Woven Wire Screens

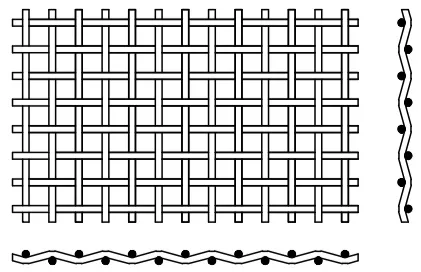

Woven wire screens are a durable and versatile type of screening media used in a variety of industrial applications. Made from high-strength steel wires, they are woven into a grid-like pattern that allows for efficient sorting, sieving, and screening of materials. These screens are used across industries such as mining, quarrying, construction, recycling, and more.

Whether you are separating coarse materials in a mining operation or sifting fine particles in a quarry, woven wire screens are engineered to deliver high performance, durability, and reliability in even the most challenging environments.

3-150mm

Feed Size

0.5mm-100mm

Mesh Size

0.5-16mm

Wire Diameter

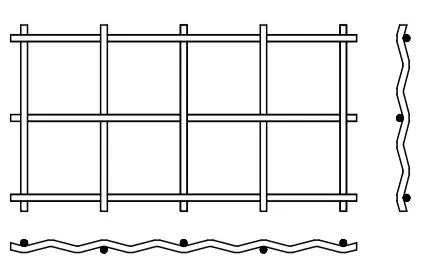

Woven Wire Screen Types

There are several types of woven wire screens, each designed to suit different screening needs. Below are some of the most common weave types:

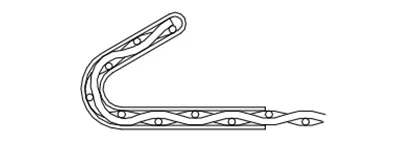

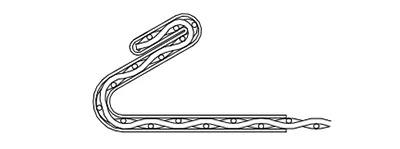

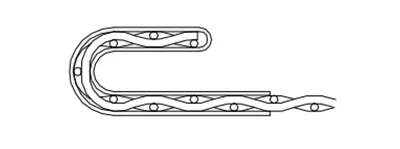

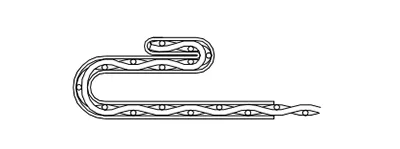

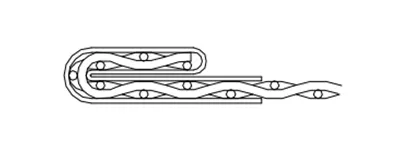

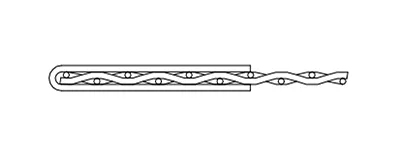

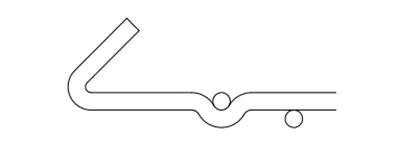

Screen Tensioning Hook Style

The tensioning hook style refers to the design of the hooks used to secure the woven wire mesh onto the screen frame. These hooks are crucial because they ensure the mesh is properly stretched and secured during operation, which improves screening efficiency and reduces wear.

Selecting the right tensioning hook style depends on your screen’s application, material handling, and the amount of vibration the system is subjected to. Choosing the right hook style helps ensure mesh integrity, reduces downtime, and prolongs the service life of your screen.

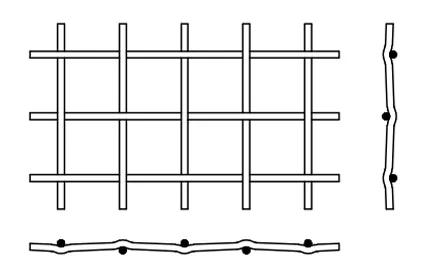

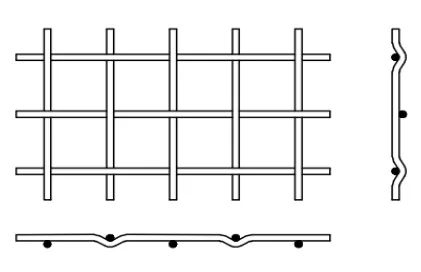

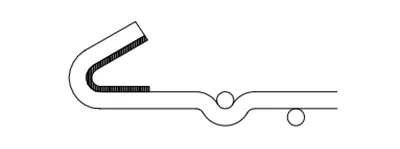

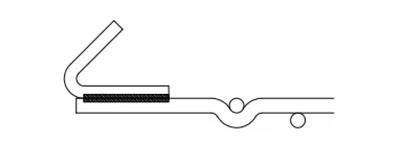

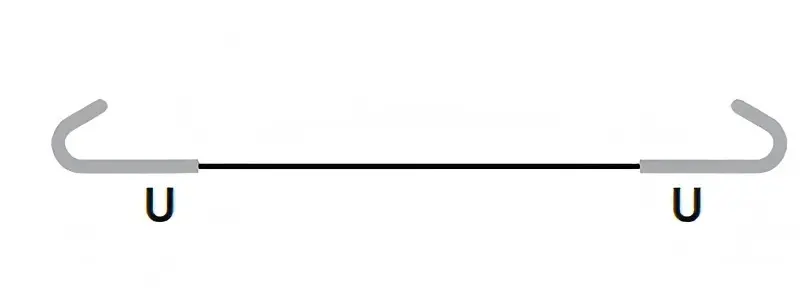

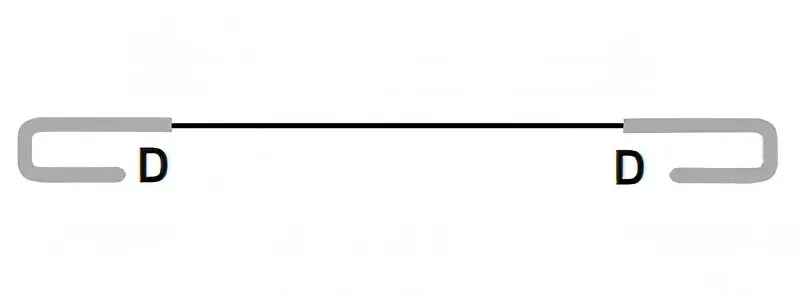

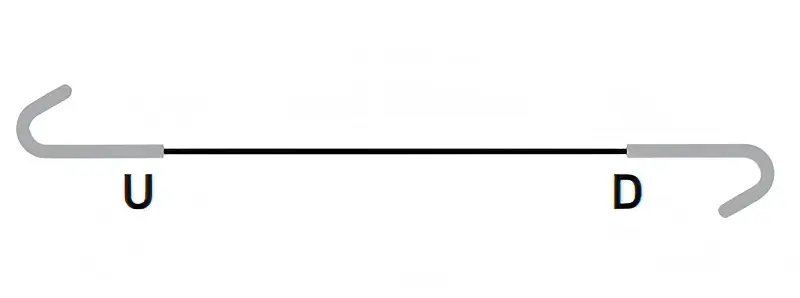

Screen Tension Hook Orientation

The tension hook orientation is crucial for ensuring that the woven wire mesh is securely and evenly stretched during operation. The orientation of the hooks affects the screen’s performance, durability, and overall efficiency. There are several common configurations for the tensioning hooks, each designed for specific applications and performance needs.

The right orientation of the tensioning hooks ensures that your mesh performs as expected and extends its lifespan. Incorrect orientation can lead to uneven mesh tension, which may result in clogging, pegging, or even breakage during high-impact operations. Selecting the correct tensioning hook style and orientation is key to maximizing your screen’s efficiency. ANPENG offers a wide range of tension hook styles and orientations to match your specific screening needs. Contact us today for advice on selecting the right configuration for your vibrating screens and optimizing your process!

Technical Specifications

| Specification | Details |

|---|---|

| Material Options | High-Carbon Steel, Carbon Steel, Stainless Steel, Galvanized Steel |

| Mesh Size | Available in a wide range from 0.5mm to 100mm |

| Wire Diameter | Customizable based on application and throughput requirements |

| Aperture Size | Varies from fine to coarse, depending on material type and screening goal |

| Standard | ASTM E 2016, ISO 9044 |

| Custom Sizes | Available upon request to fit specific screen model and deck layout |

| Service Life | Up to 30% longer than traditional screens with proper maintenance |

| Durability | Excellent abrasion resistance, impact resistance, and wear life |

Why Choose ANPENG Woven Wire Screens?

With over 20 years of experience, we have mastered the art of producing industrial-grade woven wire screens that deliver consistent, high-quality performance.

We offer screens in various materials (stainless steel, galvanized steel, high-carbon steel) and mesh sizes, ensuring a perfect fit for your application.

Our products are rigorously tested to meet industry standards and ensure they can withstand the toughest conditions.

Industries that Use Woven Wire Screens

For separating minerals, ores, and aggregates in mining operations. Ideal for handling abrasive materials and ensuring high productivity.

Used in the extraction and processing of sand, gravel, and other materials. Woven wire screens provide high capacity and consistent separation.

Helps in sorting materials like sand, gravel, and crushed stone for building projects. Essential for creating clean, high-quality aggregates.

Used in recycling plants to separate paper, plastic, glass, and other materials, ensuring that the process runs smoothly.

Also used in the food industry for sifting grains, flour, and other particles to ensure product consistency and quality.

Anpeng Factory Tour

FAQs

How do I know which mesh size I need?

The mesh size depends on the material you are processing and the target particle size you need to separate. Our experts can help recommend the best mesh size based on your application.

How long do woven wire screens last?

Woven wire screens are highly durable, and their lifespan depends on the material being processed. With proper maintenance, they can last for several years.

Can you customize the screens to fit my specific equipment?

Yes! We offer custom sizes and designs to ensure that our screens fit your equipment perfectly.