesh. Will it face rain, chemicals, or heat? Stainless steel or galvanized mesh stands up to rust and harsh weather. If you use the mesh outside or in a wet place, pick a finish that protects against corrosion. For indoor projects, you might not need as much protection.

Load and Stress

Think about how much weight or force the mesh must handle. Thicker wires give more strength. If you need to hold heavy items or keep people safe, welded wire mesh is a solid pick. For lighter jobs, like filtering or decoration, woven wire mesh works well. Always check the wire gauge and make sure it matches your needs.

Mesh Size

Mesh size means the size of the openings in the grid. Small openings work for filtering tiny things. Bigger openings let more air or light through. Pick a mesh size that fits your project. For example, use fine mesh for sieving flour or large mesh for a garden fence.

Budget

Set your budget before you shop. Woven wire mesh usually costs less at first, but it may need more repairs later. Welded wire mesh costs more upfront, but it lasts longer and needs less care. Balance your budget with how long you want the mesh to last.

Here’s a table to help you compare key factors:

| Factor | What to Look For |

|---|---|

| Material | Stainless steel, galvanized, or coated for durability |

| Mesh Size | Match to your use—small for filtering, large for barriers |

| Wire Diameter | Thicker for strength, thinner for flexibility |

| Surface Treatment | Galvanized or PVC for outdoor use |

| Application | Choose based on main purpose—support, filtering, or decoration |

| Environment | Check for moisture, chemicals, or temperature changes |

| Budget | Balance cost with quality and lifespan |

Selection Tips

- Choose the right material for your project’s environment.

- Pick the wire gauge that gives enough strength.

- Match the mesh size to your job—small for fine work, large for barriers.

- Look for coatings if you need extra protection.

- Measure your space so you buy the right amount.

- Use strong fasteners to keep the mesh in place.

- Check the mesh often for damage or rust.

- Clean and protect the mesh to make it last longer.

Note: If you feel unsure, ask an expert or a trusted supplier. They can help you pick the best mesh for your needs.

By thinking about these points, you can choose between woven wire mesh and welded wire mesh with confidence. You’ll get the right fit for your project, save money, and enjoy better results.

Conclusion

You have learned that woven wire mesh and welded wire mesh are not the same. Here is a simple table to help you remember the main differences:

| Comparison Factor | Woven Mesh | Welded Mesh |

|---|---|---|

| Core Technology | Wires are woven together | Wires are welded together |

| Flexibility | Very flexible, fits odd shapes | Very strong, keeps its shape |

| Precision | Openings can be different sizes | Openings stay the same size |

| Production Speed | Takes longer, made for special jobs | Made quickly, many at once |

When you pick a mesh, try these steps: First, think about what your project needs. Do you need support, safety, or just something that looks nice? Next, look at how much money you can spend and compare prices. Then, think about where you will use the mesh. Will it be inside or outside?

As a woven wire mesh manufacturer, Anpeng can help you select the right mesh for your application—aperture, wire diameter, material, and panel size. Send us your screening or filtration details, and we’ll recommend the best option and provide a fast quotation.

FAQ

What is the main difference between woven and welded wire mesh?

Woven wire mesh uses wires woven together, like fabric. Welded wire mesh has wires joined at each crossing point. You get more flexibility with woven mesh. Welded mesh gives you more strength.

Can I cut wire mesh myself?

Yes, you can cut both types with wire cutters or tin snips. Woven mesh cuts easier. Welded mesh may need stronger tools. Always wear gloves and eye protection.

Which mesh should I use for outdoor fencing?

You should pick welded wire mesh for outdoor fences. It stands up to weather and stays strong. Galvanized or coated welded mesh resists rust best.

Is woven wire mesh good for filtering?

Yes! Woven wire mesh works great for filters. You can choose tiny openings to catch small particles. Many people use it for sieves, strainers, and screens.

Does welded wire mesh rust?

Welded wire mesh can rust if you use plain steel. Choose galvanized or stainless steel mesh for better rust protection. These last longer outside.

Can I bend welded wire mesh?

Welded wire mesh does not bend easily. It stays stiff and holds its shape. If you need to wrap or curve the mesh, woven wire mesh works better.

How do I stop woven wire mesh from unraveling?

You can frame the edges or use clips to hold the wires in place. Some people weld or solder the ends. This keeps the mesh from coming apart.

Which mesh costs less?

Woven wire mesh usually costs less at first. Welded wire mesh costs more but lasts longer. Think about your project and how long you need the mesh to last.