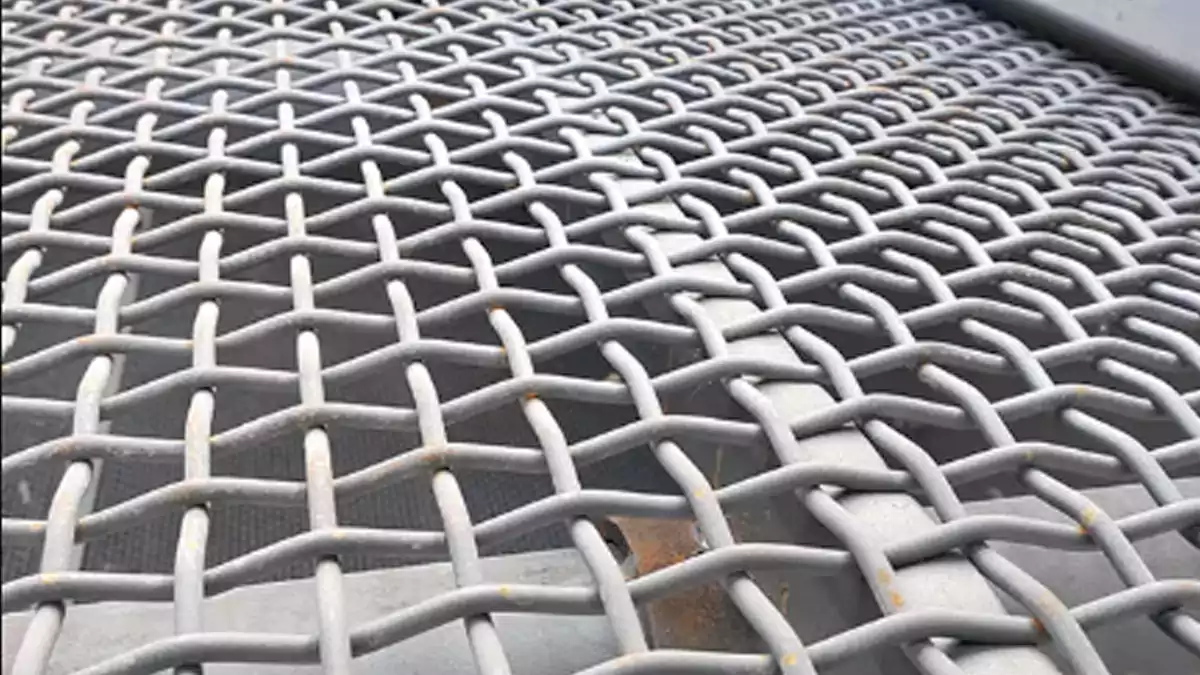

Screening Asphalt Millings: Stop RAP Screen Blinding

Processing Reclaimed Asphalt Pavement (RAP) is one of the most profitable operations in the modern aggregate and road construction industry.

Technical insights, application tips and industry news from Anpeng on screening media, wire mesh and self-cleaning screens to help you improve plant performance.

Processing Reclaimed Asphalt Pavement (RAP) is one of the most profitable operations in the modern aggregate and road construction industry.

In the aggregate and sand washing industry, processing dry material is straightforward. However, the moment moisture is introduced—whether from natural

You can make your plant quieter fast with the right vibrating screen noise reduction methods. Use rubber isolators, brush mats,

Screening wet or sticky materials can be very challenging, often leading to issues like blinding, plugging, and downtime. To maintain

You are important in the copper mining process. Copper is used in many things today. It helps run electrical systems,

Designing an aggregate processing plant or upgrading an existing circuit requires absolute precision. One of the most frequent causes of

When you hear about the amplitude of vibrating screen, think of it as how far the screen moves up and

You might hear a lot about extraction in Zinc Mining, but crushing and screening are very important for how well

The construction and demolition (C&D) recycling market is expanding rapidly, turning waste materials into valuable resources. However, processing crushed concrete