You probably wonder which is better for your needs—rubber screens or wire mesh screens. Choosing the right screening media can change how your plant runs and how much you spend on upkeep. The materials you pick for screens affect durability and operational costs. Micro screening helps lower the load on downstream treatment and boosts efficiency. Each screen type has its own strengths and weaknesses, so the best choice depends on your application. This guide will help you compare rubber screens vs wire mesh screens side by side.

Key Takeaways

- Rubber screens last a long time and make less noise. They are good for hard jobs and quieter workplaces.

- Wire mesh screens let more material pass through and sort things well. They are great for fast screening and for small pieces.

- Think about what you need to screen. Rubber screens work better with wet and sticky material, while wire mesh screens are better for dry material.

- Rubber screens can cost more at first, but they save money over time because they don’t need frequent repairs or replacement. Wire mesh screens are easy to install and remove, which helps save time when you’re busy.

- Choose what matters most to you. If you want durability and low noise, pick rubber. If you want speed and accuracy, pick wire mesh.

- You can also use both types together for the best results—for example, rubber on the top deck for strength and wire mesh on the lower deck for finer separation.

- For the best match, talk to an expert and confirm the right screen for your machine and material.

Rubber Screens vs Wire Mesh Screens Overview

Key Differences

You might wonder how rubber screens are different from wire mesh screens. Both types help you sort and separate materials. Rubber screens are made from flexible rubber panels. Wire mesh screens are made from woven metal wires. Rubber screens are used where impact and noise are important. Wire mesh screens are good when you need fast sorting and accuracy.

Rubber screens can handle heavy loads and rough materials. They soak up shock and make less noise. Wire mesh screens let more material go through. They give you exact sizing and work well with dry stuff. You can put in wire mesh screens quickly because they are light.

When you look at rubber screens vs wire mesh screens, you see rubber screens last longer in hard jobs. Wire mesh screens need to be replaced more often. Rubber screens cost more at first, but you pay less for repairs. Wire mesh screens are cheaper to buy, but you might spend more later.

Tip: Think about what you want from your screens. If you want them to last and be quiet, rubber screens may be best. If you need fast sorting and fine screening, wire mesh screens could work better.

Quick Pros and Cons

You might want an easy way to see the good and bad points of each screen. Here is a table to help you choose:

| Criteria | Rubber Screens | Wire Mesh Screens |

|---|---|---|

| Durability | High | Moderate |

| Noise Reduction | Excellent | Low |

| Impact Resistance | Excellent | Low |

| Throughput | Moderate | High |

| Screening Accuracy | Moderate | High |

| Maintenance | Low | High |

| Upfront Cost | Higher | Lower |

| Installation | Moderate | Easy |

| Handling Wet/Sticky | Good | Moderate |

| Fine Screening | Limited | Excellent |

You can see rubber screens are strong, quiet, and tough. Wire mesh screens give you fast sorting, accuracy, and are easy to put in. Rubber screens are good for big pieces and rough jobs. Wire mesh screens are best for fine screening and quick sorting.

- Rubber Screens Pros:

- Last longer in tough jobs

- Make less noise

- Handle heavy hits

- Need less fixing

- Rubber Screens Cons:

- Cost more at first

- Less space for material to pass

- Not good for fine screening

- Wire Mesh Screens Pros:

- Sort large amounts fast

- Give exact sizes for small pieces

- Easy to put in and change

- Cost less at first

- Wire Mesh Screens Cons:

- Do not last as long in hard jobs

- Need more fixing and changing

- Make more noise and shake

You can see your choice between rubber screens vs wire mesh screens depends on what you need. If you want less fixing and a quieter plant, rubber screens may be better. If you want fast sorting and exact sizing, wire mesh screens might be the right pick.

Rubber Screening Media Benefits

Durability and Wear Life

You want your screening equipment to last as long as possible. Rubber screening media stands out for its durability. You can count on it to handle tough jobs where other screens might wear out fast. The secret lies in the way rubber screening media is made. It can be manufactured thicker than other materials, which gives it a longer service life. If you work with heavy-duty or abrasive materials, you will notice that rubber screening media keeps going strong while wire mesh screens need replacing more often. This means less downtime and fewer headaches for you.

- Rubber screening media has a lower wear rate when you deal with rough, abrasive materials.

- It is designed for heavy and coarse materials that can damage wire mesh screens.

- Even though it may have fewer openings, rubber screening media lasts much longer than wire mesh screens.

- You get high wear-resistance, which means you do not have to worry about frequent replacements.

If you want reliability in your screening process, rubber screening media is a smart choice.

Noise Reduction

Noise can be a big problem in screening plants. You might find it hard to work or even talk when the machines are running. Rubber screening media helps you solve this issue. It can reduce noise levels by 10 to 15 decibels compared to wire mesh screens. That is a big difference. In fact, a 10-decibel drop sounds like the noise has been cut in half. Your team will appreciate the quieter work environment. You will also meet noise regulations more easily. Less noise means less stress and a safer place to work.

Tip: If you want a quieter plant, switching to rubber screening media can make a huge impact.

Maintenance and Cost Savings

You probably want to save time and money on maintenance. Rubber screening media helps you do just that. When you switch from wire mesh screens, you can see a big drop in cleaning time and resources. Some operations report a 41% reduction in cleaning work every year. That means you save about 120 man hours each month on just one screening line. The longer life of rubber screening media also means you spend less on replacements. Disposal costs for old screens can drop by around 60%. All these savings add up and help your bottom line.

If you want to cut down on maintenance and keep your screening process running smoothly, rubber screening media is a great option.

Impact Resistance

You want your screens to stand up to tough jobs. When you deal with large, heavy materials, you need something that can take a hit. Rubber screening media gives you that strength. It does not crack or tear when rocks or other big pieces drop onto it. You get peace of mind because your screens will not break under pressure.

Here is why rubber screening media stands out for impact resistance:

- It absorbs heavy impacts and strong vibrations during screening.

- You do not have to worry about cracks or tears, even with rough materials.

- It lasts up to 15 times longer than wire mesh screens in tough, abrasive conditions.

- You can use it for big jobs without stopping for repairs all the time.

If you want to keep your screening process running without sudden breakdowns, rubber screening media is a smart choice. You will spend less time fixing screens and more time getting work done. Your team will thank you for fewer interruptions and safer equipment.

Tip: If your plant handles large rocks or heavy loads, rubber screening media can save you money and stress.

Wet and Sticky Material Handling

Wet and sticky materials can cause big problems in screening. You might see screens clog up or get blocked, which slows down your work. Rubber screening media helps you avoid these issues. It has special anti-blinding features that keep material moving. You do not have to stop as often to clean or clear the screens.

Rubber screening media works better than wire mesh screens when you deal with wet or sticky stuff. The panels let material slide off instead of sticking. This means you get smoother screening and less downtime. You can trust rubber screening media to keep your operation running, even in tough, messy conditions.

If you want to handle wet and sticky materials without trouble, rubber screening media is your best bet. You will see better results and spend less time on maintenance.

Disadvantages of Rubber Screening Media

Lower Throughput and Open Area

You might notice that rubber screening media does not let as much material pass through as wire mesh screens. This happens because rubber panels have fewer openings. When you look at wire mesh screens, you see lots of gaps. These gaps help you move more material quickly. Wire mesh screens usually have an open area between 50 and 70 percent. That means more material can flow through during screening. Rubber screening media has a lower open area, so you get less throughput. If you work with dry or abrasive materials, you may find your process slows down. You need to think about how much material you want to screen each hour. If high speed matters to you, wire mesh screens might fit your needs better.

- Wire mesh screens have a high open area, which boosts screening efficiency.

- Rubber screening media has fewer openings, so throughput drops, especially with dry materials.

Note: If you want to screen large volumes fast, rubber screening media may not be the best choice.

Pegging and Blinding Issues

You probably worry about screens getting clogged. Pegging and blinding happen when material sticks in the openings and blocks the flow. Rubber screening media is more flexible, so it reduces blinding compared to wire mesh screens. You will see fewer blockages, but pegging can still occur, especially with sticky or wet materials. Some wire mesh screens use self-cleaning designs. These screens let the wires vibrate, which shakes loose any stuck material. That means you spend less time on maintenance and cleaning. Rubber screening media lasts longer and handles impacts well, but you may still need to clear blockages if you work with tough materials.

- Rubber screening media lowers blinding but pegging can still be a problem.

- Self-cleaning wire mesh screens help prevent pegging and blinding by vibrating freely.

- You may need to clean rubber screening media if you screen sticky materials.

Tip: If you deal with lots of sticky or wet material, look for screens with self-cleaning features.

Initial Cost

When you buy rubber screening media, you pay more upfront than for wire mesh screens. The price comes from the thicker panels and special materials used. You might feel the cost is high at first. Over time, you save money because rubber screening media lasts longer and needs less maintenance. If your budget is tight, you may choose wire mesh screens to start. You need to balance the initial cost with long-term savings. Think about how often you replace screens and how much downtime costs you. Sometimes, paying more at the beginning helps you save money later.

- Rubber screening media costs more to buy than wire mesh screens.

- You save money over time with fewer replacements and less maintenance.

- Wire mesh screens are cheaper upfront but may need more frequent changes.

Tip: Consider both the initial price and the long-term value when you pick your screening media.

You see that the disadvantages of rubber screening media include lower throughput, possible pegging and blinding, and higher initial cost. You need to weigh these factors against the benefits before making your choice.

Fine Screening Limitations

You may want to sort tiny particles. Rubber screens have trouble with this job. The holes in rubber panels are bigger than wire mesh screens. This means rubber screens cannot do fine screening well. If you need to separate small grains or powders, rubber screens may not be accurate. Wire mesh screens are better for this task. They give you exact sizing and handle fine materials easily.

Rubber screens are best for medium or large particles. If you use them for fine screening, you may see more clogging. The flexible rubber can move and close the holes. This makes it hard for small particles to get through. You may spend more time cleaning or stopping your machine to clear blockages.

Here are some things you may notice with rubber screens for fine screening:

- You get less exact sizing for tiny particles.

- The screens may clog or blind more often.

- You may need to stop your machine to clean the screens.

- You might lose some product because it cannot pass through.

If your job needs fine screening, wire mesh screens are usually better. They give you more control and better results for small sizes.

Temperature and Chemical Resistance

You may wonder how rubber screens work in tough places. High heat and strong chemicals can hurt some screens. Rubber screens, especially polyurethane ones, resist many chemicals well. They work with strong acids and can handle harsh environments. But they may not do as well in high heat as wire mesh screens.

Wire mesh screens are good in extreme heat. They keep their shape and handle high temperatures. They also resist many chemicals, so they are good for industrial jobs.

Here’s a quick comparison to help you see the differences:

| Feature | Wire Mesh Screens | Rubber Screens (Polyurethane) |

|---|---|---|

| Durability | High durability, good for industrial jobs | Varies, usually less durable than wire mesh |

| Chemical Resistance | Excellent, stands up to strong chemicals | Good, especially against strong acids |

| Temperature Resistance | Handles high temperatures | May not be best for high heat |

| Flexibility | Rigid, not very flexible | Flexible, fits many uses |

| Maintenance | Needs replacement from corrosion | Less maintenance from corrosion |

- Wire mesh screens last longer in hot or harsh places.

- You can use wire mesh for jobs with high heat or pressure.

- Polyurethane rubber screens resist corrosion and work well with acids.

- Rubber screens may not last as long in very hot spots.

Tip: If your plant has high heat or strong chemicals, check the specs before you pick your screen. The right choice keeps your work safe and running well.

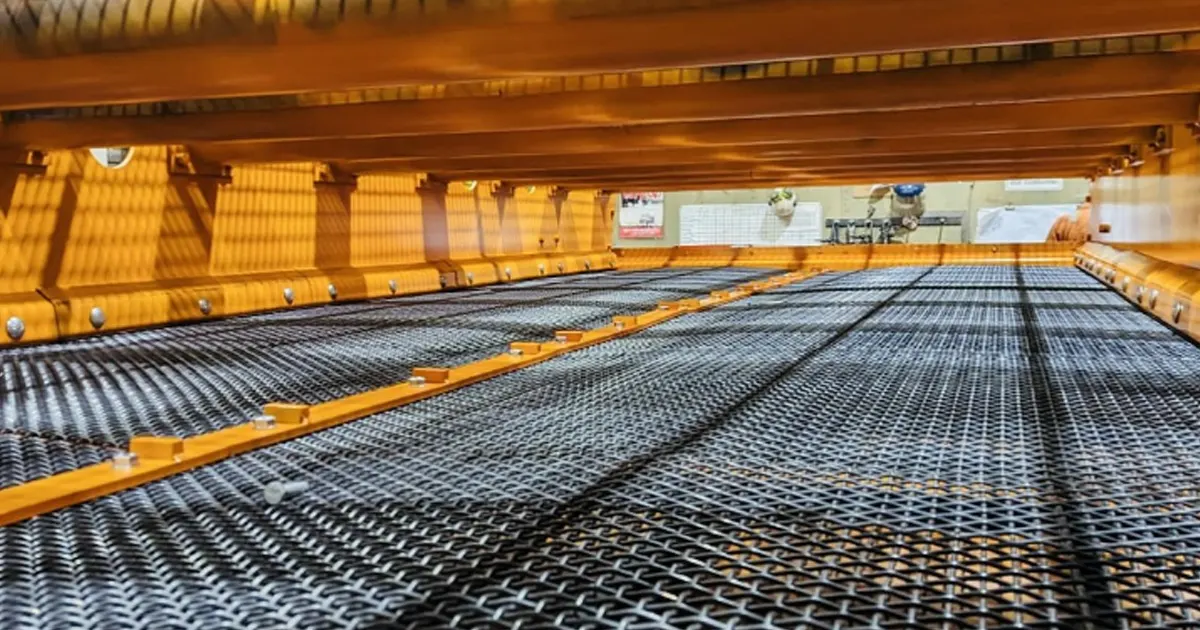

Wire Mesh Screens Advantages

High Throughput

You want to move a lot of material through your plant. Wire mesh screens help you do that. These screens have a high open area. That means more space for material to pass through. You can process large volumes quickly. This is great when you need to keep up with high demand. You will notice less clogging and fewer slowdowns. Wire mesh screens keep your operation running smoothly. You can trust them to handle busy days and heavy loads.

If you work with dry materials, you will see even better results. Dry particles move fast across the screen. You do not have to worry about sticky build-up. Your team will spend less time cleaning and more time getting work done. High throughput means you finish jobs faster and boost your plant’s output.

Screening Accuracy

You need accurate results when you separate materials. Wire mesh screens give you that accuracy. The wires are woven tightly. This creates precise openings for each particle size. You can sort fine particles with confidence. If you want to separate small grains or powders, wire mesh screens do the job well.

Let’s look at why wire mesh screens stand out for screening accuracy:

- The tight weave gives you exact sizing for every batch.

- You can trust the results, even with fine materials.

- You get less blinding and pegging, so the screens stay clear.

- You see steady performance, even at different feed rates.

Rubber screens can work for coarse jobs, but they struggle with fine screening. Thicker rubber panels do not give you the same accuracy. You may see more bouncing and less contact with the screen. Wire mesh screens keep particles moving and make sure you get the right size every time.

Tip: If you need to meet strict quality standards, choose wire mesh screens for your screening process.

Cost-Effectiveness

You want to save money without losing quality. Wire mesh screens help you do that. They cost less to buy than rubber screens. You can replace them quickly, which means less downtime. The lightweight design makes installation easy. Your team can swap out screens fast and get back to work.

Wire mesh screens give you good value for your money. You do not have to spend a lot upfront. You also save on labor because the screens are simple to handle. If you run a busy plant, these savings add up over time.

Here’s a quick look at why wire mesh screens are cost-effective:

- Lower purchase price than rubber screens

- Fast installation and replacement

- Less downtime for your operation

- Good performance for many types of screening

You can count on wire mesh screens to keep costs down and productivity up.

Versatility for Dry Materials

You want your screening process to work well with dry materials. Wire mesh screens give you that flexibility. You can use them for many types of dry products, from sand to gravel to grain. These screens handle changes in your operation without trouble. If you need to switch between different materials, you can do it fast. You do not have to worry about long delays or complicated setups.

Wire mesh screens stand out because they let you change media often. This is helpful if your plant handles different jobs each week. You can swap out one screen for another and keep your work moving. You do not lose time waiting for special tools or training. Your team can handle the change-outs with basic skills.

Let’s look at how wire mesh screens compare to rubber screens for dry materials:

| Screen Type | Efficiency Characteristics | Product Quality Characteristics |

|---|---|---|

| Wire Mesh | Best for frequent media change-outs due to varying specifications. | Offers options like stainless steel for corrosion prevention and anti-blinding solutions. |

| Rubber | Ideal for dry, high-impact applications; self-cleaning properties prevent blinding. | Effective in fine, sticky materials, improving sizing accuracy and preventing fines build-up. |

You can see that wire mesh screens give you the best results when you need to change your setup often. They also help you keep your product quality high. You can choose stainless steel if you want to prevent rust. Some wire mesh screens come with anti-blinding features. These features stop material from blocking the holes. You get a steady flow and less downtime.

If you work with dry materials, you want a screen that does not clog. Wire mesh screens let air and particles move freely. You do not have to stop your machine to clean the screen as often. This means you finish jobs faster and keep your customers happy.

Wire mesh screens also work well in dusty places. They do not hold on to fine particles. You get a cleaner product and a safer work area. Your team will spend less time cleaning up and more time getting things done.

Tip: If your plant handles many types of dry materials, wire mesh screens give you the versatility you need. You can count on them for both efficiency and quality.

You will also find that wire mesh screens are easy to install. You do not need special equipment or a big crew. One or two people can handle the installation in a short time. This makes your operation more flexible and saves you money on labor.

Wire Mesh Screens Drawbacks

Shorter Lifespan

You want your equipment to last. Wire mesh screens can wear out faster than you expect, especially when you use them for tough jobs. If you work with heavy or sharp materials, you may notice holes or tears in the mesh after a short time. This means you need to replace your screens more often. Rubber screens, on the other hand, can handle impacts better. They absorb shocks and last longer in high-wear situations. You might pay less for wire mesh screens at first, but you could spend more in the long run because you need to buy new ones more often.

When you use wire mesh screens for screening, you may see them bend or break if rocks or other hard materials hit them. Rubber screens do not have this problem as much. They keep working even when things get rough. If you want to avoid frequent replacements, you should think about how long your screens will last.

Note: A shorter lifespan means more downtime for your plant. You lose time and money every time you stop to change a screen.

Higher Maintenance Needs

Wire mesh screens need more care than you might think. You have to check them often for damage. Small tears can turn into big problems if you do not fix them right away. Cleaning is another job you cannot skip. Fine particles can get stuck in the mesh, which blocks the flow of material. You may need to stop your screening process to clear out these blockages.

Here are some common maintenance tasks for wire mesh screens:

- Inspect for holes or broken wires

- Clean out clogged openings

- Tighten loose mesh panels

- Replace worn or damaged screens

If you want to keep your screening line running, you need to stay on top of these jobs. Rubber screens usually need less attention. They resist wear and do not clog as easily. This means you spend less time fixing problems and more time making higher quality end products.

Noise and Vibration

You might notice that wire mesh screens make a lot of noise during screening. The metal wires vibrate and bang against each other. This can make your plant a loud place to work. High noise levels can bother your team and even cause hearing problems over time. You may also feel strong vibrations in the equipment. These vibrations can shake bolts loose or cause other parts to wear out faster.

Rubber screens are much quieter. They absorb sound and reduce vibration. If you want a calm and safe work area, you should think about how much noise your screens make. Less noise means a better environment for everyone.

Here’s a quick table to compare noise and vibration:

| Screen Type | Noise Level | Vibration |

|---|---|---|

| Wire Mesh | High | High |

| Rubber | Low | Low |

Tip: If you want a quieter plant and less wear on your machines, rubber screens are a smart choice.

You need to think about these drawbacks before you pick wire mesh screens for your screening process. They may cost less at first, but you could face more problems with lifespan, maintenance, and noise.

Safety Concerns

You want your team to stay safe on the job. Wire mesh screens can bring some safety risks that you should not ignore. When you work with these screens, you deal with sharp metal edges and broken wires. These can cause cuts or even more serious injuries if you are not careful.

Let’s look at the main safety concerns you might face:

- Sharp Edges and Burrs:

Wire mesh screens often have sharp edges. When you handle or install them, you can get cuts on your hands or arms. Sometimes, small metal burrs stick out from the mesh. These can poke through gloves and cause pain. - Broken Wires:

Over time, the wires can snap or break. Loose wires can stick out and scratch you. If you do not spot them, you might get hurt while cleaning or changing the screen. - Screen Failure:

If a wire mesh screen wears out or tears, it can break apart during operation. Pieces of metal can fly off and hit workers nearby. This can lead to eye injuries or worse. - Heavy Lifting:

Large wire mesh panels can be heavy. If you lift them the wrong way, you can strain your back or drop the screen on your foot.

Tip: Always wear gloves, safety glasses, and long sleeves when you handle wire mesh screens. Check the screen for broken wires before you start work.

Here’s a quick table to help you see the risks and how to stay safe:

| Hazard | What Can Happen | How to Stay Safe |

|---|---|---|

| Sharp edges | Cuts and scrapes | Wear gloves and long sleeves |

| Broken wires | Puncture wounds | Inspect before handling |

| Screen failure | Flying debris | Use safety glasses and shields |

| Heavy lifting | Back or foot injuries | Lift with care, use a partner |

You can lower the risk by following safety steps every time you work with wire mesh screens. Make sure your team knows the dangers. Train them to spot problems before they start. If you see a damaged screen, replace it right away.

Rubber screens do not have these sharp edges or broken wires. They are softer and safer to handle. If safety is a top concern for you, rubber screens might be a better choice.

Remember: A safe plant keeps everyone working and happy. Take safety seriously when you choose your screening media.

Application Suitability: Rubber Screens vs Wire Mesh Screens

Best Uses for Rubber Screening Media

You might ask where rubber screens work best. They are great for wet jobs, like sorting sand or gravel. If you have fine or sticky materials, rubber screens help stop blockages. This means your work goes smoother with fewer stops.

Rubber screens also do well in dry jobs with lots of impact. You can swap out plate screens for rubber ones to make them last longer. Modular rubber systems are tough and have lots of open space. You get screens that last longer and need less fixing.

Here are some top ways to use rubber screens:

- Wet jobs with sand and gravel

- Sorting fine, sticky, or almost-the-right-size stuff

- Dry jobs with heavy impacts

- Modular systems that need to be strong and open

Tip: If you want to spend less time cleaning, rubber screens are a good choice for tough or sticky jobs.

Best Uses for Wire Mesh Screens

Wire mesh screens are mainly used on vibrating screens and crushers to separate material into consistent size ranges. They are widely applied in mining, aggregate, quarry, and recycling operations where high throughput and accurate gradation matter.

Typical uses include:

- Scalping (top deck): Remove oversized rock and protect downstream equipment.

- Sizing (middle deck): Produce target fractions such as 5–10 mm, 10–20 mm, 20–40 mm for sale or further processing.

- Final screening (bottom deck): Control fine cuts and improve product cleanliness and consistency.

- Dewatering & rinsing support: When paired with spray bars or washing systems, screens help control carryover and improve separation efficiency.

- Stockpile and load-out quality control: Maintain stable gradation to meet project specs and reduce rework.

- Recycling separation: Classify mixed materials and improve recovery rates in C&D or industrial recycling lines.

Note: Wire mesh screens are valued for their high open area, strong tensioning performance, and reliable sizing accuracy, making them a common screening media choice for high-wear, high-volume operations.

Choosing the Right Screen

You need to think about what you are screening and your job needs. If you have big, hard materials like ores, you need a strong screen. For small materials, you need screens that sort very well. Stainless steel wire mesh is extra strong and lasts longer.

Here is a table to help you pick:

| Factor | Rubber Screens | Wire Mesh Screens |

|---|---|---|

| Material Type | Dry, rough, sticky, or wet stuff | Most jobs, fine or dry stuff |

| Durability and Wear Life | Very tough for hard jobs | May wear out faster with rough stuff |

| Cost Implications | Costs more at first | Costs less at first |

| Application Requirements | Good for jobs with lots of plugging | Works for many jobs, easy to put in |

You should think about the size and type of material, how tough the screen is, the cost, and how often you need to clean or change your screens. When you look at rubber screens vs wire mesh screens, you see both have good uses. You get better results when you pick the right screen for your job.

Callout: Always check what you need and ask an expert if you want a custom answer.

Cost and Performance Comparison

Upfront vs Long-Term Costs

When you look at new screens for your plant, the price tag can grab your attention. Wire mesh screens usually cost less to buy at first. You can get them quickly and start using them right away. Rubber screens cost more upfront. You might wonder if they are worth it.

But here’s the thing—what you pay at the start is only part of the story. Rubber screens last much longer. You do not have to replace them as often. Over time, you spend less on new screens and less on labor. If you plan to run your plant for a long time, rubber screens can save you money in the end.

Note: Sometimes, paying more at the beginning helps you save more later.

Maintenance and Replacement

You want your plant to run smoothly. Frequent stops for repairs can slow you down. Wire mesh screens wear out faster, especially if you work with rough or sharp materials. One plant in the United States saw their wire mesh screens go from lasting a month to just one week when they started screening more abrasive material. That means more downtime and more work for your team.

Rubber screens, especially polyurethane ones, last three to eight times longer than wire mesh. You do not have to change them as often. This means less downtime and lower labor costs. Here’s a quick look at how they compare:

| Factor | Wire Mesh | Polyurethane Screen |

|---|---|---|

| Wear Life | Short | Very Long (3-8x) |

| Downtime for Changes | Frequent | Minimal |

| Associated Labor Cost | High | Low |

You can see that rubber screens help you cut down on maintenance and keep your plant running.

Total Cost of Ownership

You want to know what you will really spend over time. The total cost of ownership includes everything—buying the screens, replacing them, and paying for labor. Rubber screens usually win here. They last longer and need less care. You spend less on repairs and get more work done.

Let’s compare the two:

| Factor | Rubber Screens | Wire Mesh Screens |

|---|---|---|

| Longevity | Generally more durable | May wear out faster |

| Maintenance | Lower maintenance needs | Higher maintenance requirements |

| Productivity Impact | Can lead to lower cost per ton | Initial lower cost but may increase overall cost due to wear and tear |

If you want to keep costs down and your plant working hard, rubber screens are a smart choice. They help you avoid surprise expenses and keep your screening process on track.

Making the Right Choice

Key Decision Factors

You want to pick the best screen for your plant. Start by thinking about your material. Is it wet, sticky, or dry? Does it have sharp edges or is it soft? Next, look at your budget. Rubber screens cost more at first, but they last longer. Wire mesh screens are cheaper to buy, but you may need to replace them more often.

Ask yourself these questions:

- Do you need quiet operation?

- Is high throughput important?

- Will you screen fine or coarse material?

- How much time can you spend on maintenance?

Here’s a quick table to help you compare:

| Factor | Rubber Screens | Wire Mesh Screens |

|---|---|---|

| Durability | High | Moderate |

| Upfront Cost | Higher | Lower |

| Noise Level | Low | High |

| Fine Screening | Limited | Excellent |

| Maintenance | Low | High |

Tip: Write down your top needs. This makes your choice easier.

Industry Recommendations

Many industries have their favorites. Mining and quarry plants often use rubber screens for tough jobs. These screens handle heavy rocks and reduce noise. Recycling centers like wire mesh screens. They need fast sorting and fine sizing. Food processing plants use wire mesh for clean and accurate results.

You can also ask other plant managers what works for them. They may share tips about what lasts longer or saves money. Industry groups and trade shows are good places to learn more.

Note: Your job may need a mix of both screen types. Some plants use rubber on top decks and wire mesh on lower decks.

Custom Solutions and Manufacturer Support

Every plant is different. You may need a custom screen to get the best results. A professional manufacturer can help you design the right solution. They can look at your material, your process, and your budget. You get advice that fits your needs.

Here’s how a manufacturer can help:

- Test your material with different screens

- Suggest the best layout for your plant

- Offer custom sizes and shapes

- Give support after you buy

Callout: Don’t guess when it comes to screening. Talk to an expert for the best results.

You can make a smart choice by looking at your needs, learning from others, and getting help from a pro. The right screen will save you time, money, and stress.

Conclusion

You’ve seen the pros and cons of rubber screens and wire mesh screens. The best choice depends on your job, your budget, and your material. Here’s what you should remember:

- Rubber screens last longer and run quieter.

- Wire mesh screens cost less and sort fine material better.

Need help choosing the right screen? Contact us—we’re a manufacturer of both rubber screens and wire mesh screens. We support custom sizes, apertures, wire diameter/thickness, and mounting options to match your material and operating conditions.

FAQ

What is the main difference between rubber screens and wire mesh screens?

You get rubber screens made from flexible panels. Wire mesh screens use woven metal wires. Rubber screens last longer and run quieter. Wire mesh screens sort material faster and cost less.

Can I use rubber screens for fine screening?

Rubber screens do not work well for fine screening. The holes are bigger, so small particles do not pass through easily. If you need to sort fine material, wire mesh screens are a better choice.

How often do I need to replace wire mesh screens?

You may need to replace wire mesh screens more often, especially with rough or sharp materials. Some users change them every few weeks. Rubber screens usually last much longer.

Are rubber screens good for wet or sticky materials?

Yes! Rubber screens handle wet and sticky materials well. The flexible panels help prevent clogging. You will spend less time cleaning and more time working.

Which screen type is quieter during operation?

Rubber screens are much quieter. They absorb sound and reduce vibration. If you want a calm work area, rubber screens are the way to go.

Can I mix rubber and wire mesh screens in my plant?

You can! Many plants use rubber screens on top decks for durability and wire mesh on lower decks for fine sorting. This gives you the best of both worlds.

What should I consider before choosing a screen?

Think about your material, how much noise you can handle, your budget, and how often you want to do maintenance. If you are unsure, ask a professional for advice.