When you hear mesh size vs particle size, think about the screen on a window. Mesh size tells you how many tiny openings fit in one inch of that screen, while particle size measures how big each piece of material is. The higher the mesh number, the smaller the particles that squeeze through. Check out this table for quick definitions:

| Term | Definition |

|---|---|

| Mesh Size | Number of openings in one linear inch of screen; higher mesh means smaller openings. |

| Particle Size | Size of powder particles, usually given in microns (μm) or millimeters (mm). |

Why does this matter? If you work in industrial screening, knowing the difference helps you pick the right screen and avoid problems like blocked screens or uneven material flow. As particle size increases, properties like length and width can change a lot, affecting how well your process works.

Key Takeaways

- Mesh size shows how many holes are in one inch of a screen. If the mesh number is higher, the holes are smaller.

- Particle size tells us how big each piece of material is. It is usually measured in microns or millimeters.

- Knowing the difference between mesh size and particle size helps you pick the right screen for your material.

- Using the right mesh size stops problems like blocked screens and uneven flow when you process materials.

- You should always think about particle size distribution. It changes how materials act when you screen or filter them.

- Different industries use rules like ASTM E11 and ISO 3310. These rules make sure mesh size is measured the same way.

- When you choose a screen, think about the shape of the material, how wet it is, and how you want to separate it.

- Cleaning and checking screens often makes them work better and keeps product quality high. This also lowers waste and saves money.

Definitions

Mesh Size Explained

Mesh Count

When you look at a wire screen, you might wonder how people describe how fine or coarse it is. That’s where mesh count comes in. Mesh count tells you the number of openings in one linear inch of the screen. For example, if you see a “100 mesh” screen, that means there are 100 tiny openings in every inch. You can count these openings from the center of one wire to a point exactly one inch away. Mesh count is a big deal because it helps you know how fine the screen is and what kind of particles can pass through.

Tip: Mesh count and mesh size mean the same thing. Both describe the number of openings per inch.

Standards

You might ask, “How do I know if my mesh size matches what others use?” That’s where standards come in. Different industries use standards to make sure everyone talks about mesh size the same way. The most common standards are ASTM E11, ISO 565, and ISO 3310-1. These standards tell you how to measure the openings and what size ranges to expect.

Here’s a quick look at some important standards:

| Standard | Specification | Size Range |

|---|---|---|

| ASTM E11 | Technical requirements for sieve cloth and construction | 125mm to 20µm |

| ISO 565 | Nominal metric opening dimensions for woven-wire sieves | 125mm to 20µm |

| ISO 3310-1 | Tolerances and allowable standard deviations for sieves | Principal and supplementary sizes |

These standards help you compare screens from different suppliers and make sure you get the right fit for your job.

Particle Size Overview

Measurement Units

Now, let’s talk about particle size. Particle size tells you how big each piece of material is. People use different units to measure this, depending on how fine or coarse the material is. The most common units are microns (µm) and millimeters (mm). A micron is one-millionth of a meter, and a millimeter is one-thousandth of a meter.

Here’s a table to help you see the difference:

| Measurement Unit | Definition | Application |

|---|---|---|

| Micron (µm) | One-millionth of a meter (10⁻⁶ m) | Used for fine powders and precise measurements |

| Millimeter (mm) | One-thousandth of a meter (10⁻³ m) | Used for coarser materials |

| Mesh | Number of openings per inch | Classification standard based on sieving |

In liquid filtration, you might see a micron rating. This rating tells you the smallest particle size the filter can catch. A smaller micron rating means the filter can trap smaller particles. Mesh size works the opposite way—a higher mesh number means only smaller particles can pass through.

Distribution

You rarely find materials where every particle is the same size. Instead, you get a mix of big and small pieces. This mix is called particle size distribution. When you check the distribution, you see how many particles fall into each size group. This helps you understand how your material will behave during screening or filtering.

Note: Mesh size does not give you a precise measurement of particle size. The wires in the screen take up space, so the actual opening is a bit smaller than the mesh count suggests. Always check the size distribution to get a full picture of your material.

If you want your process to run smoothly, you need to know both the mesh size of your screen and the particle size distribution of your material. This way, you can pick the right screen and avoid problems like clogging or uneven flow.

Mesh Size vs Particle Size Comparison

Key Differences

Measurement Methods

You might wonder how people measure mesh size vs particle size. The answer is that each uses a different method. Mesh size uses a simple count. You count how many openings fit in one inch of a screen. This tells you how fine or coarse the screen is. You do not need fancy tools—just a ruler and a good eye.

Particle size uses other tools. You might use a microscope, a set of sieves, or even a laser. These tools help you find out how big each piece of material is. You measure the width or diameter of the particles. Sometimes, you get a range of sizes because not all particles are the same.

What Each Describes

Mesh size vs particle size describes two different things. Mesh size tells you about the screen or filter. It shows how many holes are in each inch. This helps you know what size of particles can pass through.

Particle size tells you about the material. It shows how big each piece is. You use this information to decide which screen to use. If your particles are too big, they will not pass through a fine mesh. If they are too small, they might slip through when you do not want them to.

Here is a quick table to help you see the difference:

| Feature | Mesh Size | Particle Size |

|---|---|---|

| What it measures | Screen openings per inch | Size of material pieces |

| How to measure | Count openings | Measure particle width |

| Units | Mesh count (#/inch) | Microns (µm), mm |

| Used for | Choosing screens | Describing materials |

Inverse Relationship

Mesh Number and Particle Size

When you look at mesh size vs particle size, you will notice an important pattern. As the mesh number goes up, the particle size that can pass through goes down. This is called an inverse relationship. It means that a screen with a high mesh number has tiny openings. Only small particles can fit through.

Let’s look at some examples:

- A -6 mesh screen has only 6 openings per inch. The holes are large. Big particles, like gravel, can pass through.

- A -325 mesh screen has 325 openings per inch. The holes are tiny. Only fine powder or dust can get through.

Tip: If you want to separate fine dust from sand, pick a screen with a high mesh number. If you want to remove big rocks, use a low mesh number.

You can see why mesh size vs particle size matters so much in screening. If you choose the wrong mesh size, you might let the wrong particles through. You could end up with clogged screens or poor product quality. Always match your screen to the particle size of your material.

Particle Size Measurement

Have you ever wondered how people measure the size of particles in things like sand or powder? In factories, there are a few main ways to do this. Each way has good points and bad points. Let’s look at the most common methods.

Sieving

Sieving is easy to imagine. You pour your material onto a stack of screens with different mesh sizes. Then you shake the stack. The biggest pieces stay on top. The smallest pieces fall to the bottom.

Here’s a simple table about sieving and what to watch for:

| Aspect | Description |

|---|---|

| How it works | You put a sample through screens with different mesh sizes. This sorts the particles by size. |

| Limitations | The shape of the particles can change the results. Sieving does not work well for very fine or sticky powders. |

| Sieve Diameter vs. True Size | Sieving checks if a particle fits through a hole. It does not measure the real size. This can be confusing. |

| Influence of Particle Shape | Odd shapes can make particles seem smaller than they are. |

| Lower Limit | Sieving does not work well for particles smaller than about 38 micrometers. |

| Cohesion and Agglomeration | Sticky or wet materials can clump together. This makes the results less correct. |

| Material Attrition | Shaking can break some particles. This creates more small pieces. |

| Sieve Blinding | Particles can get stuck in the mesh. This blocks other pieces from passing through. |

| Sampling Variability | Getting a good sample is hard. Small mistakes can change your results. |

| Resolution | Sieving gives you a rough idea. It does not show much detail for each size group. |

People use sieving in mining, building, and science labs. Standards like ASTM E11 and ISO 3310 help keep the results the same everywhere.

Laser Diffraction

Laser diffraction sounds fancy, but it is used a lot. You shine a laser through your sample. The particles scatter the light. The way the light spreads out tells you the size of the particles.

This method works for powders, slurries, and sprays. You will see it used in:

- Medicine

- Chemicals

- Food making

- Building materials

- Checking the environment

Laser diffraction gives you a detailed size distribution. It shows how many particles are in each size group. It is fast and works for many sizes. You might also hear about Dynamic Light Scattering (DLS). DLS is a similar method. DLS tells you the average size and how much the sizes change. This is called the polydispersity index.

Image Analysis

Image analysis uses cameras or microscopes to take pictures of the particles. Then, a computer measures each one. This method is good for odd shapes, like flakes or fibers.

Here is a table to compare image analysis with other methods:

| Method | Description |

|---|---|

| Image Analysis (IA) | Lets you see and measure particle size and shape. This is helpful for particles that are not round. |

| Laser Diffraction (LD) | LD matches well with IA data, especially for volume and area. |

| Correlation | If IA and LD agree, you can trust your results, even for tricky shapes. |

Image analysis gives you a number distribution. This means you know how many particles are in each size group. You might see results like D10, D50, and D90. These tell you the size below which 10%, 50%, and 90% of the particles fall.

Tip: For the best results, you need to check your tools. Particle size standards, like those from TSI®, help you make sure your equipment is correct. These standards are important in places like chip factories, where even tiny mistakes matter.

No matter which method you pick, knowing the size distribution helps you control your process and get the results you want.

Practical Implications

Filtration Efficiency

When you pick a screen for filtration, you want it to work well. Mesh size is very important here. The number of openings decides which particles stay out and which go through. If you choose the right mesh size, you block unwanted debris and let good material pass. Here are some things to remember:

- Mesh size decides what particles get filtered. If you need to catch fine sand or organic debris, pick a mesh that fits their size.

- Particles between 100 and 500 microns are hard to filter. These sizes can clog screens or slip through if the mesh is not exact.

- High-performance screens with multi-layer diffusion-bonded mesh have exact pore sizes. These screens block bigger particles and make filtration better.

Tip: If you match mesh size to your material, you avoid clogged screens and keep your process smooth.

Material Selection

Choosing the right screen material is not just about mesh size. You also need to think about what you are screening and how your process works. Look at this table for key things to consider:

| Factor | Description |

|---|---|

| Material Characteristics | The type of material changes which mesh size works best. |

| Particle Size and Distribution | Use sieve analysis to match mesh size to the particles you want to separate. |

| Moisture Content | Wet or sticky materials need coarser mesh or special screens to stop clogging. |

| Particle Shape and Density | Odd shapes may need bigger openings; dense materials might need more shaking. |

| Desired Separation and Throughput | Your goals decide if you need fine or coarse mesh for better separation. |

| Required Capacity | The amount you process each hour changes your screen size and mesh choice. |

Ask yourself these questions:

- What is the smallest particle you need to filter?

- Are you working with liquids or gases? Mesh size changes with the fluid.

- What are the temperature and pressure conditions? These affect how your screen works.

- Will your screen touch corrosive materials? If yes, pick stainless steel or titanium.

- How often will you clean or replace the screen? Finer meshes need more care.

Note: Picking the right mesh size early helps you remove unwanted particles, save energy, and lower equipment wear.

Specification Interpretation

Knowing mesh and particle size specs helps you make smart choices. Mesh size tells you how many openings are in each inch of your screen. For example, a -325 mesh means particles smaller than 44 microns can pass through. If you see a -40+100 mesh, it is for particles between 149 and 420 microns.

You will also see words like nominal and absolute micron retention ratings. The nominal rating shows the average size of particles that will not pass through. The absolute rating tells you the biggest particle size that can get through. Knowing the difference helps you pick the right filter.

As mesh number goes up, the openings get smaller. Higher mesh numbers let only smaller particles through. If you match your screen to your material’s size, you get better separation, higher product quality, and less waste.

Tip: Good screening means you use resources wisely and keep your operation running well.

Common Misconceptions

Mesh Size ≠ Particle Size

You might think mesh size and particle size mean the same thing. They don’t. Mesh size tells you how many openings are in one inch of a screen. Particle size describes how big each piece of material is. If you mix these up, you could pick the wrong screen for your job.

Here are some common mistakes people make:

- Believing that a higher mesh size always means better filtration. In reality, screens with very fine mesh can cause big pressure drops and use more energy.

- Ignoring the actual size of the openings. If you only look at mesh count and forget about the wire thickness, you might end up with poor fluid flow.

- Thinking that grinding materials into finer particles will always improve their properties. For example, crushing carbon into smaller pieces doesn’t increase its iodine value. The true iodine value comes from how the carbon is activated, not its size.

Note: Finer particles may seem to have better results during testing, but that’s just because their pores are easier to reach—not because their properties have changed.

Misreading Mesh Numbers

Mesh numbers can be confusing. You might see a screen labeled “325 mesh” and think it’s better than “40 mesh.” That’s not always true. The higher the mesh number, the smaller the openings. This means only tiny particles can pass through. If you choose a screen based only on mesh count, you could face problems like blocked screens or slow material flow.

Here’s a quick table to help you avoid mistakes:

| Mesh Number | Opening Size | What Passes Through | Common Use |

|---|---|---|---|

| 6 | Large | Gravel, big rocks | Mining, quarrying |

| 40 | Medium | Sand, small stones | Construction, recycling |

| 325 | Tiny | Fine powder, dust | Chemical, lab work |

Tip: Always check both the mesh number and the wire diameter. This helps you pick the right screen for your process.

Particle Shape Impact

You might think all particles act the same when you measure them. That’s not true. The shape of each particle changes how it moves through a screen. Cylindrical, flat, or odd-shaped particles can pass through openings in different ways. Sometimes, a long particle slips through sideways, even if it looks too big.

Irregular shapes can also mess with your measurements. If you have a batch of particles that are all about the same size, their random shapes and orientations can cause big differences in what you see. This is especially true when you use sieves or other tools that rely on particles fitting through holes.

Callout: Always remember that particle shape matters. If you ignore it, you might get results that don’t match what’s really happening in your process.

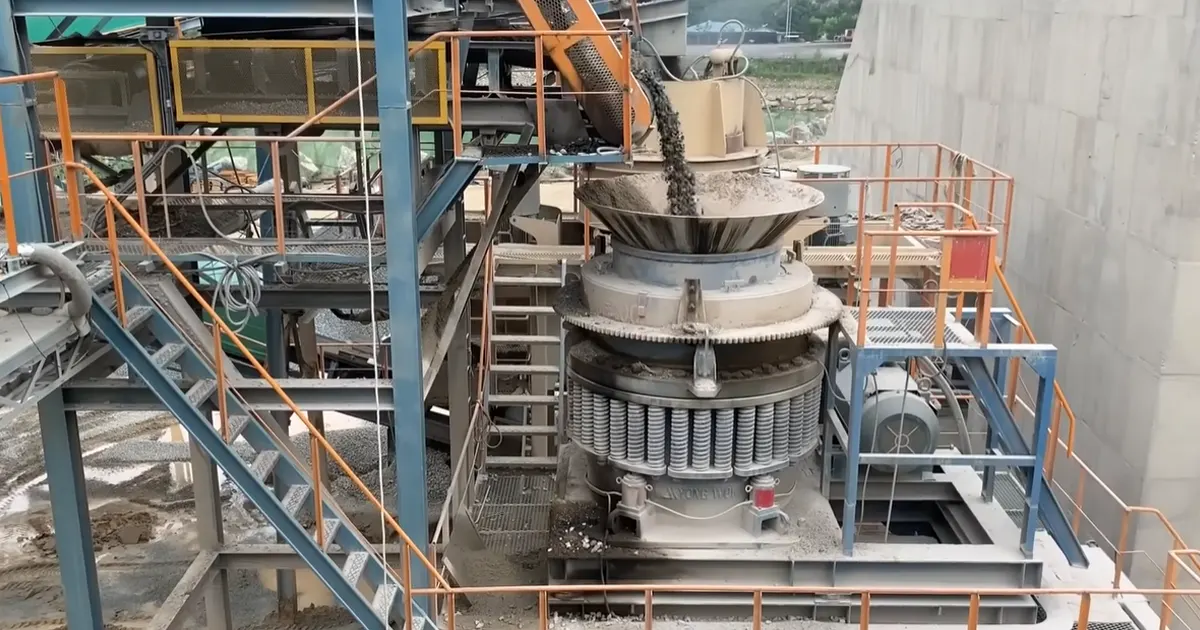

Industrial Screening Examples

Mining & Quarrying

When you work in mining or quarrying, you deal with big rocks and lots of dust. You need to separate materials by size to get the right product. Vibrating screens help you do this job. You pick the right screen media to make sure you get the best results.

Here’s how you can make screening work better in mining and quarrying:

- Choose the right screen media for the material you want to separate. This helps you get the right size every time.

- Check your equipment often. Regular maintenance keeps your screens working well and stops problems before they start.

- Measure how much of your material passes through the screens. If you see a high percentage, your screening is working well.

Tip: If you keep your screens clean and in good shape, you get more of the product you want and waste less.

Aggregate & Recycling

In aggregate and recycling plants, you need to sort crushed stone, sand, or recycled concrete into different sizes. You use vibrating screens with different mesh sizes to do this. Each mesh size lets through only certain sizes of material.

Here’s a table that shows how mesh size works in these plants:

| Mesh Size | Description |

|---|---|

| #4 | 80-100% passing |

| #8 | 65-90% passing |

| #200 | 5-15% passing |

You want most of your material to pass through the right mesh. For example, specialty crushed stone should have 80-100% passing through a #4 mesh. When you recycle concrete, you first crush it to about 3 or 4 inches. Then you crush it again to get the size you need for new projects.

- Specialty products need to be the same size every time.

- The first screen pass gets rid of big pieces.

- The next screens sort the material into smaller and smaller sizes.

Note: Clean material works better in new concrete or road projects. Removing metal and debris helps your screens last longer.

Media Selection

Picking the right screen media is a big deal. You need to think about what you are screening and how big the pieces are. Different screen types have different open areas and work better for some jobs than others.

- Choose a screen with small openings for fine materials.

- Use larger openings for bigger rocks or gravel.

- Look at the shape and size of your material before you pick your screen.

If you match your screen media to your material, you get better separation and higher quality products. You also keep your equipment running longer and avoid costly breakdowns.

Callout: Always check your material’s size before you choose your screen. The right match saves you time and money.

Conclusion

You now know mesh size tells you how many openings fit in a screen inch, while particle size measures how big each piece of material is. This difference matters because choosing the right screen boosts your product quality and keeps your process smooth. ANPENG offers woven wire screens, self-cleaning screens, PU/urethane panels, rubber panels, and punch plates for all your screening needs. If you feel unsure, talk with an expert or your screen supplier. The right advice helps you match mesh size and particle size for the best results.

FAQ

What does mesh size mean?

Mesh size tells you how many openings fit in one inch of a screen. A higher mesh number means smaller holes. You use mesh size to pick the right screen for your material.

How do you measure particle size?

You measure particle size with tools like sieves, lasers, or microscopes. Most people use microns (µm) or millimeters (mm) to describe how big each particle is.

Is a higher mesh number always better?

No, a higher mesh number means smaller openings. You need to match mesh size to your material. If you pick too fine a mesh, your screen might clog or slow down your process.

Can mesh size and particle size be the same?

Mesh size and particle size are not the same. Mesh size describes the screen. Particle size describes the material. You need both to choose the right screen.

Why does particle shape matter in screening?

Particle shape changes how material moves through a screen. Odd shapes can pass through openings in unexpected ways. You get better results when you consider both size and shape.

What standards help with mesh size and particle size?

ASTM E11 and ISO 3310 are common standards. These help you compare screens and measurements from different suppliers. You get more reliable results when you follow these standards.

How do I choose the right screen for my plant?

- Check your material’s particle size.

- Look at mesh size options.

- Think about moisture, shape, and how much you need to process.

- Ask your supplier for advice if you feel unsure.