You want to know how to calculate wire mesh weight for your project. Start by grabbing a few measurements. You need to know the length, width, mesh numbers, and wire diameter. The basic formula is wire diameter times wire diameter times mesh number divided by two. Getting the right weight helps you plan and pick the best material. Many industries use wire mesh, like food, oil, and engineering. Try a step-by-step method or online tools for the most accurate results.

Key Takeaways

- First, measure the length and width of your mesh sheets. This helps you get the right weight.

- Use a caliper to check the wire diameter. Thicker wires make the mesh stronger and heavier.

- Learn about mesh size because it changes how much material you need. Bigger openings usually make the mesh lighter.

- Find out the density of your material. Metals like stainless steel and aluminum do not weigh the same.

- Use this formula: Wire diameter squared times mesh number times width and length, then divide by two to get the weight.

- For big projects, figure out the weight for each mesh type. Add them together to get the total weight.

- Try online calculators for fast weight guesses. They make things easier and help you avoid mistakes.

- Ask your supplier if you need special mesh sizes or materials. They can give you good advice and tell you the right density.

Wire Mesh Weight Measurements

Length and Width

You need to start with the basics. Grab a tape measure and check the length and width of your mesh sheets. Most mesh sheets come in standard sizes, but sometimes you get custom cuts. Always measure from edge to edge, making sure the mesh lies flat. If you work with reinforcing mesh for concrete, you might see sheets that are 2 meters by 4 meters or even larger. Write down these numbers because you’ll use them in your weight calculation. If you have several mesh sheets, measure each one. This helps you avoid mistakes when you order or plan your project.

Tip: Double-check your measurements if your mesh sheets have bends or overlaps. Overlapping mesh can change the total weight, especially in reinforcing mesh installations.

Wire Diameter

Wire diameter tells you how thick each wire is in your mesh. You can use a caliper for the most accurate reading. Place the caliper around the wire and read the number. If you don’t have a caliper, a ruler works for larger wires, but it’s less precise. Wire diameter matters a lot for reinforcing mesh. Thicker wires make the mesh stronger and heavier. Here’s why wire diameter is so important:

- Wire diameter shows the thickness of each wire, which affects the strength and flexibility of the mesh.

- Thicker wire means your mesh lasts longer and stands up to heavy loads.

- If you pick the wrong wire diameter, your mesh might not work well, and your weight calculation could be off.

When you measure wire diameter, always check a few wires from different spots on the mesh sheets. Sometimes wires aren’t all the same thickness. This is especially true for reinforcing mesh used in construction.

Mesh Size

Mesh size means the size of the openings between the wires. You measure mesh size by checking the distance from the center of one wire to the center of the next. Mesh size changes how much material you use and how heavy your mesh sheets will be. Reinforcing mesh usually has bigger openings, while fine mesh sheets for filtration have smaller gaps.

Here’s a table showing typical mesh sizes for welded and woven mesh sheets:

| Mesh Opening Size | Wire Gauge | Wire Diameter (inches) | Wire Diameter (mm) |

|---|---|---|---|

| 4″ x 4″ | 6 | 0.192 | 4.88 |

| 6″ x 6″ | 8 | 0.128 | 3.26 |

| 8″ x 8″ | 10 | 0.102 | 2.59 |

| 1/4″ x 1/4″ | 22 | 0.025 | 0.64 |

| 1/2″ x 1/2″ | 16 | 0.062 | 1.57 |

| 2″ x 2″ | 12 | 0.105 | 2.67 |

If you work with reinforcing mesh, you’ll probably use the larger sizes like 4″ x 4″ or 6″ x 6″. For smaller projects, like insect screens or fine filters, you’ll use mesh sheets with tiny openings.

Project requirements change the mesh size you need. Construction jobs want strong reinforcing mesh with the right size and shape for safety. Filtration projects need exact mesh size to separate particles. Insect screens use mesh sheets that block bugs but let air flow.

When you measure mesh size, use a ruler or caliper. Check several spots on your mesh sheets to make sure the openings are even. This helps you get the right weight for your reinforcing mesh and keeps your project safe.

Material Density

Material density plays a big role in figuring out how much your wire mesh weighs. Density tells you how heavy a material is for its size. You measure density in units like grams per cubic centimeter (g/cm³) or kilograms per cubic meter (kg/m³). Every wire mesh uses a certain type of metal, and each metal has its own density.

You might see wire mesh made from stainless steel, mild steel, aluminum, or even copper. Each one feels different in your hand because of its density. If you use stainless steel, your mesh will weigh more than aluminum mesh of the same size and wire thickness. That’s why you need to know the density before you start your calculations.

Here’s a quick table with common wire mesh materials and their densities:

| Material | Density (g/cm³) | Density (kg/m³) |

|---|---|---|

| Stainless Steel | 7.93 | 7930 |

| Mild Steel | 7.85 | 7850 |

| Aluminum | 2.70 | 2700 |

| Copper | 8.96 | 8960 |

You can find these numbers on supplier websites, engineering handbooks, or even by searching online. If you buy wire mesh from a supplier, ask them for the exact density. Sometimes, alloys or special coatings change the density a little bit.

Tip: Always use the density for the exact material you have. If you mix up stainless steel and aluminum, your weight calculation could be way off.

Let’s say you want to calculate the weight of a stainless steel mesh. You measure the wire diameter, mesh size, and sheet dimensions. You also need the density from the table above. Plug all these numbers into your formula, and you get the weight.

If you work with custom wire mesh, you might see materials like galvanized steel or brass. These have their own densities. Don’t guess—look up the right value. You can even ask your supplier for a material certificate. This document shows the exact type of metal and its density.

Sometimes, you need to compare different materials for your project. Maybe you want a lighter mesh for easy handling, or a heavier mesh for strength. Density helps you make that choice. Aluminum mesh works well for lightweight screens, while stainless steel gives you durability for tough jobs.

You don’t need fancy tools to find density. Just grab the value from a trusted source and use it in your calculations. If you ever feel unsure, reach out to your supplier or check online calculators. Getting the density right means your wire mesh weight will be spot-on, and your project will run smoothly.

Wire Mesh Weight Formula

Basic Formula

You want to figure out wire mesh weight for your project. You need a simple formula that uses your measurements. Here’s how you do it:

- Measure the wire diameter in millimeters.

- Count the mesh number (the number of wires per unit length).

- Measure the width and length of your mesh sheets in meters.

- Use the formula below to get the weight in kilograms.

The formula looks like this:

Wire diameter (mm) x wire diameter (mm) x mesh number x width (m) x length (m) / 2 = weight (kg)

You can use this formula for most welded mesh sheets. It works for both small and large projects. If you want to check your math, try plugging in your numbers and see if the result matches what your supplier says.

Tip: Always double-check your measurements before using the formula. Small mistakes can lead to big problems later.

Welded Wire Mesh Weight per Square Meter

You might need to know the welded wire mesh weight for each square meter. This helps you compare different mesh sheets and plan your project. The weight of welded wire mesh per square meter depends on wire diameter, mesh number, and the size of your sheets.

Here’s a table showing how welded wire mesh weight changes with different wire diameters and mesh sizes:

| Wire Diameter (mm) | Mesh Number | Roll Width (m) | Roll Length (m) | Weight (kg) |

|---|---|---|---|---|

| 0.711 | 2 | 0.914 | 30.48 | 14.1 |

| 0.10 | 100 | 1 | 30 | 15.0 |

If you look at the table, you see that thicker wires and higher mesh numbers make the welded mesh heavier. You can use these numbers to estimate the weight of welded mesh for your project. If you need the weight of welded wire mesh per square meter, divide the total weight by the area of the mesh sheets.

Note: The welded wire mesh weight can change if you use custom sizes or special wire diameters. Always check with your supplier if you have unique requirements.

Adjusting for Material Type

The type of metal you choose affects the wire mesh weight. Different materials have different densities. Galvanized steel and stainless steel are common choices for welded mesh sheets. You need to know the density to get an accurate weight.

Here’s a table showing how material type changes the calculation:

| Material Type | Density (g/cm³) | Notes on Density Variability |

|---|---|---|

| Galvanized Steel | 7.85 | Density can vary based on thickness and manufacturing process. |

| Stainless Steel | Similar | Density may also vary, but generally comparable to galvanized steel. |

If you use galvanized steel, your welded mesh will weigh about the same as stainless steel mesh sheets. Sometimes, the density changes a little because of coatings or the way the mesh is made. Always ask your supplier for the exact density if you want a precise welded wire mesh weight.

Environmental factors can also change the weight over time. Stainless steel mesh resists rust and handles harsh chemicals. The chromium in stainless steel helps it fight corrosion and even self-repair if scratched. This makes it a good choice for wet or chemical-heavy places. Galvanized steel mesh is cheaper, but it can rust if the zinc coating wears off, especially in humid or tough environments.

- Stainless steel mesh lasts longer in moist or chemical areas.

- Galvanized steel mesh is budget-friendly but may corrode over time.

If you want your welded mesh sheets to last, think about where you’ll use them. Pick the right material for your environment. This helps you keep the welded wire mesh weight steady and avoid surprises later.

Tip: Always use the correct density for your material when you use the formula. This keeps your wire mesh weight calculation accurate.

Now you know how to use the formula, check welded wire mesh weight per square meter, and adjust for material type. You can plan your project with confidence and pick the best mesh sheets for your needs.

Calculate Wire Weight Steps

Gather Measurements

You want to start strong when you calculate wire weight for your project. Grab your tape measure and caliper. Measure the length and width of your mesh sheets. Write down these numbers. Next, check the wire diameter. Use a caliper for the most accurate reading. If you work with welded mesh sheets or reinforcing mesh, measure a few wires from different spots. Sometimes, wire thickness changes across the sheet.

Don’t forget to record the mesh opening size. This means you measure the distance between wires. If you use welded mesh sheets for concrete, you’ll see bigger openings. For fine screens, the gaps are much smaller. Always check several spots to make sure the mesh size stays the same.

Tip: Lay your mesh sheets flat before measuring. Overlaps or bends can change your numbers. If you work with reinforcing mesh, double-check for any overlaps. Overlapping mesh adds extra weight, so you want to get it right.

Apply the Formula

Now you have your measurements. You’re ready to calculate wire mesh weight. Use the formula you learned earlier:

Wire diameter (mm) x wire diameter (mm) x mesh number x width (m) x length (m) / 2 = weight (kg)

Plug in your numbers for wire diameter, mesh number, width, and length. If you use welded mesh sheets, this formula works for most standard projects. For reinforcing mesh, make sure you use the correct wire diameter and mesh size.

Let’s say you want to calculate reinforcing mesh for a concrete slab. You measure the wire diameter as 6 mm, mesh number as 4, width as 2 meters, and length as 4 meters. You plug these into the formula. You get the weight for one sheet. If you have more mesh sheets, repeat the process for each one.

Mistakes can happen when you calculate wire weight. Here’s a table showing common errors and how to avoid them:

| Mistake | Description |

|---|---|

| Omission of Heat Treatment | Not applying annealing and sintering can lead to ineffective formed pieces. |

| Overworking the Material | Attempting to reshape the material can cause permanent deformation, making the mesh unusable. |

| Ignoring Shape Retention Issues | Failure to notice shape retention problems indicates improper heat treatment or overworking. |

Note: Always check if your welded mesh sheets need heat treatment. If you overwork the material, you might ruin the shape. Shape retention matters for reinforcing mesh in construction.

Calculate Total Project Weight

You want to know the total weight for your project. If you use different mesh types or sizes, you need to calculate each one separately. Here’s a simple way to do it:

- Enter the dimensions for each mesh sheet (length and width).

- Specify the wire diameter and mesh opening size for every type.

- Select the material type, like stainless steel or low carbon steel.

- Add the price per kilogram if you want to estimate costs.

- Calculate the total weight and cost for your project.

If you use welded mesh sheets and reinforcing mesh together, calculate the weight for each type. Add them up for the total. This helps you plan your project and order the right amount of material.

Tip: Always double-check your numbers before you order mesh sheets. If you have overlaps, add the extra weight. For large projects, use online calculators or ask your supplier for help.

You can calculate reinforcing mesh for a small patio or a big warehouse floor. The steps stay the same. Measure, apply the formula, and add up the weights. If you use welded mesh sheets for fencing, calculate each panel. For reinforcing mesh in concrete, calculate every sheet and overlap.

If you want your project to run smoothly, get the wire mesh weight right. Accurate numbers help you avoid surprises and keep your budget on track.

Welded Wire Mesh Weight Calculation

Example Calculation

Let’s walk through a real example so you can see how to figure out welded wire mesh weight for your project. You need a few numbers: mesh size, wire diameter, sheet dimensions, and material type. Grab your tape measure and caliper. Write down the mesh size and wire diameter. Measure the length and width of your welded mesh sheet. Check the material—maybe you have carbon steel, galvanized steel, or stainless steel.

Here’s a table showing how these numbers look for different welded mesh sheets:

| Mesh Size | Wire Diameter | Length × Width | Material | Estimated Weight |

|---|---|---|---|---|

| 25×25 mm | 1.5 mm | 2 m × 5 m | Carbon Steel | ≈ 15 kg |

| 50×50 mm | 2 mm | 3 m × 6 m | Galvanized Steel | ≈ 40 kg |

| 100×100 mm | 3 mm | 4 m × 8 m | Stainless Steel | ≈ 120 kg |

You can use the formula to check these numbers:

Wire diameter (mm) x wire diameter (mm) x mesh number x width (m) x length (m) / 2 = weight (kg)

Let’s say you have a welded mesh with a mesh size of 6 x 6 inches, a length of 15 meters, a width of 1.2 meters, and a wire diameter of 6 mm. Plug these into the formula:

(6 x 6 x 0.17 x 1.2 x 15) / 2 = 55.08 kg (with a ±5% tolerance)

You get the weight for one welded mesh sheet. If you use reinforcing mesh for concrete, you follow the same steps. Just swap in your measurements.

Tip: Always double-check your numbers before you order. Small mistakes can change the total weight and affect your project.

Common Project Scenarios

You might use welded mesh sheets for many jobs. Each project needs a different approach to estimating weight. Here are some common scenarios:

- Concrete Reinforcement:

You use welded reinforcing mesh to make concrete slabs stronger. Measure each sheet and calculate the weight. Add up the total for all sheets. If you overlap sheets, include the extra weight. - Fencing Projects:

Welded mesh panels work well for fences. Measure the panel size and wire diameter. Calculate the weight for each panel. Multiply by the number of panels you need. - Industrial Screens:

Factories use welded mesh for screens and guards. You need to know the weight for safety and installation. Measure the mesh size and wire diameter. Use the formula to get the weight. - Animal Enclosures:

Welded mesh keeps animals safe. You pick the right mesh size and wire diameter. Calculate the weight for each enclosure panel. Make sure the panels are strong enough. - Custom Designs:

Sometimes you need special welded mesh shapes. Measure each piece. Calculate the weight for every shape. Add up the total for your project.

If you use reinforcing mesh in any of these jobs, always check the mesh size and wire diameter. The weight helps you plan for transport, installation, and safety. Welded mesh sheets come in many sizes, so use the formula for each one.

Note: For big projects, use online calculators or ask your supplier for help. This saves time and keeps your wire mesh weight accurate.

You now know how to estimate welded mesh weight for different project sizes and mesh types. You can handle reinforcing mesh for concrete, welded mesh for fencing, or any custom job. Just measure, calculate, and plan with confidence.

Quick Tools for Wire Mesh Weight

Online Calculators

You want to save time when figuring out wire mesh weight. Online calculators make this job easy. You just enter your measurements, and the tool does the math for you. Here are some popular options you can try:

- Steel Weight Calculator: This tool helps you get quick and accurate weight numbers for steel wire mesh. You can use it on your phone or computer.

- Metal Weight Calculator: Many engineers and contractors use this calculator. It gives reliable estimates for part weight and works for lots of steel products.

- Metal Weight Calculator: You can count on this tool for precise weight planning. It covers different steel items, including wire mesh.

These calculators help you avoid mistakes and make your project planning smoother. You don’t need to be a math expert. Just type in your numbers and get the weight you need.

Reference Tables

Sometimes you want to check wire mesh weight without using a calculator. Reference tables give you fast answers. You can look up the roll size, wire spacing, gauge, and wire size. The table shows the roll weight and the weight for every 100 square feet. Here’s an example:

| Roll Size | Spacing | Gauge | Wire Size | Roll Weight | Weight per 100 Square Feet |

|---|---|---|---|---|---|

| 5′ x 150′ | 6 x 6 | 10/10 | W1.4/W1.4 | 157 lbs. | 21 lbs. |

| 5’ x 150’ | 6 x 6 | 8/8 | W2.1/W2.1 | 225 lbs. | 30 lbs. |

| 5’ x 150’ | 6 x 6 | 6/6 | W2.9/W2.9 | 315 lbs. | 42 lbs. |

You can find these tables on supplier websites or in catalogs. They help you compare different mesh types and pick the right one for your project. You don’t need to measure every roll. Just match your mesh to the table and see the weight.

Consulting Suppliers

You might have a custom project or need a special mesh size. Sometimes online tools and tables can’t give you the exact weight. In these cases, talking to your supplier is the best move.

Suppliers know their products inside and out. They can help you figure out the weight for custom shapes, special materials, or complex designs. If you feel unsure, just ask. You’ll get expert advice and avoid costly mistakes.

Suppliers can also give you tips for handling heavy mesh or choosing the right material. They want your project to succeed. If you need a quote or have questions about weight, reach out to them.

Using quick tools like calculators, tables, and supplier advice makes your wire mesh planning much easier. You get the right weight, save time, and keep your project on track.

Special Tips for Woven Wire Screens

Unique Features

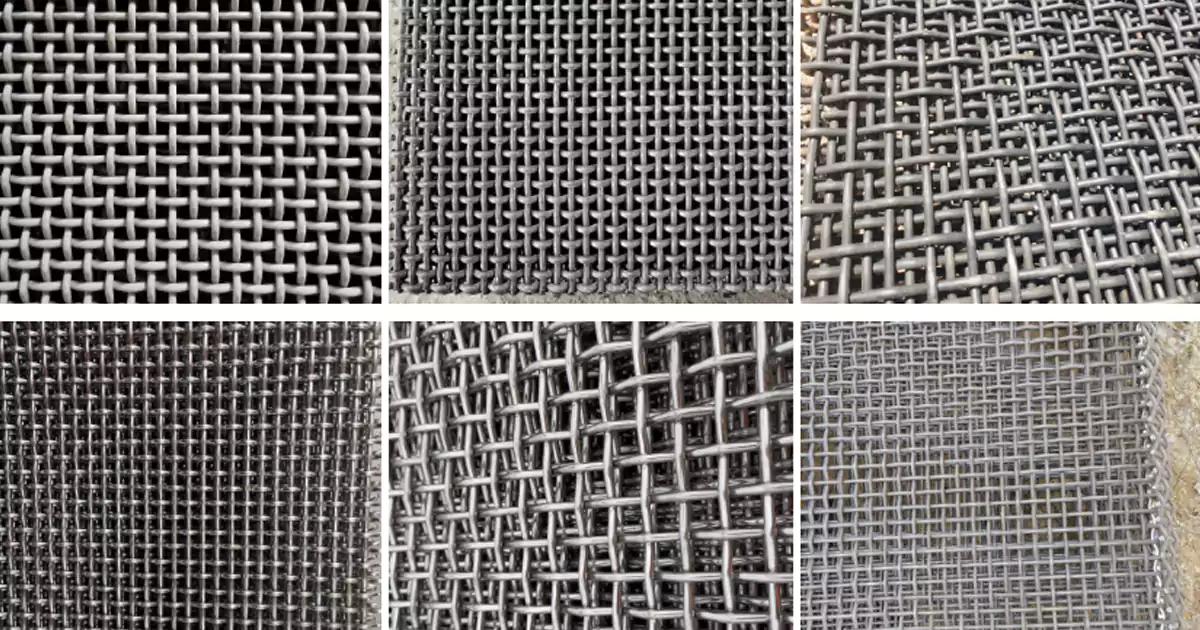

Woven wire screens are different from welded mesh in many ways. You can bend woven wire mesh to fit bumpy or odd shapes. It is easy to roll up or cut, so you can use it in many places. This makes it easier to move and install, and it changes how much weight you need for your project.

Woven wire mesh uses much thinner wires than welded mesh. Most woven screens have wires from 0.03mm to 1mm thick. Welded mesh wires usually start at 2mm and go higher. Thinner wires make woven screens lighter, so you can lift and install them easily. You also get more material choices, like stainless steel, brass, or copper. Welded mesh usually comes in fewer types, like galvanized or stainless steel.

Here’s a table that shows the main differences:

| Feature | Woven Wire Screens | Welded Wire Mesh |

|---|---|---|

| Wire Diameter | Thinner wires (0.03mm to 1mm) | Thicker wires (2mm+) |

| Weight | Generally lighter | Heavier |

| Material Options | Many choices | Fewer options |

| Flexibility | Very flexible | Less flexible |

Woven wire mesh is good for covering odd shapes or wrapping around things. Welded mesh is better for flat, strong panels, like reinforcing mesh in concrete.

Weight Calculation Differences

You need a different way to figure out the weight of woven wire screens. Woven mesh is made by weaving wires over and under each other. Welded mesh joins wires at right angles with resistance welding. This changes how you calculate the weight.

Woven wire mesh uses thinner wires and bends more easily. The mesh might stretch or move a bit when you use it. Welded mesh stays stiff and keeps its shape. When you measure woven mesh, check the wire thickness and mesh count closely. Small changes in wire size can really change the weight.

Here’s a table to help you compare:

| Feature | Woven Wire Screens | Welded Wire Mesh |

|---|---|---|

| Construction Method | Interlaced wires | Resistance welding |

| Strength | Less rigid | More rigid |

| Opening Size Precision | Can change under load | Stays the same |

| Applications | Filtration, flexible uses | Security, concrete reinforcing mesh |

Woven mesh is lighter than welded mesh for the same size. This helps if you need to move or swap screens often. Always check the mesh count and wire thickness before you figure out the weight. If you use woven mesh for reinforcing mesh jobs, remember it may not be as strong as welded mesh.

Industry Applications

Woven wire screens are used in many industries. They are important in recycling, aggregates, mining, and concrete work. In recycling, woven screens help sort materials and keep quality high. Aggregate plants use them to keep products good and speed up work. Mining uses woven screens to sort rocks and minerals. Concrete plants use woven mesh in making cement and other steps.

You can use woven wire screens for:

- Aggregate processing and washing

- Mining and sorting materials

- Concrete manufacturing

- Recycling centers

Woven screens work well in jobs with lots of shaking. If you work with sticky stuff, like recycled asphalt, you can use special woven screens that shake off stuck material. This keeps your screens clean and helps them work better.

Pick woven wire mesh if you need a light, bendy screen. Welded mesh is best for tough jobs, like reinforcing mesh in concrete or security fences. Always choose the right mesh for your project. This helps you get the right weight, strength, and results every time.

Conclusion

You now know how to calculate wire mesh weight for your project. Always measure carefully and check your numbers twice. If you feel unsure, use online tools or ask an expert. As a manufacturer, we offer custom and wholesale solutions for every project. You can choose wire thickness, mesh size, and material. Here’s a quick look at what affects weight and cost:

| Factor | Impact on Weight and Cost |

|---|---|

| Material | Stainless steel weighs more, costs more |

| Panel Size | Larger panels add more weight |

| Manufacturing | Automation keeps weight consistent |

Reach out if you want advice or a quote. We’re here to help you get the right weight for your project!

FAQ

How do I measure wire diameter for my mesh?

You can use a caliper for the most accurate reading. Place it around the wire and check the measurement. If you don’t have a caliper, try a ruler for thicker wires.

What is mesh size and why does it matter?

Mesh size shows the distance between wires. It affects how strong your mesh is and how much material you need. You should always check mesh size before starting your project.

Can I use online calculators for wire mesh weight?

Yes, you can! Online calculators help you get quick results. Just enter your measurements and material type. You’ll see the wire mesh weight in seconds.

Does material type change the weight of my mesh?

Material type makes a big difference. Stainless steel weighs more than aluminum. Always check the density of your chosen metal before you calculate the weight.

How do I estimate total mesh weight for a large project?

Measure each sheet or panel. Use the wire mesh weight formula for every piece. Add up all the weights to get your total. Double-check your numbers for accuracy.

What if my mesh sheets overlap?

Overlapping mesh adds extra weight. Measure the overlap area and include it in your total. This helps you avoid ordering too little or too much material.

Can I get help from my supplier for custom mesh sizes?

Absolutely! Suppliers know their products well. They can help you figure out the right weight and size for custom orders. Don’t hesitate to ask for advice.

Is welded mesh stronger than woven mesh?

Welded mesh is usually stronger and holds its shape better. Woven mesh bends more easily and works well for flexible jobs. Pick the type that fits your project needs.