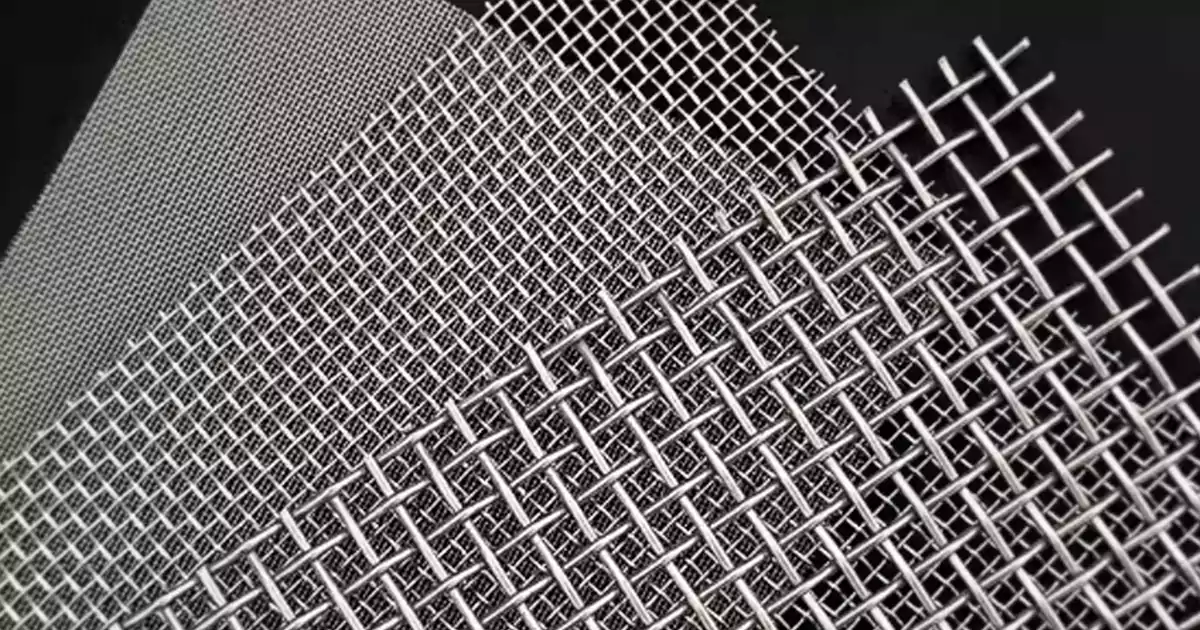

You can find stainless screen material in many places. This material uses stainless steel mesh or wire mesh to make a strong barrier. Stainless screen material is known for being strong and lasting a long time. It does not rust and can handle hard weather. People pick stainless screen material because it works well in lots of places and keeps its shape.

If you want a screen you can trust, stainless screen material is a great choice.

Key Takeaways

- Stainless screen material is tough and lasts a long time. It works well in many places.

- It does not rust or break down easily because it has chromium. This helps it stay strong for many years.

- There are different types of stainless steel, like 304 and 316. Each type is good for certain places.

- Stainless steel mesh can be used in many ways. It is good for filtering, keeping things safe, and for decoration.

- Cleaning and checking the mesh often helps it last longer.

- There are woven, welded, and perforated mesh types. Each type is made for different jobs, like filtering or keeping things secure.

- Stainless steel mesh is safe for food and pets. This makes it a good choice for homes and businesses.

- You can get mesh in special sizes and shapes. This helps meet the needs of different projects.

Stainless Screen Material Overview

What Is Stainless Screen Material

Stainless screen material is seen in many places. It uses stainless steel mesh to make strong barriers. Woven wire screens look like small grids made from thin wires. These screens can block, filter, or protect areas. Stainless steel mesh screens last a long time and work well in hard places. There are many types of mesh for different uses.

Here’s a simple table showing the most common stainless steel grades for mesh screens:

| Stainless Steel Grade | Description |

|---|---|

| SUS302 | Used for many different things |

| SUS304 | Most popular for weaving and making screens |

| SUS316 | Good at fighting rust |

| SUS304L | Low carbon version of SUS304 |

| SUS316L | Low carbon version of SUS316 |

| SUS310 | Used for high heat |

| SUS310s | Better at fighting rust than SUS310 |

| SUS430 | Ferritic stainless steel grade |

You might ask why stainless steel mesh screens are special. The answer is easy. Stainless steel mesh has chromium. Chromium makes a layer that protects the mesh. This layer helps the mesh fight rust. For example, 304 stainless steel mesh has 18% chromium and 8% nickel. If you need more protection, 316 stainless steel mesh has 2-3% molybdenum. This makes it good for use in the ocean or with chemicals.

Main Features

Durability

You want your screen to last a long time. Stainless steel mesh screens are very strong. Studies show stainless steel mesh works well for sand control and cleaning dirty water. These screens do not bend, break, or wear out easily. You can use them in busy places, and they keep working for years.

- Stainless steel mesh screens stay strong in tough places.

- You can trust them to work well for a long time.

Corrosion Resistance

You need a mesh that does not get ruined by water or chemicals. Stainless steel mesh screens are great at fighting rust. The chromium oxide layer keeps the mesh safe from rust and damage. If you compare stainless steel mesh to aluminum or galvanized steel, you see a big difference:

| Material | Corrosion Resistance | Ideal Environments | Vulnerabilities |

|---|---|---|---|

| Stainless Steel | High resistance because of chromium oxide layer | Good for ocean and salty places | Can be heavy and cost more |

| Aluminum | Good resistance, but can get damaged by other metals | Good for places that need light weight | Can get damaged by other metals |

| Galvanized Steel | Medium resistance | Good for general use | Not good for very tough places |

You can use stainless steel mesh screens in salty, chemical, or wet places. They keep working when other materials stop working.

Versatility

You want a mesh that can do many jobs. Stainless steel mesh screens are very flexible. You can use them for filtering, protecting, or even decorating. They come in many sizes and shapes. You see them in homes, factories, and even on boats. You can pick the mesh that fits your needs.

- Stainless steel mesh screens work for windows, doors, patios, and filters.

- You can choose woven, welded, or special mesh types.

Tip: If you need a screen for many uses, stainless steel mesh screens are a smart pick. They are strong, fight rust, and can be used in many ways.

Types of Stainless Steel Mesh

Woven Wire Mesh

You see woven wire mesh in many places. This type of ss wire mesh looks like a grid, where wires cross over and under each other. You get a flexible material that bends but does not break easily. Woven wire mesh stands out because you can choose the size of the openings and the thickness of the wires. This makes it perfect for jobs where you need exact openings, like filtering liquids or gases.

Here’s a quick look at how stainless steel mesh can be classified:

| Classification Criteria | Types of Stainless Steel Mesh |

|---|---|

| Production Process | Woven wire mesh, welded wire mesh |

| Weaving Method | Plain weave, twill weave, crimped wire mesh, dutch weave mesh |

| Mesh Hole Shape | Square mesh, hexagonal mesh, rectangular mesh |

| Material Type | SS304, SS316, SS430 |

| Application Area | Filter mesh, decorative mesh, window screen mesh, safety net |

You might use woven wire mesh in labs, food factories, or even in your car. It works well for filtration, decorative panels, and even in aerospace. If you need a mesh that fits odd shapes, woven wire mesh is your best friend. It’s also a top pick for stainless steel mesh screens because of its flexibility and high precision.

Tip: If you want a mesh that can handle lots of different jobs, woven wire mesh is a smart choice.

Welded Wire Mesh

Welded wire mesh gives you a strong and sturdy option. You get this type of ss wire mesh when wires are welded together at each crossing point. The result is a rigid sheet that holds its shape, even under pressure. Welded wire mesh is less flexible than woven wire mesh, but it is much stronger. You often see it used for security fencing, animal cages, or even in concrete construction.

Let’s compare woven and welded wire mesh:

| Feature | Woven Wire Mesh | Welded Wire Mesh |

|---|---|---|

| Structure | Flexible, woven wires | Rigid, welded intersections |

| Strength and Durability | Good for flexible uses | Great for load-bearing uses |

| Flexibility | Bends easily | Holds its shape |

| Common Applications | Filtration, decoration, aerospace | Fencing, cages, construction |

| Cost | Usually more expensive | More cost-effective |

You will find welded wire mesh in places where strength matters most. It is a popular choice for stainless steel mesh screens that need to protect or support heavy loads. If you want a mesh that stays flat and strong, welded wire mesh is the way to go.

Perforated Mesh

Perforated mesh is a little different. Instead of weaving or welding, manufacturers punch holes into sheets of ss wire mesh. You get a flat panel with many small holes. This type of stainless steel mesh is great for letting air, light, or sound pass through while still acting as a barrier.

You see perforated mesh in many applications:

- Building facades that look modern and help save energy

- Interior walls and ceilings for better sound control

- Ventilation panels that let air flow but keep bugs out

- Drainage covers and fencing for safety and style

Perforated mesh also works well for privacy screens and soundproofing. You can use it in staircases, seating, or even as decorative panels. If you want a stainless steel mesh that does more than just filter, perforated mesh gives you lots of options.

Note: Perforated mesh combines strength with style. You get a mesh that looks good and works hard in many places.

If you need a mesh for a special job, you can always find a type of ss wire mesh that fits. Stainless steel mesh screens come in many shapes and sizes, so you can pick the one that works best for your project.

Specialty Mesh

You might think all stainless steel mesh screens look the same, but specialty mesh brings something extra to the table. Specialty mesh is designed for jobs that need more than just basic strength or rust resistance. You get screens that solve unique problems and work in places where regular mesh just can’t keep up.

Specialty mesh stands out because it can handle very specific tasks. You see these screens in places where you need to filter tiny particles, keep out pests, or protect sensitive equipment. Some specialty stainless steel mesh screens have openings so small, you can barely see them. Others have shapes or patterns that help them fit into special machines or tools.

Let’s look at what makes specialty mesh different:

- You can use specialty mesh for filtering and sifting. These screens help you separate fine powders, grains, or even liquids. If you work in a lab or a food factory, you might see these screens every day.

- Specialty mesh works well for rodent control. You can install these screens in vents, walls, or floors to keep mice and rats out. The mesh is strong enough to stop chewing and thin enough to fit in tight spaces.

- Insect screening is another big use. Specialty stainless steel mesh screens keep out even the smallest bugs. You might use them in greenhouses, kitchens, or anywhere you want fresh air without pests.

- Some specialty mesh screens are super fine. They can go up to 500 mesh per inch. That means you get 500 tiny openings in just one inch of screen! These are perfect for filtering out dust, pollen, or other tiny particles.

Here’s a quick table to show you how specialty mesh compares to other types:

| Mesh Type | Main Use | Opening Size | Special Features |

|---|---|---|---|

| Woven Wire Mesh | General filtration | Medium to fine | Flexible, many patterns |

| Welded Wire Mesh | Security, support | Medium to large | Rigid, strong |

| Perforated Mesh | Airflow, decoration | Large to medium | Flat, stylish |

| Specialty Mesh | Unique applications | Ultra-fine to custom | Pest control, high-precision |

You can find specialty stainless steel mesh screens in science labs, food processing plants, and even in your home. If you need a screen that does more than just cover a window, specialty mesh is the way to go.

Tip: When you face a tricky problem, like filtering out tiny dust or keeping out sneaky pests, specialty stainless steel mesh screens give you the best solution. You can ask for custom sizes, shapes, or even special coatings to match your needs.

Specialty mesh shows how flexible stainless steel mesh screens can be. You get a product that fits your project, no matter how tough or unusual the job is. Next time you need a screen for a special task, remember that specialty mesh has you covered.

Key Properties of Stainless Steel

Material Grades

When you look at stainless steel mesh, you’ll notice different grades. Each grade brings its own strengths to the table. You’ll see these grades used in screens for homes, factories, and even boats. Here are the most common grades you’ll find:

- 304 stainless steel is the standard choice for general-purpose mesh. You get good durability and reliable performance.

- 316 stainless steel is called marine-grade. It works best in places with lots of saltwater or chemicals.

- 316L stainless steel has less carbon, so it’s easier to weld and keeps its shape better.

- 430 stainless steel is magnetic and offers basic corrosion resistance.

304 Stainless Steel

You’ll find 304 stainless steel in many mesh screens. It contains 18% chromium and 8% nickel. This mix gives you good resistance to rust and oxidation. If you need a mesh for everyday use, 304 stainless steel is a solid pick. It stands up well in kitchens, gardens, and most outdoor spaces. You get superior physical properties and structural strength, which means your mesh lasts longer.

316 Stainless Steel

If you need a mesh for tough environments, 316 stainless steel is your best bet. It has 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. That extra molybdenum boosts corrosion resistance, especially in places with lots of salt or chemicals. You’ll see 316 stainless steel mesh on boats, in labs, and in chemical plants. It’s known for superior physical properties and structural strength, making it perfect for long-term use in harsh conditions.

Here’s a quick table to help you compare:

| Stainless Steel Grade | Chromium Content | Nickel Content | Molybdenum Content | Corrosion Resistance Characteristics |

|---|---|---|---|---|

| 304 | 18% | 8% | N/A | Good resistance to rust and oxidation under normal conditions, but less effective in saltwater and harsh chemicals. |

| 316 | 16-18% | 10-14% | 2-3% | Superior resistance to pitting and crevice corrosion, especially in chloride-heavy environments, making it ideal for marine and chemical applications. |

Mesh Sizes

Mesh size matters when you choose a screen. You’ll see mesh density listed as the number of openings per inch. Higher mesh counts mean smaller openings. If you want to filter fine particles, pick a mesh with a high count, like 100 mesh. For bigger particles, go with a lower count. Higher mesh densities trap tiny bits but slow down the flow. Lower densities let more air or water pass through and last longer because the wires are thicker. You get better durability and longevity with lower mesh counts, especially in rough places.

- Mesh density affects filtration efficiency.

- Higher mesh counts catch fine particles.

- Lower mesh counts work better for heavy-duty jobs.

Strength and Weight

Stainless steel mesh stands out for its strength. You get a product that handles heavy loads and tough jobs. Compared to aluminum mesh, stainless steel offers much better structural strength and durability. Aluminum is lighter and resists rust, but it can’t match the toughness of stainless steel. If you need a mesh that won’t bend or break, stainless steel is the way to go. Hybrid composites with stainless steel mesh also beat aluminum in energy absorption and toughness. You get core advantages like long-term use and reliability in demanding environments.

Tip: If you want a mesh that lasts and keeps its shape, stainless steel mesh gives you the best combination of strength and durability.

Maintenance

You want your stainless steel mesh to last as long as possible. Good maintenance helps you get the most out of your screens. If you take care of them, you save money and avoid problems down the road.

Start with regular inspections. Look for signs of wear, damage, or rust. Catching issues early keeps your stainless steel mesh working well. You can spot small problems before they turn into big ones.

Cleaning is important. Use mild detergents and water to wash your mesh. Stay away from harsh chemicals because they can damage the surface. Keeping your stainless steel mesh clean helps prevent corrosion and keeps it looking new. If you work in a place with lots of dust or chemicals, clean your mesh more often.

Here are some simple steps you can follow to keep your stainless steel mesh in top shape:

- Check your mesh often for any signs of damage or rust.

- Clean with gentle soap and water. Rinse well and let it dry.

- Make sure your mesh is installed with the right tension. This stops sagging and keeps it strong.

- Add protective coatings if needed. These coatings help your mesh resist rust and last longer.

- Think about where your mesh is installed. Make sure water drains away so it does not sit on the mesh.

Tip: Always keep the surface of your stainless steel mesh free from dirt and other stuff. Clean screens work better and last longer.

If you use stainless steel mesh in tough places like factories or outdoors, maintenance matters even more. You might need to reapply protective coatings from time to time. This extra step helps your mesh fight off rust and keeps it strong.

You do not need fancy tools to take care of your stainless steel mesh. A soft brush, mild soap, and water do the job. If you see any damage, fix it right away. Small repairs keep your mesh working and save you from bigger problems later.

Taking care of your stainless steel mesh is easy if you follow these steps. You get a screen that looks good, works well, and lasts for years.

Industrial Applications

Water Treatment

You see stainless steel wire mesh play a big role in water and wastewater treatment. When you need to clean water, you want a material that lasts and does not rust. Stainless steel wire mesh gives you that. You can use it to filter out dirt, sand, and even tiny particles from water. This mesh stands up to chemicals and high pressure, so you do not have to worry about it breaking down. You get reliable filtration performance every time.

Many treatment plants use filtration mesh screens to keep water safe. These screens trap unwanted particles and let clean water pass through. You can clean and reuse these screens, which saves you money. If you want a strong and long-lasting solution for water and wastewater treatment, stainless steel wire mesh is the way to go.

Filtration and Separation

You find stainless steel wire mesh in many industrial filtration jobs. It works well because it is strong and does not wear out fast. You can use it in factories, food processing, and even in labs. Here’s why it stands out for industrial filtration:

- It handles high pressure and harsh chemicals without breaking.

- The mesh has even openings, so you get the same results every time.

- You can clean and reuse the filtration mesh screens, which makes them cost-effective.

- It works in hot and cold places, so you can use it in many industrial processing applications.

- It is safe for food and easy to keep clean.

When you need to separate solids from liquids or filter out dust, stainless steel wire mesh gives you the best results. You can trust it for reliable filtration performance in tough jobs. Many companies pick it for industrial filtration because it lasts longer and works better than other materials.

Mining and Processing

Mining is a tough job. You need equipment that can handle rocks, dirt, and chemicals. Stainless steel wire mesh is perfect for this. It does not rust, even when you use it in wet or chemical-filled places. You get strong filtration mesh screens that do not bend or break under heavy loads.

Here’s what makes stainless steel wire mesh a top choice for mining:

- It stands up to harsh and abrasive environments.

- The mesh lasts longer, so you do not have to replace it often.

- It resists corrosion, even in moist or chemical-heavy areas.

- You get strong screening solutions that keep working, even under pressure.

If you want to keep your mining operation running smoothly, use stainless steel wire mesh. It gives you safety, strength, and long service life. You can count on it for all your industrial filtration needs in mining and processing.

Tip: For any application where you need strong, long-lasting, and easy-to-clean filtration mesh screens, stainless steel wire mesh is your best friend. You get top performance in all types of industrial filtration and separation jobs.

Chemical Industry

You might wonder how stainless steel helps in the chemical industry. The answer is simple. Stainless steel stands up to tough chemicals and keeps working when other materials fail. You see it used in many places where safety and cleanliness matter most.

When you walk into a chemical plant, you notice lots of pipes, tanks, and machines. Many of these use stainless steel wire mesh. This mesh acts like a shield. It keeps dangerous chemicals from leaking and protects workers and equipment. You can trust stainless steel to last a long time, even when it touches strong acids or bases.

Filtration is a big deal in chemical processing. You need to separate liquids, catch tiny particles, and keep everything clean. Stainless steel mesh does this job well. It does not rust or break down, so you get safe and steady results. You can pick the mesh size and wire thickness that fits your needs. This means you get a custom solution for every application.

Here are some ways you see stainless steel mesh in the chemical industry:

- It filters out harmful particles from liquids and gases.

- It acts as a barrier to stop leaks and spills.

- It protects pumps, valves, and other sensitive parts from getting clogged.

- It helps with drying, sifting, and separating chemicals during processing.

You also find stainless steel mesh in containment systems. These systems keep dangerous chemicals locked away. The mesh adds strength and stops accidents. You get peace of mind knowing your plant is safer.

If you look at the applications of ss wire mesh, you see how important it is for chemical plants. The mesh works in high heat, strong chemicals, and even under pressure. You can clean it easily and use it again and again. This saves money and keeps your plant running smoothly.

Tip: Always check the mesh size and wire diameter before you choose a screen. The right choice gives you better filtration and longer life for your equipment.

Stainless steel mesh is a smart pick for any chemical industry job. You get strength, safety, and a product that fits your needs.

Architectural and Commercial Uses

Decorative Screens

You might notice stainless steel mesh in hotels, clubs, or even art galleries. These screens do more than just divide space. They add style and shine to any room. You can use them as wall panels, ceiling features, or even as room dividers. The design versatility lets you pick from many patterns and finishes. Some screens reflect light and make a space feel bigger and brighter. Others create privacy without blocking your view.

Here’s why you see these screens in so many places:

- They last a long time, even in busy areas.

- You can clean them easily, which is great for places like hospitals.

- They look modern and fit many styles.

- You can use them as background panels or see-through partitions in offices and exhibition halls.

If you want to add a touch of luxury or make a bold statement, decorative screens are a smart choice for commercial and public spaces.

Security Mesh

You want your building to look good and stay safe. Security mesh gives you both. This type of screen acts as a strong barrier against break-ins. You see it on windows, doors, and storefronts. It keeps out unwanted guests but still lets you see outside. Unlike old-fashioned bars, security mesh looks sleek and modern.

Here’s what makes security mesh a top pick:

- It stops thieves and keeps your business safe 24/7.

- The mesh blends with the building’s style, so you don’t lose curb appeal.

- You can use it for railings, gates, and entryways.

- It needs little upkeep and lasts for years.

Many businesses choose security mesh because it offers both protection and a polished look. You get peace of mind without making your building look like a fortress.

Ventilation Panels

You need fresh air in your building, but you also want to keep out bugs and debris. Ventilation panels made from stainless steel do the job well. These panels let air flow freely while protecting your space. You can use them in offices, factories, or even homes.

Check out what makes these panels stand out:

| Feature | Description |

|---|---|

| Air Control | Lets you manage airflow exactly where you need it. |

| Air Passage | Gives plenty of air for large rooms or busy areas. |

| Balance | Protects your space while letting air move easily. |

| Thickness | Stays strong and lasts, even outside in tough weather. |

| Aesthetics | Looks good and fits modern designs. |

| Maximum Airflow | Works well in places that need lots of fresh air, like factories or gyms. |

| Durability | Handles heavy use in high-traffic spots. |

| Industrial Use | Perfect for big buildings that need strong, reliable airflow. |

Ventilation panels offer both style and functional benefits. You get a screen that keeps your air clean and your building looking sharp.

Tip: If you want a solution that combines safety, style, and airflow, stainless steel mesh is the way to go for your next project.

Railing Inserts

You probably see railings every day—on stairs, balconies, or walkways. Have you ever noticed the panels inside those railings? Many buildings now use railing inserts made from stainless steel mesh. These inserts do more than just fill space. They make railings safer and give them a modern look.

When you walk through a busy mall or a public park, you want to feel safe. Railing inserts with stainless steel mesh help with that. They are strong and tough. You do not have to worry about them breaking or bending if someone leans on them. This strength means you get better security in places where lots of people gather.

You also get a fresh style. Stainless steel mesh gives railings a clean and open look. You can see through the mesh, so spaces feel bigger and brighter. Architects love using these inserts because they can pick different patterns or shapes. You might see simple squares, fancy waves, or even custom designs that match the building’s theme.

Here’s why you might choose railing inserts with stainless steel mesh:

- They create a modern and open look that fits many styles.

- You can pick from lots of designs to match your space.

- They last a long time and do not need much cleaning.

- The mesh does not rust, even if it rains or snows.

- The strong wires keep people safe, even in crowded places.

- You can see through the mesh, so you never lose your view.

You do not have to worry about cleaning, either. Stainless steel mesh railing inserts need very little care. A quick wipe with a cloth keeps them looking new. This makes them perfect for places like schools, airports, or shopping centers where you want things to stay neat and safe.

Tip: If you want railings that look good and keep people safe, try stainless steel mesh inserts. You get both style and strength in one package.

You can use these inserts indoors or outdoors. They work well on staircases, balconies, decks, and even bridges. The mesh stands up to weather, crowds, and daily use. You get peace of mind knowing your railings will last for years.

Next time you see a railing with a shiny, see-through panel, you’ll know it’s more than just decoration. It’s a smart choice for safety and design.

Residential Applications

Window and Door Screens

You want your home to feel safe and comfortable. Stainless steel mesh window and door screens help you do just that. These screens keep bugs out and let fresh air in. You can trust them to last for years, even if you have kids or pets. Many people choose stainless steel over fiberglass because it stands up to daily use and tough weather.

Take a look at how stainless steel screens compare to traditional fiberglass screens:

| Feature | Fiberglass Screens | Stainless Steel Screens |

|---|---|---|

| Durability | Less durable, can tear easily | More durable, resistant to damage |

| Security | Provides minimal security | Offers better security against intruders |

| Fire Resistance | Not fire resistant | Fire resistant |

| Weight | Lightweight | Heavier but more robust |

| Visibility | Good visibility | Good visibility |

You get better security and fire resistance with stainless steel. The mesh does not tear easily, so you do not have to replace it often. You can enjoy the view and fresh air without worrying about pests or break-ins.

Patio and Porch Mesh

You love spending time outside, but you do not want bugs to ruin your day. Stainless steel mesh works great for patios and porches. It creates a strong barrier that keeps insects out and lets you relax. You can use it for screened-in porches, sunrooms, or even outdoor kitchens. The mesh stands up to rain, sun, and wind. You do not have to worry about rust or fading.

If you have pets, you know they like to scratch and push against screens. Stainless steel mesh holds up much better than other materials. You can enjoy your outdoor space without fixing torn screens every season. The mesh also adds a layer of safety, so kids and pets stay inside while you enjoy the breeze.

Pest Control

You want your home to stay clean and pest-free. Stainless steel mesh makes that easy. The small holes block insects and rodents, but still let air flow through. You can use this mesh in vents, airbricks, and even crawl spaces. It works well in both city and country homes.

Here’s why stainless steel mesh is so effective for pest control:

- Made from 304 grade stainless steel, so it lasts a long time.

- Resists rust and damage, even in damp places.

- Fine mesh size blocks even tiny insects and rodents.

- Keeps airflow strong in important areas like vents.

- Works in all types of residential spaces, from houses to apartments.

You can trust stainless steel mesh for many applications. It helps with pest control, filtration, and even adds security. You get a screen that fits many needs in your home. When you look at the applications of ss wire mesh, you see how useful it is for keeping your home safe and comfortable.

Tip: If you want a long-lasting solution for pest control, choose stainless steel mesh. You get peace of mind and a cleaner home.

Pet-Resistant Screens

If you have pets at home, you know how curious and playful they can be. Dogs and cats love to scratch, jump, and sometimes even chew on window and door screens. Regular screens often tear or get holes after a few weeks with an active pet. You want something that stands up to your furry friends and keeps your home safe.

Stainless steel mesh screens are a game changer for pet owners. These screens are not just pet-resistant—they are almost pet-proof. You get a strong barrier that keeps your pets inside and unwanted animals outside. Many companies offer long warranties on these specialty meshes because they last much longer than regular screens.

Let’s look at why stainless steel mesh works so well for homes with pets:

- The mesh has exceptional strength. It can handle powerful chews and sharp claws.

- You do not have to worry about your pet breaking through or tearing the screen.

- Stainless steel does not rust, so your screens look good year after year.

- The mesh stays in place, even if your dog jumps or your cat climbs.

- You get peace of mind knowing your pets are safe and your screens stay intact.

Here’s a quick table to show you the main features and benefits:

| Feature | Benefit |

|---|---|

| Exceptional Strength | Can withstand powerful chews and persistent curiosity from pets. |

| Rust Resistance | Ensures longevity and maintains appearance over time. |

| Enhanced Security | Provides a sturdy solution for homes needing added safety. |

| Damage Resistance | Stays intact against heavy pressure or scratching, ensuring functionality. |

You might wonder if these screens are hard to clean or install. The good news is that stainless steel mesh is easy to wipe down with a damp cloth. You do not need special tools or cleaners. The mesh fits into most standard window and door frames, so you can upgrade your screens without a big project.

Stainless steel pet-resistant screens also help with airflow and visibility. You can open your windows and let in fresh air without worrying about your pets escaping or bugs getting inside. The mesh is fine enough to keep insects out but strong enough to stop even the most determined pets.

If you want a screen that lasts, looks good, and protects your pets, stainless steel mesh is the way to go. You get a smart solution that makes life easier for you and safer for your furry family members.

Tip: If you have a new puppy or a curious cat, consider switching to stainless steel pet-resistant screens. You will save money on repairs and enjoy a safer, more comfortable home.

Custom and Special Environments

Marine and Coastal Use

If you live or work near the ocean, you know how tough saltwater can be on metal. You want a material that stands up to harsh weather and salty air. That’s where 316 stainless steel mesh comes in. People call it “marine-grade” because it handles saltwater and chemicals better than other types. You see it used in docks, boat railings, and even fish farms.

Here’s why 316 stainless steel mesh is the top pick for marine and coastal environments:

- It resists rust and corrosion, even when waves splash it every day.

- It fights off pitting and crevice corrosion, which are common problems in salty places.

- You can use it for building projects by the sea, aquaculture cages, and even underwater barriers.

- It lasts longer than regular steel or aluminum, so you save money on repairs.

If you need a custom size or shape, manufacturers can make mesh screens just for your project. You can order in bulk for big jobs or ask for special coatings to match your needs.

Food Processing

Food factories have strict rules for cleanliness. You want equipment that keeps food safe and easy to clean. Stainless steel mesh is perfect for this job. It does not have tiny holes where germs can hide. The smooth surface makes it easy to wash and sanitize.

Why do food companies trust stainless steel mesh?

- It is non-porous and antimicrobial, so it helps stop bacteria from growing.

- You can clean it with steam, high-pressure water, or special cleaning systems.

- It stands up to strong cleaners and hot temperatures, so you can kill germs fast.

- The mesh meets FDA and EU rules for food safety, and it works with HACCP plans.

You see stainless steel mesh in conveyor belts, drying racks, and sifting screens. If you need a custom design, manufacturers can help you pick the right mesh size and finish. Wholesale options make it easy to outfit a whole factory.

Medical and Lab Settings

Hospitals and labs need the highest level of cleanliness. You want tools and trays that stay sterile and last a long time. Stainless steel mesh is a smart choice for these places. It does not rust or break down, even after many cleanings.

Here’s how stainless steel mesh helps in medical and lab settings:

- Trays and baskets made from mesh are easy to clean and resist oxidation.

- You can use them to hold surgical tools during sterilization.

- The mesh is strong, biocompatible, and safe for use with medicines and implants.

- It works well for sifting powders and for filtration in drug production.

You can clean these items with steam, special chemicals, or even in an autoclave. Regular checks and cleaning keep everything safe and up to code. If you need a special size or shape, manufacturers can create custom solutions for your lab or hospital.

Tip: If you have a unique project or need a special mesh, ask about custom manufacturing and wholesale options. You can get exactly what you need for any environment.

Conclusion

You can trust stainless screen material for many projects. It works well in factories, buildings, stores, and homes. Woven wire screens are special because they give you:

- Great strength for tough jobs

- Good protection from rust and chemicals

- Custom mesh designs for your needs

- Simple cleaning for better hygiene

If you want something you can count on, pick woven wire screens. We make custom and wholesale stainless woven screens for your next project.

FAQ

What is stainless screen material made of?

You get stainless screen material from stainless steel wires or sheets. These wires contain chromium, which helps fight rust. You see this material in woven, welded, or perforated mesh forms.

Can I use stainless steel mesh outdoors?

Yes, you can! Stainless steel mesh works great outside. It stands up to rain, sun, and even salty air. You do not have to worry about rust or damage.

How do I clean stainless steel mesh screens?

Just use mild soap and water. Wipe the mesh with a soft cloth or brush. Rinse and let it dry. Avoid harsh chemicals to keep your mesh looking new.

Is stainless steel mesh safe for food or pets?

Absolutely! Stainless steel mesh is non-toxic and safe for food contact. You can use it in kitchens, grills, or pet doors. It does not hold germs or odors.

What mesh size should I choose?

Pick a mesh size based on your needs. For tiny bugs, go with a fine mesh. For more airflow, choose a larger opening. You can always ask a supplier for advice.

Does stainless steel mesh block visibility?

No, it does not. You can see through most stainless steel mesh screens. They let in light and air while keeping out pests. You get safety without losing your view.

Can I order custom sizes or shapes?

Yes, you can! Many manufacturers offer custom mesh screens. You just tell them the size, shape, and mesh type you need. They will make it fit your project.

Tip: If you are not sure what you need, ask for a sample before you buy.