You may ask, what are self-cleaning screens? These screens help sort materials in places like mines or building sites. They use special wire shapes, shaking, or moving brushes to remove stuck pieces. This stops the screens from getting blocked like normal ones. You get smoother work and fewer delays. Self-cleaning screens make sorting better because they stop clogging and blocking, which keeps your work going well.

Key Takeaways

- Self-cleaning screens stop clogging. This helps things run smoother. There is less downtime when screens do not clog.

- These screens have special shapes and materials. They can sort many kinds of materials. They even work with wet and sticky stuff.

- You need to do regular maintenance for best results. Simple checks help your screens last longer.

- Self-cleaning screens can last three times longer than normal screens. This saves you money because you buy fewer replacements.

- Picking the right self-cleaning screen is very important. You need the right one for your material to get the best results.

- Using self-cleaning screens with vibrating machines works better. It makes things more efficient and you clean less by hand.

- Buying self-cleaning screens can help you work better. Over time, you will spend less on repairs and upkeep.

- You should check and adjust your screens often. This helps them work their best and gives you more output.

What Are Self-Cleaning Screens

Definition and Purpose

You might ask, what are self-cleaning screens and why do you need them in places like mines or recycling plants. These screens are strong tools made from wires such as high carbon steel, spring steel, or stainless steel. People use them to sort rocks, gravel, sand, or other things. The best thing is they clean themselves while working. This means you do not have to stop and pull out stuck pieces by hand.

Self-cleaning screens help you avoid problems like clogging or blinding. Regular screens can get blocked by wet or sticky stuff. This slows down your work and makes sorting less correct. With self-cleaning screens, your machines keep running well and you get better results.

Here’s a quick look at why you use these screens:

| Purpose | Description |

|---|---|

| Reduce Blinding and Plugging | Self-cleaning screens help stop material from blocking, so work goes faster. |

| Enhance Productivity | They let more material move through, so you get more done. |

| Accurate Material Sizing | These screens make sure you get the right size, which is important in making building materials. |

You see these screens a lot when you need to sort wet, sticky, or hard-to-handle materials. They work well in mining, building, and recycling because they keep things moving and help you get the right size every time.

Key Features

When you ask, what are self-cleaning screens known for, you will see some big differences from regular screens. Here are the main things that make them special:

- They need less fixing because they clean themselves.

- They work the same all the time with steady flow.

- They last longer since they do not get too dirty.

- They use shaking or flexible wires to knock off stuck stuff.

- They can filter a lot of material for different jobs.

Tip: If you want to stop wasting time and keep your screening line working, self-cleaning screens are a good idea.

Let’s compare self-cleaning screens to regular ones:

| Feature | Self-Cleaning Screens | Conventional Screens |

|---|---|---|

| Cleaning Mechanism | Special ways to clean using shaking | Needs people to clean by hand |

| Efficiency | Stays good without much help | Gets worse when stuff builds up |

| Design | Special shapes and wires that bend | Normal mesh that can get blocked |

| Maintenance Frequency | Low, works a long time | High, needs checking often |

You get more done with less work when you use self-cleaning screens. They also last longer and do not break as much.

Types of Self-Cleaning Screens

You have a few choices when you pick self-cleaning screens. Each kind works best for certain jobs or materials. Let’s look at the main types.

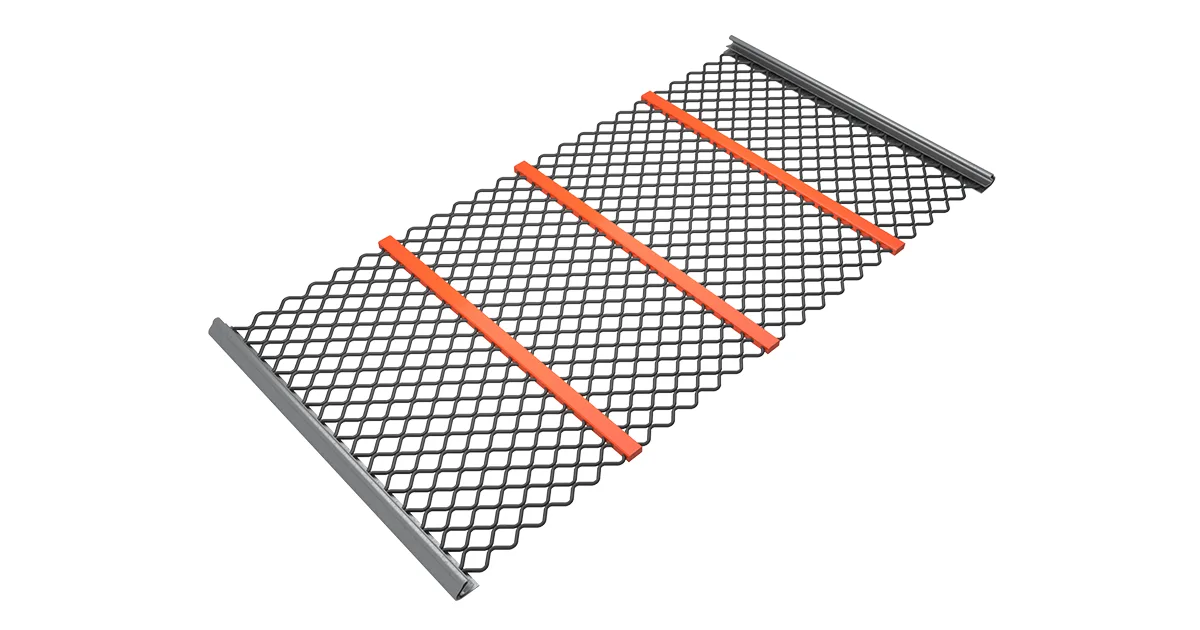

Wire Mesh Variants

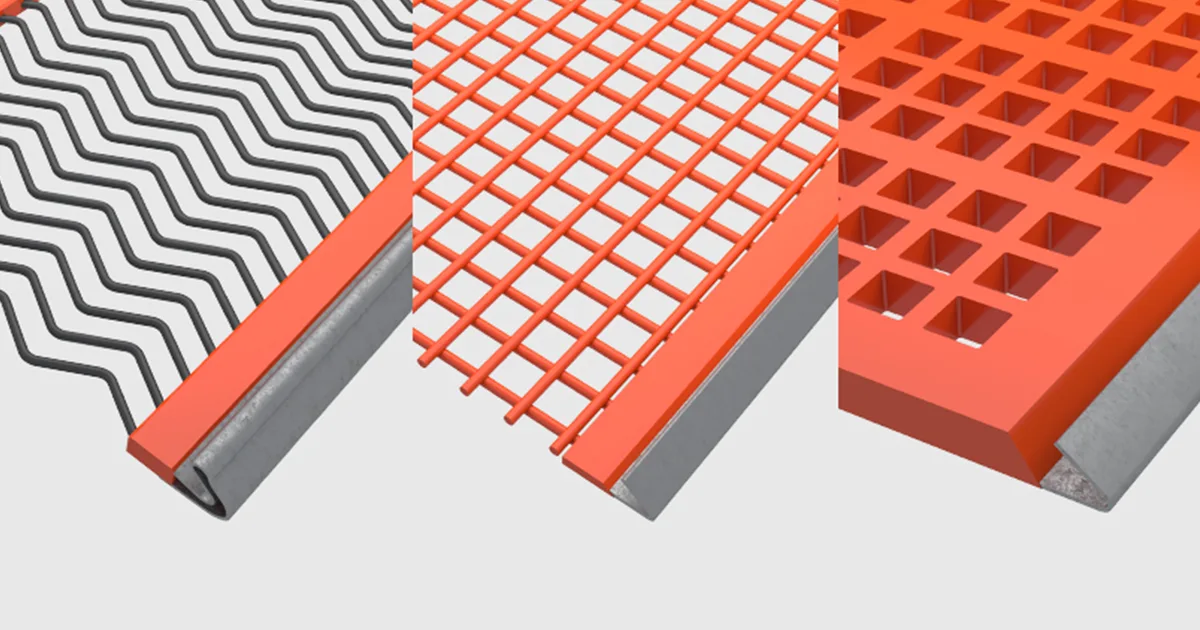

Wire mesh self-cleaning screens use different wire shapes and patterns to stop clogging. Here are some common types:

- Diamond-Aperture: Uses small shakes to keep holes open. Good for sorting things that need to be the same size.

- Wave (Corrugated)-Aperture: The wavy shape helps shake off tiny, sticky pieces. You use this when you need to get rid of very small bits.

- Triangular-Aperture: The three-sided holes move in different ways. This helps clean the screen and makes it last longer.

- Harp-Aperture: Has lots of open space and works well with wet or sticky stuff. You see this type in building and recycling.

The secret to how they work is in the flexible wire links. These wires can move and shake by themselves, so stuck stuff falls off. Sometimes, you will see polyurethane strips or rods added to help shake off tough bits. This design keeps your filtering fast and smooth.

Hybrid and Modular Designs

You can also find hybrid and modular self-cleaning screens. These mix different wire shapes or materials to handle hard jobs. For example, some screens mix steel wires with polyurethane strips. Others use special rods or frames that you can change when you need a new setup.

Hybrid screens give you the best of both worlds. You get strong filtering and less clogging, even with tricky stuff. Modular designs let you swap parts fast, so you spend less time fixing and more time working.

If you want to know what are self-cleaning screens that fit your needs, think about what you sort and how often you need to change the screen. With the right type, you can get more done and keep your machines working well.

How Self-Cleaning Screens Work

You might wonder what makes a self-cleaning screen so special. The secret is in how it keeps itself clear while you work. You do not have to stop your machines to clean out stuck pieces. Instead, the screen uses smart cleaning tricks to stay open and working. Let’s break down the main ways these screens clean themselves.

Self-Cleaning Mechanisms

Self-cleaning screens use a few clever methods to keep things moving. Each method helps stop clogging and keeps your material flowing.

Vibration and Alternating Forces

Vibration is one of the most common cleaning tricks. The screen shakes or moves back and forth. This motion helps knock off anything that gets stuck. Here’s how vibration and alternating forces help with cleaning:

- Vertical separator motion shakes loose any particles that get trapped in the openings.

- Slider shearing action breaks up hard chunks so they can fall through.

- Soft material assistance helps softer pieces move through the holes.

- Horizontal scrubbing motion rubs off fibrous or stringy stuff, so you get more material through.

- Ball cleaning action works well for odd-shaped pieces that wedge in the mesh, but it does not help much with stringy materials.

You get a steady flow because the screen keeps cleaning itself with every shake.

Mechanical Rakes and Brushes

Some self-cleaning screens use mechanical rakes or brushes. These parts move across the screen and scrape off anything that tries to stick. You see this a lot in mechanically cleaned filters. The brushes or rakes rotate or slide, making sure the screen stays clear. This method works well for sticky or muddy materials. You do not have to worry about stopping your work to clean by hand.

Turbulence and Water Flow

Water can also help with cleaning. Some screens use strong water jets or create turbulence. The moving water washes away anything that clings to the screen. This method is common in wet screening jobs or in mechanically cleaned filters that handle liquids. The water keeps the screen open and ready for more material.

Tip: If you deal with wet or sticky stuff, look for a self-cleaning screen that uses water jets or turbulence. You will spend less time cleaning and more time working.

Step-by-Step Cleaning Process

You might ask, “What happens during the self-cleaning process?” Here’s a simple step-by-step look at how a typical cleaning cycle works in mechanically cleaned filters:

- Open the lid of the filter to check inside.

- Make sure the internal brush or rake moves the right way.

- Check that the screen is not broken or torn.

- Take out the screen and spray it with a water cannon to wash off any stuck bits.

- Look for any gaps between the cleaning brush and the screen. The brush needs to touch the screen for good cleaning.

- Put some grease on the O-ring at the end of the filter. This keeps everything sealed and working well.

- Do a manual backwash now and then. This helps you check the flushing cycle, how long it takes, and the pressure.

You can see that mechanically cleaned filters make the cleaning job easy. The screen stays clear, and you do not have to stop your machines often. The self-cleaning process keeps your work moving and helps you get the right results every time.

Note: Regular checks and simple steps keep your self-cleaning screen working its best. You save time and avoid big problems.

If you use self-cleaning screens, you get less downtime and more work done. The cleaning cycle runs while you work, so you do not have to worry about clogging or slowdowns.

Technologies in Self-Cleaning Screen Filters

Anti-Clogging Wire Patterns

When you look at self-cleaning screen filters, you see that the wire patterns make a big difference. These patterns help stop clogging and keep your filtration running smoothly. You might notice that some screens use round wavy wires, while others mix straight and wavy wires. These designs help shake off dirt and keep the holes open.

Here’s a quick table to show you some common anti-clogging wire patterns and their sizes:

| Type | Aperture Size (mm) | Wire Diameter (mm) |

|---|---|---|

| Polyurethane D | 1.2 – 100 | 1 – 7 |

| Polyurethane T | 1.2 – 55 | 1 – 8 |

| Polyurethane H | 1 – 60 | 1 – 8 |

| Polyurethane W | 1 – 60 | 1 – 7 |

| Steel D | 2 – 20 | 1.2 – 4 |

| Steel T | 2 – 20 | 1.2 – 4 |

You can also find special types like Type K, which uses round wavy wires to make square holes, and Type T, which mixes straight and wavy wires for extra strength and cleaning power. These patterns let the wires move on their own, so stuck pieces fall off. This keeps your self-cleaning screen filters working longer and helps your filtration stay strong.

Self-cleaning screen filters use these patterns to vibrate at different speeds. This stops plugging and helps your filtration system last longer. Many industries now choose these filters because they work better than old-style mesh.

Flexible Wire Connections

You might wonder how self-cleaning screen filters stay so clear. The answer is in the flexible wire connections. These wires can move and shake on their own. When you use tubular backwash filters, these flexible wires help knock off anything that tries to stick. This means you get less downtime and more steady filtration.

Flexible wire connections also help with cleaning. When the wires move, they push out dirt and keep the holes open. You do not need to stop your machines as often. Tubular backwash filters use this trick to keep your filtration line running without many breaks.

If you want a filter that handles tough jobs, look for self-cleaning screen filters with flexible wires. They work well in tubular backwash filters, especially when you deal with sticky or wet stuff.

Surface Treatments and Coatings

Surface treatments and coatings make your self-cleaning screen filters even better. These treatments help stop dirt and water from sticking to the wires. You get better filtration and less cleaning work.

Here’s a table of common surface treatments:

| Treatment Type | Description |

|---|---|

| Oleophobic/superhydrophobic | Keeps soil off, water beads up and rolls away. |

| Hydrophilic/super hydrophilic | Lets water spread out, helps wash away dirt during rain. |

| Oleophobic-hydrophilic | Stops oil and dirt, lets water clean the screen. |

| Photocatalytic | Breaks down dirt using special additives. |

When you lower the contact angle on the screen, water spreads out and washes away dirt. This keeps your filtration system working longer and helps your tubular backwash filters stay clean. You do not have to worry about fast build-up or short filter life.

Tip: Choose self-cleaning screen filters with the right coating for your job. You will see less clogging and better filtration, especially in tubular backwash filters.

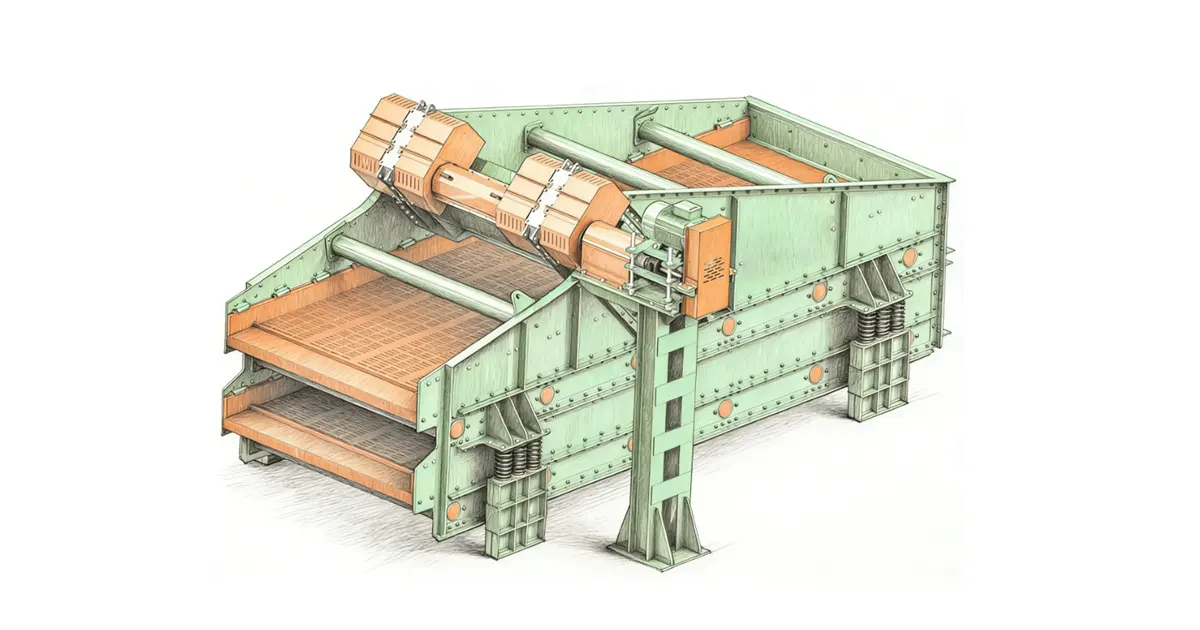

Integration with Vibrating Equipment

You might wonder how self-cleaning screens work with vibrating equipment. This is a key part of making your screening process smooth and efficient. Vibrating equipment helps your self-cleaning screens shake off stuck material. You get better results and less downtime.

When you use vibrating machines, the screens move quickly. This movement keeps the wires flexing and bouncing. Stuck pieces fall off because the vibration breaks up clumps and pushes them through the openings. You do not have to stop and clean the screens by hand. The machine does the hard work for you.

Let’s look at how this works in practice:

- Continuous Motion: The screen vibrates all the time. You see fewer blockages and more material passing through.

- Automatic Cleaning: The vibration knocks off sticky or wet bits. You do not need to pause your work.

- Better Sorting: The shaking action helps separate materials by size. You get more accurate results.

Tip: If you want to boost your screening speed, pair your self-cleaning screens with a vibrating machine. You will notice a big difference in how much you can process.

You can use vibrating equipment in many industries. Mining, construction, and recycling all benefit from this setup. You get faster sorting and less waste. Your machines run longer without problems.

Here’s a simple table to show what you gain when you combine self-cleaning screens with vibrating equipment:

| Benefit | What You Get |

|---|---|

| Less Clogging | Material moves off the screen faster |

| Higher Efficiency | More material sorted in less time |

| Lower Maintenance | Fewer stops for cleaning |

| Longer Screen Life | Less wear and tear on wires |

You do not need special skills to set up vibrating equipment with your screens. Most machines come with easy controls. You can adjust the speed and strength of the vibration. This lets you match the settings to your material type.

Some screens work best with gentle shaking. Others need strong vibration to clear tough clogs. You can test different settings to find what works for you. If you handle sticky or wet materials, try a higher vibration level. Dry materials may need less shaking.

Note: Always check your equipment for loose bolts or worn parts. Regular checks keep your system safe and working well.

You can see that integrating self-cleaning screens with vibrating equipment makes your job easier. You spend less time fixing problems and more time getting work done. Your screening line stays productive, and you get better results every day.

Benefits of Self-Cleaning Filters

Reduced Downtime

You know how frustrating it feels when your machines stop because of clogged screens. With self-cleaning filters, you spend less time waiting and more time working. These filters keep your system running by removing stuck material on their own. You do not need to pause for manual cleaning. This means your production line keeps moving, and you avoid costly delays. When you use self-cleaning filters, you can trust that your filtration process will not slow down. Less downtime means you finish jobs faster and keep your team happy.

Tip: If you want to boost your output, try switching to self-cleaning filters. You will notice fewer stops and smoother operations.

Improved Screening Efficiency

Self-cleaning filters help you get better results from your screening process. They use smart designs and steady movement to keep the screen surface clear. This leads to higher cleaning efficiency and better separation of materials. You get more usable product and less waste.

Here’s a quick look at how self-cleaning filters improve your screening efficiency:

| Parameter | Result |

|---|---|

| Optimized Screening Efficiency | 90.1% |

| Screen Surface Load | 39.6 N |

| Key Operating Parameters | Vibration frequency, amplitude, direction angle |

| Method Used | DEM-MFBD co-simulation model |

You can see that self-cleaning filters can reach over 90% efficiency. They also help lower the moisture in finished sand from 15%-20% to below 8%. You recover more than 90% of fine sand, and you use 30% less energy for drying. That means you save money and get better results at the same time.

- You get drier finished sand, which is easier to handle.

- You recover more fine material, so you waste less.

- You use less energy, which lowers your costs.

Lower Maintenance Costs

When you use self-cleaning filters, you do not have to clean or fix your screens as often. These filters remove stuck material by themselves, so you spend less on repairs and spare parts. You also avoid the need for frequent shutdowns, which saves you money and keeps your filtration system working longer.

- You clean less often, so you save on labor and parts.

- You avoid long shutdowns, which keeps your production line moving.

- High-quality self-cleaning filters, like flip-flow screens, stop clogging and blinding, so you do not need to replace screens as much.

If you want to lower your maintenance bills, self-cleaning filters are a smart choice. They help you keep your filtration system in top shape without extra effort.

Extended Screen Life

You want your screening equipment to last as long as possible, right? That’s where self-cleaning screens really shine. When you use these screens, you get more than just better performance—you also get a much longer service life. Let’s talk about why that happens and what it means for you.

First, self-cleaning screens use smart designs that help them avoid the usual problems. Regular wire mesh screens often get clogged or plugged up with sticky or wet material. When that happens, you have to stop your machines and clean them out. All that stopping and starting wears out your screens faster. Self-cleaning screens, on the other hand, keep material moving and shake off anything that tries to stick. This means less stress on the wires and fewer chances for damage.

You might wonder just how much longer these screens last. Here’s what you can expect:

- Self-cleaning screens can last up to three times longer than standard wire mesh screens.

- Polyurethane screens add even more life because they flex instead of breaking. This flexibility helps them handle tough jobs without wearing out.

- The special design of self-cleaning screens stops clogging and plugging, which means less wear and tear over time.

- Triangular-pattern self-cleaning screens have a service life three times longer than common mining screens. You can use them in many industries, so they’re a smart investment.

When you use screens that last longer, you save money. You don’t have to buy new screens as often, and you spend less time changing them out. That means your machines keep running, and you get more work done every day.

Tip: If you want to cut down on replacement costs and keep your operation running smoothly, try switching to self-cleaning screens. You’ll notice the difference in both performance and screen life.

Let’s look at some reasons why self-cleaning screens last longer:

- Less clogging means less pressure on the wires.

- Flexible materials like polyurethane bend instead of snapping.

- Special patterns, like triangular designs, spread out the force so no one spot wears out too fast.

- You spend less time stopping for repairs, so your screens don’t get damaged from frequent handling.

You can see that self-cleaning screens are built to go the distance. They handle tough jobs, keep your material moving, and save you money in the long run. If you want screens that work hard and last, self-cleaning options are the way to go.

Limitations and Considerations

Material Suitability

Not every material works well with self-cleaning screens. You need to match the screen type to what you are sorting. Some materials move better on certain screens. Here are a few options you might see:

- Polyurethane screens work best for wet jobs and dewatering. They handle water and sticky material well.

- Rubber screens are great for dry, high-impact jobs. They also do a good job with wet screening, especially for natural sand and gravel.

- Hybrid screens mix different materials. You get the benefits of both, which helps when you need extra strength or flexibility.

Self-cleaning screen mesh does a great job with wet and moist materials. You will see these screens used a lot in mining and quarry work.

If you use the wrong screen for your material, you might not get the results you want. Always check what you are sorting before you choose your screen.

Wear and Tear

You want your screens to last, but even the best ones wear out over time. When you use self-cleaning screens all day, you might notice a few common problems:

- Clogging can still happen if you push too much material through at once.

- Parts like the mesh, drive pieces, and bearings wear down with lots of use.

- Screening might not work as well if parts start to wear out.

- Sometimes, the screen can get out of line, which makes it work less smoothly.

- Rust and corrosion can show up if you use the screens in harsh places.

If you spot these issues early, you can fix them before they cause bigger problems. Regular checks help you keep your screens running longer.

Maintenance Needs

Taking care of your self-cleaning screens is important if you want them to last. You do not need to do anything fancy, but you should follow a simple schedule. Here is a handy table to help you remember what to do and when:

| Maintenance Frequency | Recommended Tasks |

|---|---|

| Daily | Clean screen decks, remove dust from motor housings, check mesh tension, inspect bolts, lubricate bearings |

| Weekly | Inspect drive belts, validate vibration amplitude, check seals, assess chute wear |

| Monthly | Conduct thorough inspections of components, validate performance metrics |

| Annual | Perform structural inspections, test spring assemblies, replace key components, full alignment check |

If you stick to this routine, you will get the most out of your screens. You will also notice fewer breakdowns and better results. Many people who use automatic self-cleaning filtration systems find that regular care makes a big difference.

Tip: Make a checklist for your team. When everyone knows what to do, your screens will stay in top shape.

Application Guidance

Choosing the right self-cleaning screen can feel tricky, but you can make it simple by following a few clear steps. You want your screening system to work well and last a long time. Here’s how you can pick the best screen for your job:

- Understand Your Facility’s Requirements

Start by looking at your own facility. What kind of place do you have? Is it a busy mining site, a recycling plant, or a construction yard? Think about how much material you need to move each hour. Check the type of debris you deal with—rocks, sand, wet clay, or something else. When you know these details, you can match your needs to the right screen. - Know the Types of Screens Available

You have a few choices. Fixed bar screens stay in one place and work well for steady jobs. Self-cleaning screens use smart designs to shake off stuck pieces. Traveling bar screens move along the material flow and clean themselves as they go. Learn what each type does best. This helps you pick the one that fits your work style. - Check Material and Construction

Look at what the screen is made of. Some screens use high-carbon steel for strength. Others use stainless steel or polyurethane for tough, wet jobs. Ask yourself, “Will this screen last in my work area?” If your site is rough or has lots of water, pick a screen that can handle it. You also want a screen that does not need a lot of fixing. - Think About Installation and Space

Measure your space before you buy. Make sure the screen fits where you want to put it. You need room to get to the screen for cleaning or repairs. If your area is tight, look for a compact design. Easy access means you can keep your screen working without trouble.

Tip: Write down your answers to these four steps before you shop. You will save time and avoid mistakes.

Here’s a quick table to help you compare your options:

| Step | What to Ask Yourself |

|---|---|

| Facility Requirements | What do I need to screen? How much? |

| Screen Types | Which type matches my process? |

| Material & Construction | Will it last in my environment? |

| Installation & Space | Does it fit? Can I reach it easily? |

When you follow these steps, you set yourself up for success. You get a screen that works well, lasts longer, and keeps your operation running smoothly. If you ever feel unsure, talk to a screen expert. They can help you match your needs to the perfect self-cleaning screen.

Comparing Self-Cleaning Screens to Other Screen Types

Woven Wire vs. Self-Cleaning Screens

You might wonder how self-cleaning screens stack up against regular woven wire screens. Let’s break it down. Woven wire screens are common in many industries. They do a good job at first, but they can clog up fast, especially with fine or sticky material. When this happens, you have to stop and clean them by hand. That means more downtime and less work done.

Self-cleaning screens use smart designs to keep material moving. They shake off stuck pieces and keep the holes open. This helps you keep your filtration system running without many stops. You get steady flow and less mess.

Here’s a table to show you the main differences:

| Feature | Self-Cleaning Screens | Woven Wire Screens |

|---|---|---|

| Clogging Resistance | Designed to be self-cleaning, reduces clogging | Prone to clogging, needs frequent cleaning |

| Throughput | Keeps flow rates steady | Flow drops as clogging builds up |

| Cleaning Efficiency | Less manual cleaning, fewer backwashes | Needs more cleaning by hand |

You can see that self-cleaning screens help you save time and keep your filtration line moving. Woven wire screens may slow you down if you deal with tough materials.

PU-Mesh and Urethane Panels Comparison

You may also see PU-mesh and urethane panels used for screening. These screens use strong plastic materials. They work well for heavy-duty jobs and last a long time. PU-mesh screens flex and bounce, which helps them handle tough loads. Urethane panels resist wear and tear, so you do not need to replace them often.

Self-cleaning screens stand out because they keep your filtration system clear. PU-mesh and urethane panels can still clog if you use them with sticky or wet material. You might need to clean them by hand sometimes. If you want less maintenance and more uptime, self-cleaning screens are a smart choice.

Tip: If you handle lots of wet or sticky stuff, self-cleaning screens can save you time and effort.

Choosing the Right Screen

Picking the best screen for your job can feel tricky. You want a screen that fits your needs and keeps your filtration system working well. Here are some things to think about:

- Check your work environment. Is it dusty, wet, or hot?

- Think about the size and type of material you need to sort.

- Decide if you need a screen that can handle touch or special controls.

- Look at how you will mount the screen. Will it fit your setup?

- Make sure the screen connects to your machines.

- Pick a screen that can handle tough jobs and last a long time.

- Watch how much power the screen uses.

If you follow these steps, you can find a screen that works best for your filtration needs. You get better results and spend less time fixing problems.

Note: Always match your screen to your material and work site. This helps you get the most out of your filtration system.

Practical Tips for Using Self-Cleaning Screens

Selection Factors

Choosing the right self-cleaning screen can make your work much easier. You want to match the screen to your material and your equipment. Here are some things to keep in mind:

- Check the size and type of material you need to sort. Some screens work better with fine sand, while others handle large rocks.

- Look at your work environment. Wet, sticky, or dusty places may need special screen coatings or materials.

- Think about how often you need to change or clean the screen. If you switch jobs a lot, modular screens can save you time.

- Make sure the screen fits your machine. Measure carefully and check the manufacturer’s guide for the right size.

Tip: Write down your needs before you buy. This helps you pick a screen that lasts longer and works better.

Installation and Tensioning

Getting the installation right is key for good performance. If you rush this step, you might see more wear or even damage. Here’s a simple step-by-step guide:

- Read the manufacturer’s instructions. Every screen is a little different, so follow their steps.

- Before you start, check the screen’s size with a laser rangefinder. Make sure it fits within a 1.5mm tolerance.

- Lay the screen flat and look for dents. Indentations should not go over 0.3mm per square meter.

- Use the center-and-spoke method. Fix the center first, then work outward. This keeps the tension even.

- Tighten the inner clamp rail bolts first, then the outer ones. The screen should feel tight, like a drum.

- Do a string test. Run a string across the screen to check for gaps between the screen and support bars. Adjust if needed.

- After installation, run a no-load vibration test. Make sure the screen moves evenly.

- Set up a maintenance plan. Check the tension and look for wear at least once per shift.

Note: Uniform tension keeps the screen from whipping or getting damaged. Never run your machine with sections missing.

Maximizing Performance

You want your self-cleaning screens to last and work well every day. Here are some easy ways to get the most out of them:

- Clean the screen surface often with a soft, lint-free cloth. This stops dirt from building up and keeps the cleaning action strong.

- Handle the screens gently. Avoid using gloves that might scratch or damage the surface.

- Adjust the sensitivity settings if your screen has touch controls. This helps prevent accidental inputs.

- Calibrate your screens on a regular schedule. This keeps everything working smoothly.

- Check for proper tension and support. If you see sagging or gaps, fix them right away.

- Don’t forget your maintenance plan. Regular checks and cleaning help your screens last longer and work better.

Tip: A little care goes a long way. With the right setup and cleaning routine, your self-cleaning screens will keep your operation running smoothly.

Conclusion

You now know how self-cleaning screens help you sort materials faster and with less hassle. These screens keep your machines running and cut down on cleaning time. If you want to boost your screening line, think about switching to self-cleaning technology. Need help picking the right screen? Reach out to ANPENG for expert advice and the best options for your job.

FAQ

What materials can you use with self-cleaning screens?

You can use self-cleaning screens with sand, gravel, rocks, coal, and even wet or sticky materials. These screens work well in mining, construction, and recycling.

How often do you need to clean self-cleaning screens?

You do not need to clean them by hand very often. The screens shake or move to clear themselves. You should still check them during regular maintenance.

Can you install self-cleaning screens on any machine?

Most machines can use self-cleaning screens. You just need to pick the right size and type for your equipment. Always check the manufacturer’s guide.

Do self-cleaning screens cost more than regular screens?

Self-cleaning screens usually cost more at first. You save money later because you spend less on repairs, cleaning, and downtime.

How long do self-cleaning screens last?

These screens can last two to three times longer than regular wire mesh screens. Flexible designs and special materials help them handle tough jobs.

Will self-cleaning screens work with wet materials?

Yes! Self-cleaning screens work great with wet, sticky, or muddy materials. The special wire patterns and vibration keep the screen clear.

What should you do if your screen still clogs?

If your screen clogs, check for damage or wrong tension. Clean it gently and make sure you use the right screen for your material. Ask an expert if you need help.

Are self-cleaning screens hard to install?

You can install them easily if you follow the instructions. Use the right tools and check the tension. If you need help, ask your supplier for tips.