Are you curious about how a double deck screen works? There are two screens stacked on top of each other. These screens sort things by their size. The top screen holds the biggest pieces. The middle screen keeps the medium pieces. The bottom screen lets the smallest pieces fall through. Vibration helps move the material across each screen. There are many discharge ports that send out the sorted pieces. The double deck screen working principle uses these parts to separate things fast and correctly. Each screen helps make sorting easier and quicker, so you always get the right size.

Key Takeaways

- Double deck screens sort things by size with two screens stacked together. The top screen keeps big pieces. The bottom screen catches medium and small pieces.

- Vibration is very important for sorting. It helps move things across the screens. It also stops blockages and keeps the machine working well.

- You can change the screen’s angle and vibration settings. This helps sort different materials better. It makes the machine work more accurately.

- Double deck screens can be used for many things. They can sort sand, clay, and waste. This makes them useful in many industries.

- Regular maintenance is needed for the best performance. Check the screen every day for damage. Clean it to stop clogs. Lubricate moving parts.

- Picking the right sieve plate material is important. Wire mesh works well for light jobs. Polyurethane panels are better for tough or wet materials.

- Double deck screens save time by sorting more material faster than single-deck screens. They can be over 96% accurate.

- Safety is very important when using double deck screens. Always follow the manufacturer’s rules. Wear safety gear and keep the work area clean.

Double Deck Screen Overview

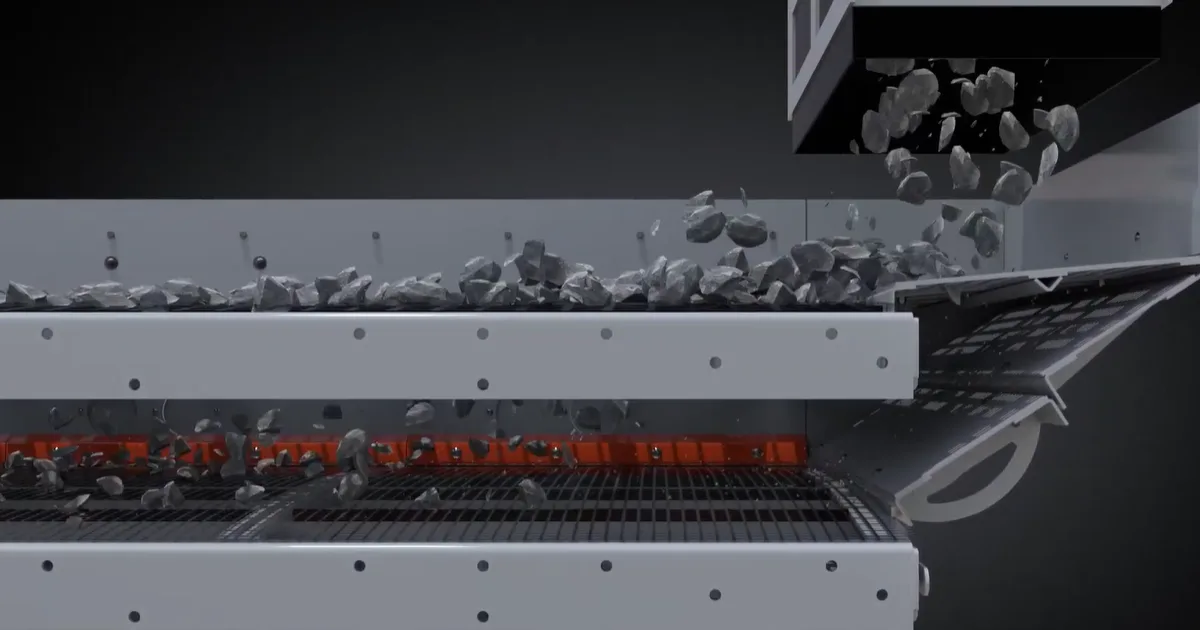

What Is a Double-Deck Vibrating Screen

A double-deck vibrating screen is a machine that sorts things by size. It has two decks, one on top of the other. Each deck has its own mesh or panel. You put material on the top deck first. The screen shakes to help sort the pieces. The biggest pieces stay on the top deck. The smallest pieces fall through to the bottom. You get three groups: large, medium, and small.

You might want to know how this is different from other screens. Here is a simple table:

| Feature | Double Deck Vibrating Screen | Other Industrial Screens |

|---|---|---|

| Screening Process | Keeps sorting materials by size all the time | Some screens do not work all the time |

| Material Handling | Can grade, dewater, and remove small bits | Depends on the type of screen |

| Sieve Plate Material | Uses stainless steel and polyurethane for more openings | Other screens may not have as many openings |

| Weight and Energy Efficiency | Light design uses less energy | Heavy screens can use more energy |

| Maintenance | Small parts are easy to change | Some screens are harder to fix |

Key Components

A double-deck vibrating screen has many important parts. Each part helps with sorting.

Upper Deck

The upper deck is where you put the material first. It has the biggest holes. The largest pieces stay here. These pieces move across and leave through a port. The upper deck lets you sort more material at once.

Lower Deck

The lower deck is under the upper deck. It has smaller holes. Medium pieces stay here. The smallest pieces fall through. The lower deck helps you get smaller pieces. You can collect medium and small pieces from different ports.

Vibration Mechanism

The vibration mechanism makes the screen shake. This shaking spreads out the material. It helps the pieces touch the mesh at the right angle. The shaking keeps the material moving. Some screens shake in a straight line. Others use strong shaking for better sorting. You can change the shaking to fit your needs.

Tip: The vibration also stops the screen from getting blocked. It keeps things moving, so you do not need to clean the screen as much.

Typical Configurations

Double-deck vibrating screens come in many shapes and sizes. Most have two layers of panels. This helps you sort material into two or three groups. Some screens have special features, like changing the angle or using different mesh.

| Configuration Type | Description |

|---|---|

| Double Deck Screens | These screens have two layers. They help you sort materials into two groups by size. |

You can use a double-deck vibrating screen to grade, remove water, or get rid of tiny pieces. The design makes it easy to change parts and settings. If you need to sort a lot of material fast and well, this screen works great.

Double Deck Screen Working Principle

How Screens Work

When you see a double deck screen, you might wonder how it works. The double deck screen working principle uses vibration and two layers of mesh to sort things by size. First, you put the material on the top deck. The screen starts to shake. This shaking helps the pieces move and split up. The biggest pieces stay on the top deck. Medium pieces drop down to the lower deck. The smallest pieces fall through to the bottom. Each deck does its own job. The vibration keeps everything moving and stops the holes from getting blocked.

Here is an easy step-by-step look at how the double deck screen works:

- Put the material on the upper deck.

- The screen shakes, so the pieces move and spread out.

- The mesh lets smaller pieces fall through the holes.

- Big pieces stay on top, while medium and small pieces go to the next deck or out the bottom.

Tip: How fast and strong the screen shakes is important. If it shakes too slowly, pieces can block the holes. If it shakes too fast, sorting may not be accurate. You can change the settings to match your material.

Material Flow and Separation

The double deck screen working principle makes sorting easy. You get three groups: large, medium, and small. The screen uses shaking and mesh size to separate everything.

Coarse Particle Removal

The top deck handles the biggest pieces. When you put material on the screen, the largest chunks stay on the upper mesh. The shaking helps these pieces move across the deck. They leave through a special port. This step keeps your process clean and stops big pieces from mixing with smaller ones.

Fine Particle Sorting

The lower deck takes care of medium and small pieces. Medium pieces land on the lower mesh. The smallest bits fall through to the bottom. The screen working principle lets you collect each size from a different spot. You get clean, sorted material every time.

| Screen Type | Screening Efficiency (%) | Variance | Range of Variation (%) |

|---|---|---|---|

| Single-deck | 56.7 | 83.78 | 38 |

| Double-deck | 61.9 | 23.69 | 21 |

You can see double deck screens work better than single-deck screens. They sort more material and keep the process steady. If you use a double deck screen, you get better results almost every time.

Discharge Ports and Product Streams

The double deck screen working principle uses special discharge ports. Each port sends out a different size of material. You collect large, medium, and small pieces from separate spots. This setup keeps your products clean and ready for the next step.

But there are some problems you might face. Sticky materials can stick to the walls. Sometimes, the flow is not smooth. Dust can escape and cause trouble. You need to keep everything sealed and safe. Workers must watch for safety risks, like lifting heavy things or standing in awkward ways. If you handle harmful stuff, you need good containment. Cleaning between batches helps stop mixing.

| Challenge Type | Description |

|---|---|

| Clinging materials | Sticky materials that stick to container walls and make discharge harder. |

| Segregation of blends | Different particle types can make product quality change during discharge. |

| Flow inconsistencies | Uneven flow can mess up material metering and cause mixing. |

| Operator safety risks | Workers can get hurt from lifting heavy things or standing in bad positions. |

| Material containment | Bad sealing can cause spills, especially with harmful stuff. |

| Dust control | Dust can be dangerous to breathe and can cause explosions when moving material. |

| Electrostatic charge build-up | Static electricity can start fires if dust is dry and easy to burn. |

| Environmental concerns | You need good containment to stop material from getting into the environment. |

| Regulatory compliance | You must follow safety and environmental rules all the time. |

| Time constraints | Delays can happen when connecting and disconnecting containers. |

| Labor requirements | Workers often need to help, which makes the process harder. |

| Product waste | Not emptying containers all the way can waste material, especially sticky products. |

| Cross-contamination risks | Cleaning between batches can slow things down, especially for sensitive jobs. |

The double deck screen working principle helps you deal with these problems. You can change the shaking, mesh size, and angle to fit your needs. Aggregate screens sort and clean material, making your process smoother.

If you look at different industries, you can see how double deck screens handle big jobs.

Screening Process Details

Material Feed

When you use aggregate screening equipment, you must watch how you add material. If you put too much on the screen, it can get blocked. This makes it hard for pieces to separate. If you add too little, you do not use the screen well. You should keep the feed steady and controlled. This helps the screen work its best and gives you clean, sorted material every time.

Tip: Always check how fast you add material. A steady flow keeps your aggregate screening equipment working well. It also helps stop problems like blocking or not using the screen enough.

Vibration and Movement

Vibration is very important for every screen. When you turn on your aggregate screening equipment, vibration moves the material across the decks. You can change how strong and fast the vibration is. If you have fine materials, high-frequency vibration helps remove the smallest pieces quickly. This makes the screen work better and helps more fine pieces fall through.

A mix of high frequency and low amplitude works best for fine materials. Big pieces bounce higher, but small ones stay close to the mesh. This setup helps you sort everything faster and more correctly. You can change the vibration settings for your material. This makes aggregate screening equipment good for many jobs.

Wet and Dry Screening Applications

You can use a screen for wet or dry jobs. Dry screening works well for free-flowing materials and does not need water. It costs less and works faster. But you need to control dust because dry screening can make a lot of it.

Wet screening is different. You use water to help separate sticky or wet materials. This method cleans the material better and removes fine pieces more easily. Wet screening is great for clay or mud, but you must handle and treat the water after. This means more work for your aggregate screening equipment.

Here’s a quick table to help you compare:

| Method | Best For | Advantages | Considerations |

|---|---|---|---|

| Dry | Free-flowing materials | Lower cost, faster processing | Dust control needed |

| Wet | Sticky or moist materials | Better cleaning, fine removal | Water treatment required |

If you work with sticky materials, wet screening gives you cleaner results. If you want to save money and work fast, dry screening is better. Your choice depends on the material and what you want. No matter what, the right screen and aggregate screening equipment help you finish the job.

Design Features

When you look at a double deck screen, you notice how each part helps you sort material better. The design features make your screen work harder and last longer. Let’s break down what matters most.

Sieve Plate Materials

You can choose from different sieve plate materials for your screen. Each type has its own strengths.

Wire Mesh

Wire mesh is a classic choice for many screens. You get good visibility and fast sorting. The mesh lets small particles fall through easily. If you want a lightweight option, wire mesh works well. You can clean it quickly, and it handles dry materials with no trouble.

Polyurethane Panels

Polyurethane panels give your screen extra toughness. These panels resist wear and last longer than wire mesh. If you deal with sharp or heavy materials, polyurethane keeps your screen working. You also get less noise and smoother movement. Cleaning is easy, and panels handle wet jobs without breaking down.

Perforated Plates

Perforated plates offer strength and stability. You see these plates in screens that handle big, rough materials. The holes come in many shapes and sizes. If you want to sort large chunks, perforated plates help your screen stay strong. You can use them for heavy-duty jobs and get reliable results.

Tip: Pick the sieve plate material that matches your job. If you switch between wet and dry screening, try polyurethane panels for longer life.

Deck Construction

Building a strong deck makes your screen last longer and work better. You want each level to do its job. The top deck sorts big pieces. The lower deck handles medium and small ones. You need easy access between decks, so you can clean and fix things fast.

Here are some things to think about when you build your screen deck:

- Make sure each deck has a clear purpose.

- Keep traffic flow smooth between levels.

- Follow local rules and codes.

- Choose materials that match your building.

- Use designs that fit your space.

- Think about sun and shade for comfort.

- Add privacy screens if needed.

- Put in railings and lights for safety.

- Plan for great views and focal points.

- Add built-in features for more use.

- Pick materials that need little care.

- Set your budget early.

- Ask experts for help.

- Use eco-friendly materials.

- Plan for future changes.

If you follow these steps, your screen deck will work well and stay safe.

Screen Angle and Settings

The angle of your screen changes how well it sorts material. You can adjust the angle to fit your needs. Lower angles help easy-flowing materials. Higher angles work for sticky or tough materials.

Here’s a quick table to show how angle affects your screen:

| Angle Range | Description |

|---|---|

| Low Angles (10-15 degrees) | Good for materials that move easily and need little shaking. |

| Moderate Angles (15-20 degrees) | Balances speed and sorting power. |

| High Angles (20-25 degrees) | Best for sticky or hard-to-sort materials. |

You can also change the drum angle. Lower angles give material more time on the screen, so you get better sorting. Higher angles move material off the screen faster. If you want the best results, check your material and adjust the frequency, amplitude, and angle. Keep an eye on your screen and make changes as needed.

Note: Changing the screen angle changes how material travels. This helps you get the most out of your screen and keeps your sorting process smooth.

Benefits and Efficiency

Throughput and Accuracy

You want your screening to be quick and correct. Double deck screens help you do both things. These screens let you sort more material in less time. You can split materials into three or four groups at once. This design makes you work two or three times faster than single-deck screens. The decks are stacked, so you get a bigger area for screening. You do not need extra space on the floor, but you still make more material.

- Double deck screens sort everything in one go.

- You get two or three times better results than single-deck screens.

- Stacked decks give you more room to screen.

- You can handle more material without needing more space.

Getting the right size matters too. Double deck vibrating screens can be over 96% correct. You always get clean, sorted pieces. You do not have to worry about mixing sizes or missing anything.

Tip: If you want to sort faster, try changing how much the screen shakes and how quickly you add material. Even small changes can help a lot.

Versatility for Materials

Double deck screens work for many kinds of materials. These screens can handle sand, trash, or even shredded tires. You do not need a new screen for every job. Just switch the mesh or panel, and you are ready.

- Manufactured sands

- Chips

- Agricultural lime

- High-moisture stuff (like silt, mud, and clay)

- Incinerator ash

- Trash and waste coal

- Clay and sand

- Slag and compost

- Leafy things and wood waste

- Peat moss

- Auto shredder fluff

- Shredded tires and roofing shingles

- Construction and demolition waste

- Refuse-derived fuel

You can use these screens for dry or wet jobs. You can sort sticky, wet, or dusty materials. Double deck screens work for almost anything you need.

Note: If you use tough materials, try polyurethane panels. They last longer and can hold heavy stuff.

Industrial Applications

Double deck screens are used in many industries. You see them in mining, recycling, and building. Each screen type does a special job. Some screens help remove water. Others sort tiny pieces or handle sticky stuff.

| Type of Screen | Application Description |

|---|---|

| Double Deck Dewatering Screen | Removes water well with two decks. |

| Double Deck High-Frequency Screen | Sorts better and finer with two layers. |

| Double Deck Banana Screen | Works faster and sorts more with a banana shape. |

| Double Deck Inclined Screen | Separates and grades better with two layers. |

| Double Deck Horizontal Screen | Splits sizes, good for dry jobs. |

| Double Deck Gyratory Screen | Handles more and sorts better with two layers. |

| Double Deck Flip-Flow Screen | Good for sticky or tiny stuff with two layers. |

Pick the screen that fits your job. If you need to sort wet sand, use a dewatering screen. If you have sticky trash, try a flip-flow screen. Double deck screens help you get the results you want in any industry.

Tip: Always pick the best screen for your material and job. This saves time and gives you better results.

Maintenance and Operation

Inspection and Care

You want your double deck screen to work well every day. Checking and caring for it keeps it in good shape. Here is an easy checklist you can use:

- Inspect the Vibrating Screen Mesh

Look for any damage or worn spots. If you see holes or rips, change the mesh. - Clean the Screen

Take off dust and dirt. Cleaning stops clogs and helps the screen work fast. - Lubricate Moving Parts

Put oil or grease on the bearings and joints. This makes parts move easier and last longer. - Tighten and Adjust Components

Check all bolts and fasteners. Tighten anything loose. Change settings if you hear odd sounds or see strange moves. - Monitor Performance

Use sensors to watch how your screen works. Look for slow speed or bad sorting. Checking often helps you find problems early.

Tip: Make a schedule for checking your screen. This helps you stop big problems and keeps your screen working well.

Common Issues

You may have some problems with your double deck screen. Knowing what to watch for helps you fix things fast.

- Sticky stuff can block the mesh.

- Vibration may feel weak or not even.

- Bolts and fasteners can get loose.

- Loud noise can make work hard.

- Sorting may not work as well as before.

If you see these problems, fix them right away. Clean the mesh, check the vibration, and tighten all bolts. Sometimes, you need to change old parts. You can also use tools to make the screen quieter and safer.

| Problem | Quick Fix |

|---|---|

| Blocked mesh | Clean or change mesh |

| Weak vibration | Change the settings |

| Loose bolts | Tighten the bolts |

| High noise | Use noise control tools |

| Poor sorting | Check mesh and vibration |

Note: Checking your screen often stops most problems from getting worse.

Safety Practices

You want everyone to be safe near your double deck screen. Good safety steps protect you and your team.

- Always follow the maker’s rules for using the screen.

- Wear ear protection if it gets loud.

- Use gloves and safety glasses when you check or clean the screen.

- Keep the area around the screen neat and clear.

- Turn off the machine before you do any work on it.

- Teach your team how to be safe and what to do in an emergency.

- Use tools to lower vibration and noise for a better workspace.

- Check your screen often to stop surprise problems.

Safety comes first! A clean screen and careful team keep your work going well.

Conclusion

You can sort things quickly and correctly with double deck screens. These machines have two decks and use shaking to split materials by size. You can move more material in less time. Double deck screens are used in mining, building, and recycling because they do two things at once.

Tell what material you have, the sizes you want, how wet it is, how much you need to sort, the screen model, deck size, and how you will set it up.ANPENG makes industrial screen mesh and can help you pick the right one. Ask them for expert help or a special screen made just for you.

FAQ

What is the main job of a double deck screen?

You use a double deck screen to sort materials by size. The top deck keeps big pieces. The lower deck catches medium ones. The smallest bits fall through to the bottom.

How do I know which sieve plate material to choose?

Pick wire mesh for light jobs. Use polyurethane panels for tough, wet, or sticky stuff. Try perforated plates for heavy-duty work.

Tip: Match the plate to your material for best results.

Can I use a double deck screen for wet materials?

Yes, you can. Wet screening works well for sticky or moist materials. Water helps clean and separate the pieces.

Note: You need to treat the water after screening.

How often should I check my screen for problems?

Check your screen every day before you start work. Look for damage, loose bolts, or blocked mesh. Regular checks help you catch issues early.

What should I do if my screen gets blocked?

Stop the machine. Clean the mesh with a brush or air. Remove any stuck material. Start the screen again when it looks clear.

Is it safe to work near a double deck screen?

You stay safe by following the maker’s rules. Wear ear protection and gloves. Keep the area clean. Turn off the machine before you fix or clean anything.

How do I change the screen angle?

Find the adjustment bolts on your screen. Loosen them. Tilt the screen to the angle you want. Tighten the bolts again.

Tip: Lower angles help easy-flowing materials. Higher angles work for sticky stuff.

What industries use double deck screens?

You see double deck screens in mining, recycling, construction, and agriculture. These screens sort sand, gravel, trash, and more.